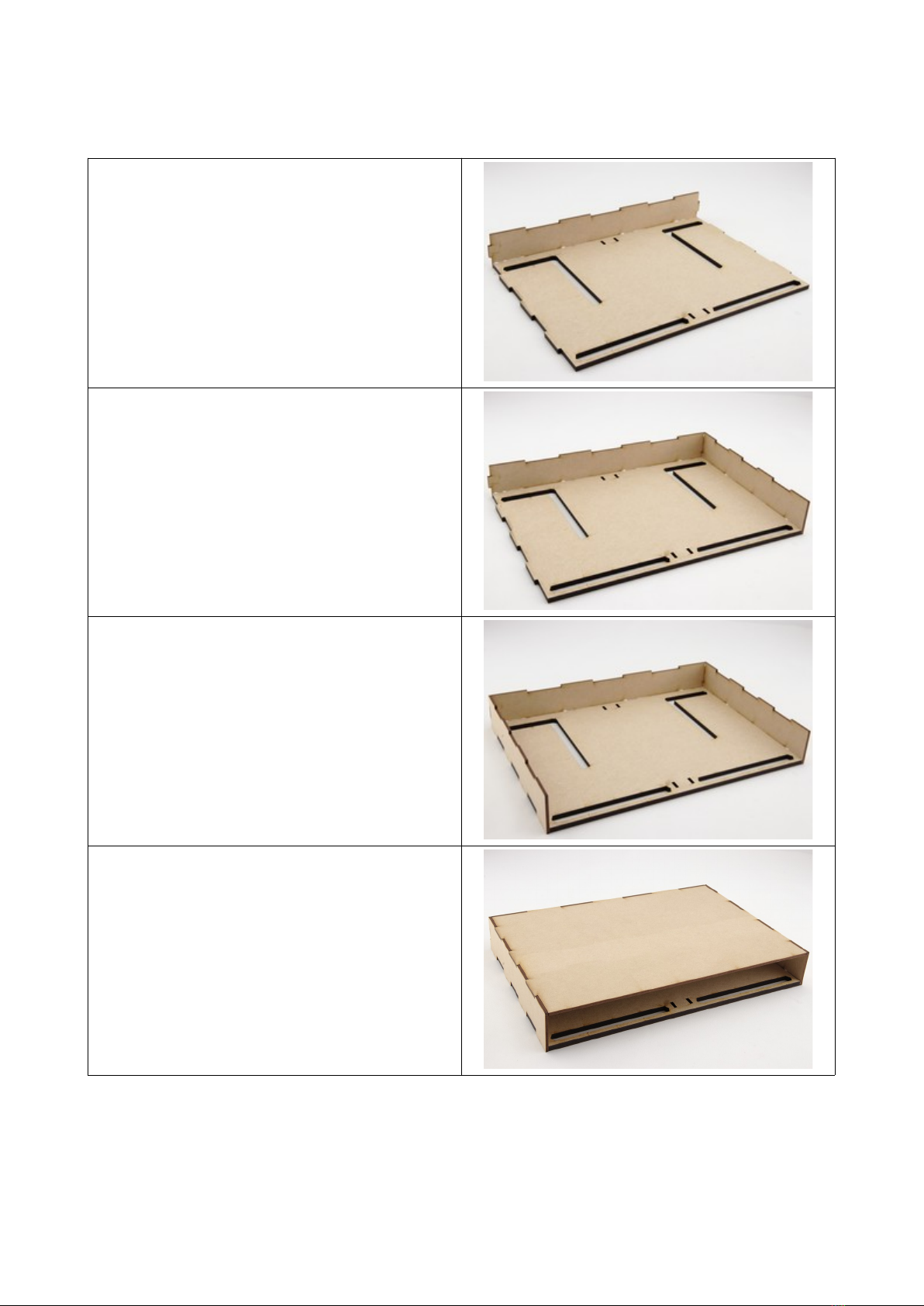

Setting the orizontal Stabilisers

1. With the fuselage held centrally and

vertically on the jig select the pair of

Wing Setting Guides that will support

the tail plane best. This largely

dependent upon the height of the

stabilisers above the jig.

2. Using a combination of the base marker

on the setting guides with the graduation

marks on the jig and also the graduation

marks on the setting guides set the angle

of the stabilisers.

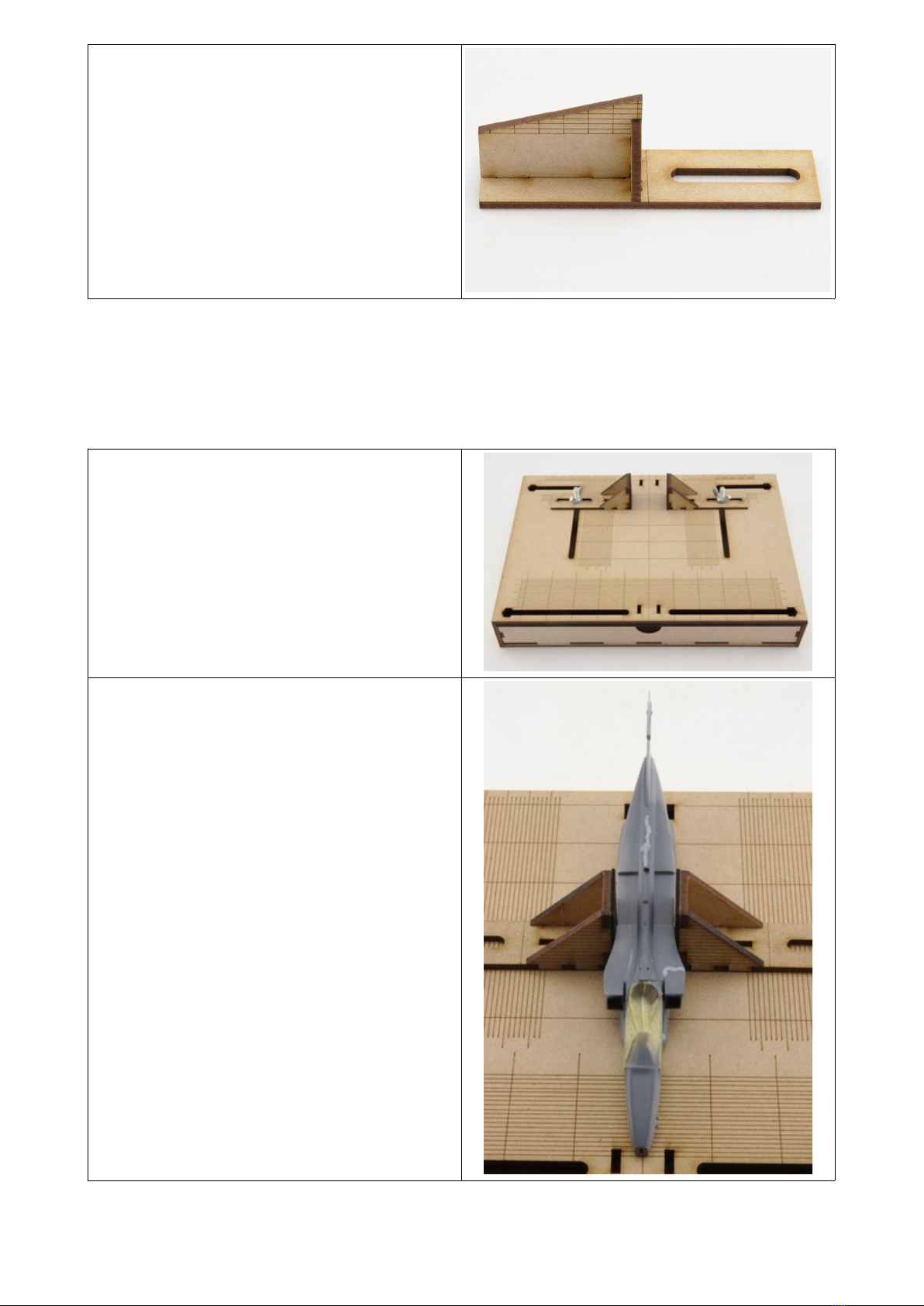

For larger models it may be necessary to utilise the main plane section of the jig in order to set the

horizontal stabilisers.

Setting the Main Plane

1. With the fuselage held centrally and

vertically on the jig select the pair of

Wing Setting Guides that will support

the wings best. This largely dependent

upon the height of the wings above the

jig.

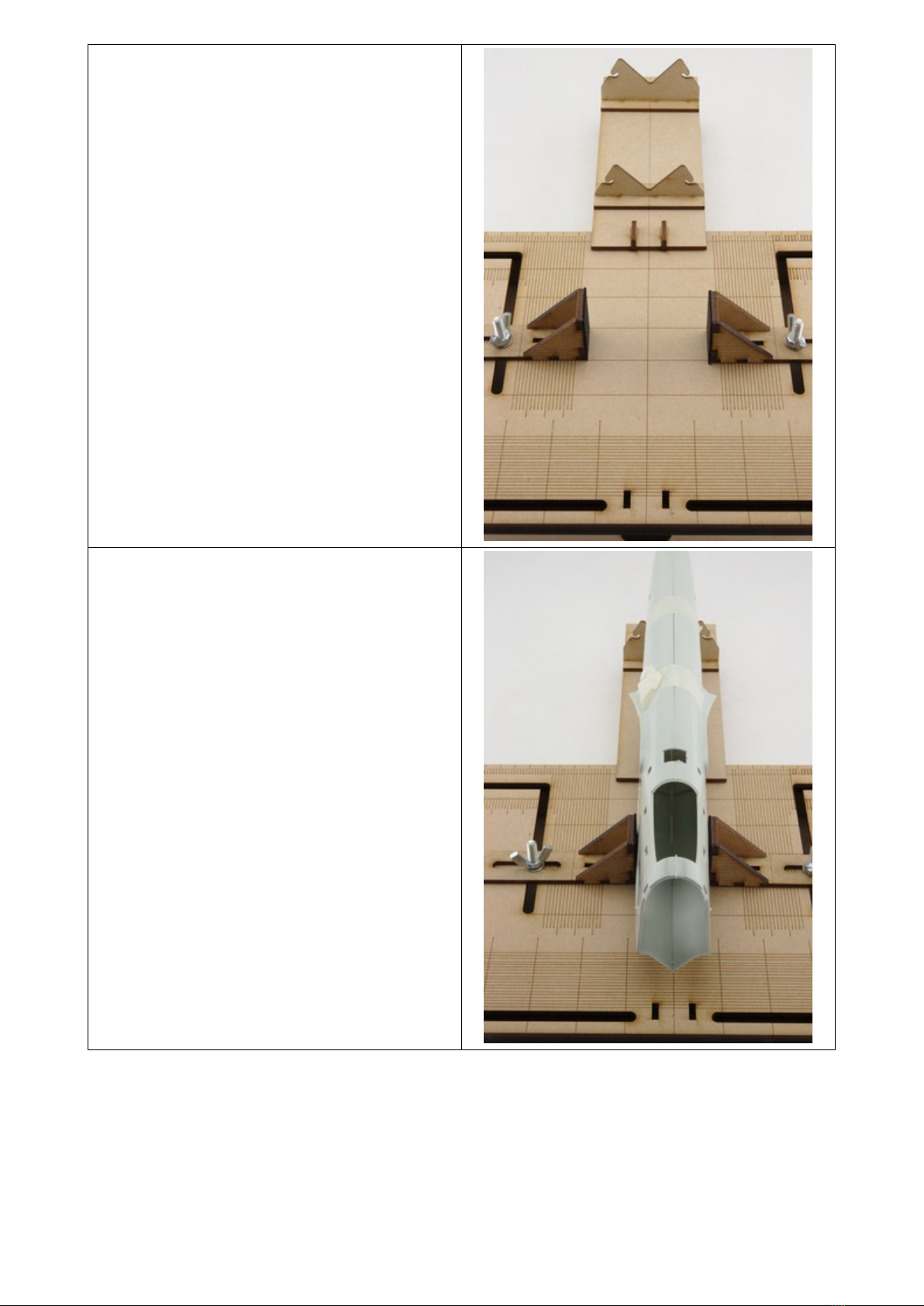

2. Set one wing to approxiamately the

correct angle and then use the Main

Plane Supports to hold the wing at the

correct rotation to get a good joint with

the fuselage.

3. Set the second wing approxiamately the

same and check that the fuselage is still

correctly aligned.

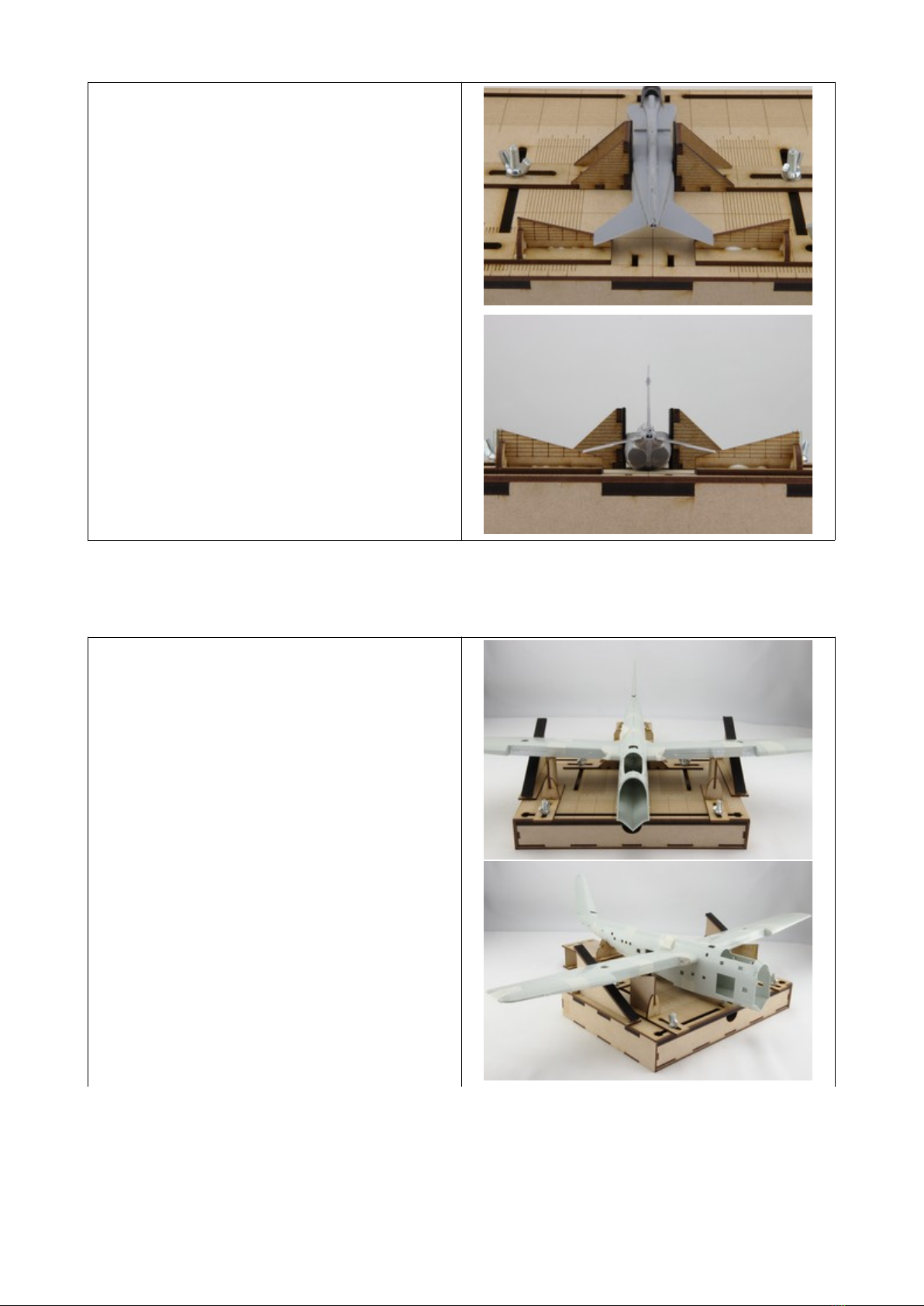

4. Adjust the wing supports using the

graduation markings on the supports and

the base to help get both sides the same.

© Copyright 2020 EBMA Hobby & Craft.