Ecolab Apex2 User manual

Apex2

Installation and

Operation Manual

370 Wabasha Street N. St. Paul, MN 55102

www.ecolab.com

© 2012 Ecolab Inc. All rights reserved.

43569/5400/0112

Part No. 9223-2253

TABLE OF CONTENTS

Getting Started

Introduction and Features .................................................................................1-2

Specifications and Dimensions ...................................................................... 3-4

Installation Equipment: “What’s in the box” .................................................. 5

Installation

Hardware .................................................................................................................. 6

Find location for Controller ........................................................................ 6

Mount I/O Enclosure (new install) ............................................................. 7

Inductive Probe ............................................................................................. 7

Rinse Thermistor ...........................................................................................8

Rinse Additive Injection ...............................................................................8

Plumbing Detergent Valve .......................................................................... 9

Optional Pressure Switch ............................................................................ 9

New Install Wiring .................................................................................................10

Machine Signals and Apex2 Power ......................................................10-11

I/O Board Connections ................................................................................12

Sealing Block .................................................................................................13

Retrofit-Kit (Converting Apex to Apex2) .......................................................14

Apex Rinse Additive Signal Wire ..............................................................14

Apex 2 I/O Board ..........................................................................................14

Notice of Existing Machine Signals and System Power ......................15

Apex Board disposal ....................................................................................16

Setting Up Controller

Controller Setup ............................................................................................... 17-18

Alarms......................................................................................................................19

Activation and Deactivation Specification .............................................19

Appendix

FAQ’s and Troubleshooting .........................................................................20-23

Performance Check ............................................................................................24

Replacement Parts Guide .........................................................................25

Apex2 Controller Menu Flow ..............................................................28-35

1.0 INTRODUCTION

This manual provides instructions for the safe installation, maintenance and

operation of this dispensing controller system. Read and understand the

contents of this manual before installing or operating the system. Retain this

manual for future reference. Safety instructions that appear in this manual

after a warning symbol and the words WARNING or CAUTION printed in bold

face are especially important.

means there is the possibility of death or serious

injury.

means there is the possibility of minor or moderate

injury.

NOTICE means the possibility of equipment or property damage only.

Principle of Apex2

The Apex2 System is a machine warewash control system that communicates

actionable and intuitive information to the customer and creates an efficient

interface for Ecolab sales representatives. This control system will help the

customer achieve superior results with improved operational efficiency.

System Features

Overall System Features

The Overall System features include:

• High resolution wide screen display

• Full text, multi-language display

• Intuitive alarm notifications

• Video play back

• Real time data collection for every rack washed

• Automated rack time calibration for conveyor and flight machines

• Customer facing Status menu for real time data

• Wireless data download and setup via Ecolab Service Manager (ESM)

• Universal main power input (100-240VAC , 50/60 Hz)

• Splash resistant enclosure

Detergent Control System

The Detergent Control System features include:

• An Inductive Probe that controls product dispensing when operating in

Probe Mode.

1

!WARNING

!CAUTION

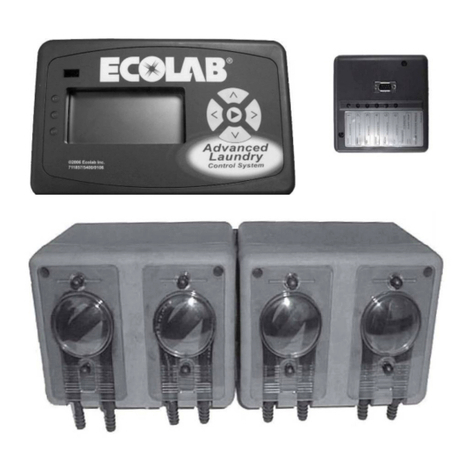

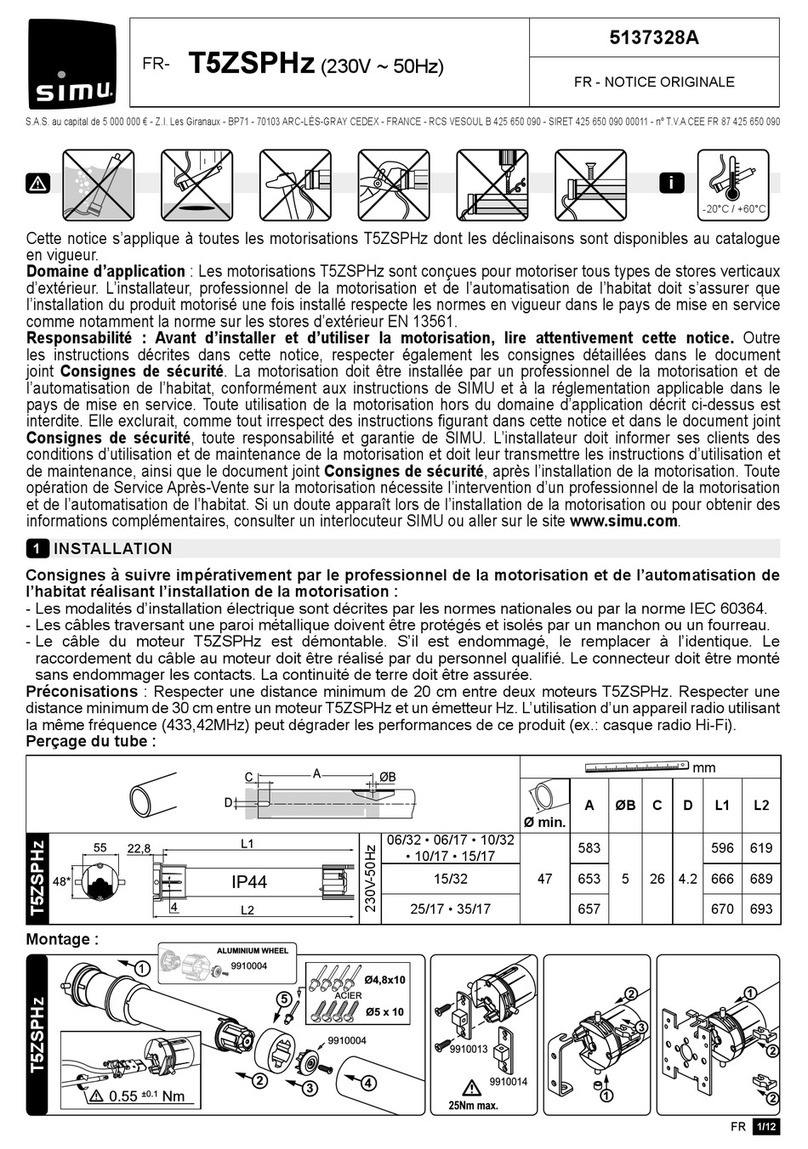

Figure 1.1

2

- “Pulse Feed” of detergent provides overshoot control when the wash

tank concentration is near the desired set point.

• A Timed Mode that is available for alternate detergent control when not

using the probe.

• A Detergent Manager that monitors probe control dispensing and

automatically switches to a base lined feed condition when a dispensing

error is detected.

Rinse Injector System Features

The Rinse Injector System features include:

• Double roller peristaltic pump.

• Squeeze tubes with different delivery rates for high or low volume

installations.

• Variable speed DC motor, 8 - 30 RPM.

• Adjustable run time and start delay (on door machines)

• Optional Pressure Switch for alternate rinse signal input.

• Rinse Manager to disable the rinse injector system during a dish machine

fill (on automatic fill dish machines).

• Pump prime capability

Sanitizer Injector System Features (optional)

The Sanitizer Injector System features include:

• Double roller peristaltic pump.

• Squeeze tubes with different delivery rates for high or low volume

installations.

• Variable speed DC motor, 8 - 30 RPM.

• Adjustable run time and start delay

• Pump prime capability

3

2.0 SPECIFICATIONS

Dimensions and Space Requirements

Controller and IO Box Dimensions

Controller Dimensions

• Height 5.6” (14.2 cm)

• Width 8.0” (20.3 cm)

• Depth 2.6” (6.6 cm)

IO Box Dimensions

• Height 9.2” (23.4 cm)

14.7” (37.3 cm) w/door open

• Width 10.7” (27.1 cm) one pump

• Depth 5.5” (14.0 cm)

Electrical Requirements

The Apex2 Controller operates within the following:

• Incoming Power

• 100 to 240VAC , 50/60Hz

• Detergent and Rinse Signal inputs

• 24 to 240VAC , 50/60Hz, or 24VDC .

5.553

9.235

12.005

10.772

14.699

Figure 2.1

Figure 2.2

8.000

8.000

3.540

4

NOTICE

If the primary voltage is 440/480 volts, separate, externally mounted

transformers are required (P/N 9230-1022).

Inputs (See Mechanical Installations for Wiring

Diagram section 4)

The Apex2 Controller operates with the following inputs (I/O Enclosure):

• Inductive Probe (mandatory for operation in probe mode)

• Rinse Thermistor (mandatory for all Apex2 Installations)

• Product Lid Switches

• Detergent Lid Switch that prevents detergent valve from opening while

the lid is open

• Solid Rinse Additive Lid Switch input that prevents rinse additive pump

from running while the lid is open.

Note: This is an optional feature used with certain external dispensers.

A jumper wire has been installed in the factory to electrically connect

this input.

• Sanitizer Lid Switch that prevents sanitizer pump from running while

the lid is open.

Note: This is an optional feature used with certain external dispensers.

A jumper wire has been installed in the factory to electrically connect

this input.

• Out-of-Product Signals

• Solid Rinse Additive Out-of-Product Signal

• Liquid Rinse Additive Out-of-Product Signal

Outputs to External Dispensers

Apex2 operates with the following outputs (I/O Enclosure):

• Solid Rinse Additive Dispenser

• Two wire output to provide 24VDC power to dispenser

Plumbing Requirements

Water supply tubing from the building water supply to the solenoid valve in the

Apex 2 I/O will normally be 1/4” O.D. copper tubing.

Note: Refer to the Installation and Operation Manual of the appropriate

Detergent and Rinse Dispensers used for this application to aid in the

installation of the Apex2 Controller.

5

3.0 INSTALLATION EQUIPMENT

Apex2 New Customer Install Kit (9223-1072)

Contents:

• Apex2 User Interface Module

• Apex2 I/O Enclosure, including:

• I/O Board, Power Supply, & Signal Wiring Harness

• Rinse Additive Pump

• Detergent Valve

• Inductive Probe (12’)

• RS-485 Communication Cable

• Rinse Thermistor

Apex2 Retrofit Kit (9223-1071)

Contents:

• Apex2 User Interface Module

• Apex2 I/O Enclosure Cover & I/O Board assembly

• Inductive Probe (12’)

• RS-485 Communication Cable

• Rinse Thermistor

Apex2 New Customer Install Kit Dual Pump

(9223-1070)

Contents:

• Apex2 User Interface Module

• Apex2 I/O Enclosure, including:

• I/O Board, Power Supply, & Signal Wiring Harness

• Rinse Additive Pump

• Third Product Pump

• Detergent Valve

• Inductive Probe (12’)

• RS-485 Communication Cable

• Rinse Thermistor

6

4.0 INSTALLATION

Apex2 Controller Installation

Disconnect electrical power supply and follow lockout/tagout procedures

before installing or performing service on the system.

Electrical and grounding connections must comply with the applicable portions

of the National Electrical Code, ANSI/NFPA 70 (latest edition) and/or other

electrical codes.

Mounting Controller

1. Choose an installation location that:

• Allows visual display of the Apex2 Controller (see figure 4.1 below)

• Permits shortest possible tube, wire, and conduit lengths.

• Provides accessibility for adjustments and servicing.

• Provides as much protection from moisture/steam and heat as possible.

2. Secure Controller

• Mount to the top or side of the dish machine using the wall mount and

L-bracket

• To flush mount to the wall or dish machine use only the wall mount

bracket

Note: Avoid mounting the controller in areas near the dish pre-scrap area, and

the rinse section of the dish machine due to excessive water, heat and food soil.

Connect RS-485 Communication Cable to Apex2 Controller

1. Remove the back cover from controller by removing the two retaining

screws.

2. Insert one end of the RS-485 communication cable to the open plug on

the controller board. Note: The other end of this cable will be connected

in the I/O enclosure

3. Install the back cover using the two retaining screws.

Mount and adjust the controller

1. Mount the controller to the wall mount bracket. It is necessary to first

depress the release tab before sliding the controller on to the wall

bracket.

2. Adjust the viewing angle of the controller by depressing the release tab

and sliding the controller on to the wall bracket. Make sure the release tab

engages with the back of the controller at one of the three positions.

!WARNING

!WARNING

Figure 4.1

Figure 4.2

Figure 4.3

7

Mount Apex2 I/O Enclosure

Attach the Apex2 I/O mounting bracket to the wall using the supplied screws

and plastic wall anchors. The installation should be secure, neat, and level. See

Figure 4-4

Inductive Probe Installation

For optimal equipment performance and reliability choose a location that is:

• A minimum of 2” (5 cm) from the tank bottom, side wall, overflow piping,

etc.

• As far as possible (2” [5 cm] minimum) from heater elements or coils

• Protected from physical hazards.

• Always underwater, with entire Probe constantly submerged, particularly

on shallow tank machines.

Before drilling the hole in the wash tank, identify and avoid any obstructions

both inside and outside the wash tank.

Installations Steps

1. Drill/Cut a 7/8” (22 mm) hole into the wash tank wall.

2. Install the rubber sealing washer onto the probe (over the threads and

against the flange on the probe).

3. From the inside of the tank, route the wire through the hole until the

probe is against the wall of the wash tank. Secure the Inductive Probe

to the wash tank using the provided retaining nut with the O-Ring against

the outside surface of the tank wall. The nut end of the Inductive Probe

must be on the outside of the machine wall, refer to Figure 4-5.

!WARNING

Figure 4.4

Figure 4.5

8

Rinse Thermistor/Injection Installation

The rinse aid injection point must be installed downstream of the vacuum

breaker, and a minimum of 6” (15.2 cm) vertically below the vacuum breaker.

Note: Some international installations require this distance to be 30 cm (11.8”).

The enclosure must be mounted so that the top of the rinse dispenser pump is

below the injection point.

NOTICE

Install fittings using Teflon tape or pipe sealant to prevent leaks

1. Identify point at which rinse additive will be injected into final rinse line.

a. If ports are available on the machine rinse line for separate

installations of the rinse injection line and the thermistor, use the

supplied 1/8” FNPT x 1/8” MNPT brass bushing ONLY.

-OR-

b. If the thermistor and rinse line must be installed in the same port, use

the supplied 1/8” brass street tee and follow the diagram below

Note: The Rinse Additive tube must be installed 1.5” (3.0 cm) past the end of

the brass tee fitting for accurate rinse temperature measurement.

2. Assemble the Visual Flow Indicator (required for NSF listing) on the

outlet side of the rinse dispensing pump by inserting the 1/8” tube fully

into one of the two 1” sections of 1/4” OD x 1/8” ID PVC tubing provided

[See Figure 4.7]

3. Install the check valve between the visual flow indicator and the rinse aid

injection point.

1.500

6”

Figure 4.6

Figure 4.7

Figure 4.8

9

Water Line Connections

Detergent Valve

1. Connect 1/4” O.D. flexible copper tubing from the building water supply

to the inlet side of the solenoid valve, located at the bottom of the Apex2

I/O enclosure.

2. Connect 1/4” O.D. flexible copper tubing from the outlet side of the

solenoid valve to the Apex Detergent Dispenser.

Note: Refer to the Installation and Operation Manual of the Apex Detergent

Dispenser for water temperature and flow rate requirements.

Pressure Switch (Optional)

If the dishmachine does not offer a separate rinse signal to activate the rinse

additive, a pressure switch will need to be installed. The rinse injector will then

be activated when the switch closes from the pressure created by the flow of

the final rinse water.

1. Locate hexagon feature on the bottom of the I/O enclosure, located in

front of the detergent valve. See figure 4.10.

2. From the outside of the enclosure, knock out the plastic piece that covers

this hexagon hole.

3. From the inside of the enclosure, insert pressure switch in the hexagon

hole. Secure pressure switch using mounting nut.

Note: See Figure 4.11 for wiring instructions.

4. Connect 1/4” copper tubing between the pressure switch on the outside of

the enclosure and the injection fitting on the final rinse line.

Note: Pressure switch is not included in the installation kit, order if needed.

Water In To Apex

Detergent

Dispenser

Figure 4.9

Figure 4.10

Electrical Installation

Disconnect electrical power supply and follow lockout/tagout procedures

before installing or performing service on the system.

Electrical and grounding connections must comply with the applicable portions

of the National Electrical Code, ANSI/NFPA 70 (latest edition) and/or other

electrical codes.

High Voltage and Machine Signal Wiring

Note: Wiring the system power and detergent/rinse signals not required for

retrofit kit.

Electric Power Supply

Apex2 is designed to be permanently connected to the dish machine to receive

the main power and dispenser enabling signals. The dish machine will normally

contain an identified terminal block for this purpose. Refer to the wiring

diagram of the dish machine. The dish machine installation should include a

disconnect switch and overcurrent protection as required by national and/or

local electric codes.

If Apex2 must be connected to a source other than the dish machine for the

main power, the electrical, overcurrent protection and grounding connections

must comply with the applicable portions of the National Electric Code, ANSI/

NFPA 79 (latest edition), and/or other local electrical codes.

The system can operate within the following specifications:

• Incoming Power

• 100 to 240VAC , 50/60Hz

• Detergent and Rinse Signal inputs

• 24 to 240VAC , 50/60Hz, or 24VDC .

Cable for Electrical Connections

A 12 foot long (3.7 m), seven-conductor power and signal wire cable is provided

and pre-connected inside the Apex2 I/O enclosure. This cable is used to

provide incoming power and dispenser enabling signals from the dish machine

to the Apex2. If this wire cannot be used because of specific reasons at the

installation, it must be replaced with 18 AWG (minimum) wire having minimum

ratings of 300V and 105°C insulation.

Conduit for Electric Cable

The power and signal wire cable between the dish machine and the Apex2

I/O enclosure must be enclosed in liquid tight electrical conduit approved for

use in damp locations. A threaded 1/2” trade size female connection exists for

connecting the conduit to the bottom of the Apex2 I/O enclosure.

10

!WARNING

!WARNING

11

Note: For proper operation, both Detergent Signal and Rinse Signal (or pressure

switch) connections must be connected for all installations.

Main Power

Connect Blue and Brown wires to constant voltage source.

Connect Green with Yellow stripe wire to verified earth ground.

NOTICE

If the primary voltage is 440/480 volts, separate, externally mounted

transformers are required (P/N 9230-1022).

Detergent Signal

Connect Yellow and White with Yellow stripe wires to dish machine detergent

power source (or wash pump circuit if no detergent power source connections

are provided).

This is a universal voltage signal input that is capable of accepting any voltage

between 24 to 240VAC, 50/60Hz, or 24VDC. (DC voltage input must observe

polarity; Yellow wire is positive.)

Rinse Signal

Connect Violet and White with Violet stripe wires to dish machine rinse power

source (or rinse solenoid valve circuit if no rinse power source connections are

provided).

This is a universal voltage signal input that is capable of accepting any voltage

between 24 to 240VAC, 50/60Hz, or 24VDC. (DC voltage input must observe

polarity; Violet wire is positive.)

NOTICE

When using the optional pressure switch, the electrical signals from the dish

machine are not used. Disconnect the violet and white/violet stripe wires

from the terminal block.

Note: For proper operation, both Detergent Signal and Rinse Signal (or pressure switch)

connections must be connected for all installations.

Main Power

Connect Blue and Brown wires to constant voltage source.

Connect Green with Yellow stripe wire to verified earth ground.

NOTICE

If the primary voltage is 440/480 volts, separate, externally mounted transformers are required (P/N 9230-

1022).

Detergent Signal

Connect Yellow and White with Yellow stripe wires to dish machine detergent power source (or wash

pump circuit if no detergent power source connections are provided).

This is a universal voltage signal input that is capable of accepting any voltage between 24 to

240VAC, 50/60Hz, or 24VDC. (DC voltage input must observe polarity; Yellow wire is positive.)

Rinse Signal

Connect Violet and White with Violet stripe wires to dish machine rinse power source (or rinse

solenoid valve circuit if no rinse power source connections are provided).

This is a universal voltage signal input that is capable of accepting any voltage between 24 to

240VAC, 50/60Hz, or 24VDC. (DC voltage input must observe polarity; Violet wire is positive.)

NOTICE

When using the optional pressure switch, the electrical signals from the dish machine are not used.

Disconnect the violet and white/violet stripe wires from the terminal block.

Table ??-??? Main Power/Signal Cable Wire Color Codes

Wire Color Connect to

Brown Main Power: 100 – 240 VAC 50/60 Hz

Blue Main Power: 100 – 240 VAC 50/60 Hz

Green w/Yellow Earth Safety Ground

White w/Violet Rinse Signal: 24-240 VAC or 24 VDC (-)

Violet Rinse Signal: 24-240 VAC or 24 VDC (+)

White w/Yellow Detergent Signal: 24-240 VAC or 24 VDC (-)

Yellow Detergent Signal: 24-240 VAC or 24 VDC (+)

Apex2 I/O Board Connections

Note: The components inside the Apex2 I/O enclosure are prewired

Pass wires through the hole in the Apex2 I/O enclosure for the cable sealing

block and connect to I/O Apex2 I/O board. Wires to pass through sealing block

include:

• Controller via RS-485 Communication Cable

• Inductive Probe

• Solid Rinse Aid Dispenser Power

• Rinse Aid IR Sensor, Out-of-product signal (connect to location ‘S’ on

Rinse Sensor Connector)

• Liquid out-of-product sensor (if using liquid rinse aid or liquid sanitizer)

• Blue to (-), Black to (S), Brown to (+)

• Rinse Thermistor

• Detergent Dispenser Lid Switch

• Pressure Switch (optional)

12

1

8

APEX

DETERGENT

LID SWITCH

SANITIZER

MOTOR

PRESSURE

SWITCH

(OPTIONAL)

DETERGENT

VALVE

APEX RINSE

MAIN POWER

RED +

BLK -

BLK S

BRN +

BLK

RED

RED

BLK

BLK

-

RED

+

BRN

+

1

4

1

6

-

+

+

+

-

-

}

}

}

DETERGENT SIGNAL

RINSE SIGNAL

(NOT USED WITH

PRESSURE SWITCH)

SANITIZER SIGNAL

POWER IN

(FROM POWER SUPPLY)

(RETRO-FIT)

POWER IN

MACHINE SIGNALS

24 VDC

WHT

WHT

BLK

-

RINSE

THERMISTOR

BLK

-

CONTROLLER

LIQUID SANITIZER

SENSOR

GRY S

IR SENSOR

RINSE LID SWITCH

JUMPER

SANITIZER LID SWITCH

JUMPER

TERMINATING

PLUG

RINSE

MOTOR

CONDUCTIVITY

PROBE

LIQUID RINSE

SENSOR

BLU -

RED

+

24-240 VAC OR 24 VDC

Controller and terminating

plug connections can be

reversed without issue

12 / 5 VDC

I/O Board

Communication

(blinking)

Figure 4.11

13

Sealing Block Installation

NOTICE

The cable sealing block must be used and correctly installed to prevent

moisture from entering the enclosure and causing damage to the electrical

components. Wrap excess cable outside of the I/O enclosure to prevent

electrical noise interference.

After making wire connections, install the cable sealing block inside the Apex2

I/O Enclosure.

1. Place sealing block underneath wires and align the guides into position.

See figure 4.12.

2. Press firmly in the forward and downward direction until the block is

securely in place. See figure 4.13.

Note: For best sealing results, avoid having cables lying on top of each as they

pass through the opening at the sealing block.

Figure 4.12

Figure 4.13

14

Retro- Kit Installation Only (Apex to Apex2)

Rinse Aid Dispenser Out of Product Signal

1. Open the front cover of the rinse dispenser by removing the stainless

steel hinge pin

2. Within the wire harness locate the white-to-white connection and

disconnect

Note: Disconnecting the white-to-yellow connection will cause the dispenser to

function incorrectly and not fill reservoir.

3. Connect the supplied grey wire to the male connector of the white wire

4. Route the grey wire out the bottom of the rinse dispenser to the Apex2

I/O Enclosure

Note: Leave the remaining white terminal connector unconnected.

5. Replace the front cover

Removing Apex Board

1. Open existing Apex controller and disconnect:

a. Probe Cable [A]

b. Phoenix Connectors [B, C, and D]

i. Pressure Switch wire leads may require loosening terminal screw

c. Rinse Motor and Detergent Valve Connectors [E]

(Do not cut wires at this time)

d. Power Supply [F]

ABCDEF

Figure 4.16

Figure 4.14

Figure 4.15

15

2. Remove Sonalert from the side of the I/O enclosure box

a. Disconnect the lead wires from the Sonalert

b. Unscrew retaining nut and discard the sonalert and wires

3. Remove existing Apex controller board and cover assembly by pulling the

cover from the Apex I/O enclosure.

a. With the cover open, and approximately horizontal, pull the cover

straight off from the I/O enclosure, causing the cover to unsnap from

the stainless steel hinge pin.

b. Do not throw the Apex board into the garbage! The board must be

disposed of properly

c. Ship to: Ecolab

Hwy 251 & Rockton Rd.

South Beloit, IL 61080

4. Install the supplied RS-485 cable sealing assembly through the Sonalert

hole.

a. Assemble the two threaded fittings around the RS-485 cable. There

should be approximately 8” (20cm) of cable exposed from the end of

the fittings

b. Place the assembly into the empty Sonalert hole and secure using the

threaded.

Figure 4.17

Figure 4.18

Figure 4.19

Figure 4.20

Apex2 I/O Board Installation

1. Install Apex2 I/O enclosure cover

a. Align cover with the stainless steel hinge pin. Press forward firmly

on the cover to snap it into place. If necessary, use pliers to squeeze

cover assembly onto hinge pin.

NOTE: Avoid twisting the front cover as this may damage the Apex2 I/O board

2. Install Apex2 I/O Board Connections

Refer to the I/O Board diagram, Figure 4.11

a. Install the 7-pin Phoenix connector (Det Lid Switch, Rinse Thermistor,

and Rinse Sensor)

b. Rinse Aid Out-of-Product Signal Wire (connect to location ‘S’ on Rinse

Sensor Connector)

c. Install the 5-pin Phoenix connector (‘Network’ and ‘Rinse Max’) to the

‘Network’ and ‘Rinse Dispenser’ pin locations on the Apex2 board

d. Install the 4-pin Phoenix connector for the (‘Pressure Switch’ and ‘San

Out’)

e. Install the supplied 4-pin jumpered Phoenix connector in the ‘Rinse Lid

Switch’ and ‘San Lid Switch’ location on the Apex 2 I/O board

f. Connect the Inductive Probe to the Apex2 I/O board. Wrap excess cable

outside of the I/O enclosure.

g. Connect the RS-485 cable into one of the open RS-485 connectors on

the Apex2 I/O board. Wrap excess cable outside the I/O enclosure.

Install the RS-485 terminating plug assembly into the other connector.

h. Cut the rinse motor wires from the connector

i. Strip wire ends

ii. Insert into the supplied 4-pin Phoenix connector in the ‘Rinse Out’

iii. Insert positive(red) into ‘+’ and negative(black) into ‘-‘

iv. Tighten screw connections

i. Cut the detergent valve wires from the connector

v. Strip wire ends

vi. Insert into the supplied 4-pin Phoenix connector in the ‘Det Out’

vii. Insert positive(brown) into ‘+’ and negative(black) into ‘-‘

viii. Tighten screw connections

j. Connect the power supply to the Apex2 I/O Board, then close enclosure

cover.

16

Figure 4.21

Figure 4.22

It is recommended that all setup of the Apex2 controller be completed using

ESM. ESM provides a streamlined approach that can speed up the setup of

the Apex2 controller in comparison to setup via the controller user interface.

All setup parameters are accessed through the “Main Menu “of the Apex2

controller. The initial setup of the Apex2 controller is aided through the use

of the Apex2 Setup Wizard that will be initiated upon initial startup of the

controller.

a. Dishmachine Mode: The dishmachine mode can be set in the “Setup

System – Machine ” menu. The dishmachine setup will determine what

dispensing parameters are available in the “Adjust Dispensing” menu. The

dishmachine modes available are below. NOTE: Specific machine make

and model must be identified within the Location’s Service Item when

teaming the Apex2 controller in ESM. Configuring the dishmachine for

chemical sanitizing must also be done within the Service Item in ESM.

i. Door Machine – Probe Mode:

1. In Door Machines, the rinse is triggered by either the rinse signal

or the (optional) pressure switch. As the rinse is triggered, the rinse

delay (if any) begins. After the delay, the rinse pump runs at the set

rinse pump speed for the programmed Rinse Pump Limit or until the

rinse input is turned off, whichever comes first.

ii. Door Machine – Timed Mode:

1. Door machine functionality, such as rack counting and rinse

dispensing, are identical in both Probe and Timed mode. However,

Timed Mode does not have a wash tank monitoring function and the

detergent dispensing is different.

When an unqualified rinse signal (a rinse signal not proceeded by a

detergent signal) is received, the detergent is dispensed for the time

set in the Initial Detergent Charge. At each subsequent detergent

signal, the detergent is dispensed for the set Detergent Valve Run

Time, at the interval set in the Detergent Dose Interval.

iii. Conveyor Machine – Probe Mode:

1. Conveyor Machine, the rinse is triggered by either the rinse signal

or the (optional) pressure switch. The rinse pump is activated with a

qualified rinse signal and will run throughout the duration of the

signal.

iv. Conveyor Machine—Timed Mode:

v. Flight Machine – Probe Mode:

b. Product Selection: Apex2 detergent, rinse additive and third product

selections are found in “Setup System – Product Selection” menus.

Several controller conditions are dependent on the specific products

chosen therefore products chosen must accurately reflect products being

used with Apex2.

17

5.0 CONTROLLER SETUP

Figure 5.1

Figure 5.2

18

i. Detergent: Product specific dispensing profiles and Out-of-Product

alarm notifications

ii. Rinse Additive: Product specific Out-of-Product alarm signal input and

Out-of-Product alarm notifications

iii. Third Product: Product specific Out-of-Product alarm notifications

c. Adjust Dispensing Parameters: The dispensing parameters are set in the

“Adjust Dispensing” menu. Only the parameters appropriate to the

machine mode chosen will be made available.

i. Detergent:

1. Detergent Set Point

a. Detergent concentration should be set by titrating the wash tank,

then adjusting the Detergent Set Point up or down as needed to

reach the desired concentration. This value ranges from 1-100 in

increments of 1 with a default setting of 50.

2. Initial Detergent Charge (Timed Mode Only)

a. Set the amount of time that the detergent will feed after the initial

feed of the dishmachine. This value ranges from 1-999 seconds in

increments of 1 second with a default setting of 10 seconds.

3. Detergent Dose Interval (Timed Mode Only)

a. Set the frequency of the Detergent Dose. This value ranges from

1-10 racks in intervals of 1 rack, with a default of 1 rack.

4. Detergent Dose Time (Timed Mode Only)

a. Set the length of detergent dispense time per the Detergent Does

Interval. This value ranges from 1-30 seconds in intervals of 0.1

seconds, with a default setting of 2.5 seconds.

ii. Rinse Additive / Third Product

1. Pump delay (Door Mode only)

a. Set the delay time for starting the rinse /third product pump

after receiving a qualified wash signal. This value ranges from

0-30 seconds in intervals of 1 second with a door machine default

of 2 seconds.

2. Pump Limit:

a. Set the maximum time that the rinse pump is allowed to run. This

value ranges from 0-50 seconds in increments of 1 second, with a

default of 10 seconds.

3. Pump Speed

a. Set the rinse/third product pump speed. This value ranges from

8-30 RPM in increments of 0.5 RPM, with a default of 15 dsRPM.

d. Alarming Parameters

i. Alarm Volume

1. Set the volume of the alarm notification. This value ranges from

0 – 10 with intervals of 1.

ii. Detergent Alarm Delay

1. Set the delay time before the controller activates the Detergent Out

of Product alarm. This setting monitors the time that the detergent

solenoid valve is open while being below the Detergent Set Point.

This value ranges from 5-1000 seconds in intervals of 5 seconds with

a default of 300 seconds.

iii. Wash Tank Change-Out

1. Set the number of racks required to activate the Change Wash Tank

alarm. This value ranges from 0-950 racks in increments of 25 racks

with a default of 250 racks.

iv. Alarm Mute Time

1. Set the duration of a muted alarm when the “Mute Alarm” button

is pressed during an active alarm. Once the inputted time expires

the screen Apex2 controller screen will revert from yellow back to

red and the audible alarm will re-sound.

Figure 5.3

Figure 5.4

Figure 5.5

Figure 5.6

Figure 5.7

This manual suits for next models

3

Table of contents

Other Ecolab Control System manuals