Echometer D User manual

Echometer Operating Manual

Model D with Compact Gas Gun

REVA

ECHOMETERCOMPANY

5001 DITTO LANE

WICHITA FALLS, TEXAS 76302 USA

PHONE: (940) 767-4334 FAX: (940) 723-7507

E-MAIL: [email protected]

WWW.ECHOMETER.COM

MS

1950

-

REV

A "MODEL D

WI

COMP

ACT

GAS

GUN

TABLE OF CONTENTS

I.

PRINCIPALS OF ACOUSTIC LIQUID LEVEL MEASUREMENT

II. GENERAL DESCRIPTION

A.

AMPLIFIER-RECORDER

B. WELLHEAD ATTACHMENT

C.

ACCESSORY COMPONENTS

III. OPERATION

IV. INTERPRETATION

V.

PROBLEM WELLS

VI. BATTERY INFORMATION

VII. TESTING THE ECHOMETER

VIII. MAINTENANCE

IX. PARTS LIST AND DRAWINGS

X.

·APPENDIX

RATE OF FILL-UP AND INFORMATION

TECHNIQUE

FOR

DETERMINING CHART

SPEED

C02 INFORMATION

N2INFORMATION

ANALYZING

WELL

PERFORMANCE

ACOUSTIC STATIC BOTTOMHOLE PRESSURES

ACOUSTIC PRODUCING BOTTOMHOLE PRESSURES

PRECAUTIONS

1. Read

Manual

before

operating

equipment.

2.

Operate

the

equipment

safely

at

all

times.

3. Securely connect Echometer

gas

gun

assembly to

the

casing

annulus

opening.

Clean

threads

if

necessary.

Tighten

securely so

the

Echometer

wellhead will

not

become

dislodged by casing

pressure

and/or shock from

the

discharged pressure wave.

4.

The

gas

valve should

be

in

the

open position

when

the

gas

gun

is

installed

on a well.

The

gas

gun

pressure

gauge

will indicate

casing

pressure

when

the

casing valve is opened.

Open valve to

pressure

slowly.

For

safety, open valve a

slight

amount

until

gas

begins

to

flow.

Do

not

open

the

valve

any

more

until

the

pressure

equalizes. Then, fully open valve.

5.

Wellhead

Pressure

Rating.

Working

Pressure

1500

PSI

Test

Pressure

4000

PSI

The

working

pressure

ratings

on

the

Echometer wellhead, fittings, nipples, etc., apply to

like-new condition.

The

ratings

must

be lowered

if

wear

or

corrosfon

has

occurred.

6.

Usually

the

gas

gun

volume

chamber

pressure

is less

than

the

working

pressure

of

the

~

fittings on

the

well. However,

if

the

gas

gun

volume

chamber

pressure

exceeds

the

working

pressure

rating

of

the

connections on

the

well, do

not

discharge

the

gas

in

the

gas

gun

into

a closed valve

as

a

dangerous

pressure

may

result.

7.

Clean

wellhead

attachment

every 500 shots, monthly,

or

whenever dirty, whichever

occurs first. Inspect

and

replace

any

worn

or

bad

parts.

8.

When

assembling

the

wellhead,

install

Microphone

after

installing

the

Housing Cap.

See

Page

VIII.

9.

Do

not

breathe

excessively

high

concentrations

of

C0

2

or

N2 gas.

10.

Recharge

battery

when

voltage drops

in

yeUow arc,

or

once a month, whichever occurs

first.

11.

Package

properly for shipment. Remove

all

heavy

objects from amplifier-recorder case.

I

PRINCIPALS

OF

ACOUSTIC LIQUID LEVEL MEASUREMENT

A pressure pulse is

generated

from a wellhead

attachment

that

is connected to

the

surface

casing

annulus

valve.

The

pressure

pulse

travels

down

the

casing

annulus

gas

and

is reflected

by collars, liquid level,

and

other

obstructions. A microphone

in

the

wellhead

attachment

converts

the

pressure pulses

into

electrical pulses which

are

amplified, filtered

and

recorded on a

strip

ofpaper. The

chart

shows

the

number

of

tubing

collars to

the

liquid level. The depth is

determined by

multiplyin~

the

number

of

tubing

collars by

the

aver~ge

tubing

length.

THE

ECHOMETER

.,

The Echometer

is

a precision

instrument

for

determining

the

depth

to liquid

in

a well.

It

is

the

most advanced

instrument

available

regardless of price. The

upper

collars, deep collars, or

the

liquid level

can

be

accented for

maximum

accuracy. Yet,

it

is

simplified for easy operation

by

the

labeling ofcontrols to

indicate

the

functions performed.

ECHOMETER SCHOOL

Echometer Company offers schools

on

the

use

and

applications of

the

Echometer. You

are

invited to

attend

free

of

charge. A

list

of

the

schools which

are

located

throughout

the

U.S.

and

Canada

will be

sent

upon

request.

Echometer Company

has

an

excellent service policy.

If

we

can

be of service, please contact

us.

Thank

you.

COMPUTER & SPECIAL APPLICATION

A

portable

laptop

computer

is

available for calculating bottomhole pressures. Also,

the

distance

to

an

anomaly

or liquid level

can

be

calculated from accoustic

travel

time

when

gas

properties

are

known.

Contact

us

for

additional

information.

GENERAL DESCRIPTION OF THE ECHOMETER

A.

AMPLIFIER-RECORDER

The

amplifier-recorder receives

the

signals

from

the

microphone, amplifies

these

signals,

filters

the

signals

to accent desired information,

and

records

the

information on

heat

sensitive

paper.

The

controls

and

their

functions follow:

AMPLIFIER POWER SWITCH

II

Ur.its

built

after

June

1, 1985. Momentarily placing

the

switch

in

the

"On" position

energizes

the

amplifier circuit for four to five minutes.

Turning

on

the

chart

drive energizes

the

amplifier circuit for

an

additional four to five minutes. Additional

battery

life will be obtained

if

the

amplifier power switch is

momentarily

placed

in

the

"Off' position immediately

after

the

record

is

completed.

Units

built

before

June

1, 1985. A toggle switch controls power to

the

amplifier.

Turn

the

switch to "On"

and

allow

ten

seconds for stabilization. As a safety precaution, a safety switch

will

automatically

turn

off

the

power

when

the

lid is closed.

SENSITIVITY

Two sensitivity controls

are

located on

the

panel. The

higher

knob is

the

COLLAR

sensitivity control,

and

it

controls

the

sensitivity when

the

filter is

in

UPPER

COLLARS or

DEEP

COLLARS. The lower knob controls

the

sensitivity when

the

filter is

in

LIQUID LEVEL.

FILTER

The

Echometer uses a very effective filter system. The filter is labeled

UPPER

COLLARS,

DEEP

COLLARS

and

LIQUID LEVEL.

The

various filter positions

tune

the

system

to record

the

type

ofsignal desired.

UPPER

COLLARS

tunes

the

amplifier to

high

frequency

signals

which

result

in

the

collars being recorded

as

sharp,

distinct "kicks".

DEEP

COLLARS passes

medium

band

signals

and

records

these

signals

similar

to smooth sine waves.

DEEP

COLLARS

accents deep collars for

greater

accuracy

in

deep

w~lls.

LIQUID LEVEL

tunes

the

system

to

the

low frequency signals found from

the

liquid level

in

deep, low pressure wells.

The

UPPER

COLLARS filter position is used on shallow wells (less

than

4000 feet),

high

pressure

wells,

dirty

wells,

and

wells

with

irregular

length

tubing. The collars

are

recorded

as

"sharp"

kicks.

The

DEEP

COLLAR filter position

is

recommended for most low pressure, deep wells below

4000 feet.

With

normal conditions,

the

upper

collars

are

strong

and

distinct,

and

the

liquid level

is

strong

and

distinct,

but

the

lower collars

are

weak

and

they

become indistinct.

The

DEEP

COLLAR filter position will accent

these

signals while removing undesired

background

noise

and

result

in

the

recording

of

lower collars. This is a more accurate record

than

a record

without

the

lower collars recorded.

11-1

PRESSURE SWITCH (Only on

units

built

before

June

1, 1985)

The

pressure

switch reduces

the

signals from

the

microphone to

the

amplifier when

operated

in

the

HIGH position. This switch is used

in

the

LOW position

with

the

gas gun, since

the

response from

the

microphone can be controlled by

the

size of

the

charge from

the

gas gun.

MICROPHONE CABLE

A shielded cable connects

the

amplifier-recorder to

the

microphone. When

installing

and

removing

the

cable, hold to

the

cable connector only. DO NOT PULL ON THE FLEXIBLE

CABLE BODY. Cable

length

can be

in

excess of 50 feet

if

desired for special conditions

with

negligible loss ofsignals. The shielded cable

prevents

stray

kicks generated by overhead power

lines

and

other

electrical disturbances. Echometer cable is superior to

standard

coaxial cable

and

should be

used

for

best

results.

TEST OUTPUT

See Section VII

RECORDER AND

PAPER

DRIVE

The

chart

drive

and

electrical

writing

pen

are

activated

by

the

toggle switch

near

the

chart

drive.

Turn

ON

the

chart

drive when

ready

to record. Approximately 12" of paper discharge

is

necessary for

the

pen

to

heat.

The

chart

paper

is replaced by removing

the

galvanometer

plate

(push back

and

lift)

and

then

removing

the

used

paper

roll. Place

the

paper

in

the

chart

drive

with

the

printed

side up. Replace

the

pen

cover plate. Be careful

not

to damage

the

pen.

THE GALVANOMETER AND

PEN

REPLACEMENT

The galvonometer does

not

require

maintenance

except for

pen

replacement

and

adjustment.

The

pen

is replaced

by

removing

the

galvanometer cover plate. The plate should be pushed

back

and

lifted. Remove

the

two screws holding

the

pen

leads

and

the

screw holding

the

pen body.

Remove

the

pen

and

insert

a new one. The

pen

teJ:lsion on

the

paper

support should be

about

5

grams

to

get

adequate

writing

darkness

and

proper

pen

response.

Turn

the

pen tension screw

90° clockwise

after

the

pen

touches

the

paper

support roller (no

paper

installed) to obtain

approximately 5

grams

pen

tension. Connect

the

red

wire

on

the

pen

to

the

terminal

block

having

a

red

wire

attached

as

before. Reconnect

the

black

wire. Be sure

that

the

tabs

on

the

pen

are

bent

up to

prevent

the

tabs

from

restricting

pen

movement.

VOLTMETER

See Section VI

"Battery

Information" for details of

battery

operation.

TIMER SWITCH (Manufactured after

July,

1984)

A

timer

places a

mark

on

the

chart

at

the

initial

pulse generation & each second

thereafter.

The

mark

should

be

on

the

printed

side of

the

chart

if

the

initial

wave is a compression wave,

and

on

the

opposite side

when

the

initial

wave is a rarefaction wave. The

timing

marks

can

be

generated

manually

by depressing

the

Timer

switch.

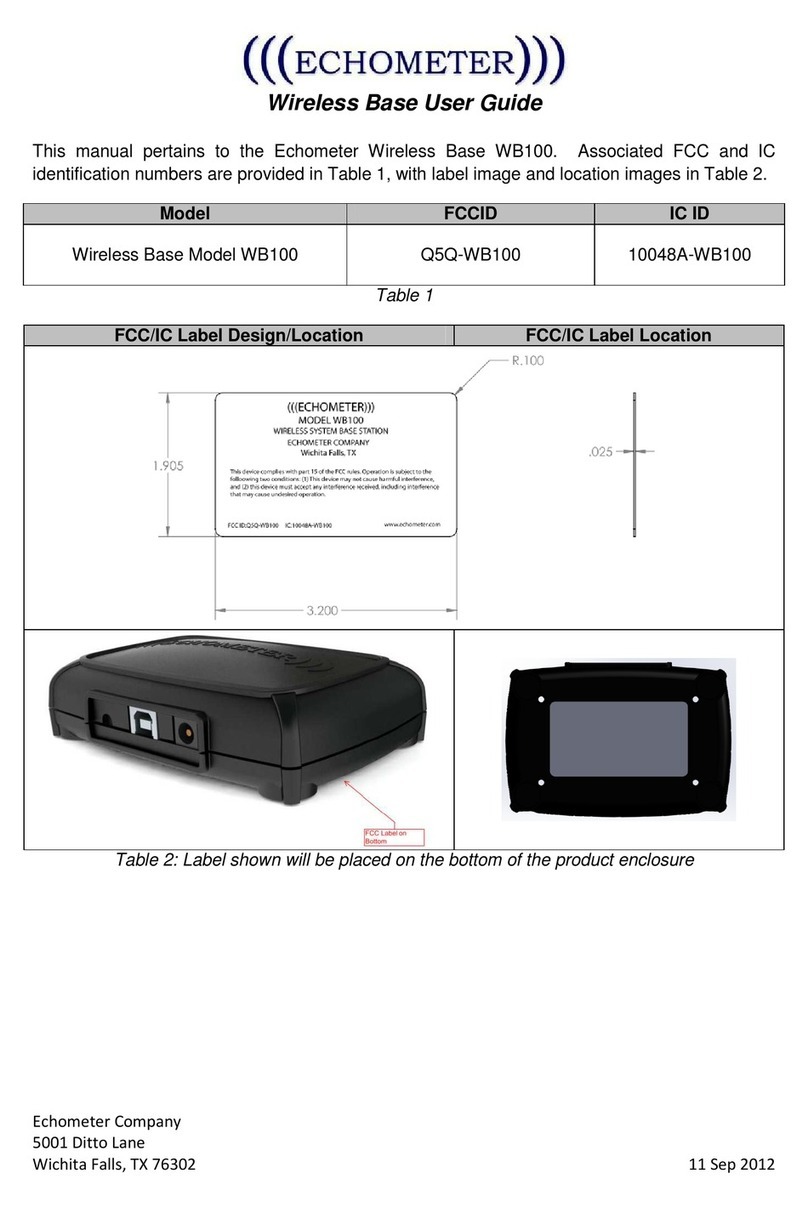

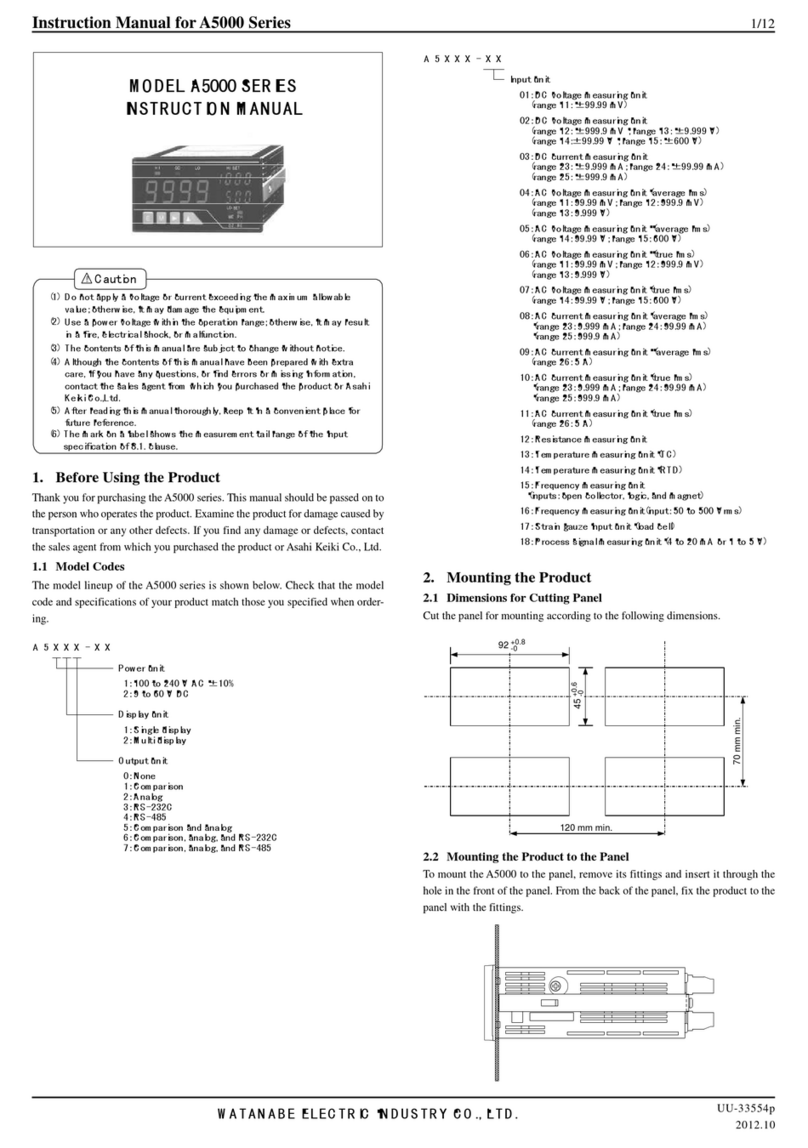

BNC

CONNECTOR

ATTACH CABLE FOR

MICROPHONE OUTPUT.

TRIGGER~

PULL

TO

RELEASE

GAS VALVE.

FILLER-BLEED

CHAMBER VALVE

GAS

CAN

BE

INJECTED

INTO

THE GAS

GUN

VOLUME

CHAMBER USING

SPECIAL ADAPTOR

ATTACHED

TO

C02

CONTAINER. GAS CAN

BE

BLED

BY

ROTATING

THE KNOB CLOCKWISE.

GAS GUN DISCHARGE

PRESSURE

GAUGE

s MEASURES PRESSURE

IN

GAS

GUN

VOLUME

CHAMBER.

COCKING

ARM

/

LIFT

THE COCKING

ARM

TO

DEPRESS

ANO CLOSE THE

..-~~_J!!:::::::::L..~~~..-~..::..~~-...

GAS VALVE.

0

~CASING

PRESSURE

QUICK

CONNECTOR

PERMITS EASY

DETERMINATION

OF

CASING

PRESSURE BY INSERTION OF

AN

ADAPTOR ATTACHED

TO

A PRESSURE

GAUGE.

~CASING

PRESSURE

BLEED

VALVE

TURN

THE

ARROW

UP-DOWN

ANO

PULL

TO

OPEN THE

POPPET

VALVE.

B.

WELLHEAD

ATTACHMENT

The

wellhead

attachment

consists

of

two parts:

the

microphone

and

the

gas

gun.

The

microphone converts acoustical signals into electrical signals.

Do

not

permit

the

electrical receptacle to become damaged or wet.

Do

not

change pressure rapidly.

II-2

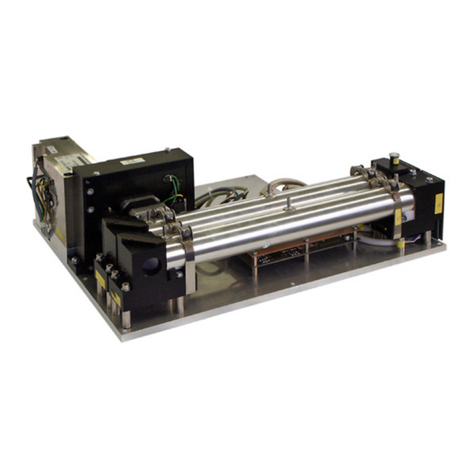

The

gas

gun

consists

of

a 10 cubic

inch

volume

chamber

with

a%"

outlet

valve.

The

outlet

valve will open

rapidly

when

the

trigger

is

pulled. This

generates

a pressure pulse.

If

the

pressure

is

greater

in

the

volume

chamber

than

the

casing

annulus,

a compression (or positive)

pressure pulse

is

generated.

If

the

pressure

is

greater

in

the

casing

annulus

than

the

volume

chamber, a rarefaction (or negative)

pressure

pulse

is

generated.

A discussion

of

the

parts

on

the

gas

gun

will be beneficial

in

operating

the

equipment. See

the

gas

gun

drawings.

PRESSURE

GAUGE

The

pressure

gauge

measures

the

pressure

in

the

gas

gun

volume chamber.

If

the

gas

gun

valve

is

open,

the

gauge

indicates

the

pressure

between

the

gas

gun

and

the

casing

annulus

valve.

If

the

casing

annulus

valve is open,

the

gauge indicates

the

casing pressure.

CASING

PRESSURE

QUICK

CONNECTOR

A

casing

pressure

quick connector is located on

the

side. A lower

range

pressure gauge

with

a

mating

adaptor

will fit into

the

casing pressure quick connector to enable

the

operator to

obtain

the

casing

pressure

when

greater

accuracy

at

low pressures is needed.

The

pressure

gauge

and

adaptor

simply

push

into

the

casing pressure quick connector.

COCKING

ARM

The

cocking

arm

is

lifted to depress

and

close

the

gas

valve.

·?

II-3

CASING PRESSURE

BLEED

VALVE

The casing

pressure

bleed valve is a poppet

type

valve to bleed

the

casing pressure. To open

the

valve,

turn

the

knob

until

the

arrow

is

up

-down

and

pull

out

the

knob. The discharge from

the

gas valve is sudden. Be careful

not

to blow

sand

or

debris which could injure personnel.

The casing

pressure

bleed valve

can

be used to

generate

the

initial

pressure

pulse. Rapidly

open

the

casing

pressure

bleed valve

and

allow

it

to

remain

open

and

bleed gas from

the

well

until

the

record is obtained.

Do

not

close

the

casing

pressure

bleed valve before

the

reflection

from

the

liquid level is obtained. Closing

the

casing

pressure

bleed valve will

result

in

another

pulse being

generated

and

multiple

reflections will be obtained from down

the

well.

FILLER-BLEED CHAMBER VALVE

The filler-bleed

chamber

valve is used to pressurize

the

gas

gun

volume

chamber

or

to

remove gas from

the

chamber.

Gas

is

added

to

the

gas

gun

volume

chamber

by

insertion

of

a

mating

quick connector

attached

to a pressurized gas source into

the

filler-bleed

chamber

valve.

Gas is bled from

the

chamber

by

rotating

the

knob clockwise. Clockwise

rotation

of

the

filler-bleed

chamber

valve

results

in

depression

of

the

valve core

and

hence bleeding

of

the

volume

chamber

thru

the

filler-bleed

chamber

valve.

TRIGGER PAWL

The

trigger

pawl

is

pulled

to

release

the

gas

valve.

If

sufficient

pressure

exists

in

the

volume

chamber

or

on

the

end

of

the

gas

valve,

the

gas valve will open.

MICROPHONE

The

microphone is a twin-disc pressure-sensitive device

that

is

vibration

cancelling.

C.

ACCESSORY COMPONENTS

The

standard

accessories include recording paper, eleven point dividers, a choice

length

microphone cable, a 110 VAC

automatic

recharger, a 12 VDC automobile cigar

lighter

recharger,

and

an

operating

manual.

A

gas

supply cylinder is necessary

on

low

pressure

wells.

Three

7.5 ounce

C0

2

containers

with

quick connect filler connector, a refill

adaptor

and

scales

are

standard

unless

the

optional

5#

bottle

with

hose

and

quick connect filler connector

are

specified.

Extra

manuals

are

free.

III

Operation

of

the

Echometer

with

Compact

Gas

Gun

Wellhead

The

compact gas

gun

is to

be

operated

in

the

Explosion or Implosion mode

depending

upon

the

casing

pressure. Use

the

Explosion

technique

when

the

casing

pressure

is

less

than

approximately

100 PSI. Use

the

Implosion

technique

when

the

casing

pressure

is sufficient to

obtain

a good record.

A. EXPLOSION ofcompressed

gas

from

the

Echometer gas

gun

can

be

used

to

generate

the

pressure

pulse.

The

pressure

pulse

is positive. (Use

with

less

than

100

PSI

casing

pressure).

1.

Securely

attach

Echometer

gas

gun

to

casing valve.

2. Close

Casing

Pressure

Bleed Valve

and

Filler-Bleed

Chamber

Valve.

Open

casing

valve slowly.

3.

Pull

trigger

ring

and

measure

casing

pressure. (Use precision

pressure

gage

with

adaptor

if

desired).

4.

Lift

cocking

arm

to

close

gas

valve.

5.

Fill

volume

chamber

with

gas

(C0

2 or N2) to 150 PSI.

Use

a

higher

pressure

only

if

the

liquid level response

is

not

distinct. Less pressure should be

used

if

satisfactory

records

are

obtained

at

lower pressures.

6.

Turn

amplifier

ON

and

allow 10 seconds for stabilization while connecting cable.

7. Select

type

of

collar

response

desired

and

increase collar

sensitivity

until

pen

response is 1

/s". (Reduce well noise

if

necessary).

8.

Turn

chart

drive

ON

and

run

12 inches of

chart

paper.

9.

Generate

pressure

pulse

by

pulling

trigger

ring.

10.

Turn

amplifier

OFF

after

operation:'

III-1

B.

IMPLOSION

of

compressed

gas

from

the

casing

annulus

into

the

Echometer

gas

gun

is

used

to

generate

the

pressure

pulse.

The

pressure

pulse

is

negative.

(Use

when

the

casing

pressure

is

between

100

PSI

and

the

working

pressure

rating

of

1500 PSI. Use

at

lower

pressures

if

satisfactory

records

are

obtained).

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Comments

1.

2.

3.

Securely

attach

Echometer

gas

gun

to

casing

valve.

Close

Casing

Pressure

Bleed

Valve

and

Filler-Bleed

Chamber

Valve

and

very

slowly

open

casing-valve. Do

not

allow

pressure

to

increase over 500

PSI

per

second.

Damage

to

the

microphone

can

result

when

rapid

pressure

changes

occur.

-

Pull

trigger

ring_

and

measure

casing

pressure.

(Use precision

pressure

gage

with

adaptor

if

desired.)

Lift

cocking

arm

to close

gas

valve.

Bleed

gas

gun

pressur.e

through

Filler-Bleed

Chamber

Valve

by

rotating

knob

clockwise

until

~he

gas

gun

pressure

has

been

decreased to

approximately

200

PSI

below

the

casing

pressure.

Use

greater

or

lesser

differential

pressure

if

greater

or

lesser

response is desired.

Turn

amplifier

ON

and

allow 10 seconds for stablization while connecting cable.

Select

type

of

collar response

desired

and

increase

collar

sensitivity

until

pen

response

is

1/s".

(Reduce well noise

if

necessary).

Turn

chart

drive-

ON

and

run

12

inches

of

chart

paper.

Generate

pressure

pulse

by

pulling

trigger

ring.

The

generated

pressure

pulse

is

negative.

Chart

i;esporrse

direction

will

be

reversed.

Turn

amplifier

OFF

after

operation.

Before

removing

the

gas

gun

from

the

casing

valve, bleed

gas

by

opening

the

casing

pressure

bleed

valve. Tlie

casing

pressure

bleed

valve is

the

solid

%"

knurled

knob.

Turn

arrows

up-doWn. Be careful.

If

sufficient

pressure

exists

behind

the

poppet

valve,

the

valve

will open itself.

If

the

pressure

is low,

pull

the

valve open.

On

deep wells,

the

filter

should

be

in

DEEP

COLLAR position.

DEEP

COLLAR

position

accents

the

lower collars.

On

shallow

wells

or

if

the

upper

collars

are

not

distinct

on a deep well,

set

the

filter

to

UPPER

COLLARS.

111-2

4.

If

the

fluid

level

is

not

recorded,

(especially on deep, low pressure wells),

after

step

7 above, place filter

in

LIQUID LEVEL position

and

increase

the

lower

sensitivity

knob

until

pen

response

is

1/s".

Then

set

filter to collar position. After

generating

the

pressure

pulse, note

the

pen

response carefully. When collar

response

has

diminished

to

1/s"

background noise, switch

the

filter to LIQUID

LEVEL

so

that

the

amplifier will be

tuned

to

the

response from

the

LIQUID

LEVEL.

5. All

pen

responses will be reversed

in

the

IMPLOSION technique since

the

pressure

is

negative

in

comparison to

the

normal

positive

pressure

pulse.

6.

If

a

larger

liquid

level response

is

desired, use a

greater

differential

pressure

between

the

gas

gun

volume

chamber

pressure

and

the

casing

annulus

gas

pressure.

Do

not

use

a

larger

differential

pressure

unless needed.

7.

Operating

the

gas

gun

at

300

PSI

requires

twice

as

much

gas

as

operating

at

150

PSI. Only

one-half

as

many

shots will be obtained from a cylinder. When

using

C0

2

gas

above 300

PSI

(at

normal

temperatures), liquid

may

form

in

the

gas

gun

which

will

result

in

considerably more

gas

being used

per

shot.

8.

When

using

nitrogen

gas,

use

a

regulator

so

that

the

pressure

cannot

exceed

the

working

pressure

rating

of

1500 PSI.

III-3

DETAILS

OF

OPERATION

Attach

Echometer wellhead to casing valve.

The

Echometer microphone should be

as

near

as

possible to

the

casing

annulus,

preferably

within

5 feet.

Short

lengths ofpipe can

mask

the

desired downhole signals. Longer

lengths

will give multiple reflections which

are

hard

to

distinguish from collar reflections. Use a

minimum

of

90°

ells

and

tees

and

direct

the

blast

directly into

the

well

if

possible. Two

inch

connections

are

preferable

but

one inch connections

are

generally satisfactory

if

the

length

of 1" pipe is held to a minimum.

The

amount

and

number

of

unfavorable conditions which

can

be

tolerated

are

determined

by

the

difficulty of

the

well.

If

the

well is easy to test,

then

a few unfavorable conditions can

be

tolerated.

If

the

well is

difficult,

the

unfavorable surface conditions

may

prevent

a satisfactory record. Normally,

unfavorable surface connections

interfere

more

with

collar

than

with

liquid level response.

Proper sensitivity

setting

is very important. Increase sensitivity

until

pen

response is 1

/s".

The

setting

indicates

the

background well noise level. Background noise is caused by surface

vibrations,

leaking

gas connections, downhole gas "popping" out ofliquid,

and

other

unstable

conditions. This background noise is

not

a

part

of

the

signals

that

result

when

the

pressure

wave is generated.

Do

not

increase

the

sensitivity

after

the

pressure wave is generated or

background noise will

be

recorded.

Background noise

must

be considered.

The

pressure wave travels down

the

well

and

is

reflected by collars

and

the

liquid level. The top collar reflections

are

strong,

and

the

lower

collar reflections become

much

weaker.

The

liquid level reflection varies from a strong signal

in

a shallow high-pressure well to a very

weak

signal

in

a deep low-pressure well. Only signals

stronger

than

background noise

can

be recorded.

It

is obvious

that

strong background noises

must

be

reduced

if

the

recording

of

lower collars

and

liquid level is obtained

in

a deep, low

pressure well. More background noise

can

be tolerated

in

high

pressure, shallow wells because

the

desired signals

are

stronger.

In

general, a background noise sensitivity

setting

of

3-5 is

sufficient on shallow

and

higher

pressure

wells, while a

setting

of5-10

may

be

required for

satisfactory

results

on a deep low-pressure well.

·?

III-4

Background noise

can

be classified

as

surface noise

or

down-hole noise.

The

source

of

the

noise can be

easily

determined

by

increasing

the

sensitivity

until

pen

movement

is obtained.

Then

close

the

casing

valve

between

the

microphone

and

the

casing

annulus.

If

the

random

pen

movement

reduces,

the

noise is

originating

from

the

other

side

of

the

valve which would be

down-hole noise

or

noise

caused

by

surface

gas

leakage

on

the

other

side of

the

valve.

If

the

pen

movement

remains

the

same,

then

the

noise is

either

surface

vibrations

or

noise caused

by

gas

leakage

from

extraneous

lines connected on

the

same

side of

the

casing

valve

as

the

wellhead.

Surface noise

generally

originates

from surface vibrations.

The

microphone is shock

mounted,

but

if

the

wellhead

attachment

vibrates,

signals

are

generated.

Wellhead

Vibrations

should

be

stopped for

better

records on deep low-pressure wells.

Vibrations

result

from

running

gas

engines,

chattering

check valves,

and

other

operating

surface

equipment.

Other

possible

surface

noises include

leaking

gas

connections,

leaking

valves,

and

operating

regulators.

Close

all

other

lines

leading

from

the

casing

annulus.

The

main

source

of

downhole noise is

gas

"popping"

out

of

a gaseous column.

When

pen

movement

occurs

at

sensitivity

settings

of

less

than

5,

always

check for a gaseous column. See

"Analyzing Well Performance"

in

the

appendix. Downhole noise

can

also

result

from

tubing

&

casing leaks.

The

filter

can

be

used

to remove background noise

in

many

cases.

Try

all

3 filter positions

if

necessary.

The

filter

position

which

has

the

highest

sensitivity

settings

for

1/s"

pen

response

often gives

best

results.

Generally,

the

downhole noise

can

be reduced

in

relation

to

the

desired

reflected

signals

by

increasing

the

casing

pressure.

Continue

to

pump

the

well

with

the

gas

vent

valves closed.

At

low pressures,

an

increase

of

10

PSI

casing

pressure

almost

always

improves

the

record

and

depresses a solid

liquid

column

about

30 feet.

If

the

liquid level

signal

is

not

obtained

due to excessive surface noise

or

downhole noise,

a

larger

signal

from

the

liquid

level

can

be

obtained by

generating

a

larger

initial

pressure

pulse.

Increasing

the

Sensitivity

above

the

background noise level

makes

interpretation

much

more difficult

and

is

not

recommended.

IV

INTERPRETATION

The normal

chart

has

a kick

at

the

beginning of

the

run

signifying

the

initial

pressure

pulse, a series ofsmall evenly spaced kicks indicating

the

collars,

and

the

large kick indicating

the

liquid level. On some

charts,

the

collars

can

be distinguished from

the

top of

the

chart

to

the

liquid level

and

each collar

can

be counted. The spacing divider can be used

if

desired. On

other

charts,

the

collars

cannot

be distinguished clearly

all

the

way down

the

chart

to

the

liquid

level kick.

In

such cases,

count

the

collars down to

the

last

distinguishable collars. Then,

extrapolate to

the

liquid level

using

the

spacing dividers

set

with

the

same spacing

as

the

last

distinguishable collars. Often

the

collars

near

the

top of

the

chart

are

closer

together

than

those

in

the

lower portion of

the

chart

on wells which

are

not venting

gas

from

the

casing annulus.

The

change is caused by

heavier

gas

settling

in

the

lower portion of

the

well. Sound

travels

slower

in

a heavy gas. The collars become closer together

near

the

bottom of

the

hole when gas

is

being

vented

at

the

surface

and

the

bottomhole temperature-is

higher

than

the

surface

temperature.

The

higher

temperature

causes

an

increase

in

the

velocity

of

sound. Be

sure

to

count

the

collars

as

accurately

as

possible down to

the

last

distinguishable collars.

In

some

cases,

the

collars

are

indistinct.

Set

the

spacing divider for .the same spacing

as

shown

by

the

best

collars

and

count from

the

instant

of"blast" to

the

liquid level

using

this

spacing.

The

liquid level

depth

can

also be determined by measuring

the

travel

time

and

knowing

the

acoustic velocity from

gas

property

data.

Acoustic velocity

charts

are

available. Also, a

portable computer

can

be used. Information is available on reque·st.

On

an

average well,

the

following

events

will be recorded on

the

chart.

A kick will show

the

initial

blast. A series of

small

kicks will indicate

the

collars,

a:nd

then

the

liquid level kick will

be recorded.

If

the

chart

is allowed to

run,

another

kick will often occur below

the

liquid level

kick. This reflected liquid level

kick

is caused by

the

blast

which

travels

down

the

well, is

reflected by

the

liquid level

back

to

the

surface, is

again

reflected by

the

casing

head

back down

the

well;

and

again

it

is reflected

by

the

liquid level back to

the

surface. The distance from

the

initial

blast

to

the

first liquid level

kick

will be equal to

the

distance between

the

first liquid

level kick

and

the

second reflected level kick. Multiple liquid level reflections on shallow liquid

levels

can

be misinterpreted. ·

.)

. -

The

direction ofkick indicates

enlargement

and

reductions.in

the

cross sectional

area

of

the

annulus.

Objects which reduce

the

cross-sectional

area

of

the

annulus

result

in

compression

waves

and

are

recorded

as

downward kicks (toward

the

printed

side of

the

chart)

when

the

top of

the

chart

is to

the

left.

Such

objects would be liners,

tubing

anchors, paraffin deposits or liquid

level. Conditions increasing

the

cross sectional

area

of

the

annulus

result

in

rarefaction waves

and

are

recorded

as

upward

kicks.

Such

conditions

are

perforations, "shot" holes,

parted

casing,

or

parted

tubing.

If

the

Implosion technique is used,

the

direction

of

pen

response will be

reversed.

0

IV-1

The

liquid

level is recorded

as

a

downwarn

kick. (See

chart

below).

If

the

liquid

level is 20

feet

or

so

in

a

"shot"

hole,

the

pen

would

first

kick

upward

then

down

as

the

sound

wave

was

reflected from

the

liquid

level. Recording

the

liquid

level below a

liner

would show a

downward

kick

at

the

liner,

and

downward

kick

at

the

liquid level,

and

an

upward

kick.

The

distance

between

the

liner

kick

and

the

liquid level

kick

is

equal

to

the

distance between

the

liquid

level

kick

and

the

liner

reflection kick.

The

liner

reflection

kick

results

when

the

liquid level

reflection

signal

is

travelling

upward

and

passes

the

liner

increase

in

cross-sectional

area.

This

generates

a

rarefaction

wave

which

returns

to

the

bottom

and

then

travels

to

the

surface

where

it

is recorded.

L1t.;v1{)

L~vEJ..

~

r ,

Hf.

-

J 7

'701#7.S

TtJ

J..I

f?VI/)

LEYEI-

-·

·f-H

t-1

f

t-,L/

l H

.

10

LI

I

'~

' J L A _,. '

..

,

f"'

f"V-Y

..

zo

/'el?

F

~I?

A-r

/tJ

A/.S

,,.

-ft

~"'INT.$

ro

~

l..J9Pll>

LEvEJ...

LI

f?/.J

I/)

L..EvEL

14/:

Z8

'J"OlkTS

l/IY/[

If

~FFleC.

//6-4/

1'

PROBLEM WELLS

The

problem of

obtaining

a good record is generally caused

by

excessive surface vibrations,

excessive downhole noise (gaseous liquid columns), improper wellhead connections,

dirty

microphone

and

electrical connections, or low casing pressure.

Excessive surface vibrations

and

downhole noise should be reduced. The SENSITIVITY

permits

an

actual

measure

ofextraneous noise. See Section III -Details of Operation.

v

The

wellhead

attachment

should be

attached

directly to

the

casing valve,

and

all

other

valves should

be

closed to

obtain

the

best

records.

Attaching

the

Echometer wellhead over 5 feet

from

the

casing

can

cause misleading reflections from

the

collar response.

Keep

the

microphone cable connectors clean

and

dry.

Stray

signals will

result

when

the

connectors

are

dirty. Also, keep

the

microphone clean.

Gaseous liquid columns caused

by

gas bubbling

through

oil

can

be a problem. Increasing

gas

pressure by closing

the

surface casing valves will generally

result

in

a liquid level reflection.

Only a small discharge

of

gas is necessary to form a gaseous column

in

a small

annulus

completion.

Larger

quantities

are

necessary to cause gaseous columns

in

large casing,

small

tubing

completions. Any well

venting

gas to

the

atmosphere,

venting

gas to

the

flow line, or

using

casing

gas

to operate

an

engine

should be checked.

The

amount

ofliquid

present

in

a

gaseous column

can

be

determined

by

a casing

presure

build-up test. Another technique is

compression of

the

gaseous column

with

casing pressure to

determine

the

gaseous columns

gradient. See "Analyzing Well Performance"

in

the

appendix.

The

best

way

to verify a liquid level

in

a producing well from

other

"kicks" (such

as

linets)

is

to cause

the

liquid level to move.

The

liquid level is

the

only "kick"

that

can

move

in

a well

and

such

a movement verifies a liquid level. A

high

level

can

be depressed

by

increasing

the

casing pressure.

An

increase

of

10

PSI

in

the

casing

pressure

will depress

the

liquid level

approximately 30 feet.

The

liquid level will rise

when

a producing well is shut-down. See

Rate

of

Fillup

Graph

for

the

amount

of

time

required for liquid level rise.

.)

If

numerous

"kicks"

are

recorded on a

chart

which

are

difficult to

interpret,

another

test

should be

taken

and

compared to

the

first test. All "kicks" should be duplicated on each

chart.

If

"kicks"

are

not

duplicated,

stray

noises caused

them

and

these

stray

noises should be stopped

as

described above.

The

effect

of

pressure

is

very

important.

Stronger

signals

are

returned

in

high

pressure

wells.

Increasing

the

casing

pressure

by 10

PSI

is beneficial

in

deep, low-pressure wells.

Atmospheric

pressure

and

vacuum

wells do

not

return

strong

signals from down

the

annulus

and

a

large

"blast"

may

be necessary.

V-1

On

rare

occasions,

paraffin

deposits,

dirty

tubing

or

other

conditions

can

result

in

downhole

conditions which

make

the

counting

of

collars

or

the

determination

of

the

liquid level difficult.

In

extreme

conditions,

it

may

be necessary to clean

the

tubing

and

casing to remove foreign

material.

BA'ITERY

INFORMATION

A sealed,

rechargeable,

lead

cell, 2.5

amp

hour,

12 volt

battery

is

used

in

the

amplifier-recorder.

The

battery

is

similar

to

the

new, sealed,

12

volt

automobile

battery.

The

Echometer

will

operate

from

the

self

contained

rechargeable

battery

or

from a

power

cord

which

is

plugged

into

the

automobile

cigar

lighter.

VI

A 110 VAC

charger

permits

charging

of

the

Echometer

battery

from a common 110 VAC

power

outlet.

Approximately

14

hours

is

required

to

charge

a discharged

battery.

The

110

VAC

charger

will

charge

the

battery

at

a 250

ma

rate

until

the

battery

voltage

reaches

about

15

volts

which

indicates

the

battery

is

almost

fully charged.

Then

the

charger

will

trickle

charge

at

a 25

ma

rate.

The

red

light

on

the

charger

is

ON

when

the

charger

is

charging

at

high

rate.

When

the

charger

is

in

trickle

charge,

the

light

is

OFF.

The

charger

whould be

left

connected

to

the

battery

until

the

red

light

goes

out

and

ceases to

turn

ON

and

OFF.

Then

the

battery

is

almost

fully charged.

The

battery

should

be

recharged

at

a

temperature

of

approximately

70°F (20°C).

Continuous

charging

does

not

damage

the

battery.

,

When

operating

with

the

cigar

lighter

power cord,

the

battery

will be

partially

charged

by

an

operating

automobile

system

in

5

to

15.

minutes,

and

will

be

completely

charged

if

the

car

is

driven

for 8

hours.

Attaching

the

power cord

to

the

cigar

lighter

with

the

engine

running

for a

_short

time

will

charge

a low

battery

sufficiently for a few tests.

The

power cord

can

be

permanently

attached

to

the

car

battery

if

desired.

The

battery

should

be

charged

when

the

operating

voltage drops

to

approximately

11.3 volts

which

is

the

top

of

the

yellow arc.

The

battery

can

be

charged

more often

if

desired.

Best

operating

performance will be

obtained

with

battery

temperatures

of

0°F to 120°F

f·l5°C

to

+50°C).

The

battery

has

less capacity· aJld voltage

at

lower

temperatures.

Failure

is

indicated

if

the

test

procedure

given

in

SectionVII does

not

produce

the

desired

results.

Temperature-

oF

oc

104 40

77

24

32 0

-4 -20

Battery

Life*

Hours

4

3.5

3

2

*Amplifier

and

chart

drive

ON:

battery

fully charged.

A fully

charged

battery

operating

at

70°F

has

sufficient

energy

to

test

1000

wells

which

requires

about

25

rolls

of

paper.

Turning

ON

the

amplifier

only will

discharge

the

battery

in

24

hours. -

Table of contents

Other Echometer Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics 356A44 Installation and operating manual

bluelab

bluelab Multimedia pHMeter Care and use guide

Endress+Hauser

Endress+Hauser Levelflex M FMP40 operating instructions

Agilent Technologies

Agilent Technologies WireScope 350 user guide

Endress+Hauser

Endress+Hauser Proline Promass I 300 PROFINET operating instructions

JGR

JGR TLS5 user manual