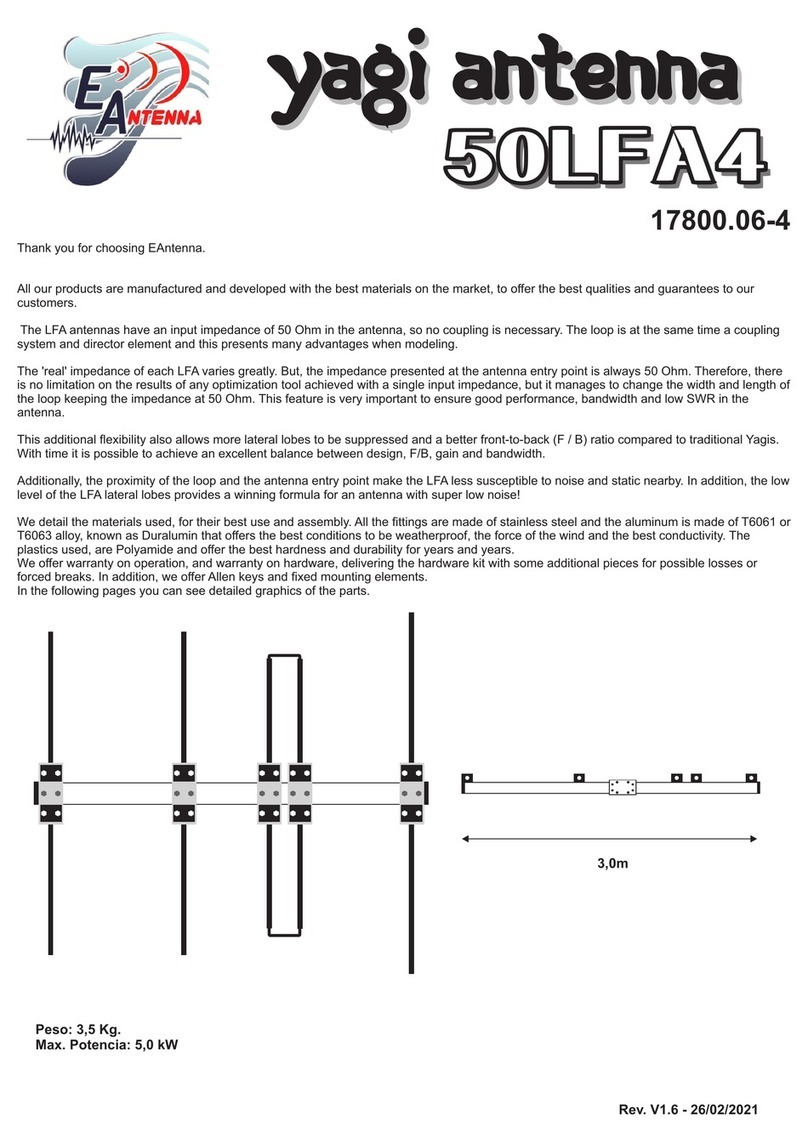

13mm Ø 10mm Ø10mm Ø 6mm Ø

ABRAZADERA 8-12mm Ø

(P01000022)

ABRAZADERA 7-11mm Ø

(P01000031)

La fijación de los elementos del Rectangulo DE, es mediante abrazadera Sin/Fin 8-12mm (P0100022) de los elementos de 13 a 10mm y la

Sin/Fin 7-11mm (P0100031) de 10 a 6 mm.

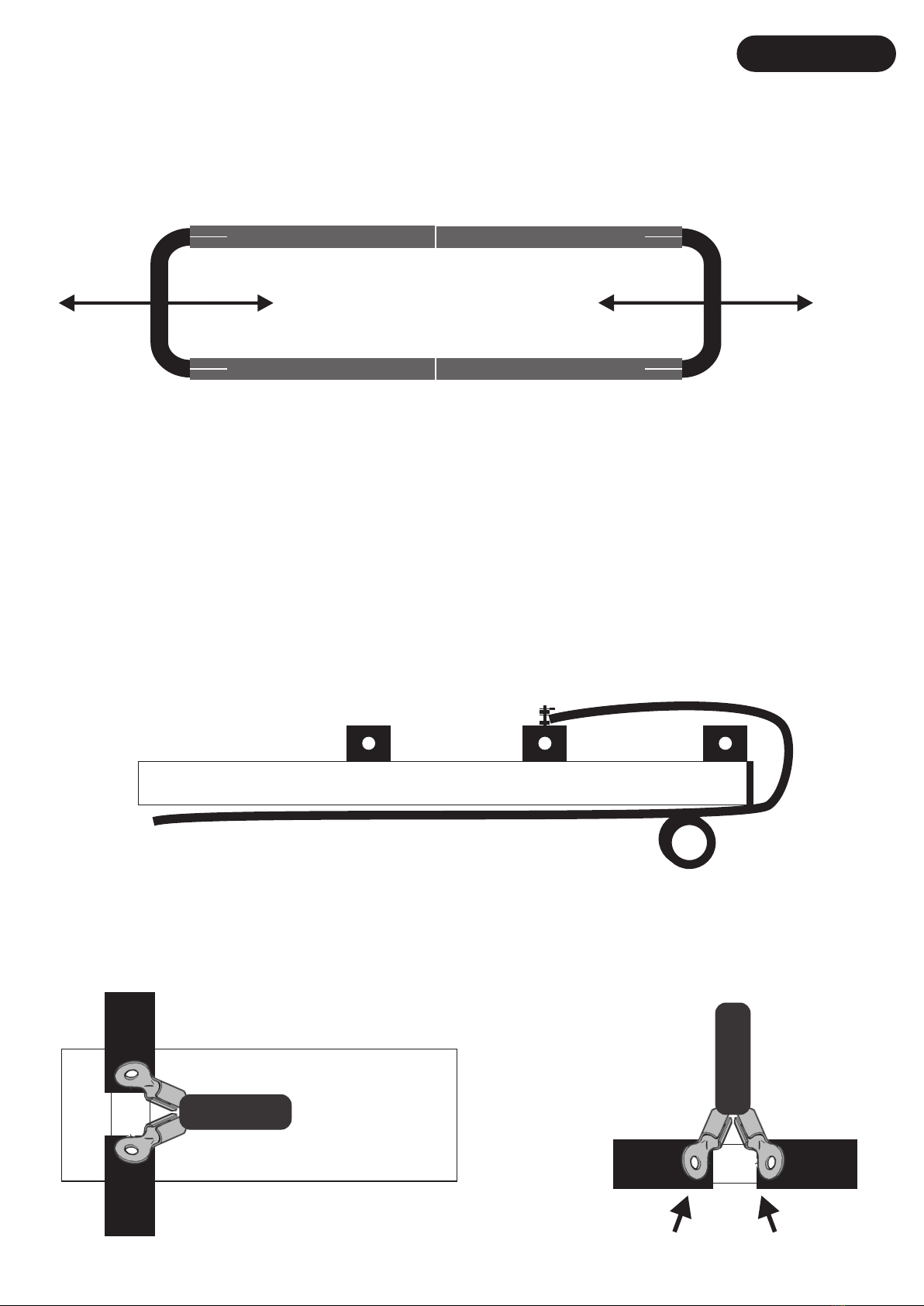

Las medidas de la pagina 2 están expresadas en medidas exteriores, o sea, midiendo desde cada extremo del tubo. Una vez que los

elementos estén ensamblados correctamente, se procede a poner cada elemento en la placa al boom, con lo que seria el ultimo paso de

montaje. Unir las placas al boom como se especifica debajo.

Una vez que tiene los elementos ensamblados, y el boom, es momento de montar los las placas al boom y después los elementos a la placa.

Lo que aconsejamos es que se empiece por el las placas al boom, si montara la antena de una pieza. Si lo que quiere es subir los elemen-

tos, una vez el boom puesto en el mástil, aconsejamos poner los elementos a las placas para su mejor unión del conjunto “placa/elemento” al

boom.

Para poner los elementos a la placa, tendría que introducir los EAHYP013 por cada extremo en cada extremo del elemento de 13mm Ø,

y con la ayuda de una cinta métrica marcar a la mitad (60cm), y una vez centrado, fijar con la otra parte del (EAHYP013) con los tornillos DIN 912

M6X40, como aparece en el dibujo inferior.

Para colocar cada placa al boom, se fija mediante los tornillos DIN 912 M6X20 y arandela DIN 9021 M6. Esta placa debe de quedar bien firme

para la colocación del elemento. El paso siguiente seria igual que los demás elementos, pero teniendo en cuenta que los tornillos que

utilizaremos son DIN 912 M6X40 y tuercas autoblocante DIN 985 M6 una vez que esté ensamblada toda la antena.

ESPAÑOL

ELEMENT ALIMENTACIÓN

Placas 6m

DIN 912 6x40mm

DIN 912 6x20mm

DIN 9021 M6

DIN 985 M6

El primer paso de ensamblaje de los elementos es colocar en orden por diámetros según la pagina 2.

Una vez hecho esto tener en cuenta que en cada extremo de los elementos hay una parte de cada tubo que tiene los agujeros mar gruesos.

Estos son los que van en el extremo hacia el extremo de la antena, ya que los agujeros anchos son donde entra la cabeza del tornillo DIN 7984

y presiona al tubo interior. Tener en cuenta que la cabeza del tornillo tiene que quedar alojada dentro del hueco del elemento y en la otra

cara, el remache tiene que quedar insertado para atornillarse con la llave allen suministrada.

Mirar ejemplo debajo:

SI NO