TABLE OF CONTENTS

PB-8010, EB810 1

Page Page

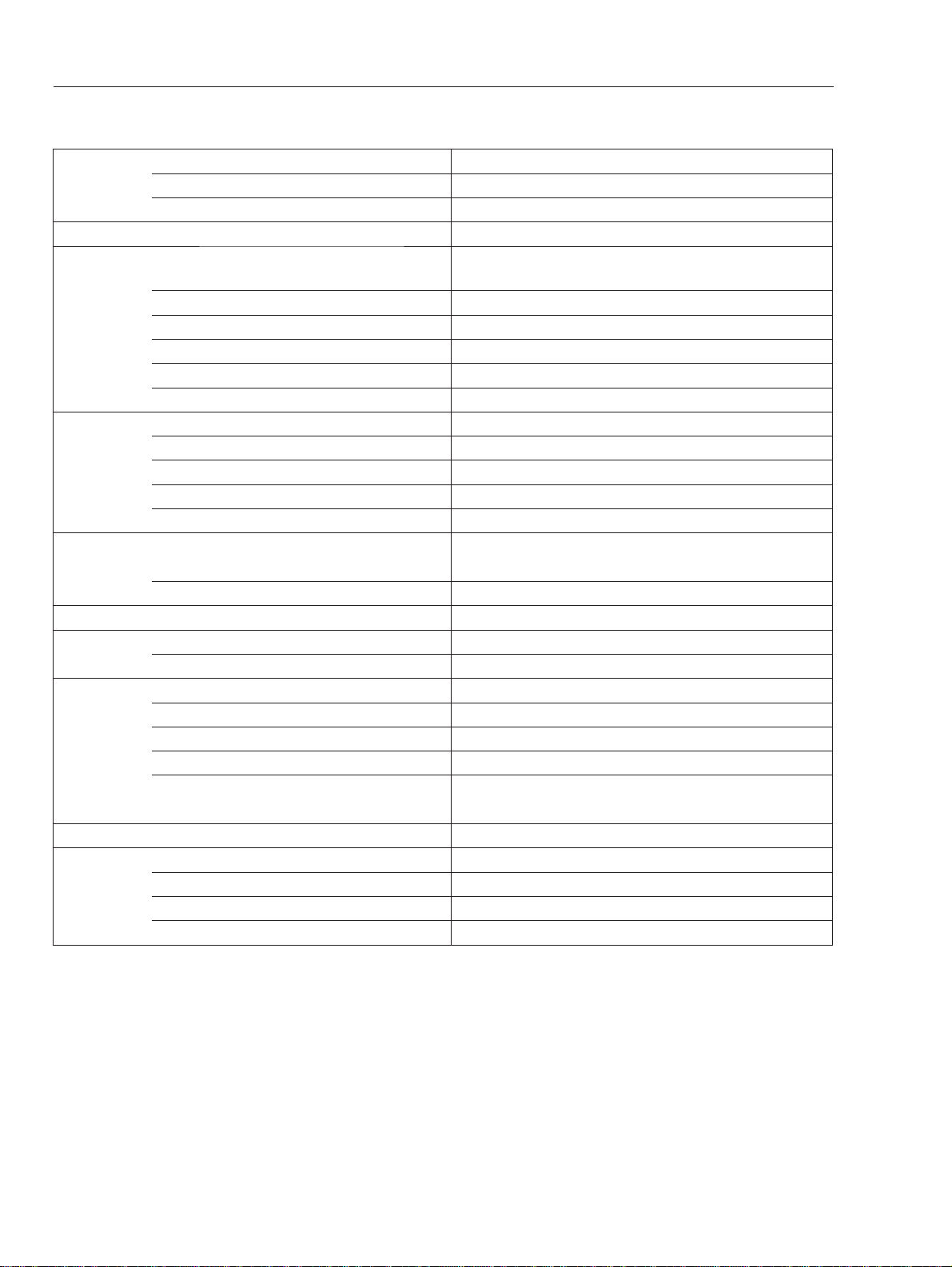

1 SERVICE INFORMATION.....................................2

1-1 Specifications ...................................................2

1-2 Technical data ..................................................3

1-3 Torque limits .....................................................4

1-4 Special repairing materials...............................4

1-5 Service limits ....................................................5

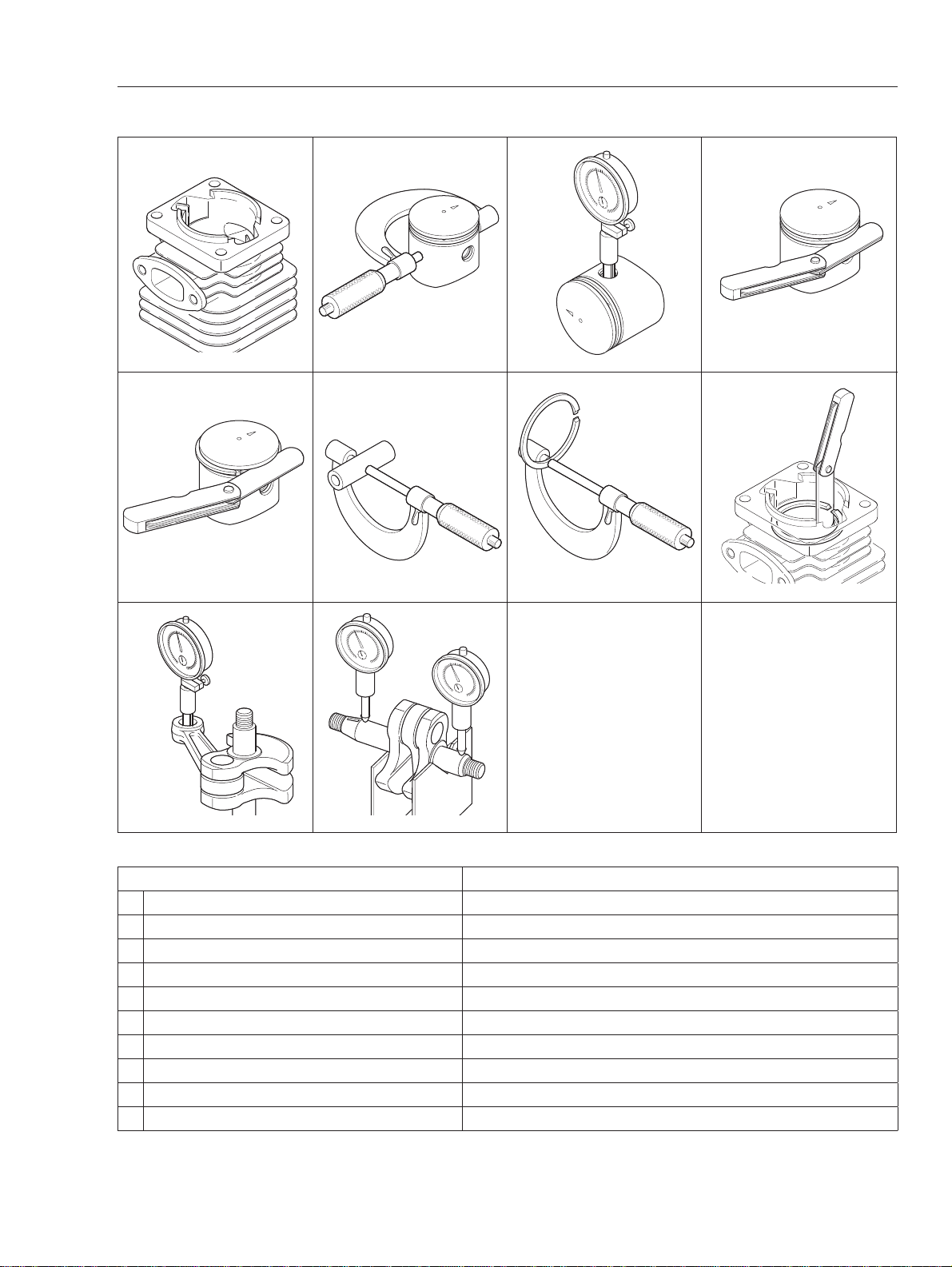

1-6 Special tools.....................................................6

2 STARTER SYSTEM..............................................7

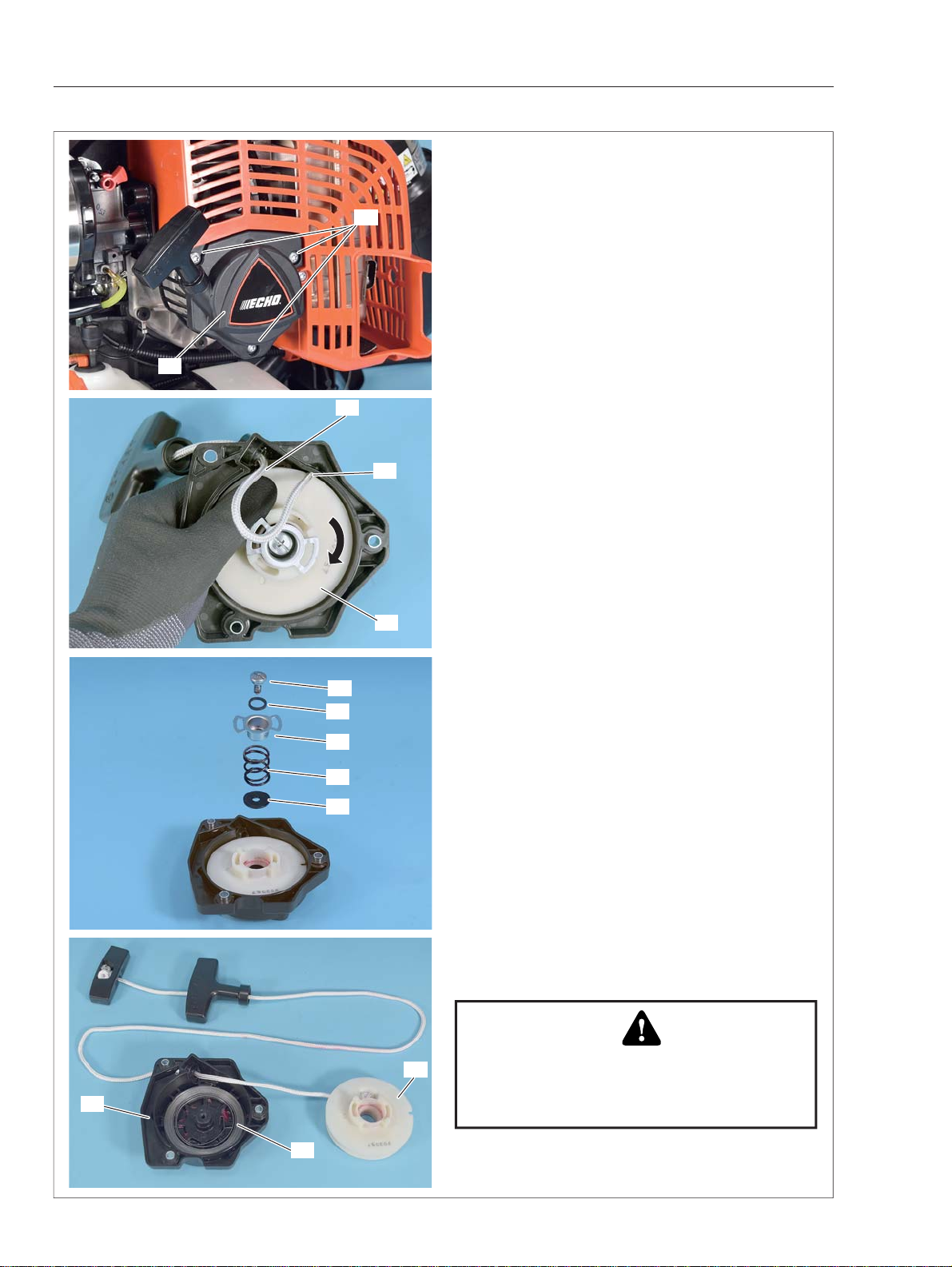

2-1 Disassembling starter assembly.......................8

2-2 Replacing starter rope......................................9

2-3 Installing rewind spring...................................10

2-4 Assembling starter..........................................12

2-5 Replacing starter pawl....................................13

3 IGNITION SYSTEM.............................................14

3-1 Troubleshooting guide....................................15

3-2 Testing spark ..................................................16

3-3 Inspecting spark plug .....................................16

3-4 Replacing spark plug cap and coil..................17

3-5 Inspecting ignition switch................................17

3-6 Replacing ignition switch................................18

3-7 Inspecting ignition coil resistance...................21

3-8 Replacing ignition coil.....................................22

3-9 Setting pole shoe air gaps..............................22

3-10 Inspecting and replacing magneto rotor.........23

3-11 Inspecting and replacing woodruff key...........23

4 FUEL SYSTEM ...................................................24

4-1 Inspecting air filter ..........................................25

4-2 Inspecting fuel cap and fuel strainer...............25

4-3 Inspecting fuel tank and line...........................26

4-4 Replacing fuel lines and grommet..................27

4-5 Inspecting tank vent .......................................28

4-6 Replacing carburetor......................................29

4-7 Testing carburetor...........................................30

4-8 Inspecting crankcase pulse passage .............31

4-9 Inspecting metering lever height ....................31

4-10 Inspecting inlet needle valve ..........................32

4-11 Inspecting diaphragm and others...................33

4-12 Inspecting main jet .........................................33

4-13 Adjusting carburetor .......................................34

4-13-1 General adjusting rules ..............................34

4-13-2 Initial setting Throttle adjust screw,

L mixture needle and H mixture needle..........34

4-13-3 Adjusting carburetor ...................................35

4-14 Checking and adjusting throttle cable ............35

5 BACKPACK FRAME ..........................................36

5-1 Removing backpack frame assembly.............37

5-2 Replacing backpack harness .........................38

5-3 Replacing backpack harness .........................39

6 BLOWER SYSTEM.............................................40

6-1 Separating fan case assembly .......................41

6-2 Replacing elbow.............................................42

6-3 Disassembling and assembling fan................43

6-4 Replacing fan case.........................................43

7 ENGINE...............................................................45

7-1 Testing cylinder compression .........................46

7-2 Cleaning cooling air passages .......................46

7-3 Inspecting muffler and exhaust port ...............47

7-4 Testing crankcase and cylinder sealings........48

7-5 Replacing oil seal ...........................................49

7-6 Inspecting cylinder..........................................50

7-7 Inspecting piston and piston ring....................51

7-8 Disassembling crankcase...............................51

7-9 Replacing ball bearings..................................52

7-10 Removing ball bearing in crankcase ..............52

7-11 Assembling crankshaft and crankcase...........53

7-12 Installing piston...............................................53

7-13 Installing piston ring and cylinder ...................54

7-14 Assembling engine assembly and

other parts ......................................................55

8 MAINTENANCE GUIDE......................................56

8-1 Troubleshooting guide....................................56

8-2 Disassembly chart..........................................58

8-3 Service intervals .............................................59