Earthworks Drum Mics

The Earthworks DrumKit™ High Denition Three-Microphone Systems™ have

had great success because they pick up drum sounds with far more detail and

accuracy than conventional microphones. This improved sound quality is due to

proprietary technologies utilized in Earthworks High Denition Microphones™.

Many drummers such as Jeff Campitelli, Steve Gadd, Keith Carlock, Ronnie

Vannucci, Anton Fig and Anthony King, in addition to many FOH engineers

touring with major artists who are using Earthworks High Denition Drum Mi-

crophones™ for overheads, toms, snare and kickdrum with exceptional results.

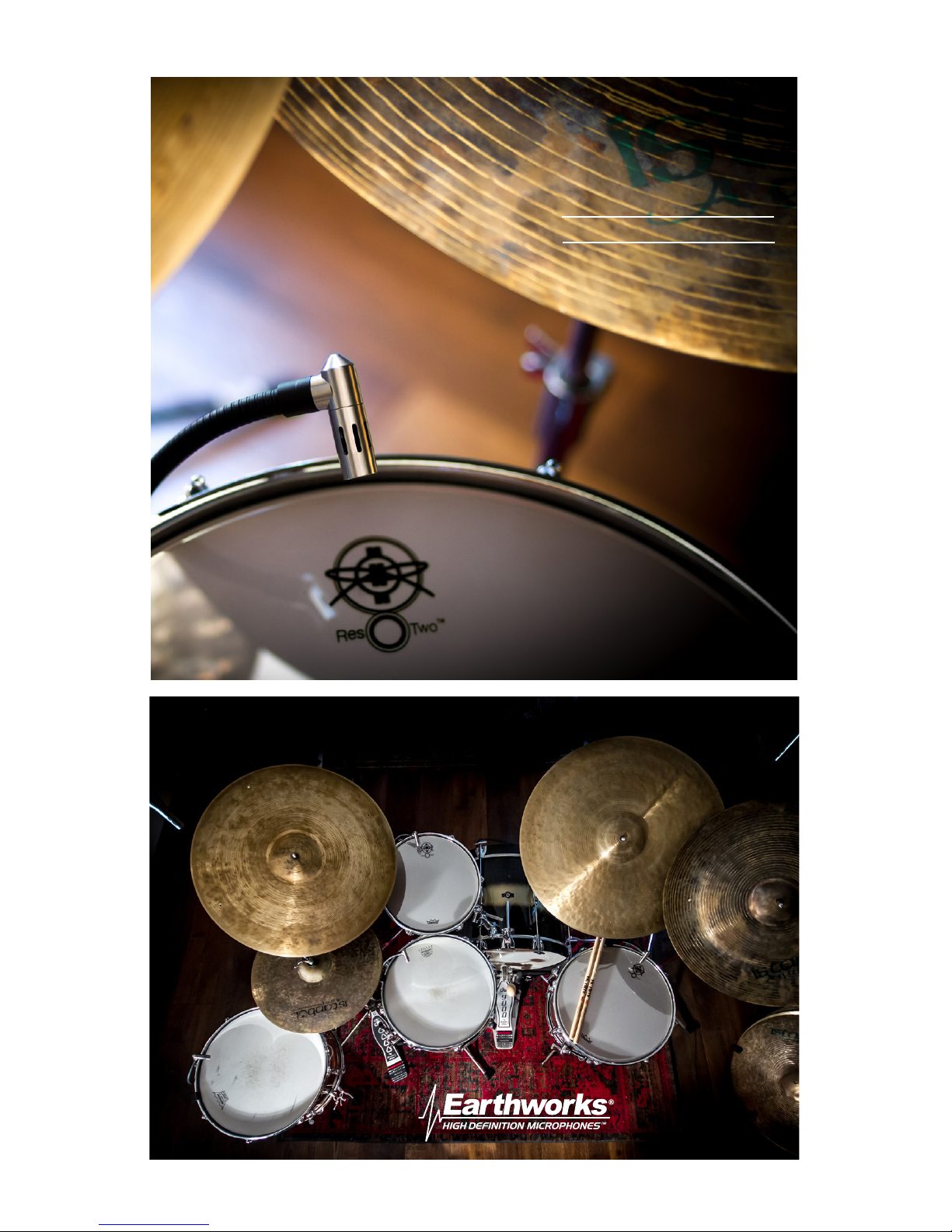

The SR25 has been a popular drum microphone for many years and will han-

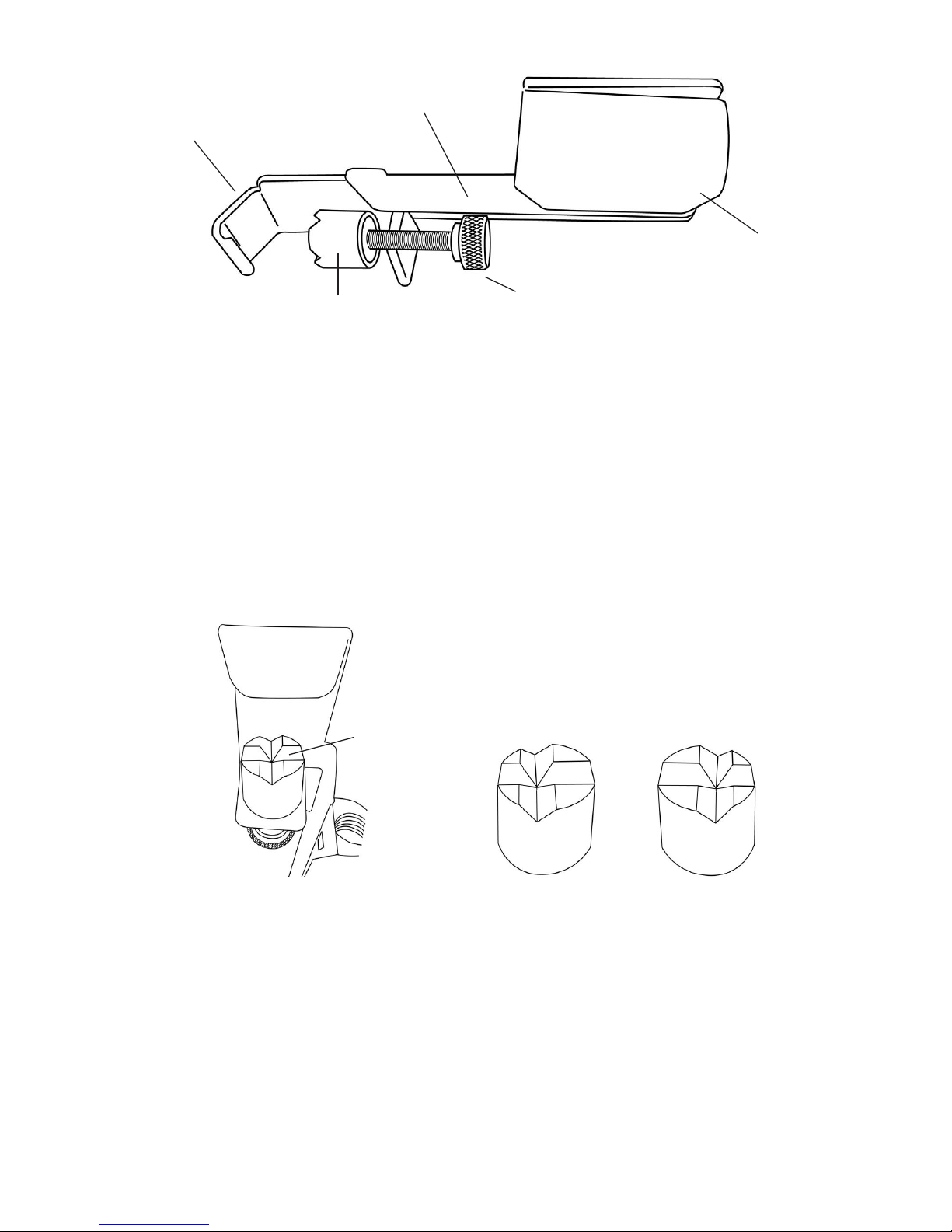

dle up to 145dB SPL. The DM20 is a new generation of Earthworks tom and

snare microphones. It features a stable gooseneck for easy positioning that

will stay in place even when the drums are played very hard. It also can handle

high acoustic sound levels up to 150dB SPL. The Earthworks proprietary

polar technology provides a stunning 32dB of rear rejection (nearly double

that of conventional microphones) and a consistent frequency response out

to 80 degrees off-axis. This vastly reduces phase cancellations, minimizes

pickup of unwanted sounds at the rear of the microphone and provides a sub-

stantial reduction in unwanted acoustic feedback for live sound applications.

Earthworks High Definition Microphones™

the New Science in Microphones

David Blackmer, the brilliant engineer who invented the innovative technol-

ogies of dbx, is also the inventor and founder of Earthworks. In the last few

years of his life, David developed a number of revolutionary technologies that

dramatically improve the sound quality and performance of microphones. In

short, Earthworks High Definition Microphones™ pick up sounds more accu-

rately and with more detail than conventional microphones. These dramatic

improvements are in the areas of impulse response, diaphragm settling time

and advanced polar technologies. Those who have heard Earthworks High

Definition Microphones™ say they have more rear rejection and more gain

before feedback in addition to hearing more detail of the attack, more subtle

detail in low level signals thereby providing a more pristine sound quality than

with any conventional microphones can provide, regardless of price.

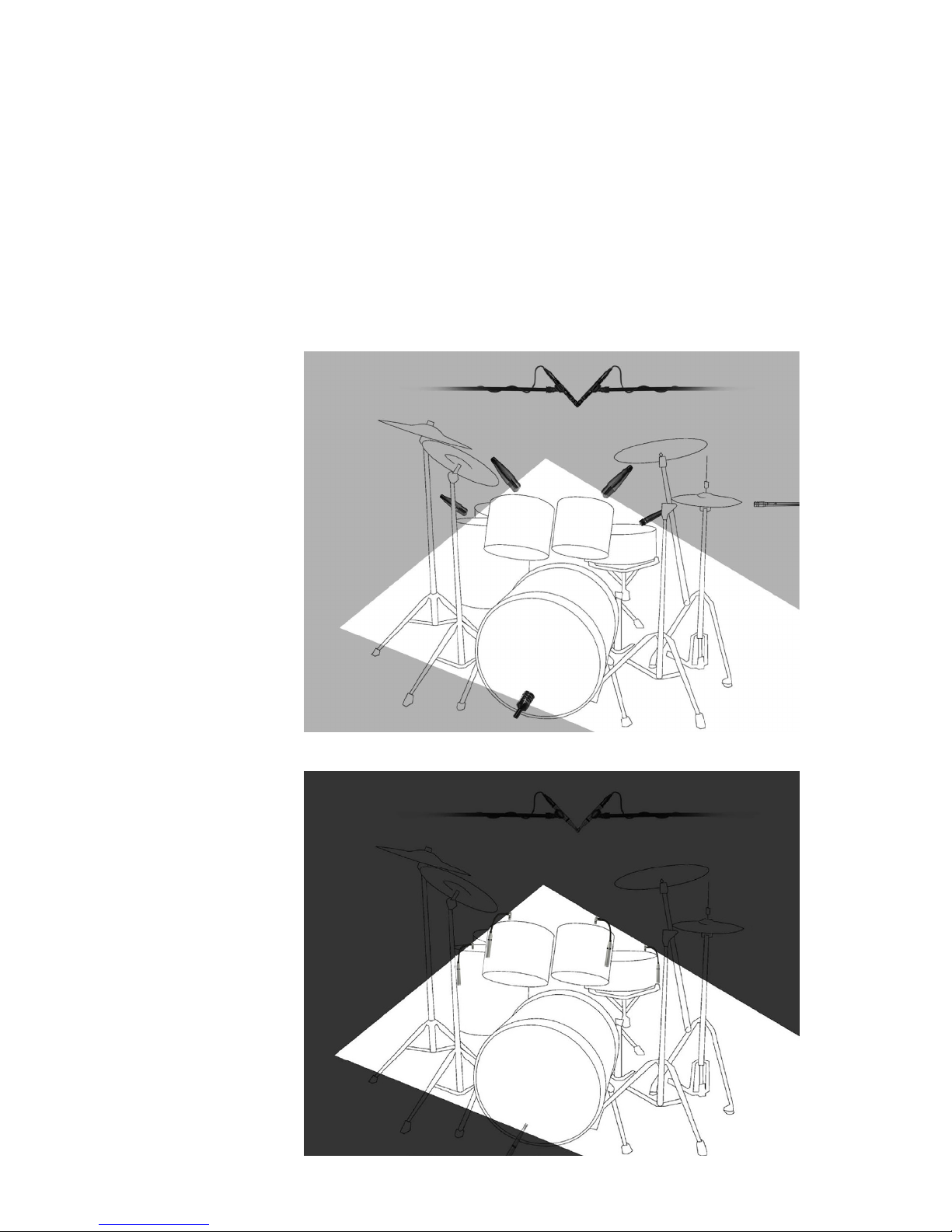

Miking Drums

There are many ways to mic drums and it seems that most every recording or live

sound engineer has their own way of doing this. Our objective is not to indicate

which drum miking approach is better, but to make suggestions and look at ad-

4