C) In conformance with AS 2550.1 clause 6.1, the operator shall review the logbook

where applicable and be satisfied about the presence of unauthorised personnel on the

crane, safe working condition of the crane and safe operation of each of the crane

movements. Authorised personnel must carry out any adjustments or alteration

needed for safe operation.

D) Any stabilisers shall be engaged prior to lifting.

E) Do not exceed the rated working Load of the Crane.

F) Ensure that all movements of the Crane are carried out under power.

G) Do NOT move the Crane/Kibble unless the safety of persons in the vicinity of the

Crane is assured. Be alert to the possibility of trapping or injuring persons in the

vicinity of the Crane when handling loads or moving the Crane.

H) Unless a dangerous situation occurs, follow directions and signals given by an

authorised person. Cease any Crane movement if a dangerous situation occurs.

I) The Operator shall hoist the load vertically and in a smooth manner at slow speeds

with minimum acceleration and deceleration.

J) Sudden stops, jerky or other movements that may cause the load to swing unduly must

be avoided. Ensure minimum impact when Crane engages ‘end stops’.

K) Movement of hook/Kibble when out of sight is only permissible when directed by an

authorised person such as a dogman, Crane chase, spotter or rigger.

L) The hook/Kibble must be raised sufficiently to avoid collision during horizontal

movement. Only when the load is freely suspended is horizontal movement

permissible.

M) When landing the Kibble, avoid developing rope slack.

N) The Operator must know the location of the main isolation switch and Fire fighting

equipment.

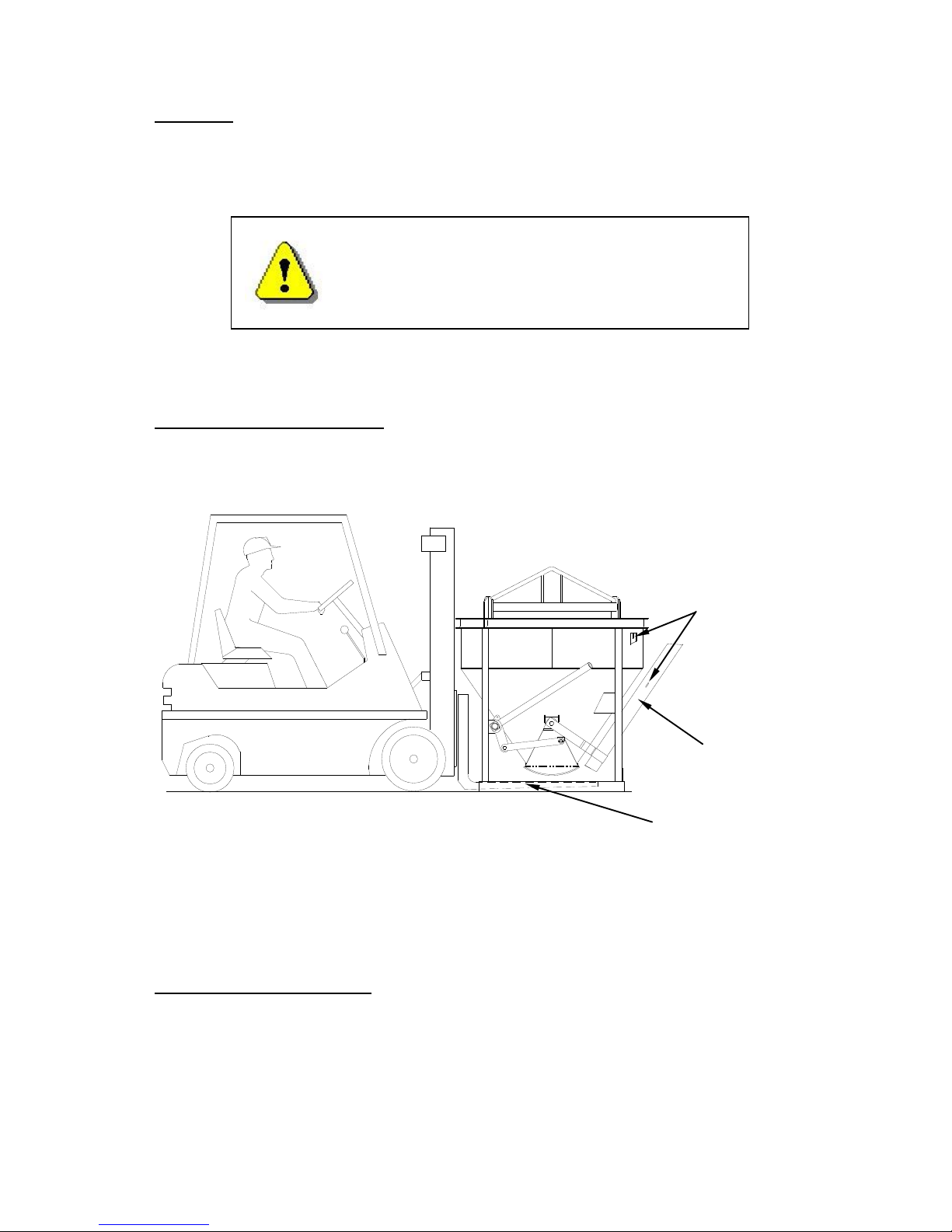

5.2 Risk Control Measures –Forklift Operations

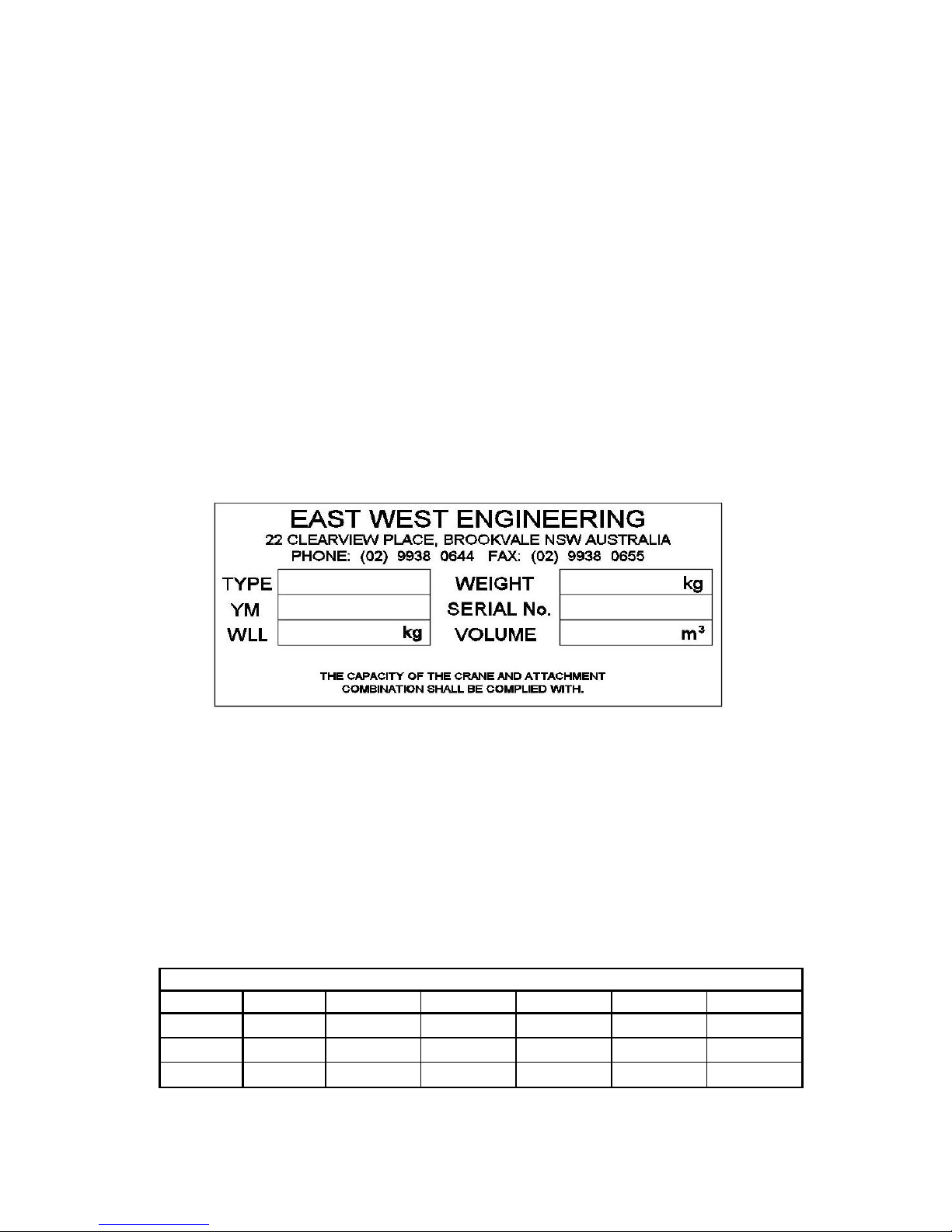

A) The Industrial Truck Operator requires a suitable Forklift licence to cover both the

Industrial Truck being operated and any attachment that has been fitted. Training in

the safe transport of the Concrete Kibble shall be undertaken before usage.

B) Authorised personnel must perform the following pre-checks immediately prior to the

use of the Industrial Truck in accordance with AS 2359.2 Clause 3.1 and 6.4 and

corrective action initiated where applicable;

Nameplate and markings regarding the Industrial Truck and Attachment capacities

are to be read and acknowledged,

Condition of lift and tilt systems on the Industrial Truck to be checked,

Inspect all tyres for wear, condition and pressure if applicable,

Liquid levels of battery cell electrolyte, oils (hydraulic, engine, transmission and

brake), cooling water and fuel to be checked,

All steering and brake controls, warning devices and lights to be checked for

effective operation.

C) Do not exceed the rated capacity of the Industrial Truck to handle the load.

D) The Industrial Trucks shall be used on a hard level surface. The area in which the

Kibble is to be used shall be assessed as suitable for the task to be undertaken. There

should be suitable clear space to safely transport the Kibble and a system developed

for handling the load.

E) Manoeuvre slowly and cautiously when the Kibble is elevated.

F) Transport the Kibble positioned as low as practicable.

G) The mast if adjustable shall be back tilted.