ECO Charge BMM User manual

Battery Monitoring

Module (BMM)

Operator / Installer Manual

2

WARNINGS

Keep open flames

away from batteries

on charge.

Risk of battery

explosion.

Be aware of

battery fumes

and electrolyte.

Do not dispose

of batteries in

the garbage.

Electrical hazard

exists inside the

charger, do not

remove the

side cover.

Always recycle lead

acid batteries.

Battery electrolyte

is highly corrosive.

Wear eye protection

when working near

batteries.

3

Contents

Warnings ....................................................................................................................................... 2

Contents ........................................................................................................................................ 3

Overview ....................................................................................................................................... 4

Installation .................................................................................................................................... 5

Configuration .............................................................................................................................. 8

Operation ....................................................................................................................................11

LED Function Indicator ........................................................................................................11

Voltage Imbalance Monitoring ......................................................................................... 12

Water Level Monitoring ........................................................................................................13

Troubleshooting ......................................................................................................................14

Maintenance ..............................................................................................................................15

Service & Warranty ................................................................................................................16

Specifications ............................................................................................................................17

BMM Serial Number

BMM Part Number

Date Supplied

Battery Model

Purchaser

Purchase Invoice Number

Fleet Number

4

Overview

13

4

5

7

6

1

2

3

4

DC Supply Terminals

Tri-color LED

Temperature Sensor

Communications Toroid

6

5

7

Electrolyte Sensor

Midpoint Voltage Sensor

Module Housing

Battery Monitoring

Module (BMM)

2

This guide covers the installation of a BMM and configuration of a BMM

and associated XHF Series Charger. For instructions on the advanced

functionality of the BMM data logging and analysis features available in the

Charger Interface Software Manual, contact your EcoCharge dealer.

5

Installation

NOTE: Before attempting installation, please read through the complete

installation instructions. The battery to be fitted should be disconnected from

any load prior to installation.

Communications and

Current Sensing Toroid

The Communications Toroid

requires the negative lead to

be removed from the battery

and placed through the toroid

and re-secured to the negative

battery terminal. Alignment of

the toroid should be made so

that the cable exits the toroid

away from the battery terminal.

Keep at least 8in (20cm)

clearance between the toroid

and the positive battery lead. A

half-sleeve on the toroid housing

is provided to secure the toroid

to the battery cable by cable tie.

Unit Location

The BMM module is designed

to sit directly on top of the

battery surface. For optimum

Bluetooth®range, locate the

module near any openings in

the battery enclosure. Cable ties

are supplied to secure the unit

to the battery straps as shown.

6

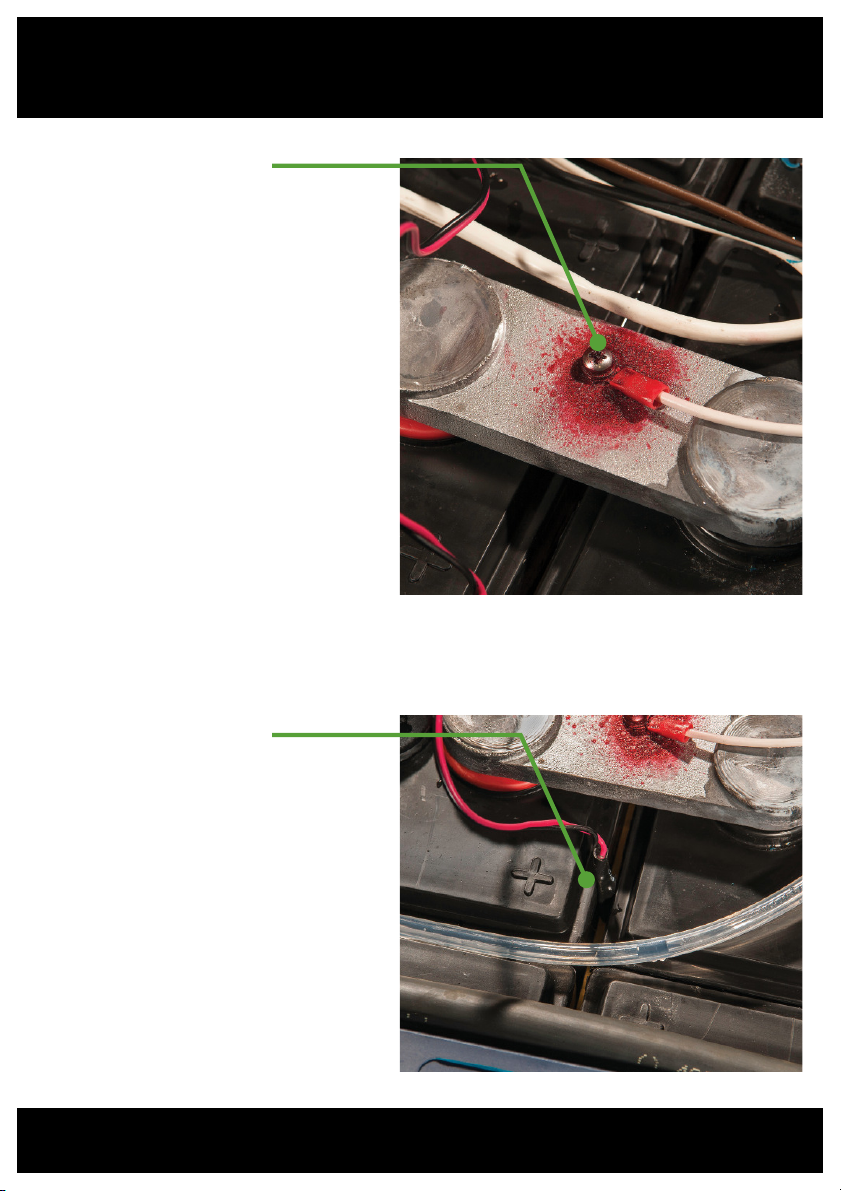

DC Supply & Voltage

Midpoint Sensor

The DC Supply wires are

terminated with ring terminals

for easy fastening to the

battery with the supplied

screws. The positive (RED) and

negative (BLACK) wires should

be fastened to the top of their

respective battery terminal

posts. The Midpoint Voltage

(WHITE) wire should be

fastened to strapping or a

terminal as close as possible

to the voltage midpoint of

the battery. It is recommended

to coat wire terminations

with corrosion inhibitor before

installation.

Temperature Sensor

The ideal location for the BMM

temperature sensor is between

the cells at the center of the

battery. Depending on the

battery type and construction,

this may not be practical. The

alternative location is cable tied

to the underside of a segment

of lead strapping. An additional

temperature sensor is built-in to

the BMM module.

Installation - continued

7

1

2

3

Electrolyte Sensor

Installation of the electrolyte sensor requires care and consideration of the cell’s

internal construction. If not required, the electrolyte sensor should be removed from

the BMM by cutting the brown sensor wire at the entry point to the BMM module.

8

Configuration

BMM Configuration

Before use, both the BMM and the charger require configuration to enable

the Automatic Profile Configuration (APC) feature.

The following instructions cover:

1. Connecting to the charger

2. Configuring the BMM with the correct battery rating details.

(see page 9).

3.Configuring the charger to enable APC functionality (see page 10).

This step applies to all chargers intended to be used with the BMM.

Required for configuration:

• The BMM installed on the battery.

• A XHF Series Charger

• Standard-A to Mini-B USB cable.

• PC or laptop running Windows Vista or later with Charger

Interface software v7.4 or later.

• Password for BMM configuration

access.

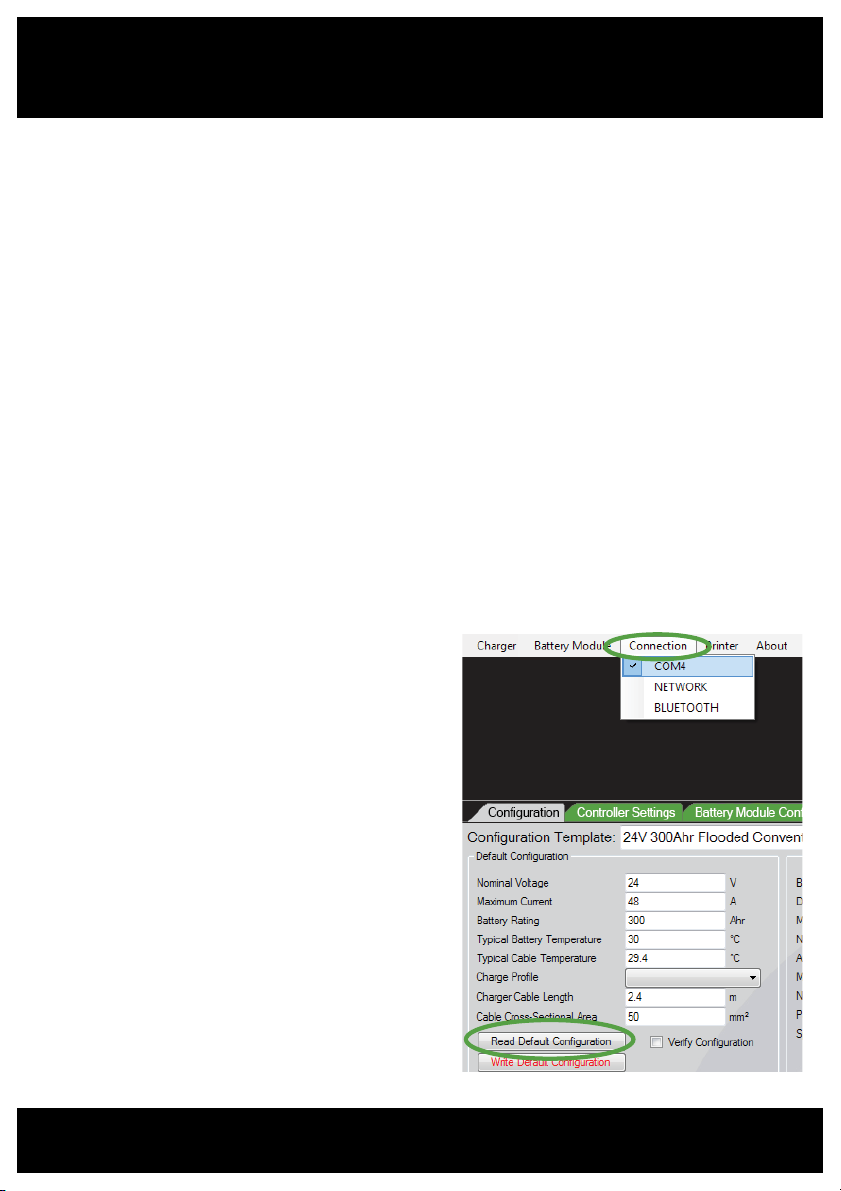

1. Setup Communication via

Charger Interface

• Connect the BMM-equipped

battery to any XHF Series

charger, connect the charger to

the PC via USB and open the

Charger Interface software.

• From the Connection menu,

ensure the appropriate COM port

is selected for the USB interface.

• Verify communications with the

charger by selecting Read Default

9

Configuration.

- If successful, the Voltage and Current details will populate the data

fields.

2. Program BMM with Configuration Parameters

• Enable the Battery Module Configuration tab from the Battery Module

menu.

• From the Battery Module Configuration tab, choose the appropriate

battery type from the template drop-down list. Click Use Values to

populate the parameter fields with the template’s parameters.

• To load the configuration parameters into the BMM module, click Write

Configuration.

• The BMM configuration can be confirmed by clicking Read

Configuration, and checking that the correct values are returned

to the parameter fields.

3. Create a BMM Identifier

The BMM should be given a unique name which allows quick identification

of the battery when reading charge logs.

• Enter a unique name in the Identification field

• Click Write to program the BMM with the new name.

- A useful name may include any combination of the site location,

truck ID, or battery ID numbers.

10

Charger Configuration

Configuration of your XHF Series charger for Automatic Profile

Configuration (APC) can be achieved by configuration via the Charger

Interface Software.

• Connect your PC to the charger via USB and ensure the charger has AC

supply.

• Check that the Charger Interface is communicating with the charger by

following the Setup steps on page 8.

• From the Charger menu, enable the Configuration tab, and ensure the

tab is visible.

• From the Configuration Template drop-down list, choose the option

“APC Enabled”.

• Ensure the adjacent drop-down lists are appropriate for charger type

and AC supply.

• Click the Use Values button to populate the parameter fields below.

•

Click Write Default Configuration to program the charger with the

selected parameters.

• Chargers intended for high rate charging should have the additional

parameter “Use Fast Charge Profile” checked, under the Controller

Settings tab.

To confirm successful configuration, the charger front display will read

“APC Enabled”.

Configuration - continued

11

Green LED: Standby

Flashes once every 2 seconds to indicate ready to-charge standby status.

Red LED: Alarm

Every 2 seconds: Water level low Every 8 seconds: State of charge low

Every 4 seconds: Temperature high,

low or sensor failed Every 10 seconds: State of health low

Every 6 seconds: Voltage imbalance Every 12 seconds: Other error has

occurred

Yellow LED: PLC Comms

Double flash every 2 seconds when communicating with the connected charger

via the battery cable.

Blue LED: Bluetooth®Comms

Flashes when a Bluetooth®device is connected to the BMM.

Operation of the BMM module is automated once installed and configured.

• Connect the BMM-equipped battery to an APC-enabled XHF Series

charger.

- The charger must display “APC Enabled” for BMM auto-configuration

operation.

• Disconnect and reconnect the battery from the charger.

- The charger will read the configuration from the BMM module and the

charge cycle will commence.

Refer to your XHF Series charger documentation for information specific to

your charger’s operation.

LED Function Indicator

The BMM module indicates various states of

operation via a 4 color LED on the top surface

of the module.

Operation / LED Function Indicator

See the Troubleshooting section for descriptions of and resolutions to BMM

alarms.

12

Battery Equalization

The BMM incorporates a Midpoint Voltage Sensor to allow monitoring of cell

imbalance.

• Voltage measured via the Midpoint Voltage Sensor on the battery is

monitored to ensure it remains within 0.5V of half the battery voltage.

• If the voltage moves outside this range a non-urgent Voltage Imbalance

alarm is triggered. The BMM then schedules an equalization charge to

commence following the current charge if connected, or following the

next completed charge.

• Should the midpoint voltage imbalance persist, further equalizations will

be scheduled. Repeated Voltage Imbalance alarms that will not clear

should be investigated as this indicates a potential battery problem.

Enabling Voltage Imbalance Monitoring

To enable voltage imbalance monitoring, ensure the BMM equipped battery

and charger are connected to a PC with Charger Interface software and

select the Voltage Imbalance Monitoring option under the Battery Module

Configuration tab.

Voltage Imbalance Monitoring

13

If installed, the electrolyte sensor allows the BMM to monitor the battery

electrolyte level. Should a low water level be detected, with Water Level

Monitoring enabled the BMM can perform the following operations:

• Display a Low Water alarm on the connected XHF series charger

display (configured for BMM operation)

• Initiate a top-up of the battery following a charge, provided both the

XHF series charger and the battery are fitted with an auto-watering

system.

Enabling Water Level Monitoring

To enable water level monitoring , ensure the BMM equipped battery and

charger are connected to a PC with Charger Interface software and select the

Water Level Monitoring option under the Battery Module Configuration

tab.

Water Level Monitoring

14

Troubleshooting

Problem Possible Cause Remedy

Water Level

Alarm

Electrolyte Sensor

indicating low cell

electrolyte

Check all cells for electrolyte level,

top up as required.

Check installation of electrolyte

sensor probe is as described in

the Installation section of this

document.

If not required, the electrolyte sensor

probe may have been removed from

the BMM module during installation.

Temperature

Alarm

Temperature sensors

indicating temperatures

outside the range

specified in BMM

configuration.

Check installation of remote

temperature sensor is as described

in the Installation section.

Voltage

Imbalance

Alarm

Sensor at the voltage

midpoint on the battery

indicating 0.5V outside

the half-battery-voltage.

The BMM automatically schedules

an equalize charge on this alarm

occurrence. Regular occurrence

indicates poor battery condition or

incorrect installation.

Check installation is as described in

the Installation section.

Charger

Indicates

Config Error

Communications

toroid may be installed

incorrectly.

Ensure installation is as described in

the Installation section.

No Charger

Comms/

No LED Activity

DC supply terminals loose

or corroded.

Ensure terminals are routinely

checked for secure fit and clean,

corrosion free condition. Always

follow battery maintenance

guidelines.

No Bluetooth®

Connectivity

BMM is too far from

device or enclosed a

conductive housing.

Ensure the BMM is located near

openings in the battery enclosure.

Establish unobstructed line-of-sight

path between BMM and reading

device, and move as close as

possible to the BMM.

15

Once installed on the battery, the BMM module requires no maintenance

other than to ensure the module and its various peripherals are secure and

clear of excess battery acid.

Routine checks on the condition of DC Supply and Midpoint Voltage terminals

should be made and any accumulated corrosion removed according to the

battery maintenance documentation.

Typical BMM Installation

Maintenance

BMM Module Negative DC Supply Communications ToroidMidpoint Voltage Sensor

Electrolyte Sensor Temperature Sensor Positive DC Supply

16

Service & Warranty

Service

Contact your local EcoCharge Dealer for service or repair.

Warranty

Enatel Motive Power warrants the product is free from defects

in material and workmanship and agrees to remedy any defect

(or at its option replace the product) for a period of one year from the

date of purchase. This warranty covers parts only.

This warranty will not apply to any product that is improperly installed,

misused, abused, used in ways the product was not designed, altered

or repaired in any way which may affect the performance or reliability of

operation, sustained damage by power surges or electrical storms, or

sustained shipping damage, or repaired by any unauthorized repair center.

Please contact your local EcoCharge dealer for repair.

Enatel Motive Power makes no other warranties, express or implied,

including any warranty of fitness for a particular purpose. In no event shall

Enatel Motive Power be responsible for indirect or consequential damages

or lost profits even if Enatel Motive Power has been advised of the possibility

of such damages. Enatel Motive Power’s sole obligation shall be the repair

or replacement of a nonconforming product.

17

Specifications

Dimensions (in): 4.33L x 2.12W x 11.0H

Toroid Internal Diameter (in): 0.74

Weight (oz): 11.6

Environmental Specifications

Ambient Temp. Range: -5ºF to 122ºF

(max. output power is derated above 122ºF)

Storage Temp.: -68ºF to 158ºF

Humidity: 5-95% RH (non-condensing)

Bluetooth® Specifications: Class 1 Bluetooth®2.0

Contains FCCID: T9JRN41-3

The Bluetooth®word mark and logos are registered trademarks owned by

Bluetooth®SIG, Inc. and any use of such marks by Enatel Motive Power

is under license.

Notes

Manufactured by:

Contact Your Local Dealer:

Enatel Motive Power Ltd

66 Treffers Road, Christchurch 8042, New Zealand.

Ph +64-3-366 4550 Fax +64-3-366 0884

www.enatel-mp.com

Battery Monitoring Module (BMM) Operator/Installer

Drawing: 150205A

Copyright © 2015 Enatel Motive Power

Table of contents