ECEFAST TDS-100M User manual

TDS-100M Manual

1

TDS-100M Ultrasonic Flowmeter

User Manual Ver.18.0

TDS-100M Manual

2

ground line(include upstream ground line

and downstream ground line)

CONTENT

1. Must-knows about TDS-100M···············································5

2. Introduction to TDS-100M··················································6

3. Menu Window Details······················································7

4.transducersinstallation

TDS-100M Manual

5

Technical Manual for new versions TDS-100M

1. Must-knows about TDS-100M

Please the users must read the following paragraphs when you use TDS-100M for the first time

The setup of a TDS-100M ultrasonic flow converter needs one of the three tools. The first tool is a parallel

LCD and keypad module which can be connected to the 20 Pins port. The second tool is a serial LCD and

keypad module which can be connected to the RS232 port. The third one is a PC-based software (under

development), by means of the software, the parameters that TDS-100M needs to work properly could be

downloaded by use of the RS232 port on the PC. If your computer does not have a RS232 port, you need to

buy a USB-RS232 converter.

(1)All setup parameter data are stored in the RAM memory temporally. Users need to solidify the

parameters, when setups are been finished, that is to store the parameter to the internal flash memory. Go to

Menu26, Select the option that says “make default paras” then pressing the ENT key will start the progress

of storing. If the current parameters are different with that in the flash memory, the system will store your

current parameters into the flash memory and then boot again. By doing so, the parameters will always be

TDS-100M Manual

6

get lost, even when both the power supply and the backup battery are removed.

(2)The zero point, that is the indicated flow under the situation of motionless liquid, has a great influence

over the linearity and accuracy of the flow meter. Users should try every possibility to perform the Zero

Setup that is located at Menu 42. Zero setup should always been performed under the condition of

motionless liquids. If Zero setup was been performed with motion of the liquid, you can use Menu 43 to

restore to the original zero point. The zero point will be stored in the RAM memory temporally when you

use Menu 42. If you want to solidify the zero point, you need to perform Menu 26 “make default paras”

function again. If this step was omitted, the system will override the RAM zero point by restoring the zero

point that is stored in the flash memory with next power-on.

(3)The internal calendar is the base of date accumulators. Incorrect date and time will cause messy

records with the date accumulators. Please the user check the calendar by input correct date and time. The

calendar runs relying on the backup battery when there is no 24VDC supply. When the battery voltage is

less than 2 volts, a new backup battery should be replaced with. Replacing the battery with a new one

should be performed with the 24VDC applied so that the accumulator data and calendar data will not get

lost.

(4)Please pay great attention to the power supply. The applied voltage should be in the range of +15V to

24VDC, or 15V to 20VAC. Avoid applying a 110VAC or 220VAC power forever, or the module will be

damaged.

(5)Pay attention to the display located on Menu 48, which shows the points of lines for the linearity

correction function. 0 stands for shutting off the function. The default value is 0. Try to make sure that

value is 0 so as to avoid abnormal flow.

(6)The latest calibrated data which are produced by performing the analog input or output calibration are

store in the RAM memory temporally. Users need to perform the M26 function to make these data be

solidified.

(7)Use Menu 49 to check if there are inputs from the RS232 port with network application. If not, please

check protocol selection software switch located at Menu 63 and the serial port parameters options located

at Menu62. Select option 1 at Menu 63 for the MOSBUS RTU application. Select option 0 for MODBUS

ASCII and FUJI extended and Simple Water Meter protocols.

(8)By a flash of the LED indicator for every 2 seconds, TDS-100M means the meter work properly. A

short flash for every second indicates no-signal or poor signal condition and a long flash for every second

shows the meter is performing a receiving gain adjusting.

2. Introduction to TDS-100M

(1) Development introduction

The TDS-100M is a compact, high performance general purpose ultrasonic flow meter module. The

design of the meter is intended to provide for users like system integrators and OEM users with a lowest

cost but of high performance flow meter. The development of the meter is based on a widely used flow

meter made by this company. The meter uses only one high performance MSP430 series microprocessor

made by Taxes Instruments.

This module can work alone without a LCD and Keypad module. The parameters that the flow meter

needed to work properly can be (1) setup by a parallel keypad module witch will be plugged onto the

parallel interface inside of the module, or by a serial keypad module witch will be plugged onto the

TDS-100M Manual

7

RS232C or RS485 port of the meter. (2) downloaded by use of a PC computer based software (the software

is under development now).

The transducers can be one the all kinds of the types made by this company, include the clamp-on type,

the insertion type, the PI- type and standard-pipe type. It can even use transducers by the users or the

transducers made by other company.

The module will satisfy the measurement requirement for most kind of liquids, such as water, sea

water, sew water and chemistry liquids. It can even measure pure paper pulp or fluids with higher density

suspend particles.

The module can be used alone as a flow meter. Users can even integrate a number of the modules into

a multi-channel flow meter that can measures up to several dozen of different pipes or a flow meter that has

higher accuracy by measures the same pipe with all the channels.

The low flow performance of this module is better compared with our previous flow meters. It can

measures a flow that is as low as 0.001m/S properly when the PI-transducers are used.

(2)Features

1. better than 1% accuracy, better than 0.2% repeatabilty.

2. 128 times of measurement and the revised software make the performance better and the indicated

flow more stable.

3. RS232 and RS485 serial port

4. One or two analog inputs.

5. Optional 4-20mAanalog output.

6. Two OCT output channels

7. Ability to measure sew water.

8. 4 kinds of different types of transducers can be used, addition with user-defined transducers.

9. The internal universal serial bus enables several output modules to be connected to it.

10. All the parameters can be solidify into the flash memory.

11. Several optional function module to be chosen to add to the main module.

12. 3 different kinds of communication protocol supported by the same time, include MODBUS.

13. Date totalizers that can record as much as 128 sets of data by day, 64 sets of data by month. All the

data can be retrieved by use of the MODBUS registers

14. 32 times of records of power-on and power-off data. Data can be read through MOBUS.

15. built-in data logger/printer, full programmable with what to be print ,the start time, interval, and

duration.

16. Programmable pulse width of OCT output.

17 Parallel interface for display and keypad.

18 plug-on-and-off display and keypad module can be connected to the serial port of the meter.

19 Almost the same menu arrangement make the users of previous version of flow meter very easy to

operate.

20 A fluid velocity threshold enables the identification of the kinds of fluid.

21. Digital inputs can be inputted by used of the analog inputs.

22. A full programmable built-in batch controller which can be started by key-pressing, inputs to the

TDS-100M Manual

8

analog inputs or through MODBUS protocol.

23. Power supply by 8-36VDC~24VDC

3. Menu Window Details

The flow meter user interface comprises about 100 independent windows. That are numbered by

M00,M01,M02……. M99,M+0,M+1 etc.

You do not need to remember all the menu windows. Just remember the most command used windows and

the proximate window numbers of some uncommonly used windows would be sufficient. You can always

use the going up and going down key to find the right window.

Note: 1 it is recommended to practice those menu windows on your flow meter while reading

this chapter for the sake of easier understanding.

2.To quickly switch to a menu window, simply press the ‘MENU’ key followed by the window

number (a two digit number). To move from one window to the next, use ‘UP’or ‘Down’keys.

00 display instant flow rate/net totalizer,adjust the units in M30-M32

01 display instant flow rate/instant flow velocity, adjust the units in M30-M32

02 display instant flow rate/positive totalizer, adjust the units in M30-M32

03 display instant flow rate/negative totalizer, adjust the units in M30-M32

04 display instant flow rate/date time

05 display heat flow rate/total heat quantity,adjust the units in M84 ,M88.

06 display temperature input T1,T2

07 display present battery voltage.(suitable to TDS16)

07 display analogue input AI3,AI4

08 display system error code

flow

rate/fl

ow

totalis

er

displa

y

09 display today net totalizer

10 input outside perimeter of pipe

*11 input pipe outer diameter,data range:0-18000mm

*12 input pipe wall thickness

*13 input pipe inner diameter

*14 choose the kinds of pipe materials

15 input sound velocity of pipe material

16 choose kinds of liner

17 input the sound velocity of liner

18 input the thickness of liner

19 input inner pipe wall absolute degree of roughness

*20 choose kinds of fluids

21 input fluid velocity

22 input fluid viscosity

*23 choose the types of transducers,including more than 20 types to use

*24 choose transducer installation method

*25 display transducer installation space

*26 parameter solidifying and setup

initial

setup

27 store and read installation parameters on installation point

TDS-100M Manual

9

28 When signal set turning poor,keep last datas,choosing”yes”means when the signal

turning poor,the flow meter display last correct measured datas.

29

。Input signal strength when the pipe flow is set to be empty.for example:inputing 65

means when the signal strength is lower than 65,the flow meter will think that there is no

liquid in the pipe and display the flow value as zero.

30 choose metric or imperial unit

31 choose instant flow rate unit

32 choose totalizer unit

33

choosing the totaliser multiplying factor which function is to multiply totaliser data

rang,normaly set it as x1

34 net totaliser switch

35 positive totaliser switch

36 negative totaliser switch

37 restore parameters setup before leaving factory and reset totaliser

38 manual totaliser(the key to control on/off)

39 choose operating language,including 8 kinds of different languages for international

users to use

flow

unit

setup

3•

setup the LCD display method,inputing 0 or 1 means regular displaying content.inputing

2-39 means automatically cycle displaying method,displaying the previous menu of

2-39,time interval is 8 seconds.when inputing accures ,displaying according to the

inputing operation.when there is no inputing operation,it will automatically enter cycle

displaying status.(detailed information in §3.1)

*40 damper coefficient

*41 Input low flow velocity cutoff value

42 Setup static zero point

43 clear zero point setup and manually setup zero point,restore default before leaving

factory.

44 Set up zero point deviant by hand

45 meter coefficient,rectification coefficient

46 input Network address identification number (IDN)

47 password protecting operation,after the meter was setup with password,only browse

menus without any modification.

48 Input degree of linearity broken line rectification data.at most there is 12 segments

broken line,used for users to rectify meter nolinear.

Choo

sing

setup

49 Network communication tester,on this window to visit the datas transfered from upper

computer to judge the problems arised during communication.

50 Optional setup of datas output at scheduled time,choose output content at scheduled

time to print,more than 20 to selet

51 Setup output time at scheduled time

sched

uled

time

output 52

Printing data flow direction control.by default printing data will flow directly to the

thermal printer hanged inside bus.setup printing data output to outside serial

port(RS485 port)

TDS-100M Manual

10

AI5

setup 53 display analogue input AI5(reserved for the TDS16 mainboard)

54 Setup of OCT totaliser pulse output,pulse width,range:6 Ms-1000Ms.

55 choose current loop mode

56 corresponding data to output of current loop 4mA or 0mA

57 corresponding data to output of current loop 20mA

58 Verification of current loop output.applied to check whether current loop is normal or

not.

59 present output of current loop

60

Date time and setup.the date time of the new flow meter is realized by CPU,when

upgrading software,time will be slow,so after upgrading,recommend to adjust the date

and time to display correctly

61 Software version information and Electronic Serial Number (ESN)

62 setup serial port parameter

63

Communication protocol choosing(including compatible protocol choosing),two

options,choosing MODBUS-RTU means using binary system MODUS-RTU

protocol.choosing MODBUS-ASCII+previous protocol means using ASCII protocol,at

this time can support several protocols simultaneously,including

MOSBUS-ASCII,previous 7 version protocol,FUJI protocol,Meter-BUSx protocol etc.

64 analogue input AI3

65 Analogue input AI4

66 Analogue input AI5

By inputing measuring range ,the flow meter will turn

current signal into data range users need,so display

related analogue input that corresponding to physical

parameter data.

67

Setup frequency range of frequency output signal.frequency signal output represent

instant flow rate value by signal frequency value.default:0-1000Hz ,

max-range:0-999Hz.output frequency signal by special frequency output unit.

68 setup lower limit flow of frequency signal output

69 setup upper limit flow of frequency signal output

70 LCD backlit control

71 LCD contrast ratio control

72 Work timer,logging work time of the meter by unit of second.it can reset.

73 setup lower limit flow of

frequency signal output

74 setup upper limit flow of

frequency signal output

75 LCD backlit control

76 LCD contrast ratio control

by setuping the lower and upper limit of alarm,confirm a

range,when actual flow is over the range set in this

window,then create a alarm signal output.alarm signal

can be transferred to outside by setuping OCT or relay.

77 beeper setup options

78 setup Open Collector Transistor output(OCT) output options

input

and

output

setup

79 setup relay(OCT2) output options

80 choose input signal of batch controller

81 batch controller

TDS-100M Manual

11

82 day/month/year totaliser,check the flow rate and heat quantity of the totalisers

83 。Automaticaly replenish flow switch during the period of power off,default status:off.this

function is not available under special conditions.

84 Choosing heat quantity unit, 0.Gj(default) 2.Kcal 3.Kw 4.BTU (imperial unit)

85 Choose temperature signal origin,if choosing inputing temperature signal by

AI3,AI4,then need temperature transmitter that can output 4-20mA current signal.

86 heat capacity,default: GB-CJ128 enthalpy potential method. Temperature difference

method is available also.

87 heat quantity totaliser switch

88 Heat quantity multiplier factor.

89 display present temperature difference and setup temperature difference sensitivity.

heat

quanti

ty

meas

uring

8• Options of installation of heat meter on supply water pipe or return water pipe

*90 Display the signal strength and signal quality

*91 Display the transit time ratio

92 Display the calculated fluid sound velocity .

93 Display the total transit time and the delta time

94 Display the Reynolds number and the pipe coefficient

diagn

osis

95 Display positive,negative heat quantity totaliser,start cycle display function.

+0 Display the time of power on/off and flow rate

+1 Display the total working time of the flow meter

+2 Display the last time of power off.

+3 Display the flow rate of last power off

+4 Display total times of power on

+5 Scentific calculator

+6 Setup threshold value of fluid sound velocity

+7 Net totaliser of this month

+8 Net totaliser of this year

added

menu

windo

ws

+9 Operating time with trouble(including power off time)

.2 store static zero point

.5 setup threshold value of Q value

.8 max instant flow rate of this day and this month

.9 serial port testing window with CMM direct output

-0 circuitry hardware parameter adjusting entrance(only inputing password to enter

following windows)

-1 4-20mA current loop calibration

-2 AI3 inputing calibration of analogue input 4 mA

-3 AI3 inputing calibration of analogue input 20mA

-4 AI4 inputing calibration of analogue input 4mA

-5 AI4 inputing calibration of analogue input 20mA

-6 AI5 inputing calibration of analogue input 4mA

-7 AI5 inputing calibration of analogue input 20mA

hardw

are

adjust

ment

menu

windo

ws

-8 zero point setup of PT100 at lower temperature(<40 )℃

TDS-100M Manual

12

-9 PT100 setup zero point at higher temperature(>55℃)

-A PT100 standard calibration at 50℃

-B PT100 standard calibration at 84.5℃

Note :* means common used menus,red color means new added or changed

functions,blue color means the menus related with heat quantity measurement

4.transducers installation

§4.1 Unpack checking

Check whether the spare parts comply with packing list,enclosure is broken or not during

transportation?did screw drop?connecting line is loose or not?if have questions,pls cotact factory.

§4.2 Power supply and cable

When users place an order,pls inform factory what kinds of power supply is

needed,normaly the power supply of the flow meter have following options:

: DC24V or DC8~36V

Transducers signal cable of TDS-100M series ultrasonic flow meter adopts high frequency special

shielded twisted pair cable.because sending and receiving circuit adopts balanced transmitting

and balanced receiving principle.so to increase the anti-interference function,little signal

consumable ,ensure the device work well in longer term.so the special signal cable supplied by

factory is the best choice for you.if using coaxial shielded radio frequency cable or poor quality

twisted pair cable,it could lower accuracy and the function of the device.when there is bigger

interference signal from outside,the device could not measure normally.

§4.3 Required installation condition

Installation of The new TDS-100M series is the easiest and convenient way in the

installation of all flow meters,just choosing a suitable measurement point,input the pipe

parameters of this pipe point to the flow meter,then fix the transducers on the pipe.

§4.3.1 choosing measurement point

To ensure measurement accuracy and stability,the installation point of tranducers should be on

the straight pipe full of well distributed fluid(when installing,the pipe must be full of liquid),comform

to following principle:

1.Pipe must be full of liquid that is uniform and easy to travel the ultrasonic beam(vertical pipe or

horizontal pipe)

2.Upstream transducer should be installed at the place where the upstream length of the straight

TDS-100M Manual

13

pipe is at least 10D and the downstream length is at least 5D where install the downstream

transducer,so the pipe length should be straight without any valve,pump,angle head, D stands for

pipe ouside diameter. The installation point should stay away from valves,pump,high pressure

current,transformers interference source etc.

3.Avoid to install on the highest point of pipe system or vertical pipe with free exit(flow down)

4.For the opened pipe or half full pipe,the transducers should be installed on U pipe.

5.The temperature and pressure on the installation point should be within the work ability of the

transducers.

6.Pay more attention to the pipe scaling in inner pipe wall,do best to choose the pipe without

scaling to install,if it is impossible ,then consider the scaling as liner to achieve better accuracy.

7.The two transducers must be installed in horizontal direction to pipe axis plane,within ±45°of axis

line horizontal plane, to prevent bubbles or not full in upper pipe or sediment in down side of pipe

to influence transducer measurement normaly.if there is space limit of installation that could not

install horizontal symmetry,then install the transducers vertically or dip angle under the condition of

no bubbles in upper parts of pipe.

TDS-100M Manual

14

§4.3.2 instrument well construction requirements

If need to install transducers in instrument well,there must be enough installation room,convenient

for people to stand up to work,distance between pipe wall and well wall is at least above

550mm,width is more than (D+550*2)mm,cement pipe width is more than

(D+700*2)mm,instrument well axial width L is more than D+1200mm.when installing

transducers,avoid the place of flange,welding line,reducing,do best to install transducers in the

range of +/-45° of horizontal position of pipe axis.

Attention:1,Do best to install transducers in the range of +/-45° of horizontal position of

pipe axis .

2,Connect the mainframe enclosure with ground.

TDS-100M Manual

15

3, Avoid the installation place of flange,welding line,reducing

4, Enough installation room,convenient for people to stand up to work

§4.4 Quickly input pipe parameter steps:

Need input following parameters when normaly measuring

1. pipe outer diameter

2. pipe wall thickness

3. pipe material

4. liner parameter(if has liner,then include liner thickness and sound velocity)

5. fluid types

6. tansducers tpye(mainframe can support many kinds of

transducers)

7. transducers installation method

8. solidificaiton parameter

§4.5 Clamp on type transducer installation method

:Before installation,choose density pipe to install transducers,and clean the installation

area,clear away rust,paint,anti-rust layer,it is the best to use angle grinder to polish,use cleaning

cloth with alcohol or acetone to clear oil and dust,coat enough couplant around the center of

installation area,attach the transducers on the pipe and fix it without air bubbles or sand between

transducers and pipe wall.

M2type

Standard S1 type L2 SENSORS

transducer Standard S1

type

Standard M2

type

Standard L2

type

Suitable pipe

diameter(mm)

DN15-DN100 DN50-DN700 DN300-DN6000

Fluid

temperature

0℃~160℃0℃~160℃0℃~160℃

Outer size 45×30×30mm 60×45×45 80×70×55

quality 75g 250g 650g

Remarks:users input transducers parameters by yourself

TDS-100M Manual

16

§4.5.1 Installation space

Installation space of clamp on type transducer is inner edge distance of the two transducers(face

to face),after inputing the required parameters in Menu,check the display on M25,that is the

installation space.

§4.5.2 Installation method

The method has 2 kinds: V method,Z method

Normaly,V method is suitable to the pipe diameters within the range: DN15-DN200mm .when

using V method can not measure the signal or the signal is poor,try to use Z method that is

suitable to the diameters are more than DN200mm or measuring cast iron.

V method(commonly used method)

Normaly,V method is standard installation method,convenient to use with precise

measurement,when installation,the two transducers horizontally align,its centre line is horizontal

with pipe axis line,suitable pipe diameter range to measure is DN15mm-DN400mm。

Z method (the most commonly used method)

When the pipe diameter is wide,or there are suspended matters in fluid,too thick scaling or

liner inside pipe inner wall,that can make the flow meter can not work normaly and signal poor by

using V method installation,so need to use Z method to install,its features are direct transfering

without reflection(called sigle sound path),little signal attenuation.

Attention:1,when installation,it is a must to clear the pipe area where to install

transducers,showing metal color

2,shield line of ultrasonic signal cable can not be connected,but not short circuit with positive

TDS-100M Manual

17

and negative pole(red and black line)

3,after transducers are connected with circuits,must apply enough sealant to prevent water in.

4,after covering the transducers,must screw and lock tightly the hole for shield line of

transducers to prevent water in.

5,use strap(stainless steel band) to fix on the center part of transducers,to make it weighted

uniform,no moving.

6,apply enough couplant around the area ,so that transducers touch pipe to prevent

air,sands,rust in,that influence the beam transfering.

§4.6 Insertion type transducer installation method

The new TDS-100M series insertion type transducer incorporates the advantages of clamp on

type and in line type transducers,its features:

Transducers can be installed directly on pipes of carbon steel or stainless steel by welding;

while for those pipes of materials like cast iron, glass fiber reinforced plastic, PVC and cement

which cannot be welded directly, special straps should be used for installation. For

those users who are in similar situation, please inform us of the precise outside diameter

of the pipe to be installed to prevent leakage.

insertion B type(insert directly)Insertion B type (for sement

pipe )

Suitable diameter Above DN80mm Above DN80mm

Installation room ≥550mm ≥700mm

Fluid temperature -40℃-160℃-40℃-160℃

Transducer material 316L stainless steel 316L stainless steel

§4.6.1 Installation tools

Special hole-drilling positioning tools made by our company (Hipeak Instrument Development Co.,

Ltd), 400w handle rotary drill (high speed adjustable is preferable), spanner and

screwdriver are needed for installing insertion transducers.

§4.6.2 Installation space

Insertion style transducers spacing is calculated based on the distance between the centers of the

two transducers along the pipe axis. The space will be shown on menu M25 when necessary data

are put into the menu, and the transducers should be installed according to this space.

§4.6.3 Installation method

There is only one way to install insertion style transducers which is called Z-method installation

and can be applied for all pipes which diameter is more than DN80mm.

§4.6.4 Locate the installation point

Input the pipe parameters on the mainframe, the installation space L (L=inside diameter-

9.113mm) will be calculated. (the two sensors must be located in the same axis plane), the

installing space L should be the distance between the centers of the two sensors horizonally.

A. Making a fixed position paper: take a 4D (D refers to the pipe inner diameter)

TDS-100M Manual

18

long and 200mm (or D) wide rectangular paper (according to actual situation on spot,

the paper tape can also be replaced by moisture-and-corrosion resistant materials), and draw

a line about 100mm from the edge;

B. Wrap the fixed position paper on the cleaned surface of the pipe, making sure that the two

paper sides are overlapping and aligned and thus the line drawn may be parallel with the pipe

axis;

C. Extend the line on the fixed position paper to the pipeline and the

cross-point between the vertical side of the fixed position paper and the extended line is A

D. Starting from A and along the edge of the position paper, the length of half of the pipe perimeter

is measured and the cross point is C; then draw a line at C to be parallel to the axis (that is, to be

parallel with the line on the position paper);

E.Removing the fixed position paper and starting from C, the installation space L should be

measured along the line, draw on the pipe ,the point is B. Thus, A and B are the points where the

transducers are to be installed. For example, L=280mm. Then two bases of ball valves should be

welded respectively on A and B, making sure the centers of bases overlap A and B respectively.

TDS-100M Manual

19

§4.6.5 Welding the base of the ball valves

For pipes that can be welded (such as steel and stainless steel, etc.), just weld the base on the

pipe (Stainless steel pipe should be welded to stainless base, please indicate in

your

order). Before welding, the rust and paint on the section where the sensors are to be installed shall

be

cleaned up by using an angle grinder, and the oil dirty and dust should be cleaned by using

acetone or

alcohol. to prevent water leakage,so the work of welding is very important, making sure the

centers of bases overlap A and B respectively,no air bubbles.

For pipes which material cannot be welded directly (such as cast iron and cement, etc.), special

hoops

(with airproof rubber pads) should be used. The bases of the ball valves have been welded on the

hoops.

These hoops are directly fixed on the pipe and make sure that the centers of the ball valves

overlap A

and B respectively. Finally, the ball valves should be closely fixed on the bases welded on the

hoops to

prevent water leakage.

§4.6.6 hole-drilling

Connect the sealed sheath of the hole-drilling machine and the outer screw thread of the

tailor-made ball valves,screw tightly,open the ball valves,push the drill pipe to touch the outer

surface of pipe;

then the drill pipe shall be locked to the handle rotary drill before the drill is switched on. During

drilling,

the drill machine should work in a low speed to avoid sticking or even drill bit breaking.after drilling

through pipe wall,pull back the drill pipe until the head of drill bit reach the ball valves spool,turn off

the ball valves,take down hole-drilling machine. ①Pipe

②Ballvalvebase

③Tailor‐madeballvalve

④Locatingdrillpipebit

⑤19superholecutter

⑥

Seal gland

TDS-100M Manual

20

§4.6.7 inserting the transducers

screw the screw mut to a position under the bottom of the transducer and screw the transducer

through the ball valve to ball valve spool. Open the ball valve and continue to screw the transducer

until the head of transducer passes the inner wall of the pipe. Before the wires

are connected, the angle of the transducer should be adjusted to make sure that the head of two

transducers can be in face to face position so as to send and receive the signals properly(the hole

for line of two transducers should be upward or downward at same time).and then fix the screw

mut,connect the wires,use silicon rubber to seal the connection place.

§4.6.8 Length calculation of the part of transducer into the pipe inner wall:

Insertion style transducer is made of stainless steel by casting. As the transducer's length A and

the pipe wall's thickness B are known, and the length part of transducer left

outside the pipe can be measured, the length of the inner part of the transducer can be

calculated through the formula: L=A-B, C=0

Note: the length A of different types of transducers are: Standard insertion type B: A=170mm;

Standard insertion type C: A=220mm, and Cement insertion type B: A=310mm.

§4.6.9 wiring

After wires being connected, screw the mut on the hole for wires (do not lose packing seal),at

last,screw seal cover tightly to prevent water leakage.

§4.6.10 Transducer wiring picture

①transducer

②ballvalvebase

③tailor‐madeballvalve

④screwthread

⑤locknut

⑥connectingbox

⑦signalcable

TDS-100M Manual

21

§4.6.11 Maintenance

The maintenance is easy,exchange the old transducer with the new transducer according to the

reverse process.

Attention:

1 during the process of welding the base of the ball valves,avoid the phenomenon of slag

inclusion,sand hole,water leakage.

2. The bases of the two ball valves should be welded on the same axis plane

to prevent poor receiving of ultrasonic waves;

3. after The holes having been drilled through, the impurities such as iron filings in the ball

valve should be cleaned

up so that the transducer probe may not get stuck or its thread get adhered;if so,still to screw

hardly,and do not stop,the transducer will be destroyed and not work well.

4. Make that the ultrasonic emitting surfaces of the two transducers are face to face (that

is, the holes for wires are in the same direction and either upward or downward);

5. After the transducer is installed, the screw mut should be screwed tightly to avoid

transducer move.

The seal cover should be screwed tightly to prevent water after wires being connected..

§4.7 In-line type transducer installation method

In-line type transducer of new TDS-100M series is characterized by easy installation and

high-accuracy measurement. When ordering, customers need to provide the actual parameters of

the pipe. The parameters of the transducer have been put into the flowmeter before leaving factory

and there is no need to input them when installing.

There are two types of pipe transducers for selection:

1. π-type transducer(DN15-DN40MM)

2. Standard pipe transducer(DN50-DN1000MM)

Parameters π-type transducer Standard pipe transducer

Material Stainless steel Carbon steel(stainless steel is optional)

TDS-100M Manual

22

Pipe size DN15-DN40MM DN50-DN6000MM

Connection: Flange type Flange type

Application of temperature -40℃~160℃

Protection class IP68(can work in water, and water depth≤3 meter)

Rated pressure please refer to following table

dimension please refer to following table

π-type Standard-pipe Flange dimension(mm)

Nominal

diameter(m

m)DN

Rated

pressure

(Mpa) L1 L2 D D1 D2 f

N-ΦFlange

thickness

15 320 95 65 45 2 14×4 14

20 360 105 75 55 2 14×4 16

25 390 115 85 65 3 14×4 16

32 450 140 100 76 3 18×4 18

40

2.5

500 150 110 84 3 18×4 20

50 200 160 125 100 3 18×4 22

65 200 180 145 120 3 18×4 24

80 225 195 160 135 3 18×8 24

100 250 215 180 155 3 18×8 26

125 250 245 210 185 3 18×8 28

150 300 280 240 210 3 23×8 28

200 350 335 295 265 3 23×12 30

250 450 405 355 320 3 25×12 32

300 500 460 410 375 4 25×12 32

350 550 520 470 435 4 25×16 34

400

1.6

600 580 525 485 4 30×16 38

400 600 565 515 482 4 25×16 30

450 700 615 565 532 4 25×20 30

500 800 670 620 585 4 25×20 32

600 1000 780 725 685 5 30×20 36

700

1.0

1100 860 810 775 5 24×25 32

Other ECEFAST Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ADS

ADS TRITON+ Installation, operation and maintenance manual

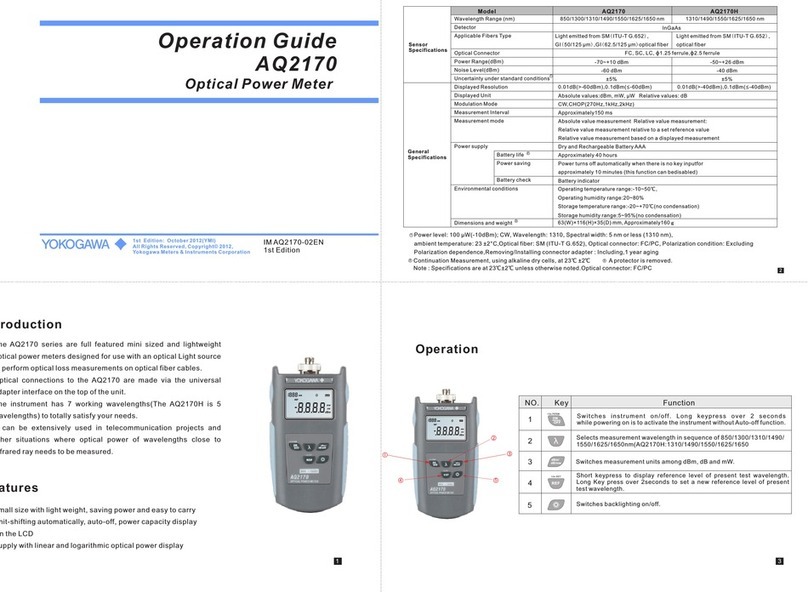

YOKOGAWA

YOKOGAWA AQ2170 Operation guide

berlinger

berlinger SmartMonitor SITE L user manual

Tuff Country

Tuff Country 32906 installation manual

Agilent Technologies

Agilent Technologies 4284A Service manual

HYTEM

HYTEM 08-02-48 Product specifications and user's guide