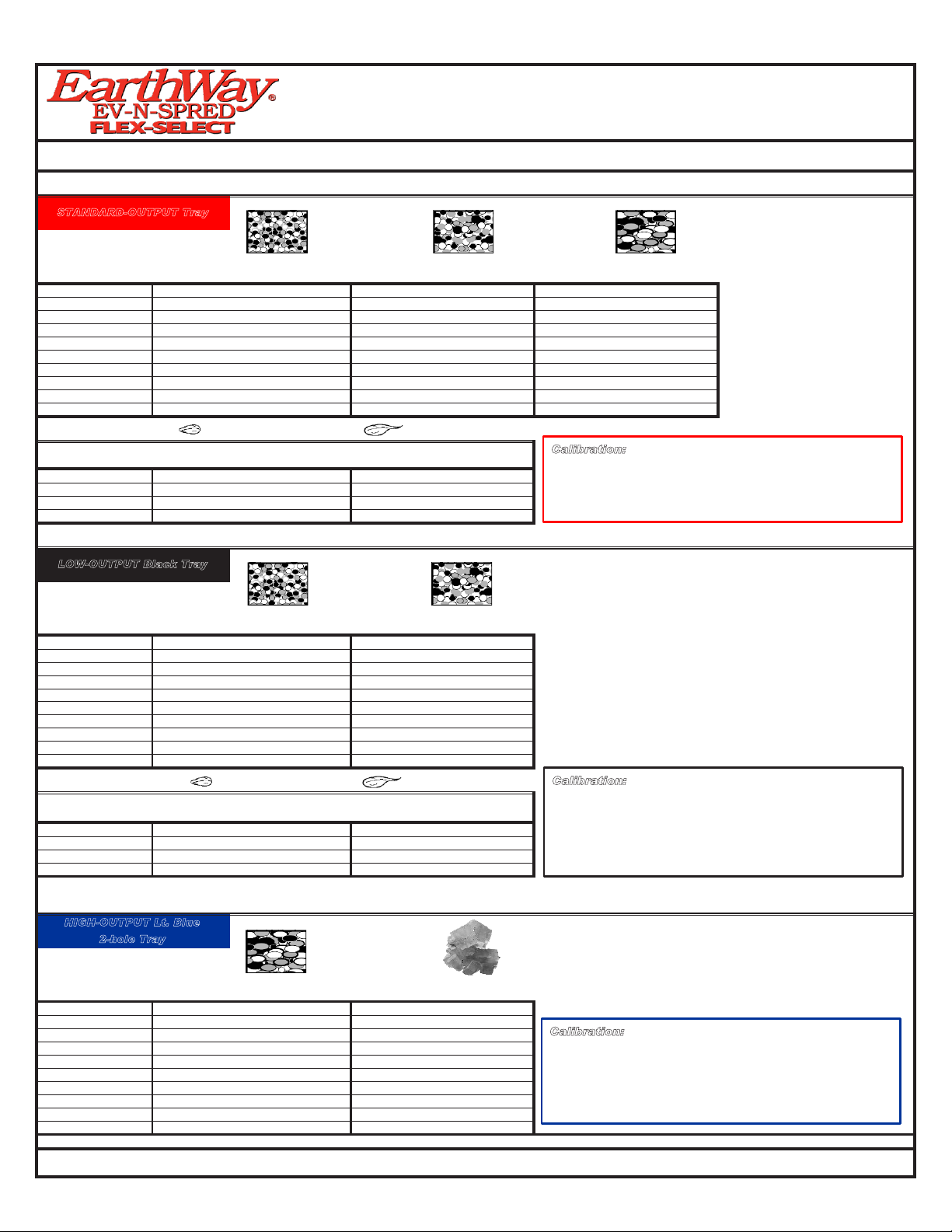

GRANULAR MATERIAL

PARTICLE SIZES: Fine/Small

(SAND) (HALF BB) (BB) Ice Melt

LBS. PER 1,000 SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD

SQUARE FEET SETTING WIDTH FT METERS SETTING WIDTH FT METERS SETTING WIDTH FT METERS

1 LB. 718' 5.5m 924' 7.3m 14 36' 11m

2 LBS. 10 18' 5.5m 13 24' 7.3m 18 36' 11m

3 LBS. 13 18' 5.5m 16 24' 7.3m 23 36' 11m

4 LBS. 14 18' 5.5m 20 24' 7.3m 27 36' 11m

5 LBS. 16 18' 5.5m 22 24' 7.3m 30 36' 11m

6 LBS. 18 18' 5.5m 25 24' 7.3m 23 = 2 pass 36' 11m

7 LBS. 20 18' 5.5m 27 24' 7.3m 25 = 2 pass 36' 11m

8 LBS. 22 18' 5.5m 28 24' 7.3m 27 = 2 pass 36' 11m

9 LBS. 24 18' 5.5m 30 24' 7.3m 28 = 2 pass 36' 11m

10 LBS. 26 18' 5.5m 22 = 2 pass 24' 7.3m 30 = 2 pass 36' 11m

GRASS SEED

LBS. PER 1,000 FINE SPREAD SPREAD COARSE SPREAD SPREAD

SQUARE FEET SETTING WIDTH FT METERS SETTING WIDTH FT METERS

2 LBS. 14 8' 2.4m 22 14' 4.3m

3 LBS. 16 8' 2.4m 25 14' 4.3m

4 LBS> 18 8' 2.4m 28 14' 4.3m

5 LBS> 20 8' 2.4m 30 14' 4.3m

GRANULAR MATERIAL

PARTICLE SIZES: Fine/Small Medium

(SAND) (HALF BB)

LBS. PER 1,000 SPREAD SPREAD SPREAD SPREAD

SQUARE FEET SETTING WIDTH FT METERS SETTING WIDTH FT METERS

1 LB. 816' 4.9m 10 20' 6.1m

2 LBS. 10 16' 4.9m 13 20' 6.1m

3 LBS. 12 16' 4.9m 18 20' 6.1m

4 LBS. 13 16' 4.9m 20 20' 6.1m

5 LBS. 16 16' 4.9m 22 20' 6.1m

6 LBS. 18 16' 4.9m 25 20' 6.1m

7 LBS. 20 16' 4.9m 27 20' 6.1m

8 LBS. 21 16' 4.9m 29 20' 6.1m

9 LBS. 23 16' 4.9m 30 20' 6.1m

10 LBS. 24 16' 4.9m 22 = 2 pass 20' 6.1m

GRASS SEED

LBS. PER 1,000 FINE SPREAD SPREAD COARSE SPREAD SPREAD

SQUARE FEET. SETTING WIDTH FT METERS SETTING WIDTH FT METERS

2 LBS. 15 9' 2.7m 21 15' 4.6m

3 LBS. 18 9' 2.7m 24 15' 4.6m

4 LBS. 21 9' 2.7m 27 15' 4.6m

5 LBS. 24 9' 2.7m 30 15' 4.6m

GRANULAR MATERIAL

PARTICLE SIZES: Large EXTRA LARGE

(BB) ROCK SALT

LBS. PER 1,000 SPREAD SPREAD SPREAD SPREAD

SQUARE FEET. SETTING WIDTH FT METERS SETTING WIDTH FT METERS

1 LB. 728' 8.5m 826' 7.9m

2 LBS. 10 28' 8.5m 11 26' 7.9m

3 LBS. 12 28' 8.5m 13 26' 7.9m

4 LBS. 14 28' 8.5m 14 26' 7.9m

5 LBS. 15 28' 8.5m 15 26' 7.9m

6 LBS. 17 28' 8.5m 16 26' 7.9m

7 LBS. 20 28' 8.5m 17 26' 7.9m

8 LBS. 21 28' 8.5m 18 26' 7.9m

9 LBS. 23 28' 8.5m 19 26' 7.9m

10 LBS. 24 28' 8.5m 21 26' 7.9m

FLEX-SELECT

®

BROADCAST SPREADER SETTING MATRIX

STANDARD-OUTPUT Red Tray

LOW-OUTPUT Black Tray

HIGH-OUTPUT Lt. Blue

2-hole Tray

©2014 Earthway Products, Inc. All rights reserved. EarthWay® EV-N-SPRED®, Flex-Select®, and SPRAY-PRO® are registered trademarks of Earthway Products, Inc.

Use of trademarks or images are prohibited unless approved by Earthway Products, Inc. 1009 Maple Street Bristol, Indiana 46507

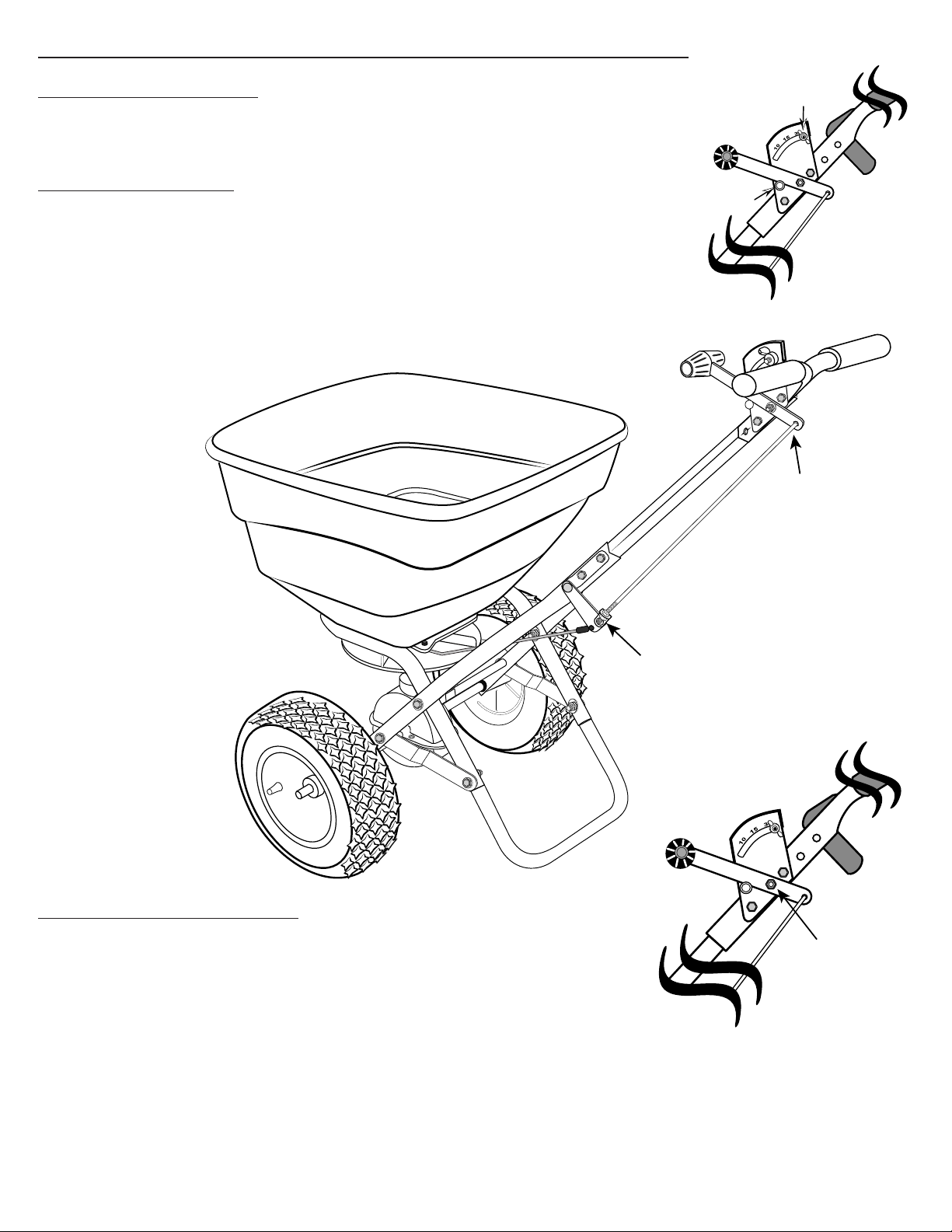

Calibration: Start by ensuring that your spreader calibration is

correct. Make sure the drop holes in the Standard-Output

Tray are fully open when the Rate Control handle is on #30. If

not, please adjust control rod at the pivot to allow for a full open

hopper holes with the handle at position at #30.

Calibration: Start by ensuring that your spreader calibration is

correct. Make sure the drop holes in the LOW-OUTPUT TRAY

are fully closed when the Rate Control Handle is resting on the

stop #0. If not, please adjust control rod at the pivot to ensure the

shut-off is fully closed with the handle at position at #0. Move

the spreader slightly to confirm the calibration because of the

cam.

Calibration: Start by ensuring that your spreader calibration is

correct. Make sure the drop holes in the HIGH-OUTPUT TRAY

are fully closed when the Rate Control Handle is resting on the

stop #0. If not, please adjust control rod at the pivot to ensure the

shut-off is fully closed with the handle at position at #0. Move

the spreader slightly to confirm the calibration because of the

cam.