DCS302 GENERAL INFORMATION

GENERAL

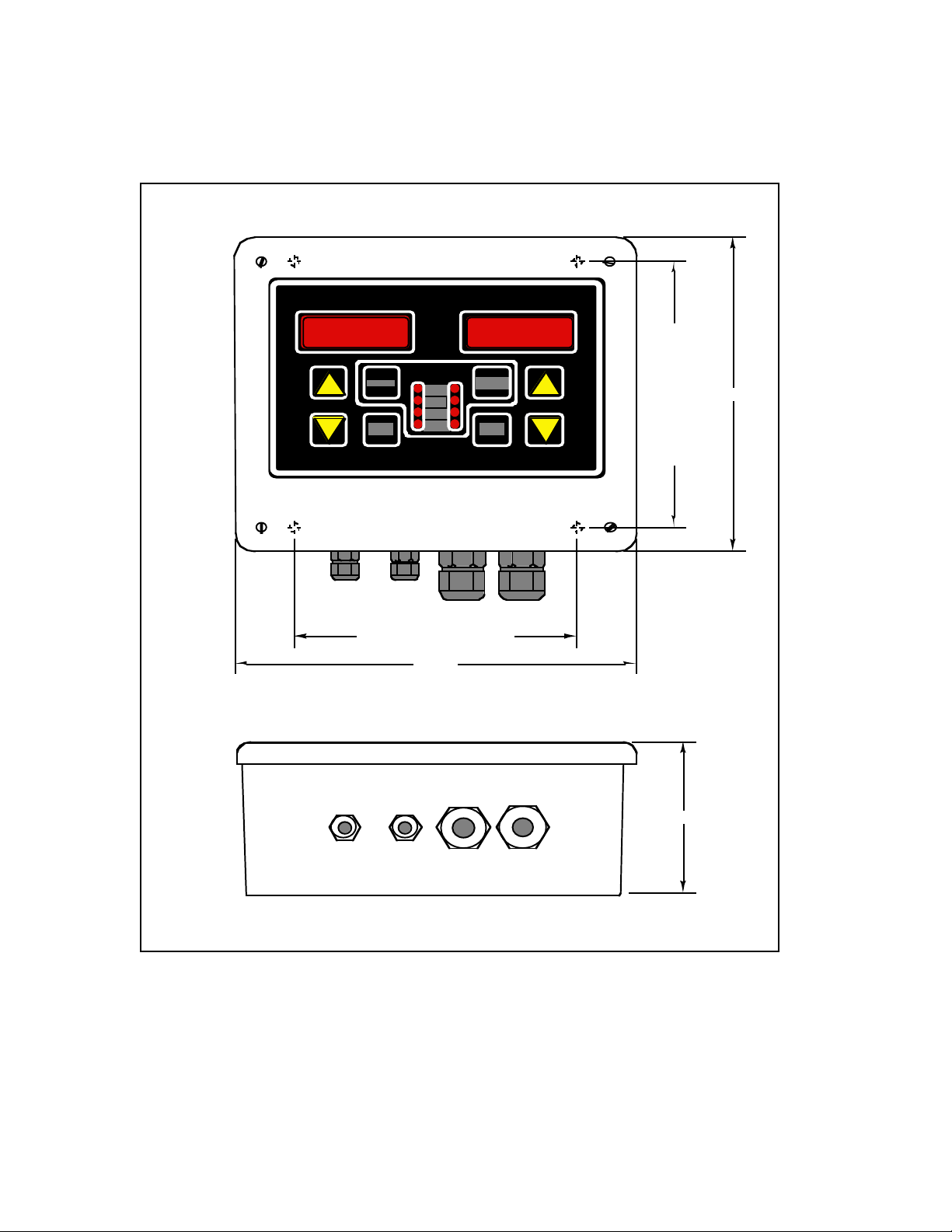

The DCS302 is a dual cylinder scale designed specifically for the water and

wastewater industry. The scale base and weighing surfaces are made of Type 2

PVC plastic and are guaranteed for five years against environmental damage.

All mechanical parts, wherever possible, are made of stainless steel or protected

with a durable chemical-resistant powder finish.

The DCS302 can accommodate any cylinder that does not exceed 12” diameter

and 150 lbs. net weight.

SPECIFICATIONS

Accuracy: …….………………………………………………………… +/- 0.25% FS

Resolution: …………………………………………………………….. 0.5 lb.

Scale Readability: ……………………………………………………… 0.1 lb.

Scale capacity: ..………………………………………………………. 300 lbs.

Safe overload capacity: ……………………………………………….. 400 lbs.

FEATURES

• Simultaneously weighs two cylinders independently and displays the net weight

on separate digital indicators.

• Wall mounting bracket and safety chains are optionally available. These can

adapt to different cylinder sizes.

• All scales are factory assembled, tested and calibrated.

ASSEMBLY

The DCS302 scale base is fully assembled at the factory. Installation and

testing procedures later in this manual.

OPERATION

See Instruction Manual EI-2000 for scale setup and operation.

WARRANTY

Eagle Microsystems warrants the DCS302 scale base to be free from all defects

in material and workmanship. Any parts that fail because of defective

Workmanship or material within five (5) years of date of shipment will be

replaced. The warranty does not include miss use, negligence or modifications.

Eagle Microsystems shall not be liable for transportation or installation charges,

or any other expenses incurred by the customer.