Copyright © 2011 Eaton Corporation. All Rights Reserved.

IPN 997-00012-82B May 2011

Tableof Contents

About This Guide

Purpose....................................................................................................................................... i

Audience..................................................................................................................................... i

Scope ........................................................................................................................................... i

Related Information .................................................................................................................. i

Reporting Problems with this Guide...................................................................................... i

For Further Information and Technical Assistance ............................................................. ii

Chapter 1 General Description

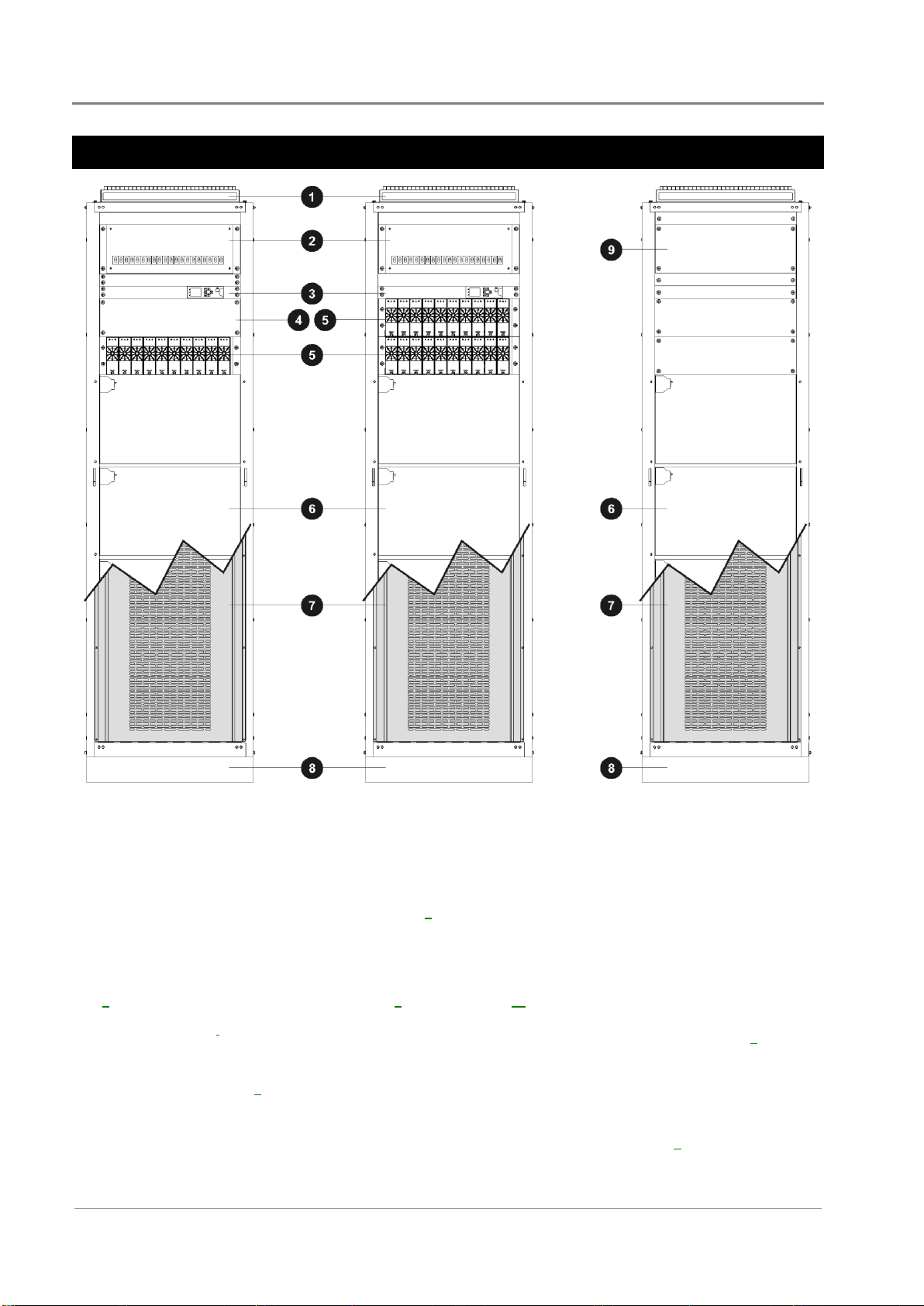

Overview ................................................................................................................................... 1

DC Power Systems................................................................................................................... 2

Rectifiers .................................................................................................................................... 3

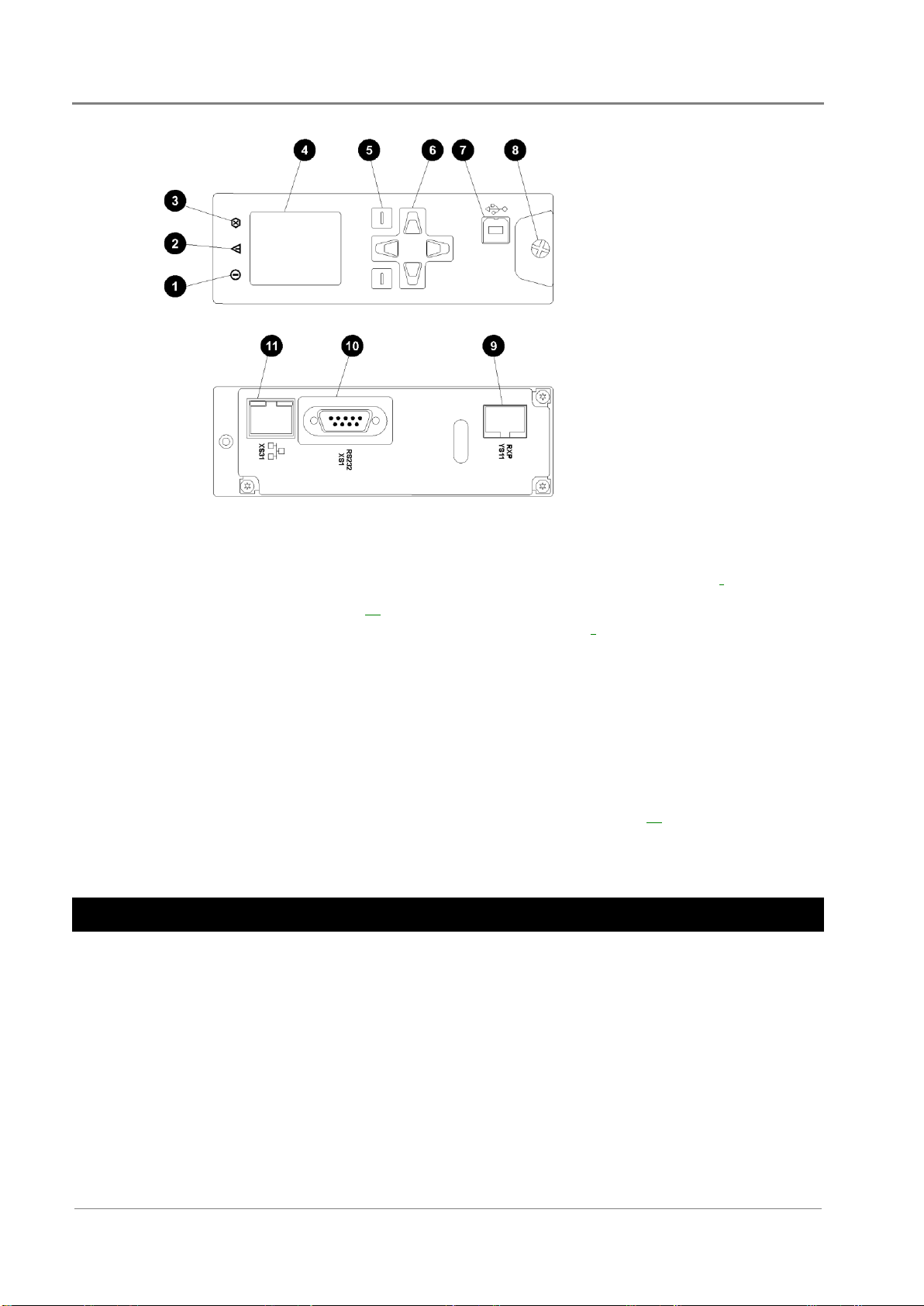

SC200 System Controller......................................................................................................... 3

Compatible Software....................................................................................................................... 4

Input/Output Board................................................................................................................ 4

Connections...................................................................................................................................... 6

Other Features .......................................................................................................................... 7

External communications............................................................................................................... 7

Low Voltage Disconnect (LVD) option......................................................................................... 7

Additional DC Distribution Module............................................................................................. 7

Battery Mid-point Monitoring Description.................................................................................. 8

Reverse Battery Detect Option....................................................................................................... 8

Bottom Cable Entry Option............................................................................................................ 8

Chapter 2 Preparation

Overview ................................................................................................................................... 9

Warnings ................................................................................................................................. 10

Inspecting the Equipment and Reporting Damage ........................................................... 12

Chapter 3 Positioning Cabinets

Overview ................................................................................................................................. 13

Preparation.............................................................................................................................. 14

Fixing Cabinets ....................................................................................................................... 14

Mounting ........................................................................................................................................ 14

Cabinet Footprint........................................................................................................................... 15

Fit the Rear Extension Cabinet (if required) ....................................................................... 15

Chapter 4 DC Cabling

Overview ................................................................................................................................. 17

DC Installation Practices ....................................................................................................... 18

Connecting the Telecom Earth Cable .................................................................................. 18

Fit or Remove Low Voltage Disconnects ............................................................................ 19

Load Cables and Circuit Breakers........................................................................................ 22

Fit DCM2000 in Battery Cabinet (if required) .................................................................... 25

Chapter 5 Battery Installation

Overview ................................................................................................................................. 27

Battery Types .......................................................................................................................... 28

Installing the Batteries ........................................................................................................... 28

Install the Batteries ........................................................................................................................ 29

Battery Cable Links for Additional Battery Racks (if required) .............................................. 31

Installation procedure................................................................................................................... 31