52-0023-0100 EP05-02 Font Conmutada (Anglès).doc 2 of 2

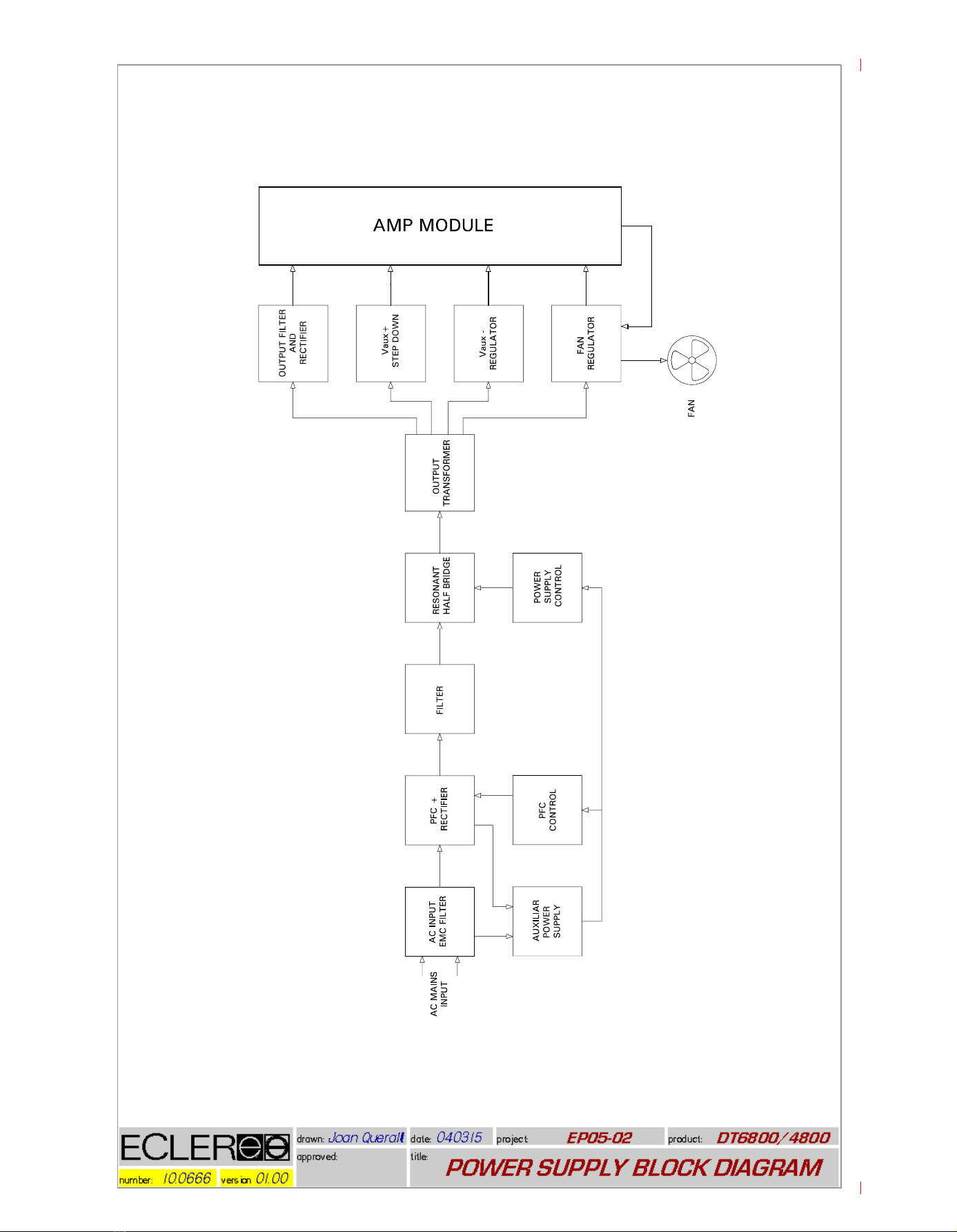

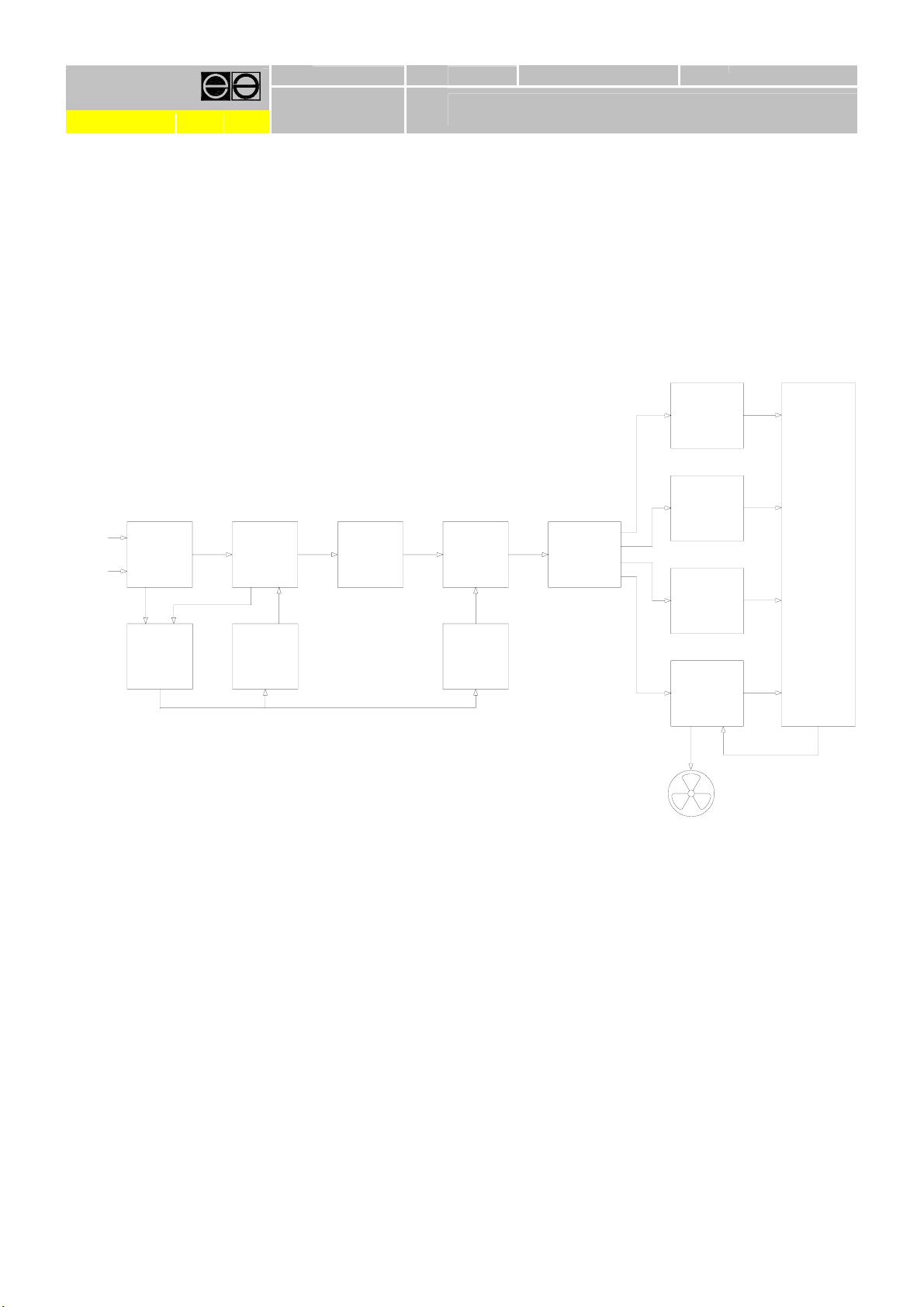

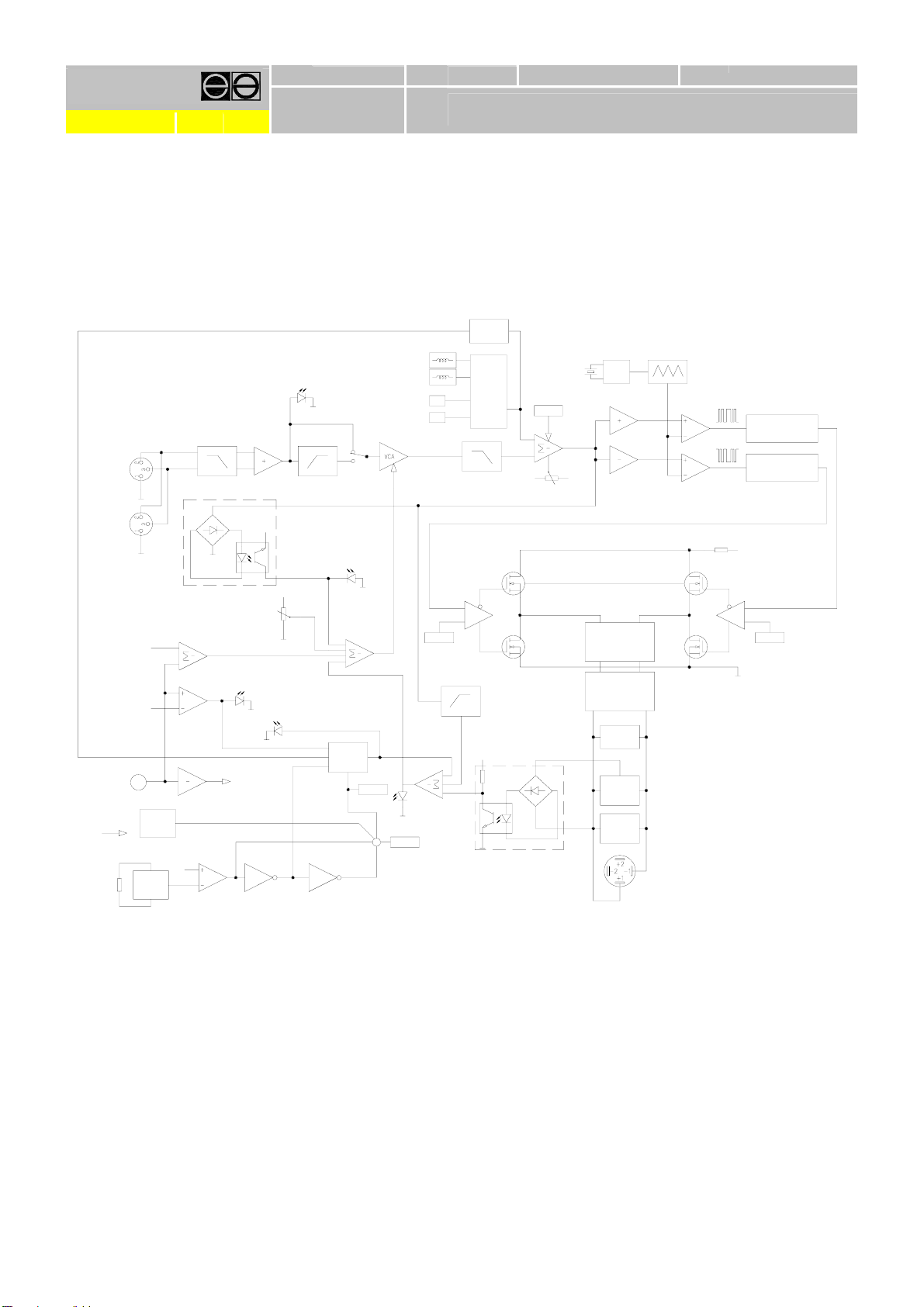

RECTIFIER, PFC AND FILTER.

These blocks are used to obtain a corrected Power consumption Factor value (phi).

This technique is used to reduce dramatically the harmonic contents of common domestic

mains signals before it reaches the power supply itself. The PFC (Power Factor Corrector)

reshapes its output mains waveform and produces a clear and smooth sine wave, in phase

with the waveform delivered through the mains supply. When this happens, the unit taps

power showing an external Power Factor (phi) almost equal to 1, thus essentially resistive.

The corrector is based on a “boost” circuit, which results to be the most appropriate for

this kind of active Power Factor Correction systems. By including a PFC in the power

supply, the mains wiring used can be thinner (less #AWG), the efficiency ratio increases,

and it also becomes easier to meet the European CE-label requirements.

PFC CONTROL.

Essentially, the controller consists on an analogical driver (a multiplier) which

multiplies the rectified input mains waveform with an error-related voltage value, obtained

from the output of the PFC circuit. The system tries constantly to match phases between

the consumed mains current sine wave and the mains voltage waveform.

AUXILIARY POWER SUPPLY.

This circuit delivers an additional power source to the control circuitry, which is

needed once the PFC starts to run. It is build around a 7815-type voltage regulator, fed

from a voltage multiplier which is connected to a secondary winging of the PFC’s toroidal

inductor. This supply has also to provide power to the Resonant Half Bridge control circuit,

which is explained next.

RESONANT HALF BRIDGE.

Resonant power supplies are conventionally shaped power supply structures (in this

case, a half-bridged supply), but in which particularly the internal current and voltages are

both tuned with the supply’s own running frequency, this is, it’s resonance rate. In our

case, the supply resonance is driven by a serial RLC circuit. As the current and voltage

flowing through R, L and C are in resonance, the switching losses are forced to be

minimal. The inductor of the RLC-cell is in fact the primary coil of the supply’s output

transformer. By this way, also the power loss at the semiconductors is very small, thus

reducing most of the circuitry’s EMI radiations.

OUTPUT TRANSFORMER.

Behind this point, the power supply can be considered like a conventional one. From

the output transformer’s both secondary coils, one delivering high power and the other low

voltage signals, all of the voltages required by the system will be obtained, once their

waveforms are rectified, filtered and stabilized when needed, using the most appropriate

circuitry for each function. In fact, this latest is the main target of our power supply.