2Eastwood Technical Assistance: 800.544.5118 >> techelp@eastwood.com To order parts and supplies: 800.345.1178 >> eastwood.com 3

The Eastwood Undercoat Gun is an efficient, adjustable design that fits most Eastwood products

packaged in screw-on cap quart containers. An adjustable nozzle controls material flow to accept a

wide range of material thickness and textures. May be used with Eastwood Undercoating, Rubberized

Undercoating, Heavy-Duty Anti-Rust, Internal Frame Coating and spray-on soundproofing products.

The included accessory flexible plastic wands can be used to apply materials in hard-to-access areas.

SPECIFICATIONS

• Operating Pressure: 40-60 PSI [2.75-4.13 Bar].

• Air Supply Requirement: 5-7 CFM [140-200 lm].

• Air Inlet: 1/4" FNPT.

• Die-cast aluminum body.

• Adjustable nozzle for application of various coating viscosities and textures.

• 7" long, aluminum trim-to-fit pick-up tube.

• 32" long, flex hose/wand with 360 degree misting nozzle is for applying thinner materials

such as rust proofing to hard-to-reach hollow areas.

• 24" long, flex hose/wand with single 1/4" orifice for applying thicker materials such as under-

coat, bed liner, soundproofing, heat barrier and more to tight spaces and internal areas of frames.

GUN SET-UP

• For optional Eastwood #16003A, Undercoating Gun Bottle use:

Prepare coating per label instructions, pour into #16003A bottle

then thread gun into open bottle top.

NOTE: The 7" pick-up tube can be used as is.

• For direct to container use:

Prepare coating per label instructions; remove threaded cap then

thread gun onto open can top. NOTE: For some containers such as

Eastwood #16032ZP or #16017ZP Heavy-Duty Anti-Rust & #16008

Rubberized Undercoating, the pick-up tube needs to be shortened.

To do so:

1. Place gun along can with underside of cap over upper rim of

and mark the pick-up tube at the point where it aligns with

the bottom rim of the can (FIG. A).

2. Cut the pick-up tube with a hacksaw on a 45 degree angle

with the open side toward the front of the gun (FIG. B).

3. Remove any burrs that remain at the cut line.

• Connect to regulated, clean and dry air supply.

GUN NOZZLE ADJUSTMENT

The Eastwood #20441 gun features an adjustable nozzle to allow spray-

ing a variety of materials and textures.

• To increase material flow for heavier-bodied materials such as

undercoat, bed liner, soundproofing, heat barrier and more;

loosen brass lock ring, turn the brass nozzle outward

(counter-clockwise as viewed from end of gun) then re-tighten

lock ring (FIG. C).

• To decrease material flow for thinner-bodied materials such as

rust proofing, rust-converter and more; loosen brass lock ring,

turn the brass nozzle inward (clockwise as viewed from end of

gun) then re-tighten lock ring (FIG. D).

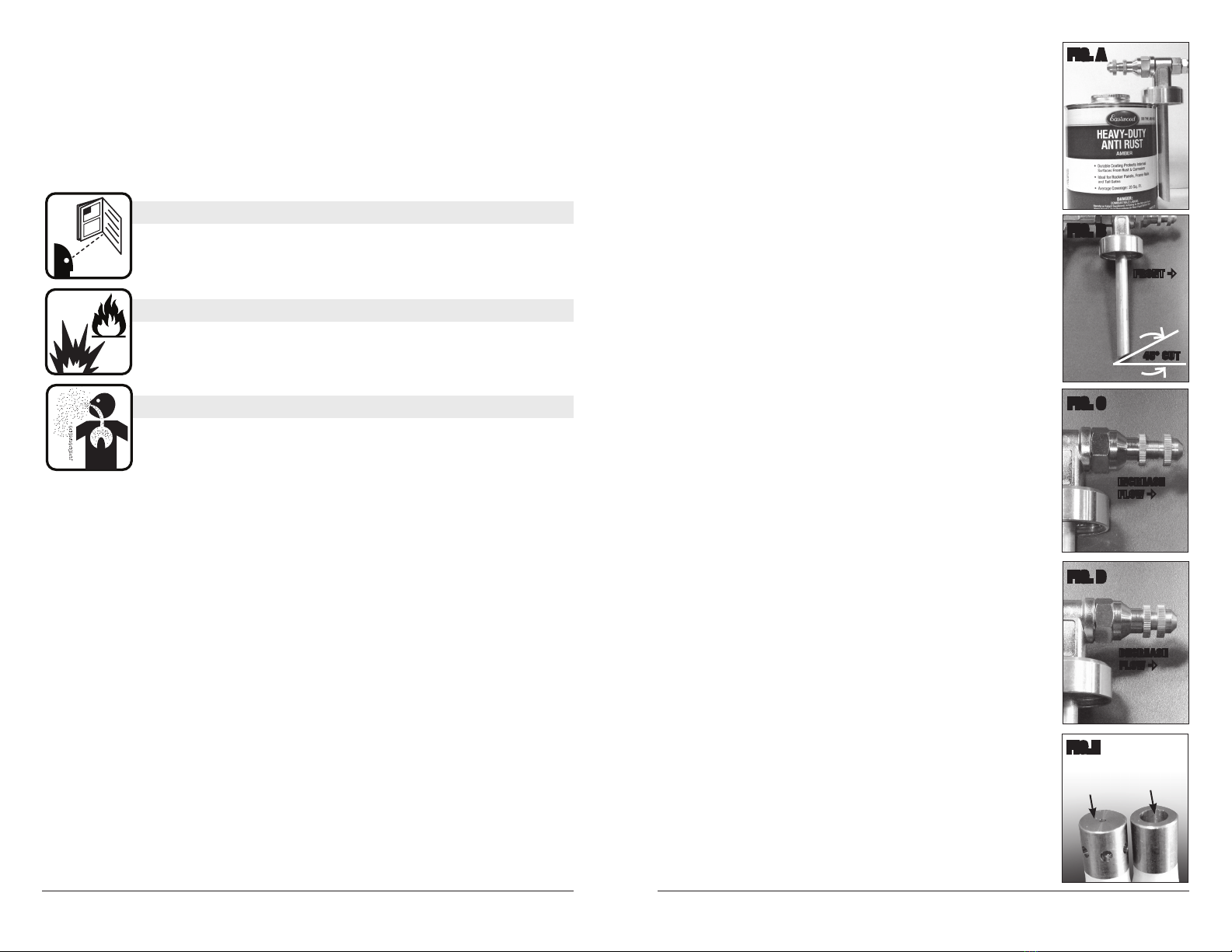

ATTACHING ACCESSORY FLEX HOSE/WANDS

The Eastwood #20441 gun includes 2 different flex hose/wands.

• The 32" long, Eastwood flex hose/wand with 360 degree

misting nozzle is best for applying thinner materials such as rust

proofing in hard-to-reach hollow areas.

• The 24" long, Eastwood flex hose/wand with single 1/4" orifice

is great for applying thicker materials such as undercoat,

bed liner, soundproofing, heat barrier and more to tight spaces

and internal areas of frames.

FIG. B

45° CUT

FRONT ¢

SAFETY INFORMATION

READ INSTRUCTIONS!

Read and understand all instructions thoroughly.

FIRE & EXPLOSION HAZARD!

Do Not use near sparks, open flame or other potential ignition source.

HEALTH HAZARD!

• Avoid breathing vapors produced by Spray Gun. Always wear appropriate

NIOSH approved breathing apparatus and use in a well ventilated area.

• Wear appropriate eye protection.

• Wear solvent-resistant gloves.

FIG. A

FIG. C

INCREASE

FLOW ¢

FIG. D

DECREASE

FLOW ¢

FIG.E

32" W/360•

MISTING

NOZZLE

24" W/ ¼"

ORIFICE