RECEIVING, HANDLING AND

INS

P

E

CT

I

O

N

The control panel, motor and accessories have been packed

in a separate container but shipped with the strainer. This

provides protection from damage during

transit and also provides for ease of storage if the controls are

not installed immediately. When first received the following

must be done:

1. Unpack and inspect for damage.

2. Report any damage to carrier immediately.

3. If controls are not installed at this time, refer to Storage

Instructions.

STORAGE

INS

T

RU

CT

I

O

NS

Repack all components in the original carton and reuse all

protective packaging. Store all components in an indoor,

clean, and dry environment. Protect from temperature

extremes. Mark cartons to protect from handling abuse.

STRAINER MODE OF OP

ERA

T

I

O

N

CONTINUOUS

BA

C

K

W

ASH

This is the most effective way to keep the strainer element

“clean”and have the least pressure loss. Continuous element

washing can be accomplished with a minimum of control

devices. However, it offers no flexibility of operation when

there are significant changes in flow volume or solids content

of the fluid.

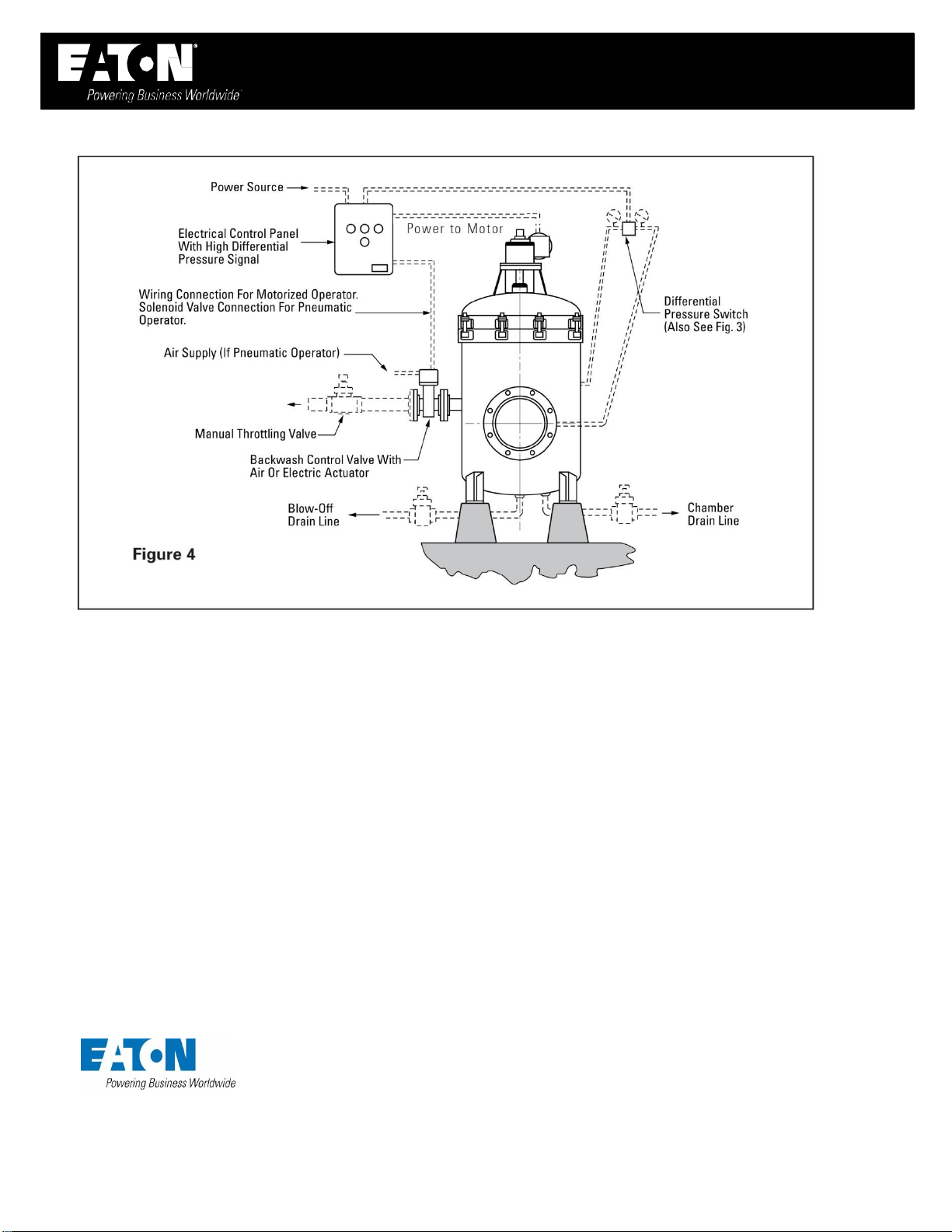

The “drain”line requires a blow-down/drain valve which may

be manually operated. Normal valve position is CLOSED.

The backwash line requires a backwash valve which may be

manually operated on the backwash line. Normal valve

position is FULL OPEN.

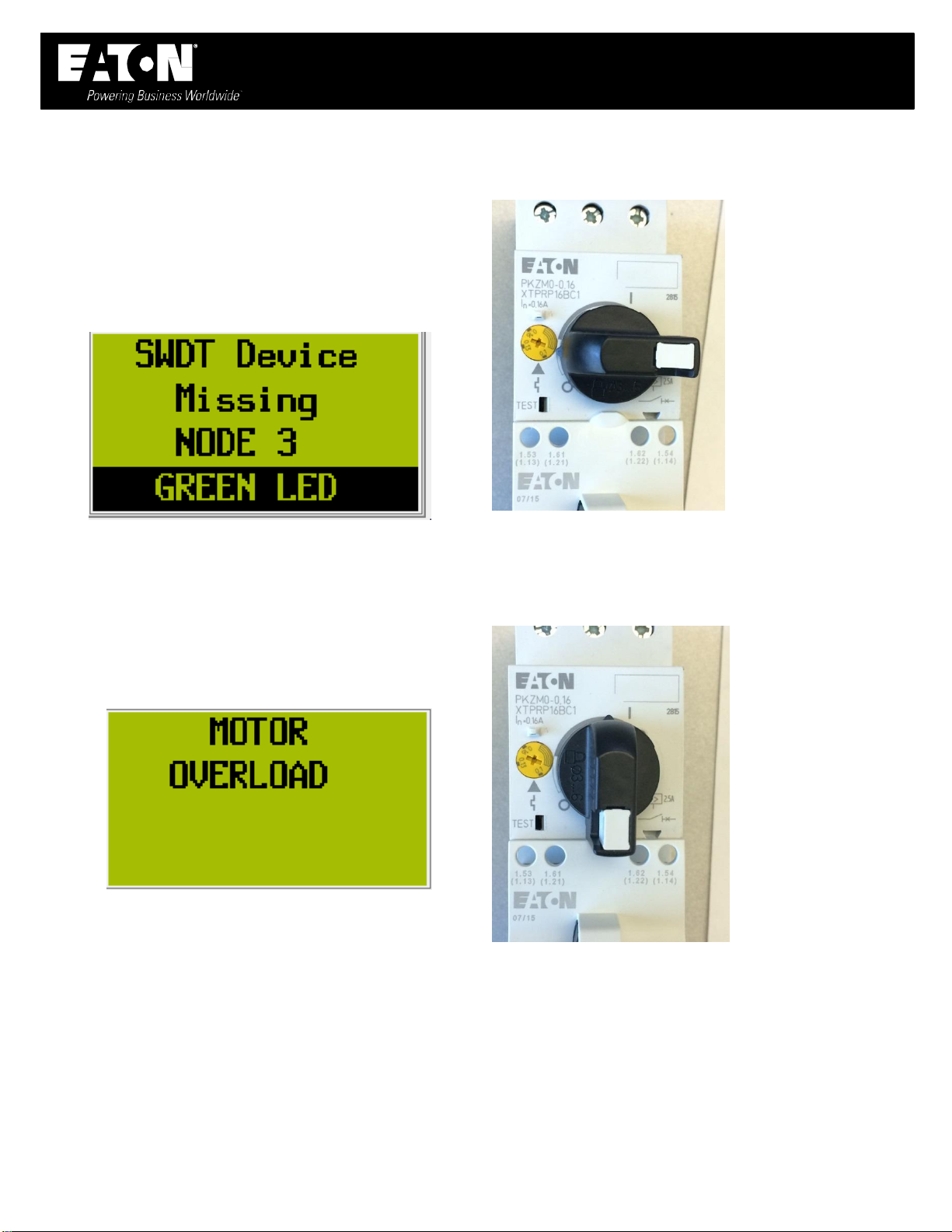

The backwash motor requires a motor starter. Furnish with

overload protection and fused disconnect.

STRAINER MODE OF OP

ERA

T

I

O

N

AUTOMATIC BACKWASH (TIMED C

Y

C

LE)

The preferred mode of operation for a self-cleaning strainer is

one where the control system will permit both intermittent and

continuous backwash as required by operating conditions.

The “drain”line requires a blow-down/drain valve which may

be manually operated. Normal valve position is CLOSED.

The backwash line requires a backwash valve, either electrically

or pneumatically operated on the backwash line. This valve

should operate only in the FULL OPEN or FULL CLOSED position.

A fully adjustable differential pressure switch is furnished to

detect the increase of pressure across the strainer. It will

activate a backwash cycle independent of the time-controlled

sequence. NOTE: Set switch at 2psi over the observed clean

pressure drop.

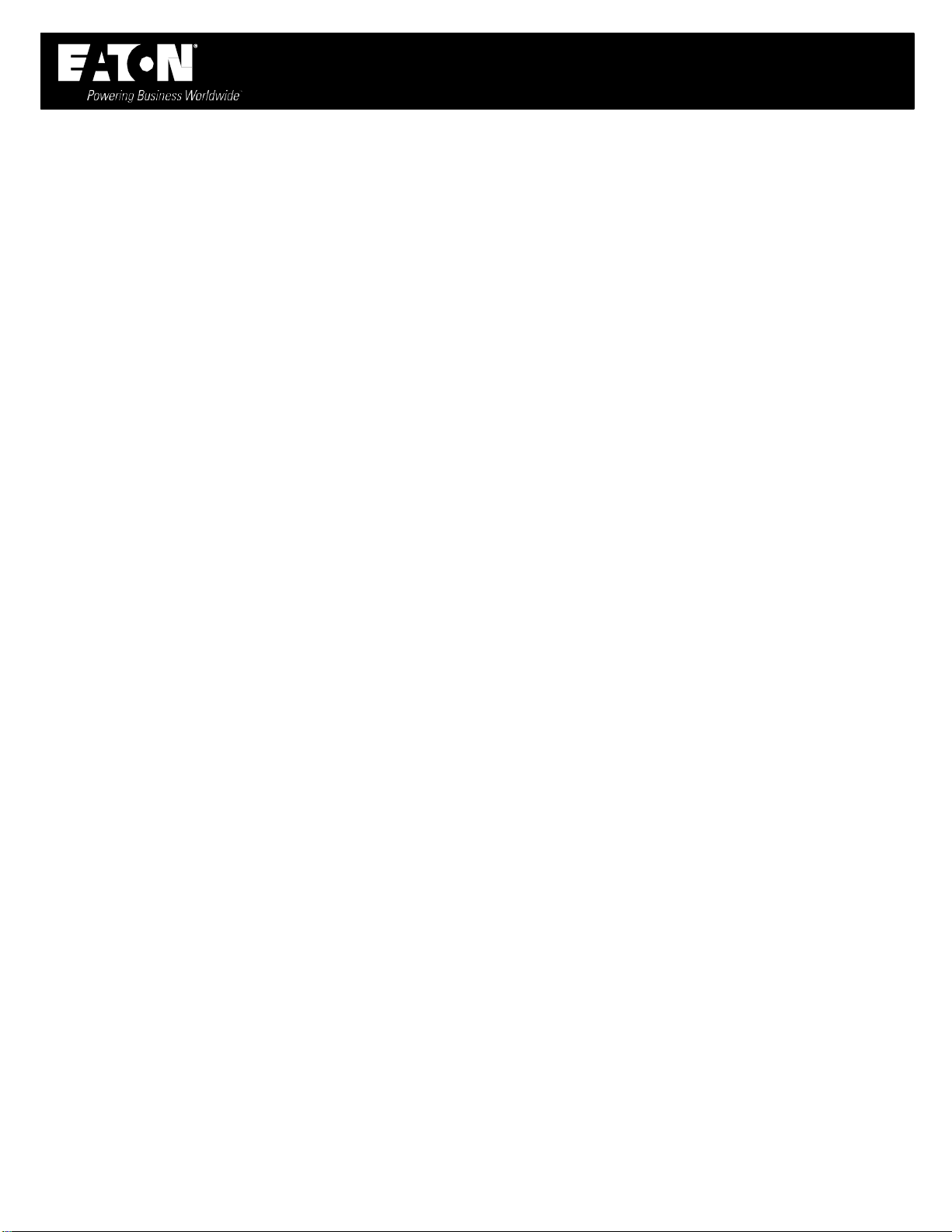

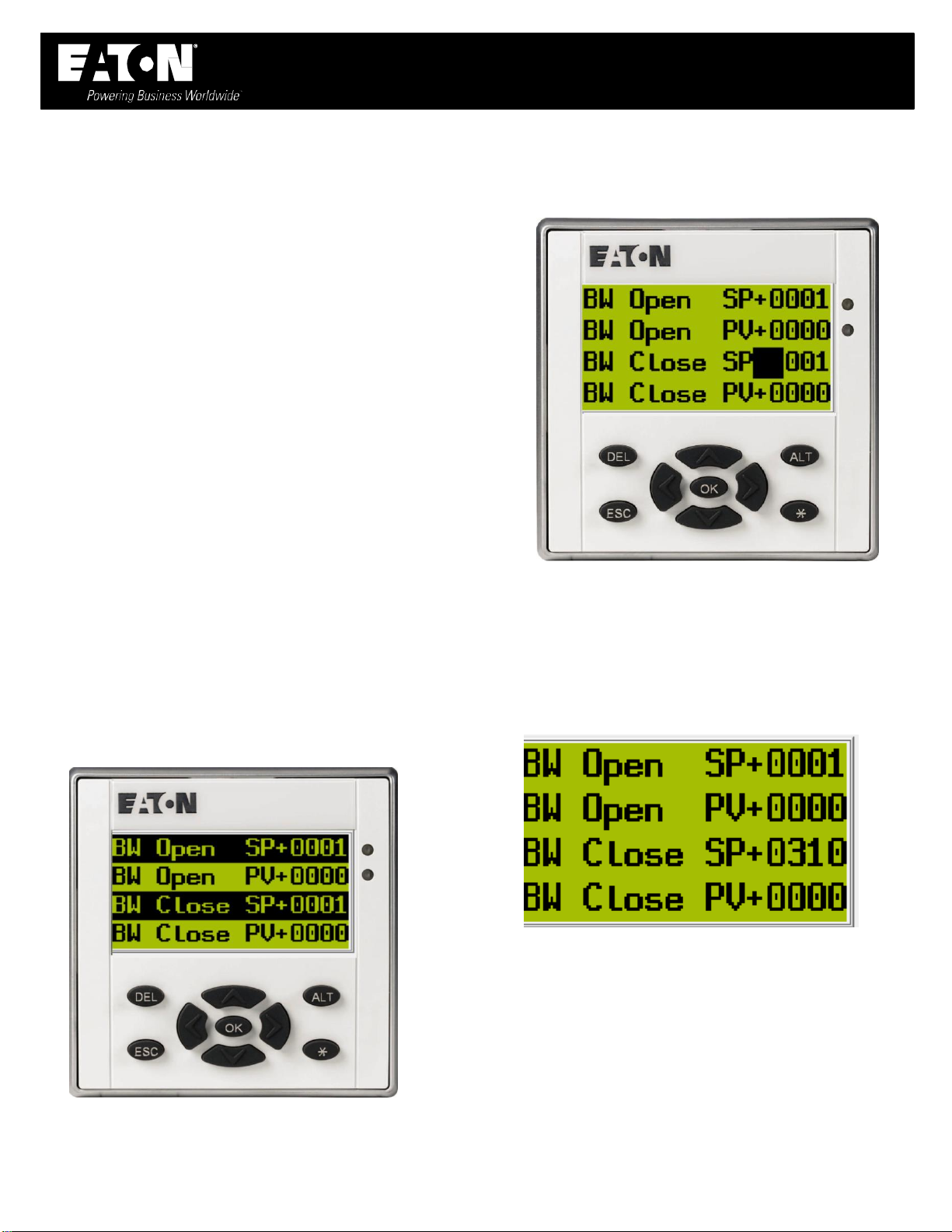

Eaton provides a control panel, containing all necessary relays,

timers, lights, switches, etc. This will initiate and monitor the

intermittent backwash cycles.

VALVE

SELE

CT

I

O

N

Several important factors to consider when selecting the

necessary valves.

Valve Type: Gate, plug, and butterfly valves can be used.

However, ball valves provide the most advantages. Ball valves,

when “Full Open”provide a uniform and straight flow path

minimizing pressure loss. Since only 90° rotation of the stem is

required to go from “Fully Closed”to “Fully Open”motorized

operators are easily adapted and provide short cycle times.

Valve Material: Iron, bronze, steel, and stainless steel are the

most common. Select valve and trim material that will not

corrode or react with the process fluid or the environment.

Pressure Rating: Select the valve class with a pressure rating

equal to or greater than the system design pressure.

Connection: Select a valve with end connections (flanged,

threaded, etc.) that will provide ease of maintenance and

trouble-free service.