To order parts and supplies: 800.343.9353 >> eastwood.com 7

ELECTRICAL CONNECTION

1. The 3 phase wiring connections are made at the Upper Terminals of the

Electrical Box (FIG 8).

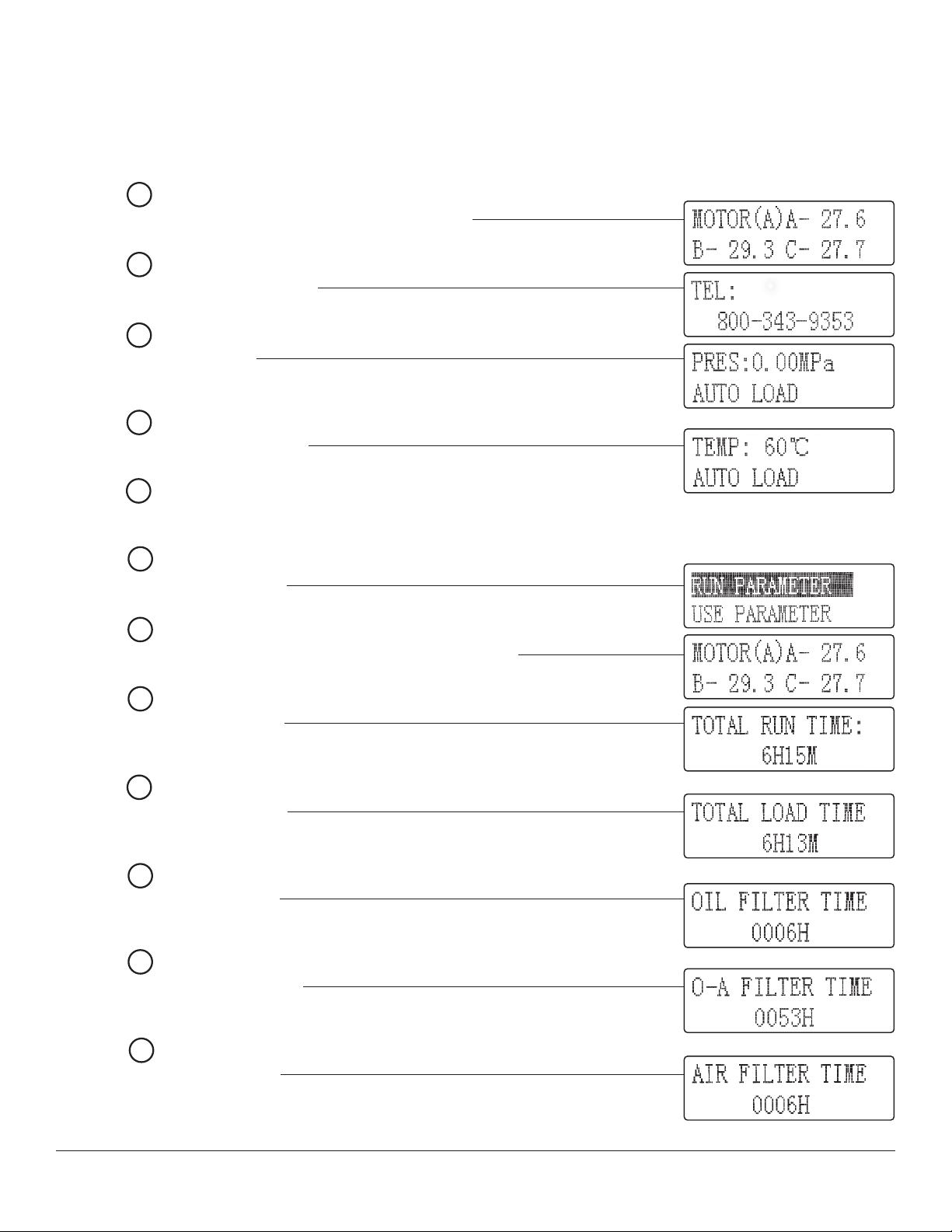

2. The Scroll Compressor features a microprocessor in the control unit

Control Panel Display which will detect incorrect phasing and will display

“ALARM1:” “PHASE REVERSE” and an audible alarm will sound.

3. If these conditions occur, it is an indication that the 3 Phase connections

have been done incorrectly. To correct, shut off power at main breaker

disconnect switch and revise the connection sequence of the three phase

upper terminals of the Electrical Box (FIG 11).

4. Press the SET Button to cancel alarm and reset the Error message in

the LCD Display window.

FIG. 8

The 3 phase wiring connections MUST be done in the proper

sequence or the motor could possibly run in reverse which

could cause severe and permanent damage to the Scroll.

3 PHASE REQUIREMENTS

• 208-240V, 60Hz, 22-amp, 3 phase voltage and amperage requirements. All wiring must be done by a licensed electrician, in accordance with

National Electric Code and state and local requirements. For best performance, the Compressor must be installed on a dedicated circuit, with

circuit breaker or fuse protection. Each time the Compressor motor starts, it will momentarily draw several times its full load amperage.

It is important to consider this start-up surge when specifying circuit breakers or fuses. If fuses are used, time-delay type must be installed.

• The voltage variation between the rated input voltage requirements and that of the actual input voltage supply must not exceed +/- 10%.

If greater variation exists, a step-up or step down transformer must be installed.

• The voltage variation between legs of the 3-phase supply must be within 5%. If greater variation exists, a voltage regulator or rectifier must

be used.

• The power supply wiring must be adequately sized to prevent dangerous overheating and low voltage at the Compressor during startup and

running. Low voltage will cause difficult starting, overheating, and excessive tripping of circuit breakers. The wire gauge must be increased for

longer wire runs to accommodate the increased resistance inherent in longer runs. Refer to the National Electric Code to determine the proper

wire gauge for your wire run length. Low voltage can also be caused by low supply voltage from the power company, or from other equipment

running on the same line.

• For safety reasons, install a main breaker disconnect switch in the line from the electrical panel to the Compressor within momentary reach

of the Compressor. When the switch is off, all power to the Compressor is disconnected. When the switch is on, the compressor will start and

stop automatically as it will be controlled by the pressure switch.

S