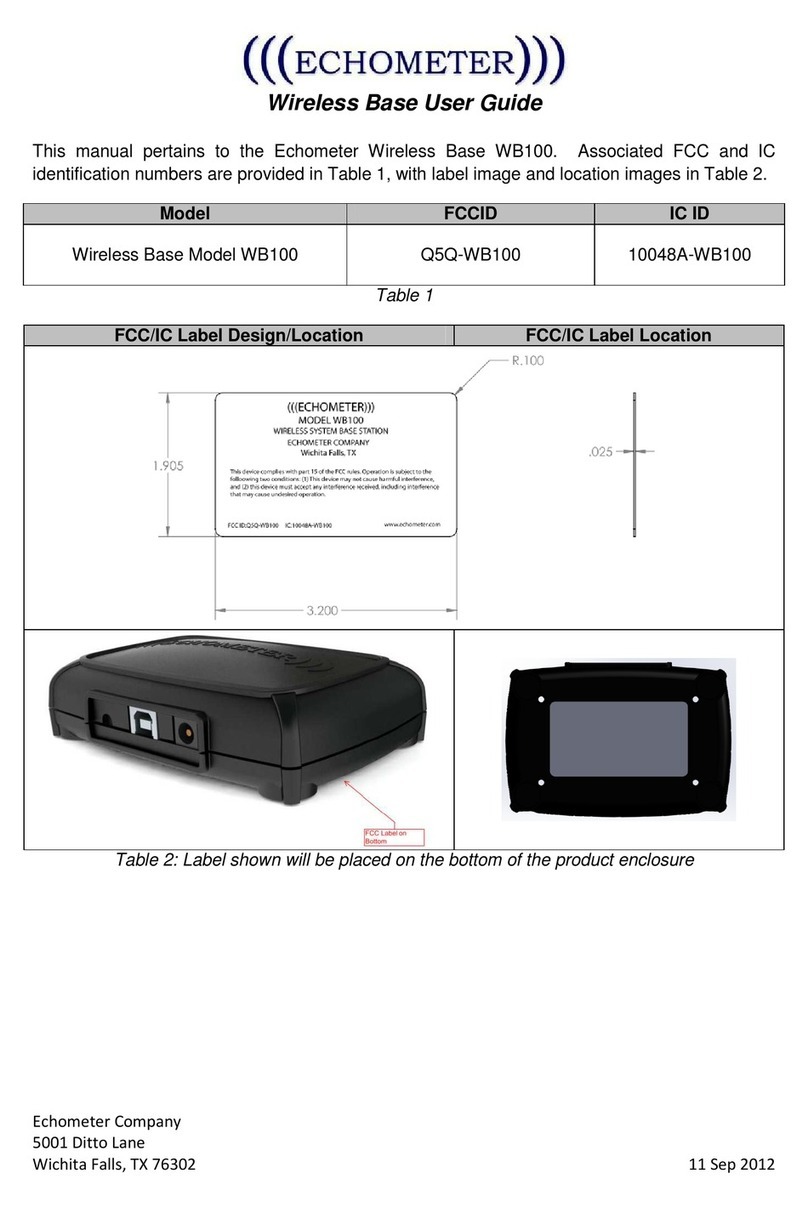

Echometer M User manual

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 1Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Echometer Model-M

Digital Dual Channel Fluid Level Instrument

Introduction

This operating manual contains information about the Echometer Model M Fluid Level Instrument including operating

procedures, maintenance, shooting problem wells, chart interpretation and technical papers relating to the optimization

of producing wells. Please read the first 25 pages and view the example of the strip chart output forms and charts on

wells before operating the instrument. Additional technical papers can be accessed from the Echometer Web page,

www.echometer.com, these articles offer additional information on the use of acoustic fluid level instruments to

optimize production. Please read these papers at your convenience.

Limits of Liability

Echometer Company reserves the right to revise its software and publications with no obligation of Echometer

Company to notify any person or any organization of such revision. In no event shall Echometer Company be

liable for any loss of profit or any commercial damage, including but not limited to special, consequential, or other

damages.

Information in this document is subject to change without notice and does not represent a commitment on the part

of Echometer Company. The software described in this document is furnished under a license agreement or

nondisclosure agreement. It may be used or copied only in accordance with the terms of the agreement. It is

against the law to copy the software or any medium except specifically allowed in the license or non-disclosure

agreement.

Copyright Notice

Copyright 1997,1998,1999,2000,2001,2002,2003 Echometer Company. All rights reserved. Federal copyright

law protects this manual. No part of this manual may be copied or distributed, transmitted, transcribed, stored in a

retrieval system or translated into any human or computer language, in any form or by any means, electronic,

mechanical, magnetic, manual, photographic, photocopy, scanning, or otherwise, or disclosed to third parties

without the express written permission of Echometer Company.

Trademarks

AWP, TWM, QRod, EchoPUMP, Compact Gas Gun are trademarks of Echometer Company

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 2Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Table of Contents

Introduction...............................................................................................................................................1

Limits of Liability..............................................................................................................................1

Copyright Notice................................................................................................................................1

Trademarks.........................................................................................................................................1

Table of Contents......................................................................................................................................2

1 - Safety Considerations..........................................................................................................................4

Echometer Schools.............................................................................................................................4

Additional Information.......................................................................................................................4

2-Principles of Acoustic Measurements...................................................................................................5

Recording and Interpretation of Signals.............................................................................................5

Depth Calculation ..............................................................................................................................6

3 – General Description – Model M.........................................................................................................7

Instrument Panel....................................................................................................................................8

Wellhead Attachments..............................................................................................................................9

Remote Fire Gas Gun.......................................................................................................................11

High Pressure Gas Guns...................................................................................................................12

Accessories..........................................................................................................................................12

Model M Modifications and Enhancements…………………………………………………………13

4 - Operation...........................................................................................................................................15

General Recording Procedure ..........................................................................................................15

Operation of the Model M with the Compact Gas Gun...................................................................16

Operation of the Model M with the Remote Fired Gas Gun............................................................17

Recommendations for Optimum Performance.................................................................................18

Automatic Gain Setting (AGS) Mode Characteristics.....................................................................19

Manual Gain Setting (MGS) Mode Characteristics.........................................................................19

Collar Channel Automatic Gain Control (AGC) .............................................................................19

Liquid Level Channel Gain Control.................................................................................................19

5 - Interpretation .....................................................................................................................................20

6 - Problem Wells...................................................................................................................................21

7 - Battery and External Power Information...........................................................................................22

Important Notes and Instructions for Rechargeable Batteries..........................................................23

8 - Testing/Troubleshooting....................................................................................................................24

Amplifiers Check.............................................................................................................................24

Filters Check ....................................................................................................................................24

Microphone Cable check..................................................................................................................24

Microphone Check...........................................................................................................................24

9 - Maintenance ......................................................................................................................................25

Compact Gas Gun Pressure Rating..................................................................................................25

Compact Gas Gun Disassembly and Assembly Special Precautions...............................................25

Remote Fire Gas Gun Pressure Rating.............................................................................................26

Remote Fire Gas Gun Disassembly and Assembly Special Precautions .........................................26

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 3Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

10 – Calculation of Bottomhole Pressures..............................................................................................27

11 – APPENDIX.....................................................................................................................................28

FIGURE 1a - COMPACT GAS GUN ASSEMBLY DRAWING..................................................28

FIGURE 1b - REMOTE FIRE GAS GUN ASSEMBLY DRAWING...........................................29

FIGURE 2 - ECHOMETER PANEL..............................................................................................30

FIGURE 3 – INITIAL HEADER AND SYSTEM TEST (SHOWN ½ SCALE)............................30

FIGURE 4 – DATA INFORMATION FORM AND TIME STAMP .............................................30

FIG. 5 – UPPER/LOWER COLLARS ACCENTEDFIG. 6 – PROVE LIQUID LEVEL...............31

FIG. 6 – PROVE LIQUID LEVEL..................................................................................................32

Fig. 7 – WELL WITH LINER .........................................................................................................33

FIG. 8 – RECORDS OF COMPRESSION/RAREFACTION INITIAL PULSEACOUSTIC

RESPONSES FROM DOWNHOLE ANOMALIES.......................................................................34

ACOUSTIC RESPONSES FROM DOWNHOLE ANOMALIES..................................................35

Amplifiers And Filters Test .............................................................................................................35

Amplifiers And Filters Test .............................................................................................................36

MICROPHONE CABLE TEST.......................................................................................................37

Microphone Test..............................................................................................................................38

Rate of Fill-up Graph.......................................................................................................................39

USE OF RATE OF FILL-UP INFORMATION..............................................................................40

CARBON DIOXIDE CYLINDER...................................................................................................41

CARBON DIOXIDE INFORMATION (CO2)................................................................................42

NITROGEN INFORMATION (N2).................................................................................................43

FIG. 9 – CO2 CYLINDER W/ HOSE .............................................................................................44

FIG. 10 –Filler Connector for 7.5 OZ. CO2 CYLINDER................................................................45

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 4Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

1 - Safety Considerations

Read this manual before operating the equipment.

Please observe all safety rules in operating this equipment. The pressure ratings of the Echometer gas gun and

all fittings, hoses, etc. should always exceed actual well pressure. Because the casing pressure normally increases

during a build-up test, caution should be exercised that the well pressure does not exceed equipment pressure

ratings.

Do not use worn or corroded parts. A used or corroded fitting may not withstand original pressure rating.

All safety precautions cannot be given herein. Please refer to all applicable safety manuals, bulletins, etc.

relating to pressure, metal characteristics, temperature effects, corrosion, wear, electrical properties, gas

properties, etc. before operating this equipment.

The tests should not be undertaken if the operator, the test equipment and the well are not in conditions to

operate safely. This equipment should not be used if the operator is tired, ill or under the influence of alcohol,

drugs or medication.

Echometer Schools

Echometer Company offers schools on the use and applications of this equipment. You are invited to attend free of

charge. A list of the schools, which are taught throughout the United States and Canada, will be sent upon request

or can be viewed at http://www.Echometer.com

Additional Information

Please contact Echometer Company to obtain additional information or to clarify any questions that you may

have in regard to the use of this instrument. The street and mailing address, phone number, fax number and e-mail

address are given on the first page.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 5Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

2-Principles of Acoustic Measurements

Acoustic liquid level instruments were developed in the 1930's. An acoustic wellhead attachment is connected to an

opening in the casing annulus at the surface of a well as shown in Figure 1 in the appendix. The acoustic wellhead

attachment consists of an acoustic pulse generator, a microphone and optionally a pressure gage. Throughout the

years, acoustic pulse generators have included a dynamite cap, 45-caliber blank, 10 gauge black powder blank, a

compression gas pulse and a rarefaction gas pulse. The explosive dynamite caps and blanks are a safety hazard and

have resulted in damage to wells and environment. While these explosive sources should not create a problem if the

casing annulus contains only hydrocarbon gas, major explosions have occurred when oxygen was allowed to enter the

casing annulus during work-overs or when special conditions resulted in a vacuum in the casing annulus

The versatility, economy and convenience of gas guns have resulted in widespread use of this type of acoustic pulse

generator. The expansion of gas from a volume chamber into the well generates the acoustic pulse. In most cases,

compressed CO2or N2gas is loaded into the volume chamber, which is charged to a pressure greater than the well

pressure. A valve in the wellhead attachment is opened rapidly, either manually or electrically, resulting in a pressure

pulse being generated in the casing annulus gas. The acoustic pulse travels through the gas in the casing annulus and

is partially reflected by changes in cross sectional area such as tubing collars, tubing anchors, casing perforations, etc.

The remaining pulse energy is then reflected by the gas/liquid interface at the depth of the liquid level. The reflected

signals travel back to the surface of the well where they are detected by the microphone.

The microphone within the wellhead attachment converts the reflected acoustic signal into an electrical signal

consisting of a series of pulses, which correspond to the sequence of reflections. The microphone must operate over

a wide pressure range from a vacuum to the maximum pressure that exists in the wells being tested. The microphone

should be designed to cancel the mechanical vibrations of the wellhead while remaining sensitive to the acoustic

signal reflections.

Recording and Interpretation of Signals

An amplifier/recorder filters and amplifies the electrical signal from the microphone and records the enhanced

signals on a strip chart. Modern instruments use analog to digital converters and microprocessors to improve the

signal quality and print the chart. The frequency content of the reflected acoustic signals varies depending on the

characteristics of the initial pulse, the pressure in the gas, the distance traveled and the type of cross sectional area

change. In general, as the pulse travels in a gas, the amplitude of the signal decays. The high frequency energy

decays more rapidly than the low frequency energy. Thus, the acoustic response from the collars at the top of the

well contains high frequency energy, the response from deep collars contains medium frequency and the signal

from the liquid level is mostly low frequency energy. This is especially apparent in deep wells with low casing

pressure. Fluid level instruments are designed to include various filters, which can be used to accent signals that

correspond to these frequency ranges. The Model M records the signal on the dual channels. One channel is tuned

to higher frequencies from the collars while the second channel is tuned to low frequencies from the liquid level.

Single channel instruments can be operated in any of these modes and it is possible to switch from one frequency

response to another while the instrument is recording. Initially, the single channel instrument is operated in the

collar mode (high or medium frequency), which is then switched to the liquid level mode (low frequency) when the

collar signal fades. Switching may be manual or automatic.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 6Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Depth Calculation

In most cases, once a strip chart record has been obtained and the liquid level signal has been identified, the

operator must count the number of tubing collar reflections from the surface to the liquid level in order to calculate

its depth. The corresponding number of tubing joints, multiplied by the average joint length yields the distance to

the liquid level.

Other techniques are available for determining the liquid level depth. When other signals are identified on the

chart, such as those generated by gas lift mandrels, liner tops, tubing anchors or perforations, the known depth of

these anomalies can be used to calculate the depth to the deeper liquid level by the ratio of chart distance or

elapsed time. When the lengths of tubing joints vary considerably, so that an average joint length is not

representative, some operators placed an over-sized tubing collar (marker) to serve as a depth reference.

When the specific gravity or the composition of the gas in the annulus is known with some accuracy, then the

velocity of sound in the gas can be calculated. The acoustic wave round-trip travel time from the initial pulse to

the liquid level reflection is read directly from the strip chart, which displays timing marks. The round-trip travel

time is divided by two and multiplied by the acoustic velocity to calculate the depth to the liquid level.

Still another technique involves measuring the acoustic velocity of the gas by sampling the casing gun into a tube

of sufficient length to measure the velocity of sound in the gas by pulse testing. This technique is applicable only if

the well continuously vents gas from the annulus so that a representative sample of the gas sample obtained at the

top of the well will not be representative of the gas in the well.

The most common application of an acoustic liquid level instrument is to measure the distance to the liquid level in

the casing annulus of a well. However, it can also be applied to measurements inside tubing. Other applications

include determination of the distance to the mud or kill liquid level during drilling and work-overs. The acoustic

instruments can be used to measure the distance to any change in cross-sectional area inside pipe or in the annulus.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 7Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

3 – General Description – Model M

The Echometer Model M is a dual channel, microprocessor controlled amplifier/recorder. It permits better

interpretation of reflections from downhole anomalies since two different filters are used to improve the signal.

Processing and simultaneously recording reflected signal using two separate amplifiers having different frequency

response, improve the ability of the operator to distinguish downhole obstructions from enlargements. The

response from the liquid level (orreduction in annulus area) is opposite to the response from an enlargement such

as a hole in the casing. The Model M uses modern electronics, integrated circuits, chart drive system and a thermal

printhead, which result in a very compact and lightweight system.

The dual channel Model M accents and records collars on one channel, and the liquid level response on a second

channel. The collar channel can be set to record sharp upper collars or deep collars. Selecting the proper collar

filter will result in more accurate determination of the number of tubing collar reflections from the surface to the

liquid level. The lower trace accents the signals from the liquid level, tubing anchor, gas-lift mandrels, casing

perforations and other major anomalies.

A microprocessor is used with an analog to digital converter, memory chip, amplifiers, clock, timing circuit and

other electronic components to improve the performance and utility of the instrument. When an acoustic pulse is

generated in the well, the signals reflected from the collars at the top of the well are large but rapidly attenuate.

The microprocessor is programmed to evaluate the signal level and increase or decrease the collar amplifier gain as

necessary to optimize the quality of the recording. The collar and other signals will be recorded at a width of

approximately 0.6-inch (12-mm), which simplifies the manual counting of the collars since the amplitude of the

collar signal is maintained automatically. The automatic control of the recording level is called automatic gain

control.

The microprocessor is used in conjunction with a timer. Since these instruments are used throughout the world, the

universal coordinated time and date are printed on the strip chart. Also, the timing capabilities of the

microprocessor, clock and timing circuit are used to place labeled markers at one-second intervals beginning from

the instant the acoustic pulse is generated. This allows the operator to determine the round trip travel time very

accurately. The travel time and the distance to the liquid level are used to compute the acoustic velocity of the gas

in the annulus. The acoustic velocity the casing pressure and average temperature can be input to the utility

program AWP for Windows to compute the gas gravity and the pressure distribution in the well, including the

pump intake pressure and the pressure at the perforations.

In addition to recording both collar and liquid level signals simultaneously, the digital printhead generates a

header, an analysis form, and prints the values of background noise, battery voltage and special instructions on the

strip chart.

The entire instrument is contained in a waterproof, dustproof plastic housing having dimensions of 11 by 10 by 5

inches and weighs 11 pounds (5 kg). The following section describes the instrument panel and the function of the

various controls.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 8Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Instrument Panel

The instrument panel is shown schematically in Figure 2 in the appendix. The following controls are used for

operating the instrument and for checking that it is operating correctly:

•Power Switch:

Momentarily placing the switch in the ON position energizes the amplifier, activates a red light that indicates

that the battery is powering the electronics and records a header on the strip chart. The microprocessor

performs a system test and checks the battery voltage. If the battery voltage is low, a message is printed to

charge the battery. If the system is OK, the chart drive stops after printing the battery voltage and test signals

on the collar and liquid level channels, and the message " TURN ON CHART DRIVE TO TEST WELL".

The power can be turned off manually, or the power will automatically turn off after approximately 15 minutes

of non-use.

•Upper Collars/Lower Collars Switch:

This two-position switch selects whether the collar channel is connected to the high frequency (Upper Collars)

or medium frequency (Lower Collars) filter circuits.

•Collars Gain

This knob controls the gain of the collar channel. The most counter-clockwise position (AUTO) activates

automatic gain setting and should be used first always. In the AUTO mode, the gain is set automatically.

Having the gain indicator on a value greater than 1 when the chart drive is turned on allows the operator to

control the amplifier gain by setting the gain control knob as desired before the “shot” is detected. After the

“shot” is detected, the instrument uses the gain setting when the shot is detected and the operator cannot adjust

the gain.

•Liquid Level Gain

This knob controls the gain of the liquid level channel. The most counter-clockwise position (AUTO)

activates automatic gain setting and should be used first always. In the AUTO mode, the gain is set

automatically. Having the gain indicator on a value greater than 1 when the chart drive is turned on allows the

operator to control the amplifier gain by setting the gain control knob as desired before the “shot” is detected.

After the “shot” is detected, the instrument uses the gain setting when the shot is detected and the operator

cannot adjust the knob.

•Chart Drive Switch

This switch is used to turn on and off the chart drive. Turning the switch to ON begins the data acquisition

sequence. This consists of printing the data forms followed by the gain settings and the noise level on both

channels, followed by the statement GENERATE PULSE and the recording of the two channels. The chart

drive continues on until the switch is turned OFF.

•Input Connector

This BNC INPUT connector is the input to the amplifiers. When acquiring data, this INPUT connector must

be connected to the microphone connector on the acoustic wellhead using a good coaxial cable with clean

connectors.

•Remote Fire Connector

Connects the instrument to the solenoid valve of a remote fire gas gun if a remote fire gun is utilized.

•Remote Fire Switch

Depressing this switch operates the solenoid valve on a remote fired gas gun by applying 12 volts to the

solenoid coil. Depress the switch for 1 second to fully release gas from the chamber.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 9Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

•Battery Charger Connector

Attaching the 110 VAC or the 220 VAC battery charger or the 12V-car battery power cable to this connector

charges the built-in battery.

•Test Connector and Test Switch (on units serial number 4999 and below only.)

This TEST connector should be attached to the INPUT connector using the coaxial cable in order to check

that the instrument and the coaxial cable are operating correctly. Depressing the test switch applies a test

signal to the input of the amplifier via the TEST connector and the coaxial cable.

•Chart Paper Drive

Pushing the spring-loaded aluminum plate cover towards the right and lifting it from the left side accesses the

chart paper. The paper is dropped into the cavity so that it unrolls counter-clockwise. After inserting the

paper roll, the aluminum cover is replaced. The printed Echometer logo on the paper should face up since

only this side of the paper is heat sensitive. The heat sensitive paper supplied by Echometer Company

operates over a wide temperature range and is made for the Echometer Chart drive system. The chart drive

has a paper sensor to determine when paper exists in the drive. If the sensor detects that paper is not present,

power is not supplied to the printhead. If paper is not present in the drive system and power is supplied to the

printhead, the printhead will be damaged because the small heating elements in the printhead will be

overheated. Using paper that is not of the proper width may result in printhead failure. Use only Echometer

paper to insure proper operation of the printhead and chart drive system.

Wellhead Attachments

Compact Gas Gun

The Compact Gas Gun consists of a microphone and a ten cubic inch volume chamber with a ¼” outlet

valve. The outlet valve will open rapidly when the trigger is pulled. This generates a pressure pulse. If

the pressure is greater in the volume chamber than in the casing annulus, a compression pulse is

generated. If the pressure is greater in the casing annulus than in the volume chamber, a rarefaction

pulse is created. A differential pressure must exist between the volume chamber and the casing annulus

for a pressure pulse to be generated. The operator has the choice of using an explosion or implosion

pulse.

Compression (Explosion) Pulse

Explosion utilizes an external gas supply to generate an acoustic pulse in the well. In the explosion

mode, the volume chamber is charged from an external gas supply to a pressure in excess of the well

pressure. Operating in the explosion mode keeps the inside of the chamber cleaner and results in less

maintenance.

Rarefaction (Implosion) Pulse

If the well’s casing pressure is greater than 200 PSI, implosion can be used. This method uses the

well’s pressure to generate a pulse. Use the gas gun filler/bleed valve to release gas from the volume

chamber. An external gas supply is not necessary to operate in the implosion mode. Operation in this

mode forces sand, moisture and other debris into the gas gun volume chamber and thus requires more

maintenance including frequent replacement of “O” rings.

Description of Compact Gas Gun Control Functions (refer to drawing)

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 10 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Volume Chamber Pressure Gauge

The volume chamber pressure gauge measures the pressure in the gas gun volume chamber. During normal operation, the

volume chamber is charged to 100-psi more than the casing pressure. Use additional pressure if required for satisfactory

results. If the internal gas valve is open, the gauge indicates the pressure between the gas gun and the casing annulus valve.

If the casing annulus valve is open, the gauge indicates the casing pressure.

Casing Pressure Gauge Quick Connector

The quick connector is located on the side of the housing. A precision pressure gage having a range close to the pressure

being measured will fit into the quick connector to enable the operator to obtain the casing pressure and casing pressure

change with sufficient accuracy to perform calculations of producing BHP and casing gas flow rate.

Cocking Arm

The cocking arm is lifted to depress and close the valve between the gas chamber and the casing.

Casing Pressure Bleed Valve

This valve allows bleeding the pressure between the casing valve and the compact gas gun. Turn the knob counter clockwise

to release the pressure. Verify that the casing valve is closed before opening the bleed valve.

Gun Filler-Bleed Valve

The filler-bleed valve is used to pressurize the gas gun volume chamber or to remove gas from the gas gun volume chamber.

Gas is added to the chamber from a pressurized external gas source by insertion of mating quick connector, into the filler &

bleed valve. Gas is bled from the chamber by rotating the knob clockwise. This action depresses the internal valve core

and releases the gas from the volume chamber to the atmosphere.

Trigger Pawl

The Trigger Pawl is pulled to release the gas valve between the gas gun volume chamber and the casing. If sufficient

pressure exists in the volume chamber or on the end of the gas valve, the gas valve will open.

Microphone

The microphone is a twin-disc pressure sensitive device that is vibration canceling.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 11 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Remote Fire Gas Gun

The remotely fired gas gun generates an acoustic pulse and detects the downhole reflections. The gas gun contains

a volume chamber, which is filled with compressed gas to deliver the acoustic pulse to the well. A microphone

housed in the gas gun detects the shot, collars and other wellbore reflections, and liquid level. The standard unit

has a working pressure of 1500 PSI.

Gas Valve and Solenoid

The solenoid serves as a trigger mechanism to initiate the acoustic pulse. When energized, the solenoid lifts a small

plunger and allows gas pressure to bleed off the top of the gas valve. Gas pressure then forces the gas valve open, causing

an acoustic pulse to be delivered to the well as the gas flows from the volume chamber into the well, (see the remote fire

gun diagram.) The gas valve does not hold pressure from the well. Therefore, gas pressure must be applied to the volume

chamber inlet port in order to close it. Whenever the valve is left open, well fluids will flow backwards through the gun

and into the volume chamber. This flow may entrain sand and other debris. These deposits may prevent the gas gun from

operating properly. To minimize this potential problem, it is advisable to charge the volume chamber with clean gas

before the casing valve is opened and as soon as the strip chart from any shot has been recorded. This will prevent the

well fluids and debris from entering the solenoid gas valve mechanism and causing a malfunction of the firing mechanism.

Volume Chamber Pressure Gauge

The volume chamber pressure gauge measures the pressure in the gas gun volume chamber. It should be used to

determine if the chamber pressure is sufficiently high (explosion mode) to generate the acoustic pulse. The volume

chamber pressure should be approximately 100-psi in excess of casing pressure unless additional pressure is required to

obtain desire results.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 12 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Casing Pressure Gauge or Optional Transducer

The casing pressure and casing pressure buildup during the acoustic test must be measured with an accurate and sensitive

pressure gauge or sensor. The Remote Fire Gas Gun supplied with the Echometer Model M is equipped with a quick

connect gauge that covers the range 0-200 psig. The user should consider the option of obtaining several gauges

covering different pressure ranges.

Charging the Gas Volume Chamber

To charge the volume chamber, first connect the filler adapter to a 7.5 oz. CO2bottle. Then, press the adapter against

the filler fitting on the gun. When these two fittings are pressed together, a valve core in the bottle is depressed and gas

will flow from the bottle into the volume chamber. Charge the chamber to at least 100 PSI above casing pressure before

attaching the gas gun to the casing annulus valve to prevent debris from entering the gas gun internal valve parts. The

volume chamber pressure can be read on the gun-mounted gauge. A 5-LB, CO2bottle and hose with connector can be

used to change the gun, if desired.

High Pressure Gas Guns

The 5000-psi gas gun is normally used in the implosion mode. It has an excellent noise-canceling microphone and

generates a very good pulse when the 1/2-inch ball valve is opened rapidly and the well pressure exceeds 200-psi. When

the 5000-psi gas gun becomes dirty due to debris imploding from the wellbore, the volume chamber and the microphone

assembly can be easily flushed with a solvent. The 5000-psi gas gun requires very little maintenance. It is excellent for

gas lift, flowing and high-pressure shut-in wells. It can be used in the explosion mode by charging the gas gun volume

chamber to a pressure in excess of the well pressure.

The 15000-psi High Pressure Gas Gun operates in the implosion mode only. Excellent results have been obtained at

pressures above 1500-psi through needle valves with 1/8-inch orifices, which are standard in most high-pressure wells.

For more details please refer to the Gun-Microphone Assemblies brochure in the appendix.

Accessories

Battery Charger (110 V- AC) or (220 V - AC if requested)

Automobile Battery Cable

Automobile Cigarette Lighter Cable

Casing Pressure Gauges

Precision Test Gauge

Precision Digital Gauge

Gas Cylinders

2-1/2 LB CO2

5 LB CO2

Nitrogen Cylinder

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 13 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Model M Modifications and Enhancements

The following changes have been made to improve the Model M performance and versatility starting with serial

number 5100. 1) The year, date and local time can be printed on each chart. 2) A chart operation delay switch

“ARM” has been added to allow the operator to “ARM” the Recorder and then walk over to the gas gun and fire the

shot before the chart drive starts to record data. The chart will record one second of acoustic data before the shot, then

record the shot and then the reflected acoustic data. 3) The well performance analysis header can be printed or not

printed on the strip chart. Other internal electronic features have been added in addition to these operating features.

The new panel, the information header and the well analysis header are shown below.

1. Year, Date and Time Setting The Enhanced Model M has provisions for setting year, date and local time in the

field. Previous units were set at Echometer Company factory for Universal Coordinated Time at Greenwich,

England. Thus, each operator had to determine from the universal time setting what time that the chart was

obtained at his particular location if he was outside of the Universal Coordinated Time Zone in England. The date

and time on the enhanced Model M are set as follows. There are two small holes located in the lower panel to the

left of the input connector. See picture on the next page. A small probe such as a straightened paper clip is

inserted into either hole to depress either of two switches below the panel. To set the year, month, date and time,

depress and hold down the switch below the left hole and turn the amplifier POWER switch ON. The instrument

will enter the Date/Time setting mode and will print instrument information including the current year, month, date,

and time. Pressing the switch below the left hole with the paper clip will decrement the year and pressing the

switch below the right hole will increment the year. The number of times that the switch is depressed controls the

amount of change. Turning the chart switch from OFF to ON to OFF will reprint the selected year. Again, the

year can be changed by depressing the switches below the left or right holes. Turning the chart switch from OFF to

ON to OFF without depressing either the left or right switches will advance the settings mode to the next unit (year,

month, day, hour, minute). Turning the Amplifier switch “Off” will exit the setting mode.

2. “ARM” Delay Start Function The Enhanced Model M has a new mode of operation that has been added to

facilitate operation in normal or hazardous environments with a one-person crew. The Model M chart drive will

not be actuated until the gas gun initial pulse is generated and the electronics senses the gas gun initial pulse.

When the “ARM” button is depressed and held down while the chart drive is turned on, and the chart drive will not

run until the electronics senses the large initial gas gun pressure pulse. The chart drive will not activate when the

chart drive switch is turned on. A data delay memory system is present in the Model M electronics that saves data

for later printing. When the shot is detected by the electronics, the chart will be started and the header will be

printed followed by the delayed acoustic data beginning with the last second of acoustic background noise before

the shot was detected. Then, the Model M prints acoustic data of the initial pulse and the reflected acoustic signal

until the chart drive is switched “Off” or 30 seconds maximum. Auto and manual gains are operational but

response is delayed by the memory system. IMPORTANT: wait at least 5 seconds after the “ARM” button is

depressed while the chart drive is switched on for the system to measure background noise before actuating the gas

gun pulse. When using CSA and ATEX certified equipment, the Model M is to be 25’ from the well in a “safe”

area and connected by a single coaxial cable to the Certified Compact Gas Gun or Certified 5000 Psi Gas Gun.

3. Chart Header The chart header is supplied from the Echometer factory with the following information showing

instrument identification and also the second insert below showing well analysis. A switch on the processor circuit

board permits selection of just the first header if desired. This header shows the ID, Version of software in the unit,

Serial Number and other information. The header also shows the POWER ON/SELF TEST and immediately

below, indicates whether the unit did PASS or FAIL the self test. Thus, the external test connector and the test

pushbutton on earlier units have been eliminated. Please refer to the sample chart shown below for an example of a

PASS test. Immediately below the self test, the Battery voltage is displayed. The unit can be charged every night

without damaging the battery using the supplied Echometer AC charger; or, the unit can be charged when the

battery voltage drops to 11.5 volts.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 14 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

The special chart insert that follows the initial heading above allows the operator to indicate the producing rate

efficiency and maximum production rate by hand input of the casing pressure and casing pressure build up rate

along with other information to perform a well analysis that is hand written onto the chart itself. The software

program “Analyzing Well Performance 2000” (for calculating the production rate efficiency and maximum

production rate) can be downloaded from www.echometer.com. Contact John Ryan at 940-767-4334 Ext 22 or

email John@echometer.com for written instructions if you desire to delete the following from the chart header.

Remote Fire Gas Gun When both collar and liquid level gain controls are set to the “AUTO” position, the

Model M will automatically provide a fire signal to the Remote Fire Gas Gun after the chart drive is turned ON.

When manual gain settings are used, the FIRE pushbutton is used to provide a fire signal to the Remote Fire Gas

Gun. The recorder must be connected to the Remote Fire Gas Gun solenoid by the proper Echometer cable.

Year, Month, Date and Time

Adjustment Access Holes

ARM Switch

Amplifier Power Switch

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 15 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

4 - Operation

Operation of the instrument is simple. First the acoustic wellhead should be attached to the casing annulus valve,

and the cable connected between the microphone and the instrument. The valve between the casing annulus and the

flow line should be closed to prevent the casing annulus gas from venting into the flow line causing excessive

noise.

General Recording Procedure

When the power switch is turned on, a red LED light indicates that the battery is powering the electronics. The

chart drive turns on and a header is printed as shown in Figure 3 in the appendix. Next, a system test is performed

which also displays the battery voltage. If the battery voltage is low, a message to charge the battery is displayed.

Then, the message is printed to "Turn on the chart drive to test well" and the chart drive stops until the chart drive

switch is turned to the ON position. At this point the operator selects the type of collar response (filter) desired.

Sharp upper collars can be selected for special applications such as shallow wells, irregular tubing length, dual

tubing strings and other special applications. The lower collar position is selected for most deep wells especially

with low casing pressure. Normally, both gain controls are set to the AUTO position and only changes from these

settings are necessary for those cases when satisfactory recordings are not obtained in the automatic position. When

the chart drive is activated, the form shown in Figure 4 is printed on the strip chart. This form is designed to insure

that the operator will write all the pertinent information about the well and the test. This includes the well

designation, the casing pressure, the casing pressure buildup rate and the latest well production test results. The

universal coordinated time stamp is beneficial for tracking the sequence of shots and calculating the exact time

interval between shots. The time interval is necessary when calculating rate of change in liquid level from which

can be computed the well influx (or injectivity) rates or to compute pressure buildup rates. Next, the acoustic

analysis form is printed on the strip chart. During the time that the forms are being recorded on the strip chart, the

instrument measures the background noise on both channels and then analyzes the noise in terms of peak to peak

amplitude and records the AUTO position when the chart drive is turned on, later adjustment of the gain control

does not affect amplifier gain. Then, a message to generate the pulse is printed on the strip chart. When the shot is

generated, the instrument detects the large signal and prints a vertical dotted line to mark zero time on the chart.

Each second thereafter another mark is recorded and labeled with the corresponding elapsed time in seconds. If

the “shot” is not detected by the electronics (which is indicated by the zero time mark), a larger pulse must be

generated so that the electronics will detect the initial pulse. After the zero time mark is printed on the chart,

operator adjustments of the gain control do not affect amplifier gain. This prevents the operator from increasing

the gain, which might result in noise being mistaken for a liquid level kick. The operator turns off the chart drive

after the liquid level response and other desired information is observed on the chart. The acoustic liquid level test

can be repeated by reloading the gas chamber, turning on the chart drive, and generating another acoustic pulse. If

the operator desires to manually select the amplifier gain, the gain control knob must be set at a value greater than

one before the chart drive is turned on. The collar channel gain should be set so that the response is approximately

1/8 inch (3 mm) before the shot. The liquid level channel gain should be set so that the response is 1/16 inch (1

mm) before the shot. Operator adjustment of the gain control after the “shot” is detected and the zero time mark is

recorded does not affect amplifier gain. If the recording level is excessive from downhole anomalies such as a

tubing anchor or perforations, a lower gain setting should be used. Both channels may be set in AUTO gain setting

mode or both in manual gain mode or one channel may operate in manual while the other is set to AUTO. Figure 5

shows two records. The upper record is with the filter setting on upper collars and the lower record shows the

response when the filter setting is lower collars.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 16 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Operation of the Model M with the Compact Gas Gun

The compact gas gun is to be operated in the COMPRESSION (Explosion) or RAREFACTION (Implosion) mode. The

operator should use the Compression (explosion) technique when the casing pressure is less than approximately 100 psig.

The Rarefaction (implosion) technique may be used whenever the casing pressure is sufficient to obtain a good record.

COMPRESSION (EXPLOSION) MODE

Expansion of gas from the Echometer gas gun is used to generate a pressure pulse. The pressure pulse is positive since the

gas chamber is charged to a pressure that exceeds the well pressure by at least 100-psi.

1. Securely attach the Echometer Gas Gun to the Casing Valve.

2. Close the Casing Pressure Bleed Valve and Filler Bleed Chamber Valve.

3. Lift the Cocking Arm to close the internal gas valve. This prevents debris from entering the volume chamber.

4. Open the Casing Valve to the Echometer Gas Gun slowly and Close the casing valve to the flow line.

5. Measure the Casing Pressure using the precision pressure gauge.

6. Record Time and Casing pressure.

7. Fill the volume chamber with gas (CO2 or N2) to at least 100-psi in excess of the Casing Pressure.

8. Connect the coaxial cable from the microphone to the Input of the Model M.

9. Turn Power Switch to ON.

10. Select the type of collar response desired and set the gain controls to AUTO.

11. Turn chart drive ON.

12. Generate pressure pulse by pulling Trigger Ring, after “Generate Pulse” is displayed on chart.

13. Turn chart drive OFF after detecting the liquid level signal.

14. Inspect the record and repeat the shot if the signal quality is not satisfactory.

15. Turn power switch to OFF after operation.

16. Record Time and Casing Pressure.

17. Close the Casing Valve between Echometer Gas Gun and the well.

18. Open the Casing Pressure Bleed Valve and release the pressure.

19. Open the Casing Valve to the flow line.

20. Remove the Echometer Gas Gun from the casing valve.

RAREFACTION (IMPLOSION) MODE

Gas is released from the well into the gas gun volume chamber to generate the initial pulse. Debris, moisture, corrosive

liquids and chemicals, and other foreign material may be imploded into the gas gun volume chamber, which will increase

maintenance requirements and may cause corrosion on the inside of the volume chamber.

1. Securely attach the Echometer Gas Gun to the Casing Valve.

2. Close the Casing Pressure Bleed Valve and Filler Bleed Chamber Valve.

3. Open the Casing Valve to the Echometer Gas Gun slowly and Close the casing valve to the flow line.

4. Pull Trigger Ring.

5. Lift the Cocking Arm to close the internal gas valve.

6. Measure the Casing Pressure using the precision pressure gauge.

7. Record Time and Casing Pressure.

8. Bleed the gas chamber pressure through the Filler-Bleeder Chamber Valve by rotating the knob clockwise until the

gas gun pressure has decreased to approximately 200-psi below the casing pressure reading. Use greater or less

differential pressure depending on the quality of the recording.

9. Connect the coaxial cable from the microphone to the INPUT of the Model M.

10. Turn Power Switch to ON.

11. Select the type of collar response desired and set the gain controls to AUTO.

12. Turn chart drive ON.

13. Generate pressure pulse by pulling Trigger Ring, after “Generate Pulse” is displayed on chart.

14. Turn chart drive OFF after detecting the liquid level signal.

15. Inspect the record and repeat the shot if the signal quality is not satisfactory.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 17 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

16. Turn power switch to OFF after operation.

17. Record Time and Casing Pressure.

18. Close the Casing Valve between Echometer Gas Gun and the well.

19. Open the Casing Pressure Bleed Valve and release the pressure.

20. Open the Casing Valve to the flow line.

21. Remove the Echometer Gas Gun from the casing valve.

Operation of the Model M with the Remote Fired Gas Gun

The main differences in operating procedure are that the Remote Fired Gas Gun initial pulse is generated by

depressing the Remote Fire Button on the control panel, and that this gun can only be used in the Compression

(Explosion) Mode.

1. Securely attach the Echometer Remote Fire Gas Gun to the Casing Valve.

2. Charge the gas chamber to at least 100-psi in excess of the estimated well pressure to prevent debris from

entering the volume chamber and the solenoid dart valve assembly.

3. Close the gas gun's Casing Pressure Bleed Valve.

4. Open the Casing Valve to the Remote Fire Gas Gun slowly.

5. Close the casing valve to the flow line.

6. Measure the casing pressure using the precision pressure gauge.

7. Record Time and Casing Pressure

8. Verify that the volume chamber pressure is at least 100-psi in excess of the Casing Pressure.

9. Connect the coaxial cable from the microphone to the Input of the Model M.

10. Connect the remote fire cable from the gun to the REMOTE FIRE connector.

11. Turn Power Switch to ON.

12. Select the collar FILTER and set the gain controls to AUTO.

13. Turn chart drive ON.

14. Generate pressure pulse by depressing the Remote Fire button for approximately one second to insure full

opening of the solenoid valve.

15. Turn chart drive OFF after detecting the liquid level signal.

16. Inspect the record and repeat the shot if the signal quality is not satisfactory

17. Turn power switch to OFF after operation.

18. Record Time and Casing Pressure.

19. Close Casing Valve to the Remote Fire Gas Gun.

20. Open the Casing Pressure Bleed Valve and release the pressure.

21. Open the Casing Valve to the flow line.

22. Disconnect cables and remove the Echometer Gas Gun from the casing valve.

NOTES

1. On deep, low pressure wells; first select the lower collar position.

2. If the initial pulse is not detected which is indicated by the zero timing mark, use a larger initial pulse.

3. If the liquid level is not detected (especially in deep wells with low casing pressure), the volume chamber

pressure should be increased in increments of 300-psi up to the limit of the available gas supply.

4. Do not use a larger volume chamber pressure than needed. Operating the gas gun at 300-psi requires twice as

much gas as when operating at 150-psi. Only one half as many shots will be obtained from a gas cylinder.

5. When using CO2gas above 300-psi (at normal temperatures), liquid may form in the gas gun, which will result

in considerably more gas being used per shot.

6. When using nitrogen gas, use a regulator so that the pressure will not exceed the working pressure rating of

1500-psi.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 18 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Recommendations for Optimum Performance

The Echometer wellhead should be as near as possible to the casing annulus (or the tubing) preferably within 5

feet. Short (5-10 ft) lengths of pipe can mask the desired downhole signals. Longer (20-60 ft) lengths will generate

multiple reflections, which are hard to distinguish from collar reflections. Use a minimum of 900ells and tees and

direct the blast straight into the well if possible. Two-inch connections are recommended, but one inch

connections are generally satisfactory if the length of 1 inch pipe is kept to a minimum.

Proper sensitivity setting is very important. Select the AUTO gain setting for the first shot. The background noise

level is indicated on the chart. Surface vibrations, leaking gas connections, gas “popping” out of the gas/liquid

interface and other unstable conditions, cause this noise. This background noise is not a part of the signals when

the pressure wave is generated. The instrument will automatically record the background noise at a low level and

larger collar and liquid level signals will be recorded at larger amplitudes, which simplifies the interpretation of the

chart. When operating in the AUTO mode, adjusting the sensitivity after the chart drive is tuned ON does not

change the automatic gain selection made by the electronics and software.

The pressure pulse travels down the well and is reflected by tubing collars and the liquid level. The signals from

upper collar reflections are strong, but the collar response becomes weaker as the pressure pulse travels long

distances to the bottom of the well so that the reflections from the lower collars may be weaker than the

background noise. The liquid level reflection varies from a strong signal in a shallow high pressure well to a very

weak signal in a deep low pressure well. Only signals stronger than the background noise are meaningful in the

recording. It is obvious that strong background noises must be reduced if the recording of lower collars and liquid

level is to be obtained.

Background noise can be classified as surface mechanical vibration noise or acoustic noise. The source of noise

can be determined easily by increasing the sensitivity until signal deflection is obtained. Closing the casing valve

between the microphone and the annulus will cause a reduction in the noise level if its source is acoustic noise. If

the signal level remains the same, then the noise is caused either by surface vibrations or by gas leakage from

extraneous lines connected on the same side of the closed casing valve as the microphone. The microphone is

shock mounted, but if the wellhead attachment vibrates excessively, unwanted signals are generated. Wellhead

vibration result from running gas engines, chattering check valves and other reciprocating surface equipment. It

may be necessary to eliminate wellhead vibrations to obtain better quality records in deep low-pressure wells. All

other lines leading to the casing annulus should be closed.

The main source of down-hole acoustic noise is gas "popping" out of a gaseous annular liquid column or liquid

falling into the wellbore. Downhole noise can also result from tubing and casing leaks. Generally, the down-hole

acoustic noise can be reduced in relation to the desired reflected signals by causing an increase in the casing

pressure. In order to do this, continue to pump the well with the casing vent valve closed. At low pressures, an

increase of 10-psi in the casing pressure almost always improves the record and it only depresses the liquid level by

30 feet.

If the signal from the liquid level is not detected due to excessive surface vibration noise or down-hole acoustic

noise, a larger signal from the liquid level can be obtained by generating a larger initial pressure pulse. Also,

increasing the sensitivity so that the background noise level exceeds 1/8 inch, generally will make interpretation

much more difficult and is not recommended.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 19 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

Automatic Gain Setting (AGS) Mode Characteristics

The Echometer Model M uses a microprocessor, which is programmed to evaluate the signal level before the shot

and set the amplifier gain as necessary to optimize the quality of the recording. The AGS mode on either or both

channels is activated by selecting the AUTO position before the chart drive is turned ON. Both channels are

normally operated in the AUTO mode. Changing the gain control setting from AUTO after the chart drive is

turned ON will not affect the amplifier gain. In both channels, the AUTO mode detects the noise level in the well

and adjusts the GAIN SETTING of both amplifiers so that the noise signal is recorded at a width of 1/8inch on the

collar channel and 1/16 inch on the liquid level channel. The noise level in mV peak-to -peak and the gain settings

(such as A: 7.1) is printed on the header just before the legend "GENERATE PULSE" is printed. The "A:"

signifies the system was in the AUTO gain setting mode and the "7.1" indicates the gain setting.

Manual Gain Setting (MGS) Mode Characteristics

MANUAL gain setting mode is selected by locating the gain control knob to a value greater than 1 before the chart

drive is turned ON. When the acoustic traces are displayed, adjust the gain on the collar channel until 1/8-inch

response is obtained. Adjust the liquid level channel gain control until 1/16-inch response is obtained. Lower gain

settings may be beneficial when the traces are over-driven. Higher settings on the liquid level channel, so that the

background noise is 1/8-inch, may be beneficial if the liquid level response is weak. The gain controls should not be

adjusted after the initial pulse is generated. Both channels can be set to manual mode, or either channel can

operate in manual mode while the other channel is in AUTO mode, or both channels can be set to AUTO mode.

Collar Channel Automatic Gain Control (AGC)

The gain of the COLLAR channel amplifier is automatically controlled so that the signal level is maintained at

0.6 inch peak to peak until the amplifier gain is increased to the setting that results in the background noise being

recorded at an amplitude of 1/8-inch. This results in a record showing collars at an amplitude of 0.6 inch when

strong collar signals are received. When the collar signal level fades to the background noise level or less, the

collar trace and noise will be recorded at 1/8-inch, which indicates to the operator that collars are no longer

distinguishable on the trace.

Liquid Level Channel Gain Control

When operating in the AGS mode, that is, the liquid level gain control is in the AUTO position before the chart

drive is turned ON, the LIQUID LEVEL channel amplifier gain is kept fixed at the setting that is established

automatically by measurement of background noise prior to the shot. AGC is not used. For large, reflected

signals after the shot, the liquid level channel recording will show that these peaks and valleys are clipped. This

method will insure that even low amplitude reflections caused by minor changes in cross section of the annulus (or

tubing) as well as the liquid level signal from deep low-pressure wells will be detected as long as their amplitude

exceeds the noise level. Adjusting the liquid level gain control after the chart drive is turned ON will not affect the

amplifier gain in the AUTO mode.

When operating in the MGS mode, that is, the liquid level gain is set greater than 1 before the chart drive is turned

ON, the liquid level gain control should be manually set so that the noise response is 1/16-inch before the shot. The

gain control knob controls the gain. AGC is not used. On deep low-pressure wells, the manual gain control can be

set so that the background noise is recorded at 1/8-inch before the shot is desired. If reflections from downhole

anomalies are excessive, use a lower gain setting. In manual gain mode, the proper gain should be set before the

initial pulse is detected by the electronics, which is indicated by the zero timing mark. When the initial pulse is

detected, the electronics maintains the gain setting selected by the operator at the time of the pulse detection, and

does not permit an increase in gain by the operator, which could result in the background noise being amplified and

mistaken for the liquid level.

Echometer Company Model – M Manual Phone: (940) 767-4334

5001 Ditto Lane Page 20 Fax: (940) 723-7507

Wichita Falls, Texas 76302, U.S.A. E-Mail: info@echometer.com

5 - Interpretation

In an average well, the following events will be recorded on the chart: a kick will show the initial blast. A series of

small kicks will indicate the tubing collars and then the liquid level kick will be recorded. If the chart is allowed to

continue to run, another kick will often occur after the liquid level kick at twice the time of the first reflected liquid

level kick. This is a signal that corresponds to the pulse traveling from the gun to the liquid level and then to the

surface where it is reflected by the wellhead back down the well and is again reflected by the liquid interface back

to the surface. In shallow and in high pressure wells there may be numerous other reflections from the liquid level.

These are known as "multiples" of the pulse. Since all these signals have traveled the same distance at the same

speed the distance (time) from the initial blast to the first liquid level reflection will be equal to the distance (time)

between the first liquid level kick and the second reflected level kick. Multiple liquid level reflections on very

shallow liquid levels, which are 20 to 60 ft from the surface, can be misinterpreted as collar reflections.

The normal chart has a kick at the start of the trace which corresponds to the initial pressure pulse, a series of small

evenly spaced kicks indicating the collar signals and a large kick indicating the liquid level. On some charts the

collars can be distinguished from the beginning of the chart to the liquid level signal and all the collars can be

counted. The most accurate procedure is to use the eleven point dividers and to mark off groups of ten collars

directly on the chart. On other charts the collars cannot be distinguished clearly all the way from the beginning to

the liquid level reflection. In these cases it may be convenient to repeat the test trying to improve the signal to noise

ratio so as to be able to count a large percentage (better than 60%) of the collars in the well. In these cases it is

necessary to count the collars to the last discernible collar reflection signal and then extrapolate the count to the

liquid level, using the eleven point dividers set on the last collar spacing. The total number of collars counted

multiplied by the average tubing joint length results in the depth to the liquid level. This assumes that the range of

tubing joints is similar for all tubing in the well. This procedure may not be used if there are significant differences

in the lengths of tubing joints. Alternative methods to determine the depth to the fluid level are discussed in the

following section.

On both channels, the direction of kick indicates enlargements and reductions in the cross sectional area of the

annulus (or internal diameter of pipe if shooting down tubing). For an explosion signal, objects which reduce the

cross sectional area of the annulus result in compression reflections and are recorded as downward kicks when the

top of the chart is at the left of the operator. Such objects would be liners, tubing anchors, paraffin deposits or the

liquid level. Conditions that increase the area of the annulus result in rarefaction reflected waves and are recorded

as upward kicks. Such conditions include perforations, "shot" holes, parted casing, parted tubing and the end of the

tubing casing annulus. If an implosion pulse is used, then the responses will be reversed from those of an explosion

pulse.

Please refer to the appendix where several examples of traces corresponding to various wells and different cases of

signals are presented.

For the explosion pulse the liquid level is recorded as a downward kick. If the liquid level is 20 feet or so in a

"shot" hole, then the signal would first deflect upwards, then down as the sound wave is reflected from the liquid

level. Recording the liquid level below a liner will show a downward kick at the liner and a downward kick at the

liquid level then an upward kick if the recorder is still running. The upward kick corresponds to the signal

generated at the liner by the wave which was reflected at the liquid level and which is returning to the surface.

When the wave passes from the narrow liner to the larger casing a portion of the wave is converted to a rarefaction

pulse, which then travels down to the liquid level and then to the surface where it is recorded.

Table of contents

Other Echometer Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Precision Digital Corporation

Precision Digital Corporation Survivor PD662 quick start guide

kirchgaesser

kirchgaesser TEM-EX-L operating instructions

mru

mru VARIOluxx user manual

CeYeKo

CeYeKo PDIS01 user manual

Sekonic

Sekonic STUDIO DELUXE? L-398A operating instructions

SPARLING

SPARLING MainLine FM-104 Installation, operaton & maintenance manual