OPERATING INSTRUCTIONS.

Read the entire SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before using this product.

Use this tool for the manufacturer’s intended purpose only. Use other than that

which is described in this manual can result injury or property damage.

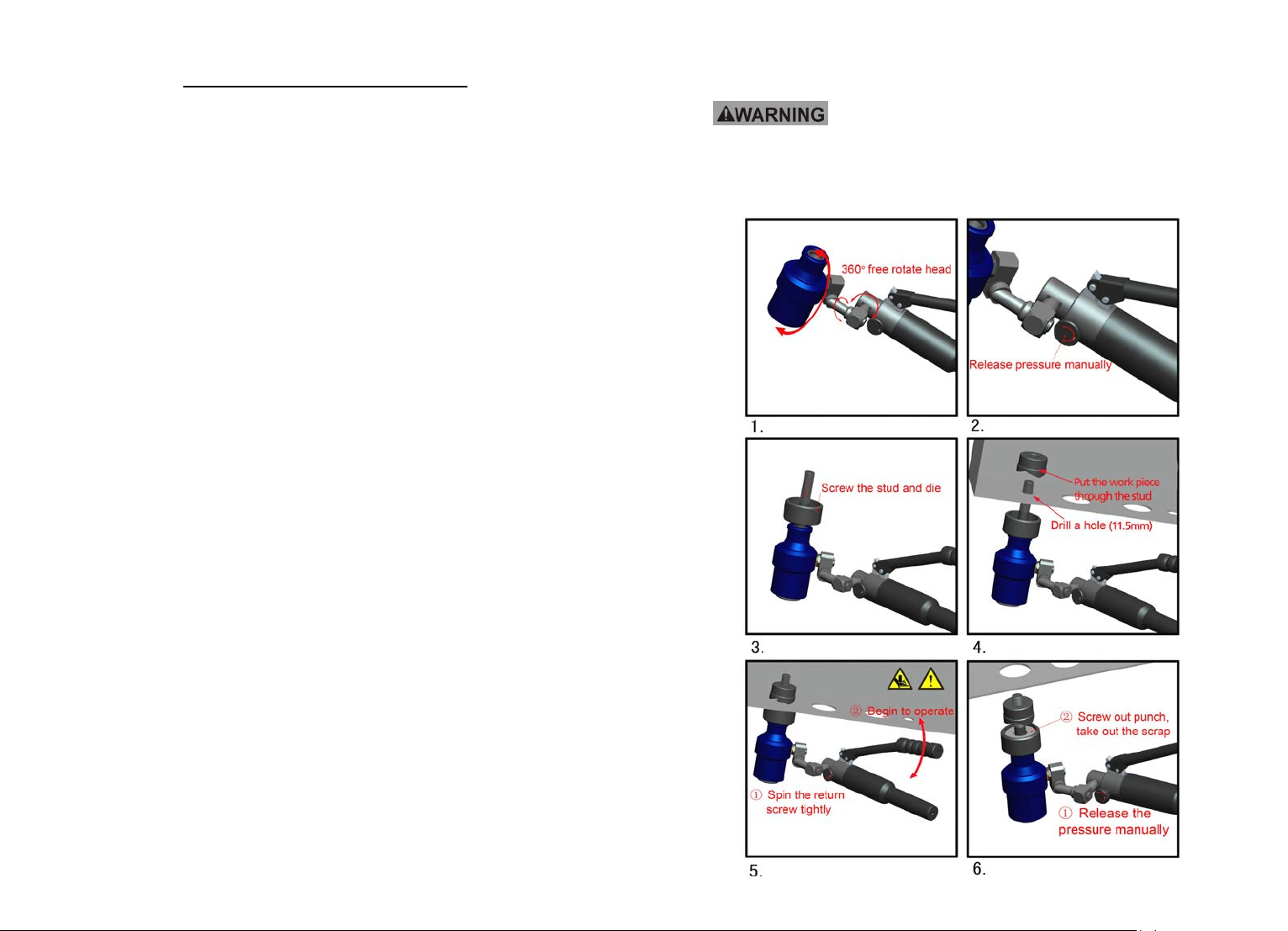

1. Select the appropriate punch, die and draw stud for appropriate size hole.

Do not exceed the rated capacity of this tool; otherwise it will cause a

component failure, which could throw broken parts with great force. Failure to

observe this warning can result injury or death.

2. Drill a small pilot hole by electric drill on the metal sheet, then use a drill bit that is

slightly larger than the draw stud, drill a larger hole.

3. Thread the draw stud completely into the ram, but not too tight, just snug.

4. Slide the spacer onto the draw stud to protect the cylinder, and the die after, then put

the draw stud through the hole. Lastly, thread the punch facing the steel plate. Make

sure the spacer, punch, die and material are as tight as you can get them by hand..

An improper setup could cause the component damage.

5. Pump the active handle till completely punched and until the handle will no longer

move.

Do not operate the pump after ram motion stops. Continuing to operate the

pump lever after the ram stops will damage the ram. If the ram stops before

the hole is complete, stop pumping, check that the setup is correct and that

you have not exceeded the tool’s capacity. See the setup instruction. if

necessary, disassemble the setup and add or remove the spacer.

Make sure the punching cycle is completed during the operation to avoid the

scrap remaining on the punch.

3. Service

Have your Hydraulic Punch Driver serviced by a qualified service technician using

only identical replacement parts. This will ensure that the safety of the Hydraulic

Punch Driver Kit is maintained.

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates on the tool which carry important safety information.

If unreadable or missing, contact with the agent to replace.

2. This product is not a toy, keep it out of reach of children.

3. Do not slide your fingers in the punch dies profile.

4. Do not use the tool without punch die.

5. Release the hydraulic pressure before disconnecting the hoses or couplers, and before

servicing the pump or accessory

6. Hand –tighten all couplers completely before operating the pump.

7. Do not use hands to check for leakage.

8. Do not hold hose or coupler while the hydraulic system is pressurized.

9. Do not use this tool near live circuits.

10. The warnings, precautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which cannot

be built into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Test Equipment Depot - 800.517.8431

99 Washington Street - Melrose, MA 02176

TestEquipmentDepot.com