Echo HCAS-2200 Mounting instructions

Other Echo Trimmer manuals

Echo

Echo GT-200R - PARTS CATALOG SERIAL NUMBER 10001001-... Instruction Manual

Echo

Echo SRM-225 User manual

Echo

Echo SRM-210AE User manual

Echo

Echo PRO ATTACHMENT SERIES PAS-230 User manual

Echo

Echo PAS-280 User manual

Echo

Echo GT-200R - PARTS CATALOG SERIAL NUMBER 07001001-... Instruction Manual

Echo

Echo 99944200545 User manual

Echo

Echo 99944200840 User manual

Echo

Echo HC-156 User manual

Echo

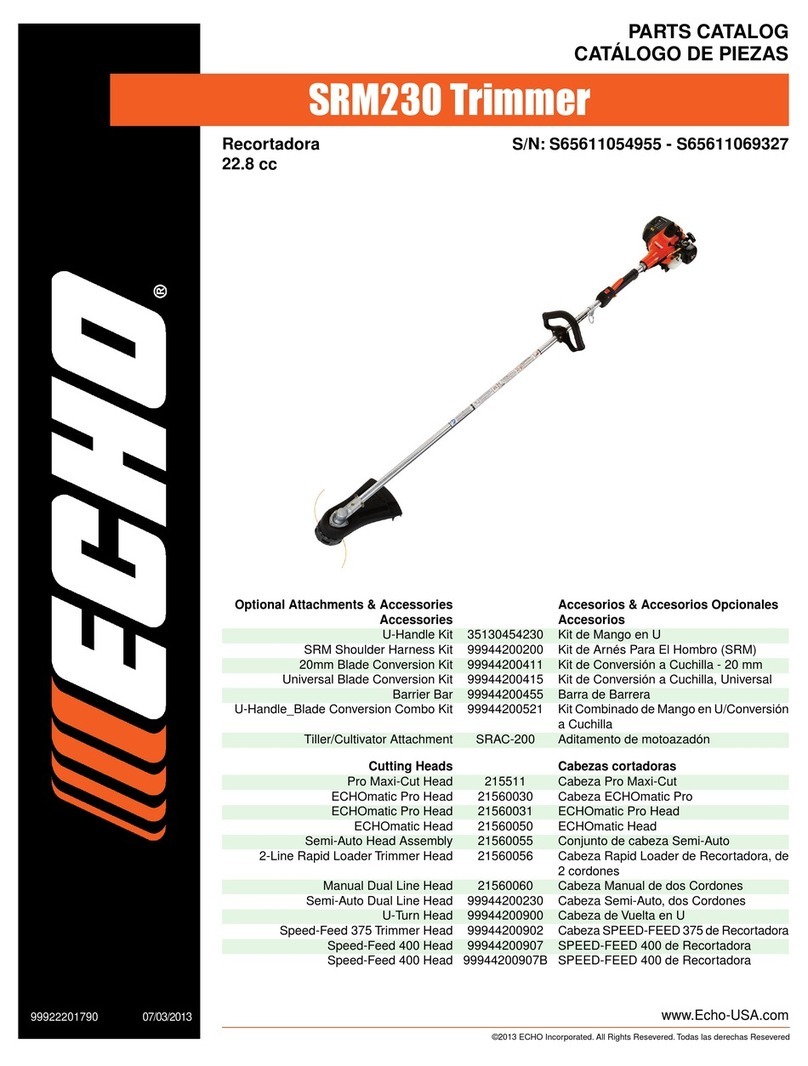

Echo SRM-230 Instruction Manual

Echo

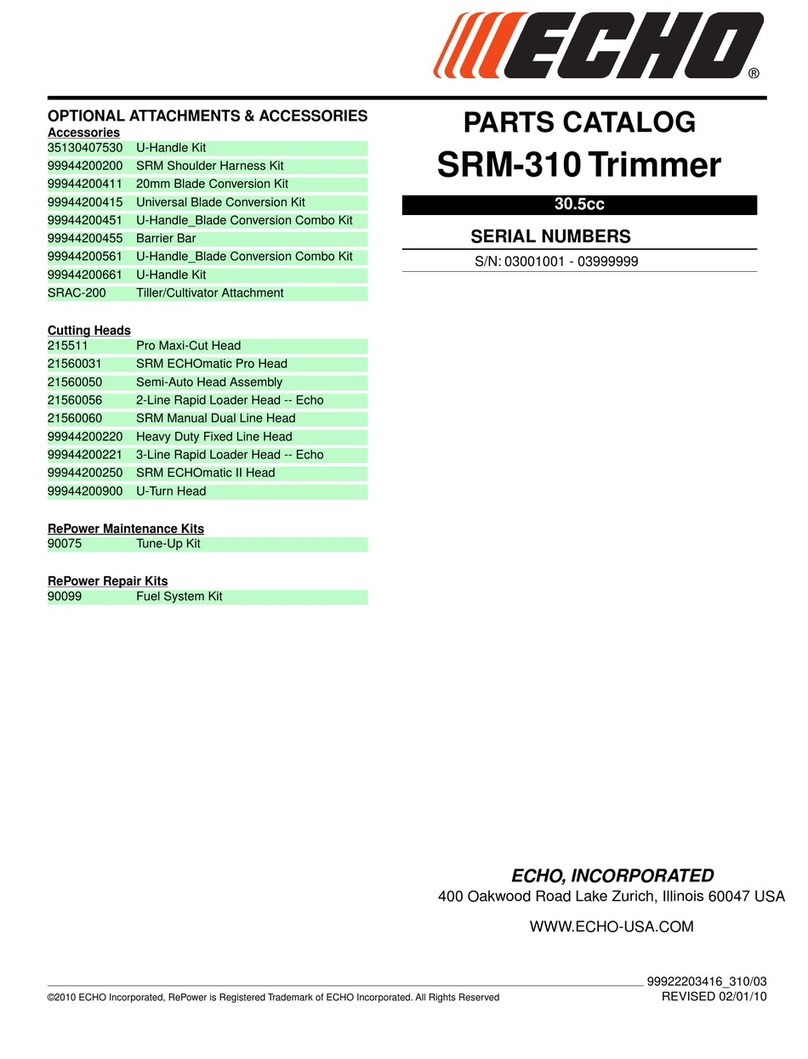

Echo SRM-310 Instruction Manual

Echo

Echo GT-225SF User manual

Echo

Echo SRM-225SB User manual

Echo

Echo SRM-3800 User manual

Echo

Echo SRM-3020T User manual

Echo

Echo SRM - 260S User manual

Echo

Echo DSRM-2600 User manual

Echo

Echo SRM-22GES User manual

Echo

Echo HSD 600 Profi User manual

Echo

Echo GT-225i User manual