This manual is effective for all filters of the type series DNR 405-635, DNR 630, DNR 1001-8201, DNR 1005-8205, DNA 250-2050,

DNL 630, EDNR, EDNA and EDNL and related specifications. It contains certain requirements and instructions which ensure

unobjectionable operation of the filter. It can be completed with specific additional instructions by the operator himself if necessary.

The pressure filters listed above are intended for the filtering of liquid media.

1. Safety instructions

- Prior to operating the filter, manual and maintenance instructions have to be read carefully.

- Follow the instructions of this manual under any circumstances!

- The manufacturer does not assume liability for any damage, which occurs due to disregarding these instructions.

- If operations are carried out differently, the safety of the pressurized device can not be assured!

- Operating conditions given in the data sheet, especially excess pressure, temperature range and operating fluid, have to be

followed unconditionally. Variation of these parameters can cause damage to important pressure holding parts and sealing. Also

take in consideration the compatibility of filter components with the operating fluid.

- Under working conditions the filter housing is pressurized. Do not try to loosen or remove any part of the filter or the filter housing

during operation. The operating fluid could escape at high pressure and high temperatures.

This does not apply for parts of the decompressed or the turned off side of the filter (see „Maintenance“).

- Leaking operating fluid always bears the danger of injuries and burns!

- Do not open the filter housing until you made sure it is not pressurized any more!

- Touching parts of the filter may cause burning, depending on the operating temperature.

- When exchanging the filter keep in mind that it might have operating temperature. Danger of burning!

- Always wear safety goggles and gloves when working on the filter!

- If you come into contact with the operating fluid please follow the instructions of the fluid manufacturer!!

- Only use original spare parts.

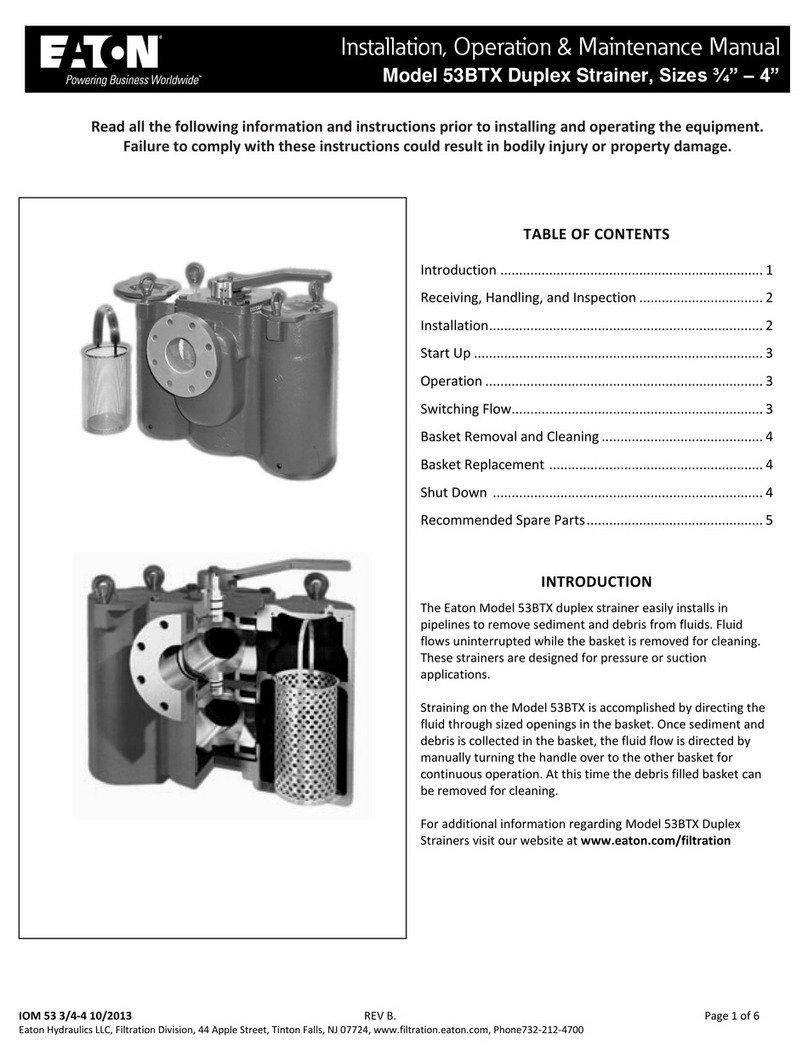

2. Installation

The filter is supplied and delivered ready to be installed. The fitting position of the filter is vertical. The filter has to be fitted with

fastening screws in size and amount according to the corresponding fastening bore holes of the filter housings. The fitting of the filter

has to be carried out in the way that the least possible transmission of tensible forces on the filter housing and the change-over valve

is given. The connection of the pipework has to be made with flanges for pipework.

Ensure upon assembling that

- no dirt and no impurities of foreign fluids penetrate the filter

- the connections for input and output are correctly connected to the pipe system

- the pipe system is connected with the filter; as stress-free as possible

- the extension to demount and the accessibility to the service elements is guaranteed

Filter with electrical respectively electronical clogging indicators have to be installed according to the unit specific conditions and

according to the technical parameters of the corresponding data sheets.

3. Commissioning

Before commissioning the completeness of the filter (filter elements and seals) and the cleanness have to be controlled.

Air bleeding of the controlled filter has to be carried out to the following instructions:

- The positioning pin of the selector shaft has to be located in the middle position

- Opening of the air-bleed screws or air-bleed connections (air-bleed connections according to data sheet 1651 and

connection of suitable airbleeding tubes with collecting pan for the flow out of the operating fluid

- Connection of the unit volume flow (reduced volume flow; from 10 to 50 l/min) until bubble-free operating fluid flows out of both

airbleeding tubes

- Disconnection of the unit volume flow

- Remove the airbleeding tubes and close the air-bleed bore holes or air-bleed connections (air-bleed connections

according to data sheet 1651)

- Connection to the required filter side at the positioning pin of the selector shaft

Take a look at the indicating labels and change-over indications at the filter.

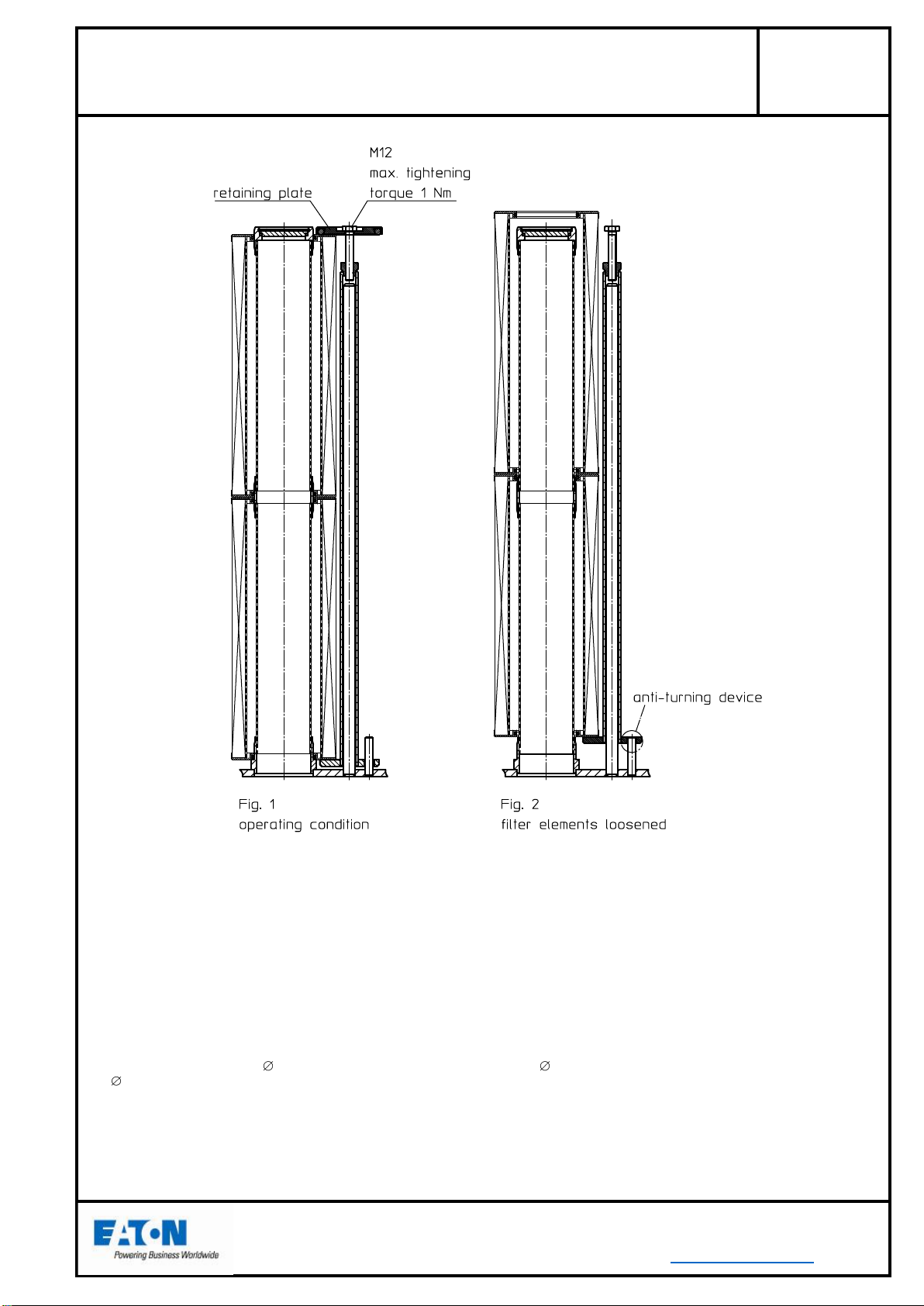

4. Change of Elements

The changing of the filter elements is necessary when reaching the unit specific pressure difference respectively reaching the

maximum pressure difference given by the clogging indicator. If there is no unit specific definition, the change of the elements

should be done at a maximum of p 6 bar.

The filter element can be changed during operation. This has to be carried out as follows:

- Opening of the pressure balance valve

- Switching over the positioning pin from the operating side through the other side

(Take a look at the indicating labels and change-over indications at the filter)

- Closing the pressure balance valve

- Connect the air-bleed and the drain plug of filter side to be maintained with suitable pipes and place a collecting pan for the

operating fluid flowing out