1) Removetherubberstopper

fromtheinternalsolution

fillingopeninganduse a

syringetoremovethe

internalsolution.

CODE:04137900

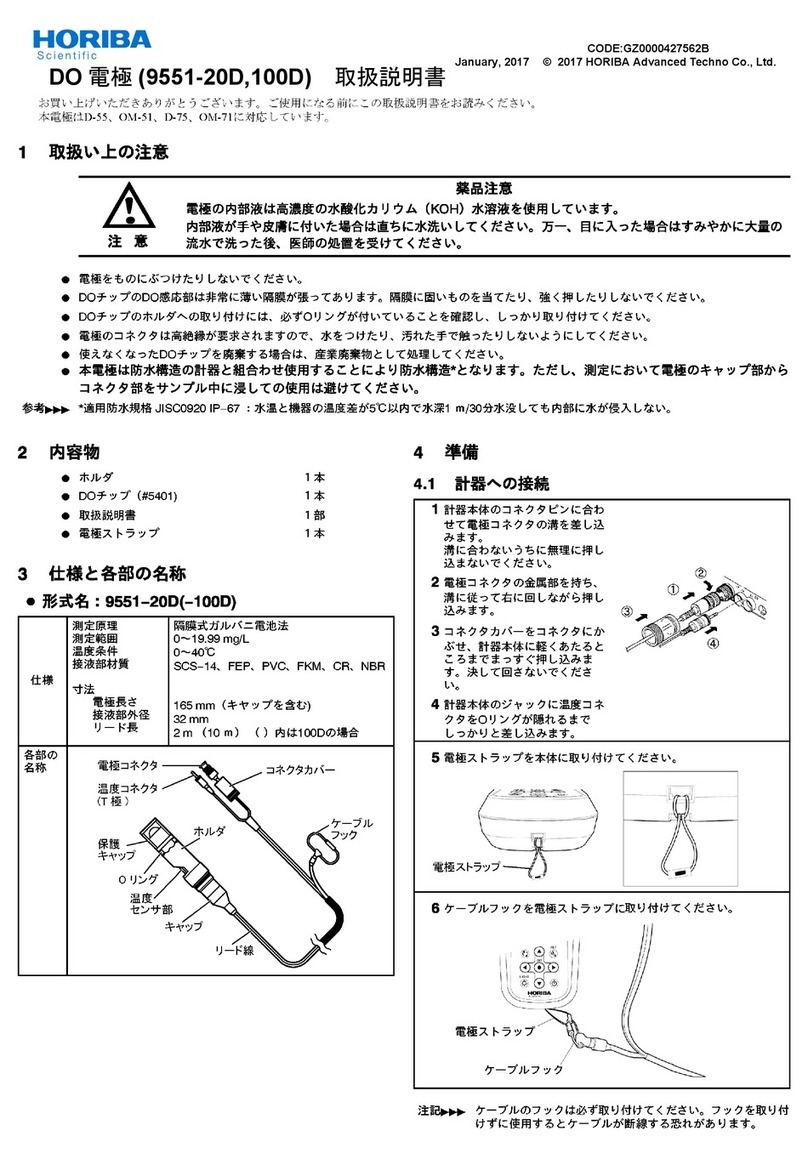

pHELECTRODEFORLOWCONDUCTIVITYWATERAND

NON-AQUEOUSSOLVENTSINSTRUCTIONMANUAL

InordertoensurecorrectusageofthepHelectrode,besuretoreadtheseoperatinginstructionscarefullybeforeusage.

ThispHelectrodehasimprovedresponsivenessinlowconductivity

waterandnon-aqueoussolvents.ItcanbeusedwiththeF-10,M-10and

F-20seriesofpHmeters.The6377isa3-in-1electrodethatcontainsa

glasselectrode,referenceelectrodeandtemperaturecompensation

electrodewithinasinglebody.The1076Aisaglasselectrode.Referto

thediagramsbelowtoverifythespecificationsforyourelectrode.

pHrange pH0〜14

Temperaturerange 0〜60℃

Internalelectrode Ag/AgCl

Internalsolutionfor 3.33mol/LKClsolution(Cat.No.300)

referenceelectrode

Liquidjunction Moveablesleeve

Materialofthepartsthatcome

Glass

incontactwiththeliquid

pHmeterssupported F-10,D-10,M-10,F-20 series

pHrange pH0〜14

Temperaturerange 0〜100℃

Internalelectrode Ag/AgCl

Referenceelectrodes 2060A,2660A,2565A

supported

Temp.electrodessupported

4163

Materialofthepartsthatcome

Glass

incontactwiththeliquid

pHmeterssupported F-10,M-10,F-20 series

Type

Features

Specifications

Theelectrode

6377-10D

A3-in-1electrodewithsuperiorresponsivenessinlowconductivity,

lowbufferabilityaqueoussolutionsandnon-aqueoussolventssuchas

alcohol.Ithasamoveablesleevetypeofliquidjunction.

Theelectrodecanalsobeusedformoregeneralapplications.

1076A-10C

Aglasselectrodewithsuperiorresponsivenessinlowconductivity,low

bufferabilityaqueoussolutionsandnon-aqueoussolventssuchasalcohol.

Aseparatereferenceelectrodeandtemperaturecompensationelectrode

arerequired.Theelectrodecanalsobeusedformoregeneralapplications

.

Liquidjunction Protectivecap

Internalsolutionfilling

openingrubberstopper

Cap

Leadwire

ProtectivecoverfortheconnectorElectrode

connector

Temperature

connector

pHsensing

membrane

Protectivecap

Cap

Leadwire

Protectivecoverfortheconnector

Electrode

connector

pHsensingmembrane

2

1)

Pushtheelectrodeconnectorasfaras

itwillgoontotheBNCterminalpinof

thepHmeter.Thenrotateittothe

rightuntilitlocksintoplace.

2) Covertheconnectorwiththe

protectivecover.

3)

Pushthetemperatureconnector

(forthe1076A,thisistheconnector

forthecorrespondingtemperature

compensationelectrode)asfarasit

willgoontotheTterminalofthe

pHmeter.

4)

Forthe1076A,attachtheconnector

forthecorrespondingreference

electrodetotheRterminalofthepH

meter.

3B

4

3)

Forthe6377andsleevetypereferenceelectrodes2660Aand2565A,move

thesleeveasshowninthediagrambelow.Aftercheckingtheoutflowofthe

internalsolution,lightlypullthesleeveinthedownwarddirection.

6

2) Addnewinternalsolution.

5

2. pH Meter Connection

1.SpecificationsandtheElectrode

3. ProceduresforFirstTimeUsage

orAfterLong-TermStorage

Forthe1076A,performtheseoperationsonthereferenceelectrode.

CODE : I041379100

1) BesuretouseCat.No.300internalsolutioninthereferenceelectrode.Ifyou

mustusesomeotherinternalsolution,usea1076Aglasselectrodeand2565A

doublejunctionreferenceelectrodecombination.Placetheappropriateinternal

solutionintheouterchamberofthe2565A.

2) Thiselectrodemaybeusedtotakemeasurementsofalcoholicsolutionswhich

haveverysimilarpropertiestowater,andofnon-aqueoussolventsthatcontain

alargeproportionofwater(greaterthan5%).However,theresponsivenessand

stabilityisnotasgoodasforaqueoussolutions.

3) Theelectrodeconnectorsrequireahighdegreeofinsulation.Donotletthem

getwetortouchthemwithyourhands.

4) Whenahighdegreeofaccuracyisrequired,aftercalibration,washthe

detectionapparatusmorethan3timeswithpure(deionized)waterandsoakit

for10minutesmoreinpure(deionized)waterbeforetakingmeasurements

1)

Ifthereareanybubblesontheinsideoftheliquidjunctionopeningof

thesleeveliquidjunction,orinthethinpartoftheglasspipe,shakethe

electrodelightlyupanddowntofreethebubbles.

Bubbles

opening

9

1) Ifthereisnotenoughinternal

solution,removetherubber

stopperfortheinternal

solutionfillingopeningand

addmoreinternalsolution.

5

2) Washtheelectrodemorethan

3timeswithpure(deionized)

water.Lightlywipeawayany

waterdropletswithtissue

paper.

7

3)

Immersetheelectrodeinthe

sampleliquid.Besuretokeep

thesurfaceleveloftheinternal

solutionoftheelectrodeabove

thesurfacelevelofthesample

liquid.Alsobesuretoremovethe

rubberstopperfortheinternal

solutionfillingopeningwhen

takingmeasurements.

Surfacelevelof

internalsolution

8

4.Measurement(Calibrations)

5.Precautions

〈forboth6377and1076A〉

〈6377〉

6.RegularMaintenance

1) Iftheelectrodeisusedforlongperiods,theinternalsolutionin

thereferenceelectrodemaybecomecontaminatedbythe

sampleliquid,orbecomediluted.Performtheoperations

describedinstep3.ProceduresforFirstTimeUsageorAfter

Long-TermStorageonceevery3to6months.

2) Iftheinsideoftheprotectivecapbecomesdry,washitwithpure

(deionized)water.Afterremovinganyexcesswater,supplement

itwithenoughpure(deionized)watertosoakthesponge.

3) Iftheresponsetimeoftheelectrodeoritsreproducibilityhas

fallen,washtheelectrodeusingtheproceduresdescribedbelow.

Rinseitwellwithpure(deionized)waterandsoakonlytheglass

membraneforseveralhoursinpure(deionized)waterbefore

takingmeasurements.

Ordinarydirt : Wipewithgauzesoakedinaneutral

detergent.

Oilydirt : Wipewithgauzesoakedinan

appropriateorganicsolventsuchas

alcohol.

Dirtcontaininginorganiccomponents : Soakforapproximately2hoursin1

mol/Lhydrochloricacid.Besurenot

toimmersetheliquidjunctioninthe

hydrochloricacid.

2)

Ifthesleeveliquidjunctionbecomeshardenedwithprecipitatedcrystalsfromthe

internalsolutionandwillnotmove,soakitinwarmwaterofabout30to40

degreestodissolvetheprecipitate.Movethesleeveliquidjunctiontakingcare

nottodamageit.Checktheoutflowoftheinternalsolutionbeforeusage.

(Submittingthesleeveliquidjunctiontoanultrasoniccleanerisalsoeffective.)

3)

Pressthesleevelightlydown.Ifyoupushittoostrongly,itwillcausea

largeincreaseintheliquidjunctionpotentialandgiveriseto

measurementerrors.Ifthesleeveisnotclosedtightlyenoughthenthe

internalsolutionmayseepouttoorapidly,orthesamplesolutionwill

seepin.Ifthesamplesolutionseepsin,itwillcausealarge

measurementerror,andtheinternalsolutionwillhavetobereplaced.

6

I0041379000A.pdf2 10.3.210:32:21AM

1) Removetherubberstopper

fromtheinternalsolution

fillingopeninganduse a

syringetoremovethe

internalsolution.

CODE:04137900

pHELECTRODEFORLOWCONDUCTIVITYWATERAND

NON-AQUEOUSSOLVENTSINSTRUCTIONMANUAL

InordertoensurecorrectusageofthepHelectrode,besuretoreadtheseoperatinginstructionscarefullybeforeusage.

ThispHelectrodehasimprovedresponsivenessinlowconductivity

waterandnon-aqueoussolvents.ItcanbeusedwiththeF-10,M-10and

F-20seriesofpHmeters.The6377isa3-in-1electrodethatcontainsa

glasselectrode,referenceelectrodeandtemperaturecompensation

electrodewithinasinglebody.The1076Aisaglasselectrode.Referto

thediagramsbelowtoverifythespecificationsforyourelectrode.

pHrange pH0〜14

Temperaturerange 0〜60℃

Internalelectrode Ag/AgCl

Internalsolutionfor 3.33mol/LKClsolution(Cat.No.300)

referenceelectrode

Liquidjunction Moveablesleeve

Materialofthepartsthatcome

Glass

incontactwiththeliquid

pHmeterssupported F-10,D-10,M-10,F-20 series

pHrange pH0〜14

Temperaturerange 0〜100℃

Internalelectrode Ag/AgCl

Referenceelectrodes 2060A,2660A,2565A

supported

Temp.electrodessupported

4163

Materialofthepartsthatcome

Glass

incontactwiththeliquid

pHmeterssupported F-10,M-10,F-20 series

Type

Features

Specifications

Theelectrode

6377-10D

A3-in-1electrodewithsuperiorresponsivenessinlowconductivity,

lowbufferabilityaqueoussolutionsandnon-aqueoussolventssuchas

alcohol.Ithasamoveablesleevetypeofliquidjunction.

Theelectrodecanalsobeusedformoregeneralapplications.

1076A-10C

Aglasselectrodewithsuperiorresponsivenessinlowconductivity,low

bufferabilityaqueoussolutionsandnon-aqueoussolventssuchasalcohol.

Aseparatereferenceelectrodeandtemperaturecompensationelectrode

arerequired.Theelectrodecanalsobeusedformoregeneralapplications

.

Liquidjunction Protectivecap

Internalsolutionfilling

openingrubberstopper

Cap

Leadwire

ProtectivecoverfortheconnectorElectrode

connector

Temperature

connector

pHsensing

membrane

Protectivecap

Cap

Leadwire

Protectivecoverfortheconnector

Electrode

connector

pHsensingmembrane

2

1)

Pushtheelectrodeconnectorasfaras

itwillgoontotheBNCterminalpinof

thepHmeter.Thenrotateittothe

rightuntilitlocksintoplace.

2) Covertheconnectorwiththe

protectivecover.

3)

Pushthetemperatureconnector

(forthe1076A,thisistheconnector

forthecorrespondingtemperature

compensationelectrode)asfarasit

willgoontotheTterminalofthe

pHmeter.

4)

Forthe1076A,attachtheconnector

forthecorrespondingreference

electrodetotheRterminalofthepH

meter.

3B

4

3)

Forthe6377andsleevetypereferenceelectrodes2660Aand2565A,move

thesleeveasshowninthediagrambelow.Aftercheckingtheoutflowofthe

internalsolution,lightlypullthesleeveinthedownwarddirection.

6

2) Addnewinternalsolution.

5

2. pH Meter Connection

1.SpecificationsandtheElectrode

3. ProceduresforFirstTimeUsage

orAfterLong-TermStorage

Forthe1076A,performtheseoperationsonthereferenceelectrode.

CODE : I041379100

1) BesuretouseCat.No.300internalsolutioninthereferenceelectrode.Ifyou

mustusesomeotherinternalsolution,usea1076Aglasselectrodeand2565A

doublejunctionreferenceelectrodecombination.Placetheappropriateinternal

solutionintheouterchamberofthe2565A.

2) Thiselectrodemaybeusedtotakemeasurementsofalcoholicsolutionswhich

haveverysimilarpropertiestowater,andofnon-aqueoussolventsthatcontain

alargeproportionofwater(greaterthan5%).However,theresponsivenessand

stabilityisnotasgoodasforaqueoussolutions.

3) Theelectrodeconnectorsrequireahighdegreeofinsulation.Donotletthem

getwetortouchthemwithyourhands.

4) Whenahighdegreeofaccuracyisrequired,aftercalibration,washthe

detectionapparatusmorethan3timeswithpure(deionized)waterandsoakit

for10minutesmoreinpure(deionized)waterbeforetakingmeasurements

1)

Ifthereareanybubblesontheinsideoftheliquidjunctionopeningof

thesleeveliquidjunction,orinthethinpartoftheglasspipe,shakethe

electrodelightlyupanddowntofreethebubbles.

Bubbles

Liquidjunction

opening

9

1) Ifthereisnotenoughinternal

solution,removetherubber

stopperfortheinternal

solutionfillingopeningand

addmoreinternalsolution.

5

2) Washtheelectrodemorethan

3timeswithpure(deionized)

water.Lightlywipeawayany

waterdropletswithtissue

paper.

7

3)

Immersetheelectrodeinthe

sampleliquid.Besuretokeep

thesurfaceleveloftheinternal

solutionoftheelectrodeabove

thesurfacelevelofthesample

liquid.Alsobesuretoremovethe

rubberstopperfortheinternal

solutionfillingopeningwhen

takingmeasurements.

Surfacelevelof

internalsolution

8

4.Measurement(Calibrations)

5.Precautions

〈forboth6377and1076A〉

〈6377〉

6.RegularMaintenance

1) Iftheelectrodeisusedforlongperiods,theinternalsolutionin

thereferenceelectrodemaybecomecontaminatedbythe

sampleliquid,orbecomediluted.Performtheoperations

describedinstep3.ProceduresforFirstTimeUsageorAfter

Long-TermStorageonceevery3to6months.

2) Iftheinsideoftheprotectivecapbecomesdry,washitwithpure

(deionized)water.Afterremovinganyexcesswater,supplement

itwithenoughpure(deionized)watertosoakthesponge.

3) Iftheresponsetimeoftheelectrodeoritsreproducibilityhas

fallen,washtheelectrodeusingtheproceduresdescribedbelow.

Rinseitwellwithpure(deionized)waterandsoakonlytheglass

membraneforseveralhoursinpure(deionized)waterbefore

takingmeasurements.

Ordinarydirt : Wipewithgauzesoakedinaneutral

detergent.

Oilydirt : Wipewithgauzesoakedinan

appropriateorganicsolventsuchas

alcohol.

Dirtcontaininginorganiccomponents : Soakforapproximately2hoursin1

mol/Lhydrochloricacid.Besurenot

toimmersetheliquidjunctioninthe

hydrochloricacid.

2)

Ifthesleeveliquidjunctionbecomeshardenedwithprecipitatedcrystalsfromthe

internalsolutionandwillnotmove,soakitinwarmwaterofabout30to40

degreestodissolvetheprecipitate.Movethesleeveliquidjunctiontakingcare

nottodamageit.Checktheoutflowoftheinternalsolutionbeforeusage.

(Submittingthesleeveliquidjunctiontoanultrasoniccleanerisalsoeffective.)

3)

Pressthesleevelightlydown.Ifyoupushittoostrongly,itwillcausea

largeincreaseintheliquidjunctionpotentialandgiveriseto

measurementerrors.Ifthesleeveisnotclosedtightlyenoughthenthe

internalsolutionmayseepouttoorapidly,orthesamplesolutionwill

seepin.Ifthesamplesolutionseepsin,itwillcausealarge

measurementerror,andtheinternalsolutionwillhavetobereplaced.

6

I0041379000A.pdf2 10.3.210:32:21AM

1) Removetherubberstopper

fromtheinternalsolution

fillingopeninganduse a

syringetoremovethe

internalsolution.

CODE:04137900

pHELECTRODEFORLOWCONDUCTIVITYWATERAND

NON-AQUEOUSSOLVENTSINSTRUCTIONMANUAL

InordertoensurecorrectusageofthepHelectrode,besuretoreadtheseoperatinginstructionscarefullybeforeusage.

ThispHelectrodehasimprovedresponsivenessinlowconductivity

waterandnon-aqueoussolvents.ItcanbeusedwiththeF-10,M-10and

F-20seriesofpHmeters.The6377isa3-in-1electrodethatcontainsa

glasselectrode,referenceelectrodeandtemperaturecompensation

electrodewithinasinglebody.The1076Aisaglasselectrode.Referto

thediagramsbelowtoverifythespecificationsforyourelectrode.

pHrange pH0〜14

Temperaturerange 0〜60℃

Internalelectrode Ag/AgCl

Internalsolutionfor 3.33mol/LKClsolution(Cat.No.300)

referenceelectrode

Liquidjunction Moveablesleeve

Materialofthepartsthatcome

Glass

incontactwiththeliquid

pHmeterssupported F-10,D-10,M-10,F-20 series

pHrange pH0〜14

Temperaturerange 0〜100℃

Internalelectrode Ag/AgCl

Referenceelectrodes 2060A,2660A,2565A

supported

Temp.electrodessupported

4163

Materialofthepartsthatcome

Glass

incontactwiththeliquid

pHmeterssupported F-10,M-10,F-20 series

Type

Features

Specifications

Theelectrode

6377-10D

A3-in-1electrodewithsuperiorresponsivenessinlowconductivity,

lowbufferabilityaqueoussolutionsandnon-aqueoussolventssuchas

alcohol.Ithasamoveablesleevetypeofliquidjunction.

Theelectrodecanalsobeusedformoregeneralapplications.

1076A-10C

Aglasselectrodewithsuperiorresponsivenessinlowconductivity,low

bufferabilityaqueoussolutionsandnon-aqueoussolventssuchasalcohol.

Aseparatereferenceelectrodeandtemperaturecompensationelectrode

arerequired. Theelectrodecanalsobeusedformoregeneralapplications

.

Liquidjunction

Protectivecap

Internalsolutionfilling

openingrubberstopper

Cap

Leadwire

ProtectivecoverfortheconnectorElectrode

connector

Temperature

connector

pHsensing

membrane

1

Protectivecap

Cap

Leadwire

Protectivecoverfortheconnector

Electrode

connector

pHsensingmembrane

2

1)

Pushtheelectrodeconnectorasfaras

itwillgoontotheBNCterminalpinof

thepHmeter.Thenrotateittothe

rightuntilitlocksintoplace.

2) Covertheconnectorwiththe

protectivecover.

3)

Pushthetemperatureconnector

(forthe1076A,thisistheconnector

forthecorrespondingtemperature

compensationelectrode)asfarasit

willgoontotheTterminalofthe

pHmeter.

4)

Forthe1076A,attachtheconnector

forthecorrespondingreference

electrodetotheRterminalofthepH

meter.

3B

4

3)

Forthe6377andsleevetypereferenceelectrodes2660Aand2565A,move

thesleeveasshowninthediagrambelow.Aftercheckingtheoutflowofthe

internalsolution,lightlypullthesleeveinthedownwarddirection.

6

2) Addnewinternalsolution.

5

2. pHMeterConnection

1. SpecificationsandtheElectrode

3. ProceduresforFirstTimeUsage

orAfterLong-TermStorage

Forthe1076A,performtheseoperationsonthereferenceelectrode.

CODE : I041379100

1) BesuretouseCat.No.300internalsolutioninthereferenceelectrode.Ifyou

mustusesomeotherinternalsolution,usea1076Aglasselectrodeand2565A

doublejunctionreferenceelectrodecombination.Placetheappropriateinternal

solutionintheouterchamberofthe2565A.

2) Thiselectrodemaybeusedtotakemeasurementsofalcoholicsolutionswhich

haveverysimilarpropertiestowater,andofnon-aqueoussolventsthatcontain

alargeproportionofwater(greaterthan5%).However,theresponsivenessand

stabilityisnotasgoodasforaqueoussolutions.

3) Theelectrodeconnectorsrequireahighdegreeofinsulation.Donotletthem

getwetortouchthemwithyourhands.

4) Whenahighdegreeofaccuracyisrequired,aftercalibration,washthe

detectionapparatusmorethan3timeswithpure(deionized)waterandsoakit

for10minutesmoreinpure(deionized)waterbeforetakingmeasurements

1)

If there are any bubbles on the inside of the liquid junction opening of

the sleeve liquid junction, or in the thin part of the glass pipe, shake the

electrodelightlyupanddowntofreethebubbles.

Bubbles

Liquidjunction

opening

9

1) Ifthereisnotenoughinternal

solution,removetherubber

stopperfortheinternal

solutionfillingopeningand

addmoreinternalsolution.

5

2) Washtheelectrodemorethan

3timeswithpure(deionized)

water.Lightlywipeawayany

waterdropletswithtissue

paper.

7

3)

Immersetheelectrodeinthe

sampleliquid.Besuretokeep

thesurfaceleveloftheinternal

solutionoftheelectrodeabove

thesurfacelevelofthesample

liquid.Alsobesuretoremovethe

rubberstopperfortheinternal

solutionfillingopeningwhen

takingmeasurements.

Surfacelevelof

internalsolution

8

4.Measurement(Calibrations)

5.Precautions

〈forboth6377and1076A〉

〈6377〉

6.RegularMaintenance

1) Iftheelectrodeisusedforlongperiods,theinternalsolutionin

thereferenceelectrodemaybecomecontaminatedbythe

sampleliquid,orbecomediluted.Performtheoperations

describedinstep3.ProceduresforFirstTimeUsageorAfter

Long-TermStorageonceevery3to6months.

2) Iftheinsideoftheprotectivecapbecomesdry,washitwithpure

(deionized)water.Afterremovinganyexcesswater,supplement

itwithenoughpure(deionized)watertosoakthesponge.

3) Iftheresponsetimeoftheelectrodeoritsreproducibilityhas

fallen,washtheelectrodeusingtheproceduresdescribedbelow.

Rinseitwellwithpure(deionized)waterandsoakonlytheglass

membraneforseveralhoursinpure(deionized)waterbefore

takingmeasurements.

lartuenanidekaosezuaghtiwepiW:tridyranidrO

detergent.

nanidekaosezuaghtiwepiW:tridyliO

appropriateorganicsolventsuchas

alcohol.

Dirtcontaininginorganiccomponents : Soakforapproximately2hoursin1

mol/Lhydrochloricacid.Besurenot

toimmersetheliquidjunctioninthe

hydrochloricacid.

2)

Ifthesleeveliquidjunctionbecomeshardenedwithprecipitatedcrystalsfromthe

internalsolutionandwillnotmove,soakitinwarmwaterofabout30to40

degreestodissolvetheprecipitate.Movethesleeveliquidjunctiontakingcare

nottodamageit.Checktheoutflowoftheinternalsolutionbeforeusage.

(Submittingthesleeveliquidjunctiontoanultrasoniccleanerisalsoeffective.)

3)

Pressthesleevelightlydown.Ifyoupushittoostrongly,itwillcausea

largeincreaseintheliquidjunctionpotentialandgiveriseto

measurementerrors.Ifthesleeveisnotclosedtightlyenoughthenthe

internalsolutionmayseepouttoorapidly,orthesamplesolutionwill

seepin.Ifthesamplesolutionseepsin,itwillcausealarge

measurementerror,andtheinternalsolutionwillhavetobereplaced.

6

I0041379000A.pdf2 10.3.210:32:21AM

April, 2020 © 2017-2020 HORIBA Advanced Techno, Co., Ltd.

Conformable standards

This equipment conforms to the following standards:

RoHS: EN50581

9. Monitoring and control instruments

Authorised representative in EU

HORIBA Europe GmbH

Hans-Mess-Str.6,

D-61440 Oberursel, Germany

For any questions regarding this product, please contact your local agency,

or inquire from the following website.

http://global.horiba.com/contact_e/index.htm

http://www.horiba-adt.jp

31, Miyanonishi-cho, Kisshoin Minami-ku, Kyoto, 601-8306, Japan

pH electrode for low conductivity water and non-aqueous solvents

Instruction Manual

CODE:GZ9100229025C

3013001055.indd 3-4 20/04/16 16:50