Revision

Semi-Auto Control Installation, Operation & Maintenance

Teflon®and Viton®are a trademarks of DuPont™. Nordel™ is a trademark of The Dow Chemical Company. Kynar®is a trademark of Elf Atochem North America, Inc.

Page 1 of 4

Description ............................................................................................. 1

Specifications......................................................................................... 1

Service Requirements ....................................................................... 1

Materials of Construction................................................................... 1

Connections....................................................................................... 1

Design Temperature.......................................................................... 1

Airborne Noise Emissions ................................................................. 1

Installation.............................................................................................. 1

Connect Air Supply............................................................................ 1

Connect Electrical Supply ................................................................. 1

Transportation ................................................................................... 2

Securing to Foundation ..................................................................... 2

Checklist............................................................................................ 2

Commissioning Procedure ................................................................ 2

Operation ............................................................................................... 2

Operational Modes................................................................................. 2

Filtering.............................................................................................. 2

Cleaning ............................................................................................ 2

Purging .............................................................................................. 2

Control Logic .......................................................................................... 2

Purge Sequence......................... Fehler! Textmarke nicht definiert.

System Faults............................. Fehler! Textmarke nicht definiert.

Troubleshooting ..................................................................................... 3

Symptoms.......................................................................................... 3

Possible Faults .................................................................................. 3

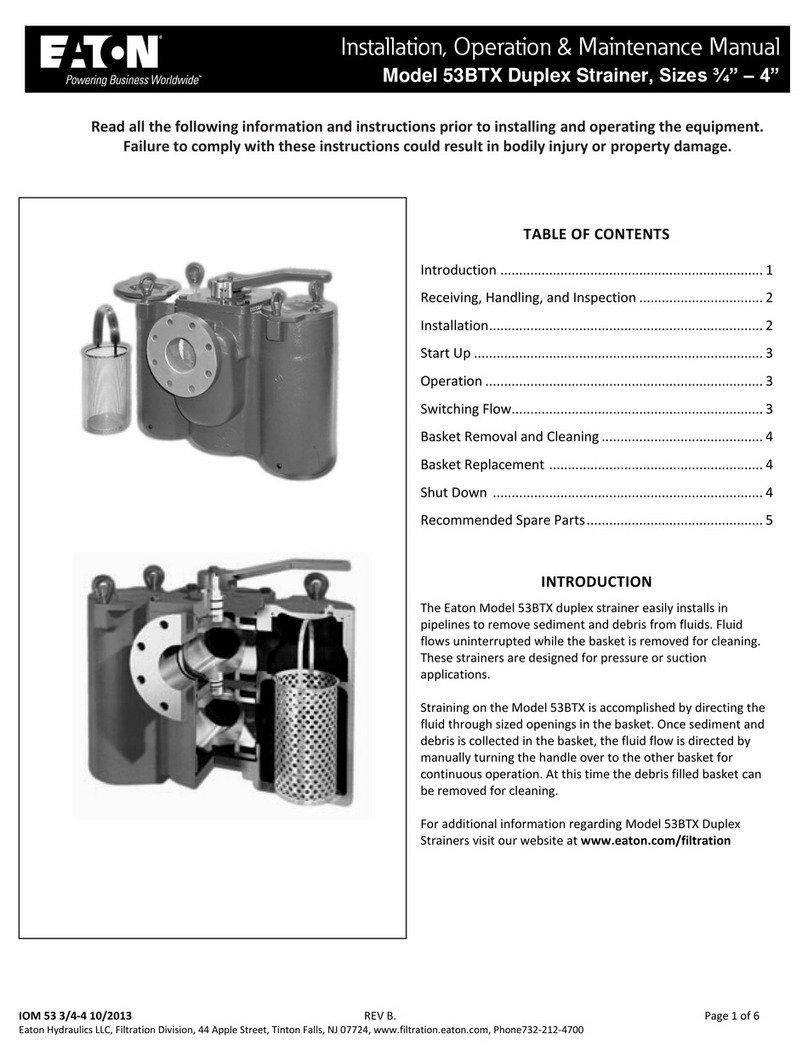

Description

Each filter Station of a DCF filter system consists of a stainless steel

cylindrical filter screen sealed within a stainless steel filter housing.

Unfiltered process fluid enters the filter housing through the upper port.

The process fluid enters the inside of the filter screen from above and

the filtrate flows through the filter screen, exiting the filter housing

through the lower port. The filter screen traps filtered contaminants on

the inside of the filter screen. The contaminants are periodically

scraped off the surface of the filter screen by a cleaning disc which

travels up and down the surface of the screen. These contaminants are

deposited in a collection (purge) chamber in the bottom of the filter

housing where they are periodically purged out of the bottom port of the

filter housing.

The use of Teflon®tape is not recommended

for all pipe connections. Teflon

®tape tends to break off

and clog orifices. Electrical supply voltage must match

the automation enclosure rating. Incorrect supply

voltage will cause damage and may cause injury.

prevent electrical shock, follow proper safe work

procedures when working on electrical circuits.

Specifications

This lists the general control specifications for a typical Mechanically

Cleaned semi automatic filter system.

Service Requirements

Electrical: 24V DC, 120V AC 50/60 Hz, Single phase supply.

Air: Minimum 60 PSIG (4 bar), Maximum 116 PSIG (8 bar) at 2.5 cfm

(70.79 L/min) clean, dry, non-lubricated air.

Materials of Construction

All welded and wetted materials are type 316/316L stainless steel. The

material selection for this vessel was based on the information provided

when the unit was ordered. It is the customer’s responsibility to ensure

material compatibility.

Connections

Air supply: ¼” NPTI (standard)

Design Temperature

Temperatures vary based on elastomer and cleaning disc materials.

Maximum temperature for lid and element elastomers: Viton®and

Teflon®400 °F (204 °C), Buna-N 220 °F (104 °C), EPT 300 °F

(149 °C)

Maximum temperature for cleaning disc materials: Polyethylene

180 °F (82 °C), Kynar®285 °F (140 °C), Teflon®400 °F (204 °C),

Urethane 175 °F (79 °C)

Airborne Noise Emissions

<70 dB(A) During normal operation

Installation

This document applies to the installation of the filter unit controls. See

additional instructions for the installation of the filter vessel.

Connect Air Supply

1. Install an air supply block valve, air filter and air supply bleed

valve (all customer supplied) before the solenoid valves.

2. Connect the air supply line to the air supply block valve (customer

supplied).

3. If not already assembled, connect the air lines from the solenoid

valves to the filter unit. On the cleaning disc solenoid valve,

connect port ‘B’ to the lower air port on the linear actuator.

Connect port ‘A’ to the upper air port on the linear actuator. When

the filter is ON, the solenoid valve is de-energized and the linear

actuator is retracted (at the top of the filter element). When the

linear actuator solenoid is energized, the cleaning disc is pushed

to the bottom of the filter housing.

4. Connect the purge valve solenoid port ‘B’ to the left port (when

facing the actuator with the indicator pointing up) on the purge

valve rotary actuator. Connect solenoid port ‘A’ to the right port

(when facing the actuator with the indicator pointing up) on the

purge valve rotary actuator. When the filter is ON, the solenoid

valve is de-energized and the purge valve is closed. When the

solenoid is energized, the purge valve opens.

Connect Electrical Supply

1. All wiring and power connections need to meet local electrical

code requirements.

2. No holes have been provided in the automation enclosure for

incoming wiring. A hole in the enclosure will need to be made in a

suitable location to receive incoming electrical wiring. Protect