4

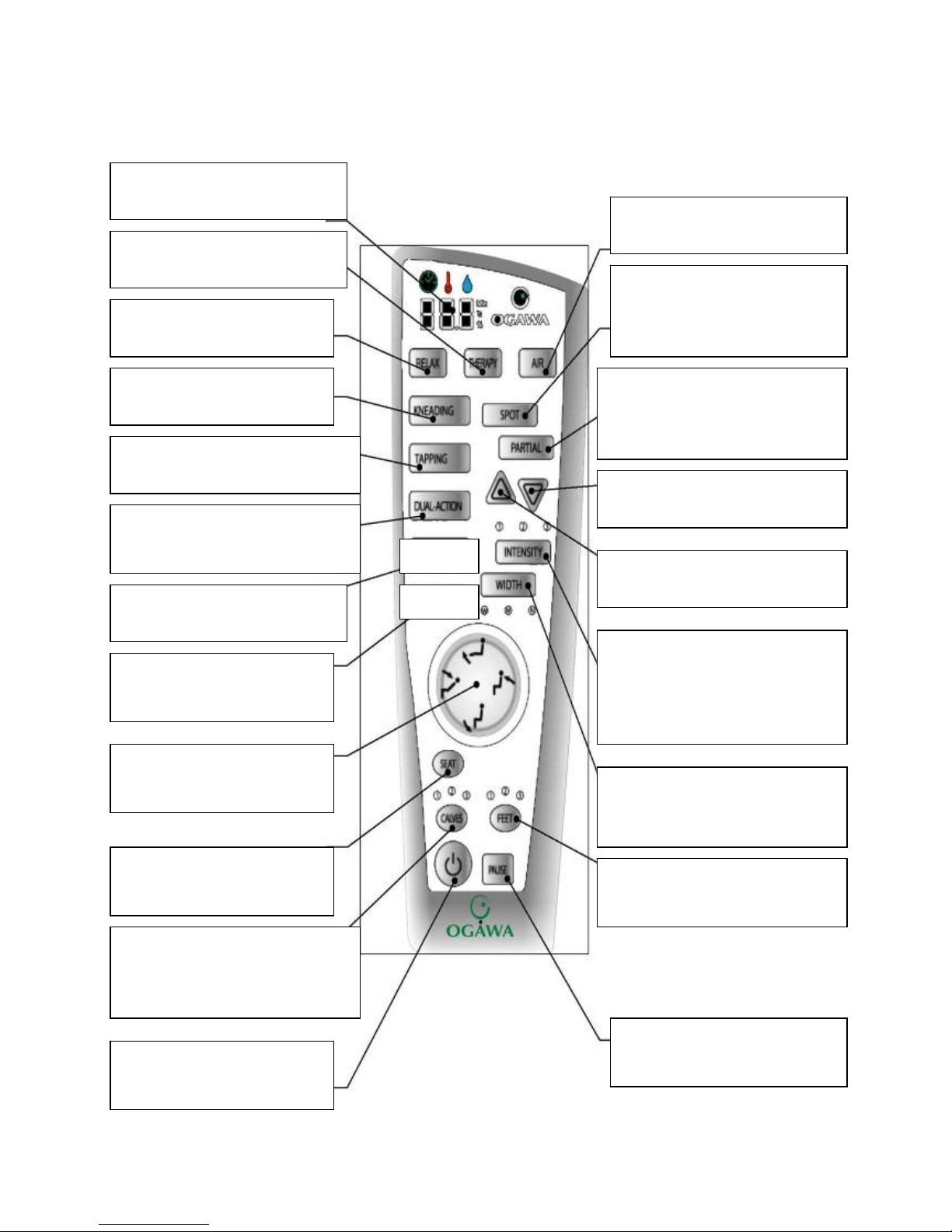

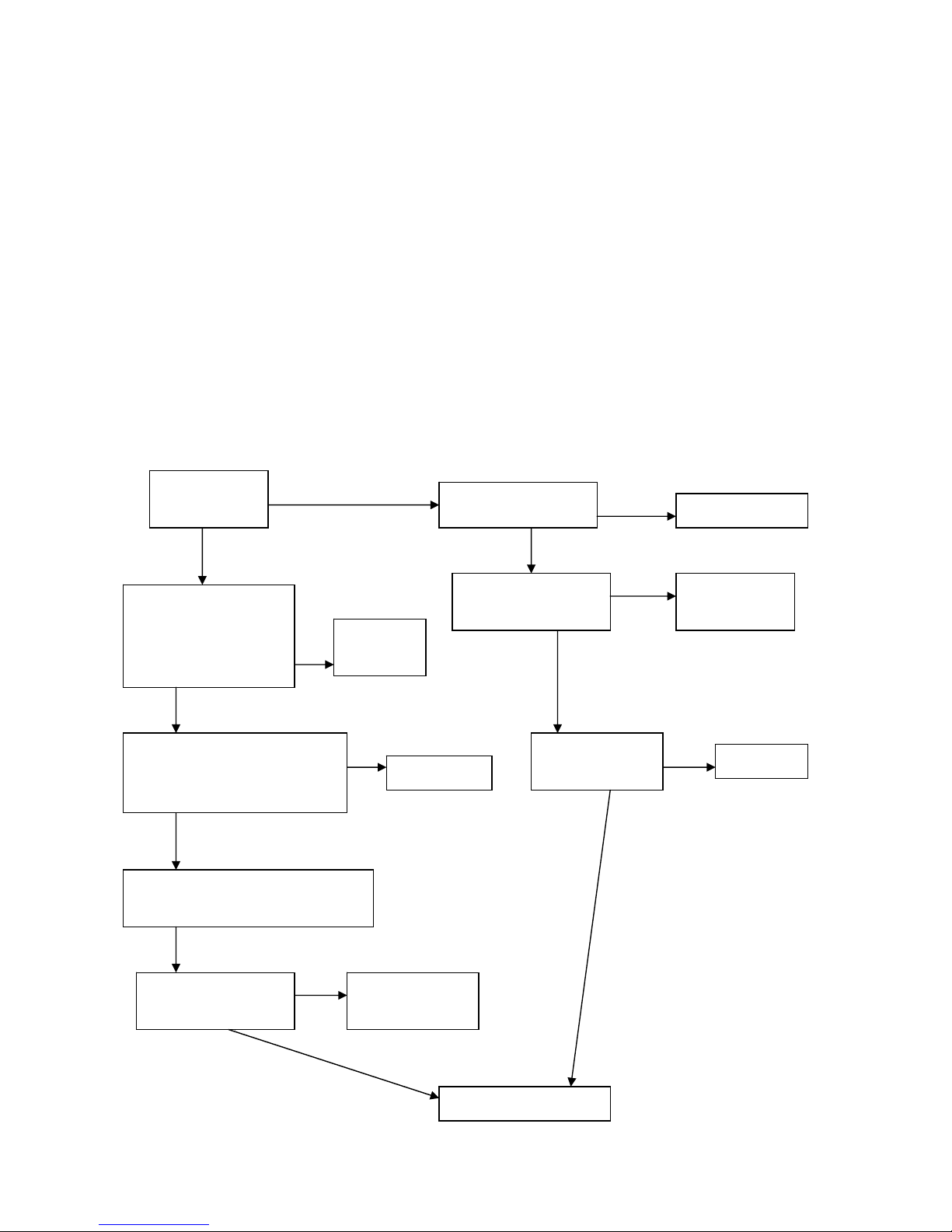

III.Name and functions of components (remote controller)

Keys for actuators

Allows adjusting the angle of

back rest and foot rest

LCD display

Displays time and temperature

RELAX key Allows starting

up automatic kneading program

WIDTH adjust key

Width between knead balls can be

adjusted at 3 levels. Only limited to

TAPPING, ROLLING

INTENSITY adjust key

Massaging intensity can be

adjusted at 3 levels. Only limited to

KNEADING, TAPPING, SWEDISH,

DUAL-ACTION, RELAX, THERAPY,

AIR

ON/OFF

Allows starting and stopping the

chair.

THERAPY key Allows starting

up automatic tapping program

AIR key Allows starting up

automatic charging program

SEAT key Allows starting

vibrators and charging gas-bags

in the seat pad.

CALVES key Allows starting

vibrators and charging gas-bags in

the calves rest. Intensity can be

adjusted at 3 levels

FEET key Allows charging

gas-bags in the foot rest. Intensity

can be adjusted at 3 levels

PAUSE key

All the action will be broken off

by this key

SPOT key Allows starting spot

massage just in the current

position. Position can be adjusted

by UP and DOWN

PARTIAL key Partial massage

taking the current position as the

center with height 16 cm. Center can

be adjusted by UP and DOWN

DOWN key Mechanical main unit

will run down by holding down it.

UP key Mechanical main unit will

run up by holding down it.

KNEADING key Full-back

mode, intensity can be adjusted.

TAPPING key Full-back mode,

intensity and width can be adjusted.

DUAL-ACTION key Full-back

mode of kneading and tapping,

intensity can be adjusted.

ROLLING key Full-back mode,

width can be adjusted.

HEATING key Allows starting

and stopping the heating in back

pad and foot rest

Heating

Rolling