For more information visit: www.eaton.comwww.eaton.com

www.eaton.comwww.eaton.com

www.eaton.com

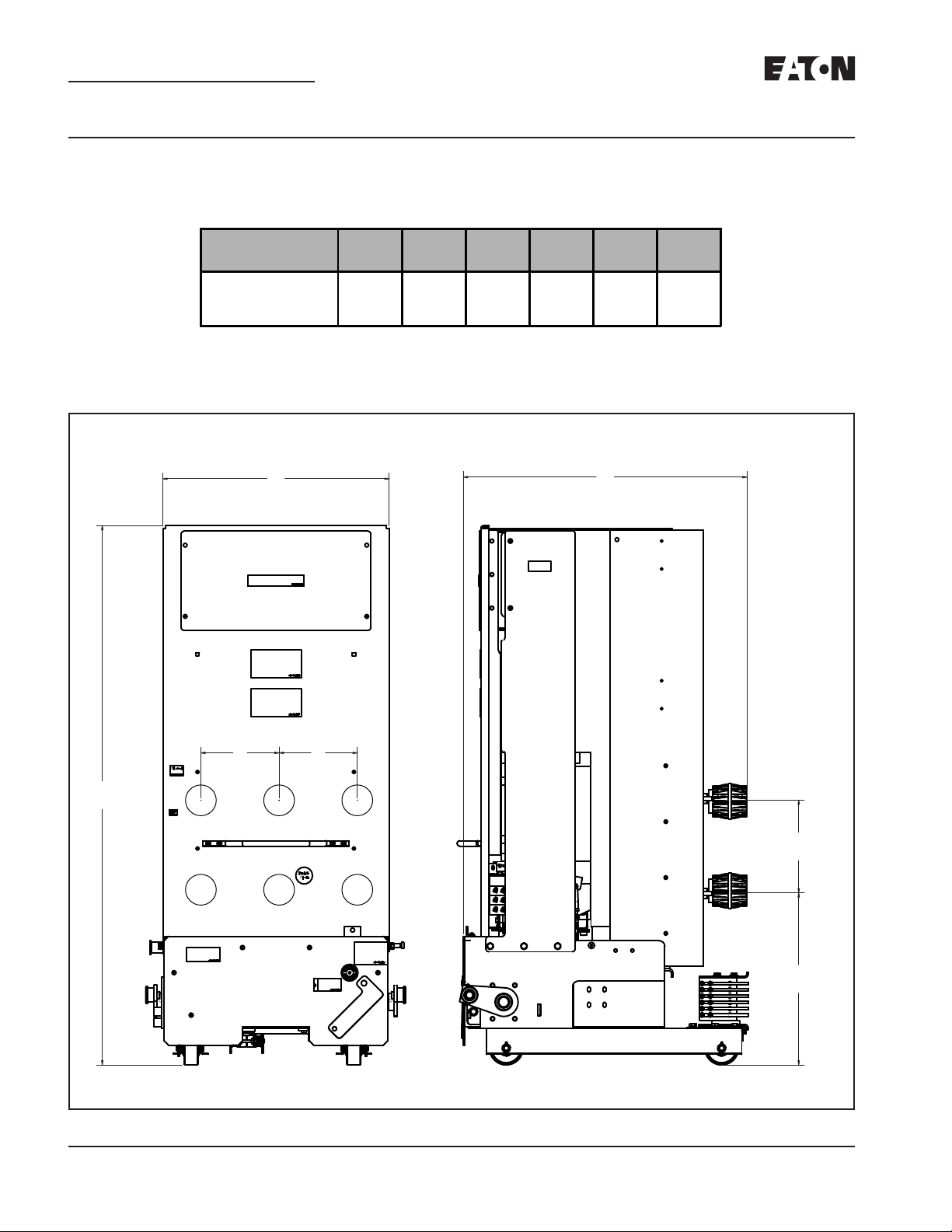

Instructions for

VSR-Series Type 5HK

Vacuum Motor Starter

IB01301027E

IB01301027E

Page 2Page 2

Page 2Page 2

Page 2 Effective: May 2008Effective: May 2008

Effective: May 2008Effective: May 2008

Effective: May 2008

Table of Contents

SECTION1:INTRODUCTION ......................................................................................................................................... 5

1.1 AVAILABLE 5HK-VSR MOTOR STARTER REPLACEMENTS ................................................................................................................................... 5

SECTION 2: SAFE PRACTICES ..................................................................................................................................... 7

SECTION3:RECEIVING, HANDLINGANDSTORAGE ......................................................................................................... 8

3.1 RECEIVING .......................................................................................................................................................................................................... 8

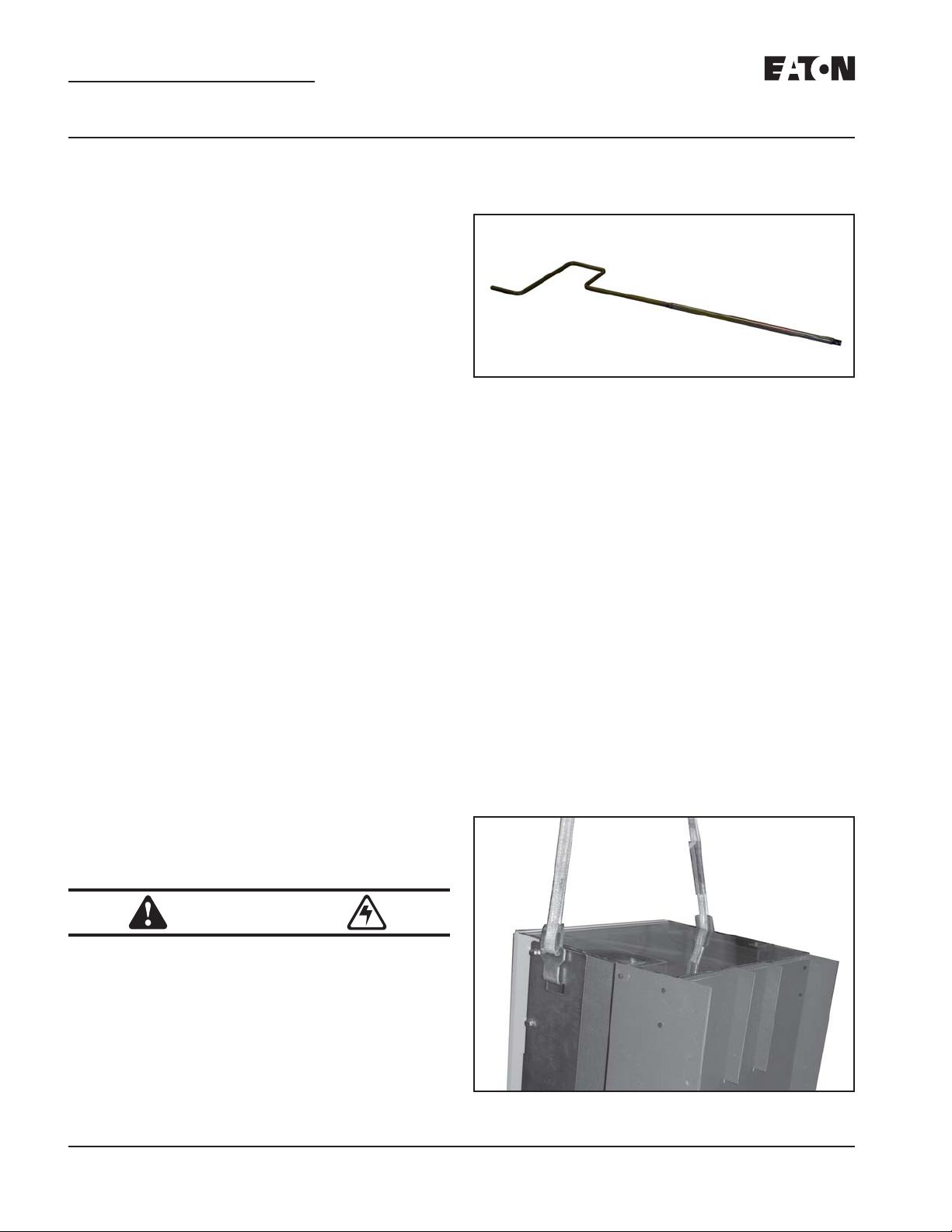

3.2 HANDLING .......................................................................................................................................................................................................... 8

3.3 STORAGE ............................................................................................................................................................................................................. 8

3.4 5HK-VSRAPPROXIMATEWEIGHTS ...................................................................................................................................................................... 9

SECTION 4: INSTALLATIONAND INSPECTION .............................................................................................................. 12

4.1 EXAMINATION FOR DAMAGE ............................................................................................................................................................................. 12

4.1.1 NAMEPLATEVERIFICATION ............................................................................................................................................................................. 12

4.2 INITIAL INSPECTIONAND OPERATION ............................................................................................................................................................... 12

4.3 VACUUM INTERRUPTER INTEGRITY ................................................................................................................................................................... 12

4.4 INSULATION INTEGRITY ..................................................................................................................................................................................... 13

4.5 INTERRUPTER WEAR CHECK ............................................................................................................................................................................. 13

4.6 PRIMARY CIRCUIT RESISTANCE ........................................................................................................................................................................ 13

4.7 ELECTRICAL OPERATIONS CHECK .................................................................................................................................................................... 13

4.8 INSERTION PROCEDURE .................................................................................................................................................................................... 13

4.9 REMOVAL PROCEDURE ..................................................................................................................................................................................... 15

SECTION 5: DESCRIPTIONAND OPERATION ................................................................................................................. 16

5.1 CONTACTOR OPERATION ................................................................................................................................................................................... 16

5.2 PHASE BARRIERS .............................................................................................................................................................................................. 18

5.3 SECONDARY DISCONNECTS .............................................................................................................................................................................. 18

5.4 INTERLOCKS ...................................................................................................................................................................................................... 18

5.5 LEVERING-IN INTERLOCK .................................................................................................................................................................................. 18

5-6 MISCELLANEOUS ITEMS .................................................................................................................................................................................... 19

5-6.1 GROUND CONTACT ......................................................................................................................................................................................... 19

5-6.2 OPERATIONS COUNTER ................................................................................................................................................................................... 19

5-7 LEVERING DEVICE ............................................................................................................................................................................................. 19

SECTION6: INSPECTIONANDMAINTENANCE ............................................................................................................... 20

6.1 GENERAL ........................................................................................................................................................................................................... 20

6.2 VACUUM INTEGRITY CHECK .............................................................................................................................................................................. 20

6.3 INTERRUPTING WEAR CHECK ........................................................................................................................................................................... 20

6.4 INSULATION INTEGRITY CHECK ......................................................................................................................................................................... 21

6.5 CONTACT RESISTANCE CHECK .......................................................................................................................................................................... 21

SECTION7: REPLACEMENTOFCOMPONENTS .............................................................................................................. 22

7.1 REPLACEMENT OFVACUUM INTERRUPTERS .................................................................................................................................................... 22

7.1.1 ADJUSTINGVACUUM INTERRUPTERS ............................................................................................................................................................. 22

7.2 Coil Replacement ............................................................................................................................................................................................... 23

7.3 Control Board Check and Replacement .............................................................................................................................................................. 23

7.4 STOPASSEMBLY REPLACEMENT ....................................................................................................................................................................... 23

7.5 AUXILIARY CONTACT MAINTENANCEAND REPLACEMENT .............................................................................................................................. 24

7.6 MECHANICAL LATCH ......................................................................................................................................................................................... 25

7.6.1 LATCH REMOVAL ............................................................................................................................................................................................. 25

7.6.2 LATCH INSTALLATION ..................................................................................................................................................................................... 26

SECTION8: REPLACEMENTPARTS .............................................................................................................................. 27