5

#+ &%" +(*"&%)

+"#*%%"*)

All built-in units are supplied with factory installed flexible steel conduit and applicable wiring.

()*%"% %"*)

All freestanding units are factory supplied with a cord and plug. Please check to make sure that the plug matches the receptacle.

1) 120V units supplied with a NEMA 5-15P plug configurations.

2) 2 0V units supplied with a NEMA 6-15P plug configurations.

FOR FREESTANDING UNITS, PLUG UNIT ONLY INTO A RECEPTACLE OF COMPATIBLE VOLTAGE AND PLUG

CONFIGURATION. IF THE APPROPRIATE RECEPTACLE IS NOT AVAILABLE, CONTACT A CERTIFIED ELECTRICIAN

TO INSTALL THE CORRECT OUTLET. SEE “ELECTRICAL RATING CHART” BELOW.

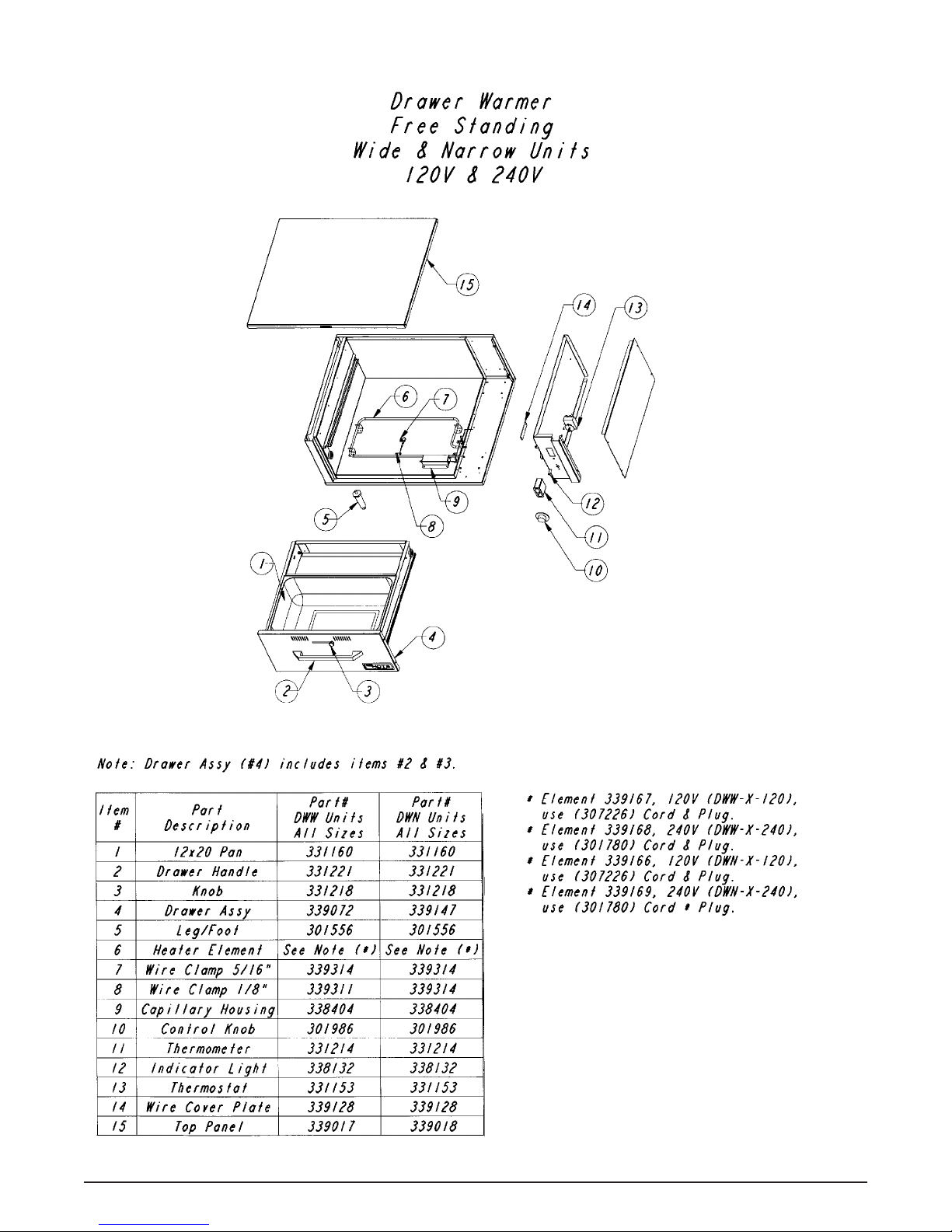

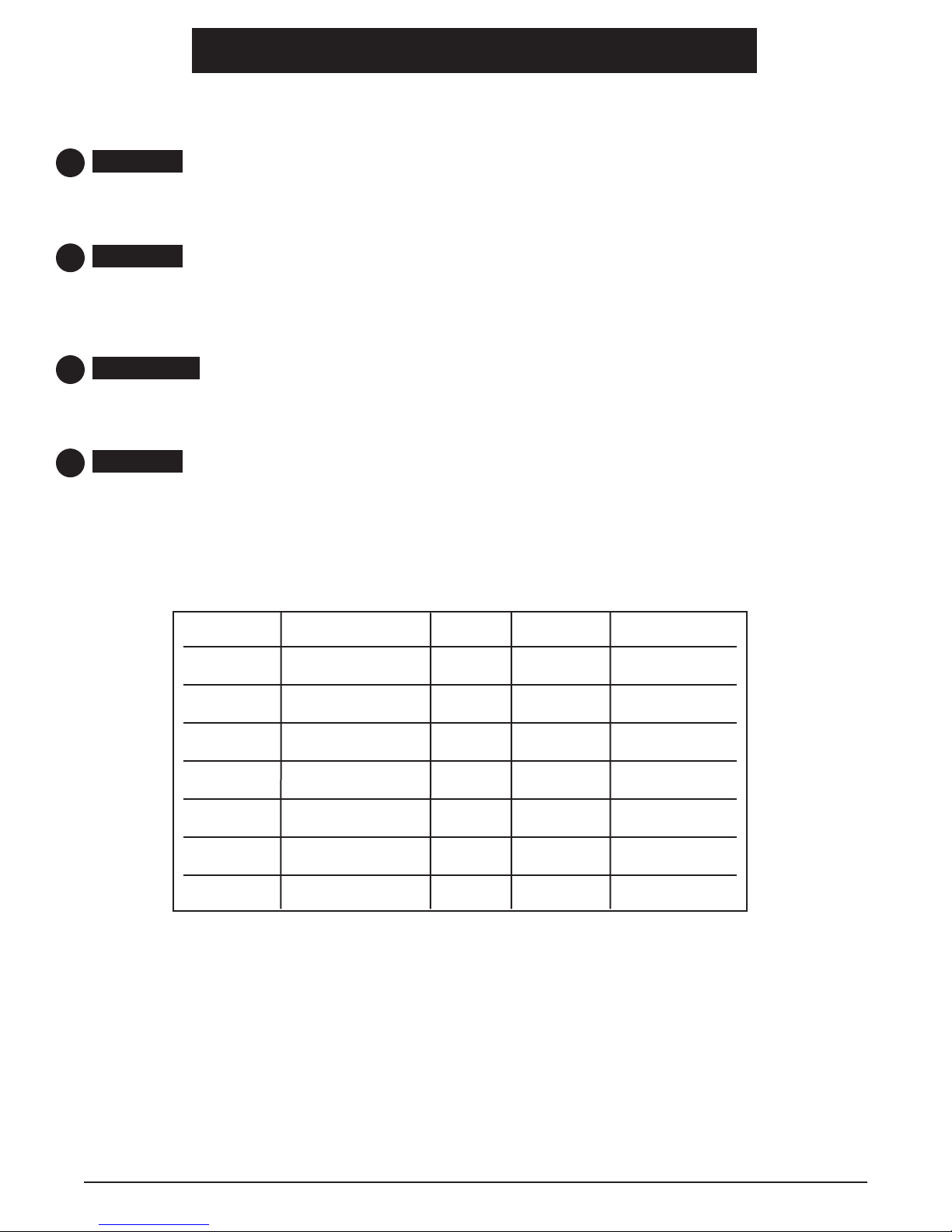

Model Watts Amps Plug Length Depth Height

DWW-1-120 450 3.8 NEMA 5-15 29˝ 231⁄4˝ 161⁄4˝

DWW-1-240 450 1.9 NEMA 6-15 29˝ 231⁄4˝ 161⁄4˝

DWW-2-120 900 7.5 NEMA 5-15 29˝ 231⁄4˝ 265⁄8˝

DWW-2-240 900 3.8 NEMA 6-15 29˝ 231⁄4˝ 265⁄8˝

DWW-3-120 1350 11.3 NEMA 5-15 29˝ 231⁄4˝ 37˝

DWW-3-240 1350 5.6 NEMA 6-15 29˝ 231⁄4˝ 37˝

DWN-1-120 450 3.8 NEMA 5-15 21˝ 273⁄4˝ 161⁄4˝

DWN-1-240 450 1.9 NEMA 6-15 21˝ 273⁄4˝ 161⁄4˝

DWN-2-120 900 7.5 NEMA 5-15 21˝ 273⁄4˝ 265⁄8˝

DWN-2-240 900 3.8 NEMA 6-15 21˝ 273⁄4˝ 265⁄8˝

DWN-3-120 1350 11.3 NEMA 5-15 21˝ 273⁄4˝ 37˝

DWN-3-240 1350 5.6 NEMA 6-15 21˝ 273⁄4˝ 37˝

DWW-1BI-120 450 3.8 Conduit 31˝ 231⁄4˝ 121⁄4˝

DWW-1BI-240 450 1.9 Conduit 31˝ 231⁄4˝ 121⁄4˝

DWW-2BI-120 900 7.5 Conduit 31˝ 231⁄4˝ 231⁄8˝

DWW-2BI-240 900 3.8 Conduit 31˝ 231⁄4˝ 231⁄8˝

DWW-3BI-120 1350 11.3 Conduit 31˝ 231⁄4˝ 34˝

DWW-3BI-240 1350 5.6 Conduit 31˝ 231⁄4˝ 34˝

DWN-1BI-120 450 3.8 Conduit 23˝ 263⁄4˝ 121⁄4˝

DWN-1BI-240 450 1.9 Conduit 23˝ 263⁄4˝ 121⁄4˝

DWN-2BI-120 900 7.5 Conduit 23˝ 263⁄4˝ 231⁄8˝

DWN-2BI-240 900 3.8 Conduit 23˝ 263⁄4˝ 231⁄8˝

DWN-3BI-120 1350 11.3 Conduit 23˝ 263⁄4˝ 34˝

DWN-3BI-240 1350 5.6 Conduit 23˝ 263⁄4˝ 34˝

Electrical Rating Chart