Ecom Instruments CP 440 User manual

Bedienungsanleitung

Instruction Manual

Manuel d’Instructions

CP 440

15

Contents Page

1. Introduction 16

1.1 CP 440 Display and Controls 16

2. Operation 17

2.1 Set-up and configuration 17

3. Supervisory Mode 18

4. Normal Operation 20

5. Specifications 21

6. Appendix 1: CP 440 Calibration Procedure 22

7. Available Ranges 26

8. Warranty and Liability 27

16

1. Introduction

The CP 440 combines the high accuracy of digital electronics with the

convenience and ease of use of an analog test gauge. Accurate to

± 0.05% FS, the CP 440 can be used as a calibration reference, or in any

application where high accuracy pressure measurement is required.

Many user configurable functions have been designed into the CP 440 in-

cluding sampling rate, TARE, damping, auto shut off, and min-max. Once

the gauge is configured, settings can be locked and password protected

to prevent unauthorized changes to configuration.

Unpacking:

Check to see that your CP 440 has arrived intact. Batteries are factory

installed unless you have purchased the optional 24V powered version, in

which case batteries are not supplied or installed.

1.1 CP 440 Display and Controls

Pressure display

Selects an action in

configuration.

Also turns the back-light on/off

Turns Power on/off

Enters set-up and

configuration menus

Zeros the display,

Scrolls forward

through menu displays

Recalls min and max

readings. Scrolls

backwards through

menu displays

0 - 100% bar graph

Engineering Units

17

2. Operation

Power: The standard CP 440 is supplied with 3 AA batteries installed.

If you purchased the optional 24Volt powered version, batteries are not

installed. Connect a 24V power supply to the terminal block on the rear of

the gauge, noting proper polarity.

Do not install batteries when external power will be used.

Push the power button momentarily to turn the unit on. Push it again to

turn it off.

2.1 Set-up and configuration:

Push the CONFIG button to access the user-settable functions on the

gauge. Each time the CONFIG button is pressed; the display advances to

the next function. Once a function has been set, press ENTER to exit the

configuration menu, or CONFIG to continue with further configuration. In

order, the configuration menu and operation is as follows:

1. Engineering Units set. The unit is shipped configured to display Psi.

By pressing the 6and 5(ZERO and MAX/MIN) keys you can scroll

forward and backwards through the 18 standard engineering units

plus a one custom unit/scale. When the desired unit is displayed,

press ENTER or CONFIG. Pressure will now be displayed in the chosen

engineering units.

See the Specifications section of this manual for a list of available

engineering units.

See the Supervisory Mode section for details on setting up custom

units.

2. Set Auto Off. The auto-shut off can be set in 1 minute increments from

1 to 30 minutes or “off” (continuous operation). The unit is shipped set

for 30 minutes. Use the 6and 5keys to set the desired interval. The

“off” setting is at the low end of the choices, below 1 minute.

3. Display battery voltage. Actual voltage and a percent of life bargraph

indicate battery condition

18

4. Display actual temperature. The CP 440 is temperature compensated,

this displays the temperature measured by the internal sensor.

The value can be set to degrees F or degrees C using the arrow keys.

5. Set damping. Choices are “on” and “off” set with the 6and 5keys.

Turning damping on will smooth readings from pulsating pressure

sources.

6. Set sample rate: This determines how often pressure is sampled and

the display is updated. Choices are 0.5, 1, 3, and 10 samples/second.

Note that 10/sec provides the fastest response time.

7. Set TARE. This allows you to set a constant offset value, which is then

subtracted from the measured pressure. For example if a TARE is set at

30 Psi, and the measured pressure is 37 Psi, the displayed value will

be 7 Psi. A pressure of 27 Psi would be displayed as –3 Psi.

The tare value is set manually with the 6and 5keys, and is based on

the engineering units and resolution selected for display. TARE value

can be set to the maximum range of the gauge.

The bar graph will always display the actual pressure based on the full

range of the gauge regardless of the tare setting. This is done for safe-

ty to insure that even with a “0” reading that pressure is being applied

to the gauge.

8. Function Lock: Access to each of the settable parameters above can

be turned “off” once set, to prevent unauthorized changes to configu-

ration. This is accomplished through a password protected “superviso-

ry mode”. Press ENTER to access the supervisory mode, or CONFIG to

return to normal operation.

3. Supervisory Mode

Press ENTER when “FUnC LOCK” is displayed, 0PWRD will be displayed

on the gauge. The password to enter supervisory mode is 101, set using

the 6and 5keys. Holding a key continuously will cause the display to

advance more quickly for faster setting. The password is factory set and

cannot be changed.

19

1. Your CP 440 is shipped from the factory with all setting access

“unlocked” or available to be changed.

2. In supervisory mode each of the parameters can be locked or unlo-

cked using the 6and 5keys. Select LOC (lock) for those parameters

you do not want to be accessible, and UnLOC (unlock) for those can

be accessed.

3. In order, the functions that can be unlocked, locked or accessed are:

• Zero function (enable/disable)

• Set pressure units (enable/disable)

• Auto shutdown adjustment (enable/disable)

• Damping settings (enable/disable)

• Sample rate setting (enable/disable)

• Tare setting (enable/disable)

• Custom engineering units (set scale factor)

4. Use the CONFIG key to scroll through the above choices, and the 6

and 5keys to lock and unlock features. Press CONFIG to continue

scrolling through the parameters, pressing ENTER at any point saves

your settings and returns the gauge to normal operation.

When a function is “locked, it cannot be accessed or changed from its

current state. To change a locked function, enter the supervisory mode,

and unlock the function. Once it is changed, you may enter superviso-

ry mode to lock access again.

5. Setting a custom engineering unit or scale: The last menu choice in

supervisory mode is SET FACTR. This allows you to set a multiplier

factor from 0.001 to 100, creating a custom scale. The set factor will be

multiplied by the Psi measured, the result will be displayed.

For example: 40 Psi is the equivalent of 1000 g of product in a tank.

You want to display the product weight , using a 100 Psi gauge. By

setting a factor of 25, a 40 Psi pressure would display as 1000 (40 x

25). The engineering unit displayed on the CP 440 will be “Cust”.

20

4. Normal Operation

Turning the backlight on and off: Press the ENTER button.

Zeroing the display: Press and hold the ZERO button.

MAX/MIN: The CP 440 stores minimum and maximum pressure values

in memory. Pressing the MAX/MIN button once will display the minimum

pressure from memory. Pressing the MAX/MIN button again will display

the maximum pressure from memory. After about 2 seconds, the gauge

returns to normal (live display) operation. To clear the MAX/MIN memory

registers, press and hold the MAX/MIN button for 2 or more seconds until

“CLr” is displayed.

The analog bar graph at the bottom of the display indicates the applied

pressure level relative to the full range of the gauge. Keep in mind that if a

TARE value has been programmed into the gauge, the displayed pressure

will not reflect the true pressure applied.

Changing the Batteries

Grasp the face ring on the CP 440, turn it approximately 1⁄4 turn coun-

terclockwise and remove. The face of the gauge can now be lifted to

expose the battery holder. Install three AA batteries noting proper polarity.

Reassemble the case making certain that the face is properly oriented.

If you purchased the optional 24 Volt powered version, the terminals for

power input are located on the rear of the gauge. To apply power simply

connect 24 volts to the rear terminal block taking care to observe proper

polarity.

WARNING

Gauges ordered with the external power option will not come

with batteries installed. Batteries MUST NOT be installed when

operating on external power.

Battery life

Battery life is about 1500 hours (60 days) of continuous use with the

backlight off. With intermittent use, batteries could last a year or more.

There is a low battery icon in the upper left of the display. It will appear

when battery level is low. Replace batteries per recommendations found

in the specifications section of this manual.

21

RS-232 Interface

An RS-232 interface is standard on the CP 440. Serial communication

can be used for configuration, calibration, and to transfer measurement

data from the gauge.

5. Specifications

All specifications cover the temperature range from 0°C to +50°C, unless

otherwise noted.

Available Input Ranges

See page 26 for a table of available ranges in psi plus equivalent ranges

and resolution for all engineering units

Accuracy

Positive Pressure: ±0.05% FS

Vacuum: ±0.25% FS (500 psi gauge ranges and below)

For gauges with full scale ranges equal to, or less than 30 psi (2 bar),

vacuum operation is limited to -5psi (-350 mbar) for operating temperatu-

res above 30° C.

Over Pressure Protection:

Ranges from 15 psi to 500 psi: 3x input pressure range

1,000, 3,000, and 5,000 psi ranges: 2x input pressure range

10,000 psi: 1.5x input pressure range

Temperature Compensation

0°C to +50°C (32°F to +122°F) to rated accuracy

Standard Engineering Units

psi, bar, kg/cm2, inH2O (4°C, 20°C or 60°F), ftH2O (4°C, 20°C or 60°F),

cmH2O (4 °C and 20 °C), mH2O (4°C and 20°C), kPa, mbar, inHg, mmHg,

Torr

One custom unit (user programmable)

Media Compatibility

Liquids and gases compatible with 316 stainless steel

22

Environmental

Operating Temperature -10 °C to +55 °C (14°F to 131°F)

Storage -20 °C to +70 °C (-4 °F to +158 °F)

Mechanical

Dimensions 4.5“ (diameter) x 2.2“ (depth) x 5“ (height)

Pressure Connection: 1⁄4” NPT Male

Housing: Stainless steel, meets NEMA 4/IP65

Display

5-1/2 Digits, 0.65“ (16.53 mm) high

20-Segment bar graph, 0 to 100%

Power

Battery three (3), size AA alkaline batteries, optional 24 VDC power.

Battery Life 1,500 hours without backlight

2,000 hours at slow sample rate

Low Battery Indicator icon is displayed near the end of battery life

Approvals

CE approved

6. Appendix 1: CP 440 Calibration Procedure

Overview

Calibration adjustment of the CP 440 is performed electronically ´via inter-

nal software with the case closed. There are no mechanical adjustments;

all calibration commands and adjustments are done via the keypad, using

the display to guide the user through the calibration process.

Eight calibration points are used in the adjustment program, working from

full scale to zero at pressures equaling 100%, 87.5%, 75%, 62.5%, 50%,

37.5%, 25%, 12.5%, and 0% of full scale plus vacuum.

Note: This is an ambient temperature calibration, and should be perfor-

med at an ambient temperature of 23°C ± 3°C (72° F ± 5° F). Calibration

outside this temperature range will invalidate the temperature compensa-

tion program in the CP 440.

23

Calibration Interval

You should check performance of the unit at the interval required by your

calibration program. We recommend adjustment when measurement

deviates by more than 75% of the specified accuracy, or 0.04%

Test Equipment

Verification and calibration of the CP 440 requires pressure and/or vacu-

um standards able to produce and indicate pressures from vacuum to the

full-scale range of the unit under test. In order to maintain the specified

accuracy of the CP 440, standards should have a TUR of 4:1 or better.

Connections:

The PI uses a 1/4 NPT male connection in the pressure input port. Various

adapters may or may not be needed to connect to the pressure standard.

Always make sure the hose, tubing, and fittings etc have a rated working

pressure at or above the pressure of the unit. Also it is important that there

be no leaks when performing calibration; use Teflon tape where appropriate.

Entering Calibration Mode:

After you have made your connections, turn the power on while holding

the CONFIG key. Use the arrow keys to enter the password. The pass-

word is 101. If you have entered calibration mode correctly the display

should look as shown below. The pressure value displayed will be the

full-scale value of the gauge.

Procedure:

Screens shown in this manual represent the displays shown with a 500

psi Gauge. The CP 440 will prompt the technician for the appropriate

pressure at each calibration point.

Use the Pressure Standard to output 500.00 psi (100%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown in the illustration that follows.

500.00

PSI

CAL MODE

24

Use the Pressure Standard to output 437.50 psi (87.5%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown below.

Use the Pressure Standard to output 375.00 psi (75%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown below.

Use the Pressure Standard to output 312.50 psi (62.5%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown below.

Use the Pressure Standard to output 250.00 psi (50%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown below.

437.50

PSI

CAL MODE

375.00

PSI

CAL MODE

312.50

PSI

CAL MODE

250.00

PSI

CAL MODE

25

Use the Pressure Standard to output 187.50 psi (37.5%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown below.

Use the Pressure Standard to output 125.00 psi (25%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown below.

Use the Pressure Standard to output 62.50 psi (12.5%). After the output

has stabilized, press the ENTER key to continue. As the unit takes rea-

dings, the screen will show -------. When the readings are complete the

screen should look as shown below.

Use the Pressure Standard to output 0.00 psi. After the output has

stabilized, press the ENTER key to continue. As the unit takes readings,

the screen will show -------. When the readings are complete the screen

should look as shown below.

187.50

PSI

CAL MODE

125.00

PSI

CAL MODE

62.50

PSI

CAL MODE

0.00

PSI

CAL MODE

26

Use the Pressure Standard to output -12.00 psi. After the output has

stabilized, press the ENTER key to continue. As the unit takes readings,

the screen will show -------. When the readings are complete the unit will

reset and power up in normal mode.

7. Available Ranges and Resolution by Engineering Unit

psi Range 15 30 100 300 500 1000 3000 5000 10000

Engineering

Unit

psi 15.000 30.000 100.00 300.00 500.00 1000.0 3000.0 5000.0 10000

bar 1.0342 2.0684 6.8947 20.684 34.474 68.947 206.84 344.74 689.47

mbar 1034.2 2068.4 6894.8 20684 34474 68948 NA NA NA

kPa 103.42 206.84 689.48 2068.4 3447.4 6894.8 20684 34474 68948

kg/cm21.0546 2.1092 7.0307 21.092 35.153 70.307 210.92 351.53 703.07

cmH20@4°C 1054.6 2109.3 7030.9 21093 35154 70309 NA NA NA

cmH20@20°C 1056.5 2113.0 7043.4 21130 35217 70434 NA NA NA

mH20@4°C 10.546 21.093 70.309 210.93 351.54 703.09 2109.3 3515.4 7030.9

mH20@20°C 10.565 21.130 70.434 211.30 352.17 704.34 2113.0 3521.7 7043.4

inH20@4°C 415.21 830.42 2768.1 8304.2 13840 27681 83042 NA NA

inH20@20°C 415.95 831.89 2773.0 8318.9 13865 27730 83189 NA NA

inH20@60°F 415.61 831.23 2770.8 8312.3 13854 27708 83123 NA NA

mmHg@0°C 775.73 1551.5 5171.5 15515 25858 51715 NA NA NA

inHg@0°C 30.540 61.081 203.60 610.81 1018.0 2036.0 6108.1 10180 20360

ftH20@4°C 34.601 69.202 230.67 692.02 1153.4 2306.7 6920.2 11534 23067

ftH20@20°C 34.662 69.324 231.08 693.24 1155.4 2310.8 6932.4 11554 23108

ftH20@60°F 34.634 69.269 230.90 692.69 1154.5 2309.0 6926.9 11545 23090

Torr 775.73 1551.5 5171.5 15515 25858 51715 NA NA NA

-12.00

PSI

CAL MODE

27

8. Warranty and Liability

Under the general terms and conditions of business, ecom instruments

GmbH offers a 2-year warranty for function and materials on this product

under the specified operating and maintenance conditions. Not covered

are all wearing parts (e.g. batteries, sensors, displays, lamps, etc.) as well

as calibrations.

This warranty does not extend to products that have been used impro-

perly, altered, neglected, damaged by accident or subjected to abnormal

operating conditions or improper handling. In the event of a warranty

claim, the faulty device should be sent in. We reserve the right to readju-

st, repair or replace the unit.

The above warranty terms represent the sole rights of the purchaser to

compensation and apply exclusively and in place of all other contractual

or statutory warranty obligations. ecom instruments GmbH does not

accept liability for specific, direct, indirect, incidental or consequential

damages or losses, including the loss of data, regardless of whether they

are caused by breach of warranty, lawful or unlawful actions, actions in

good faith or other actions.

If in certain countries the restriction of statutory warranty and the exclu-

sion or restriction of in-cidental or consequential damages is unlawful,

then it may be possible that the above restrictions and exclusions do not

apply for all purchasers. If any clause in these warranty terms should be

found to be invalid or unenforceable by a competent court, then such a

judgement shall not affect the validity or enforceability of any other clau-

se contained in these warranty terms.

ecom instruments GmbH

Industriestr.2

D-97959 Assamstadt

Tel.: +49 (0) 62 94 / 42 24-0

Fax: +49 (0) 62 94 / 42 24-90

E-Mail: sales@ecom-ex.com

Internet: www.ecom-ex.com

5200 AL 01 A00 10/05 Änderungen vorbehalten! Subject to change without notice!

Table of contents

Other Ecom Instruments Test Equipment manuals

Popular Test Equipment manuals by other brands

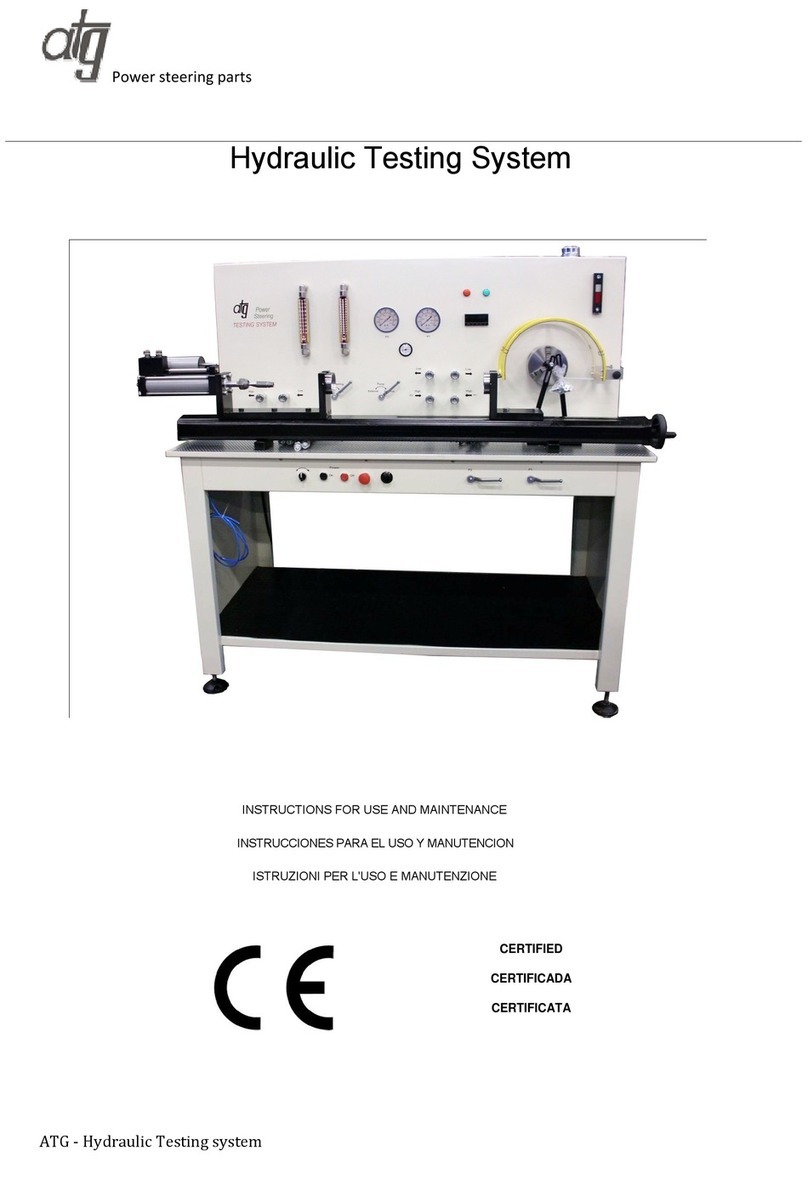

ATG

ATG Hydraulic Testing System Instructions for use and maintenance

Extech Instruments

Extech Instruments TK36 owner's guide

Rubarth Apparate

Rubarth Apparate RUMED 4001 Operating and maintenance instructions

Amprobe

Amprobe DMIII user manual

Inficon

Inficon TC1000 operating manual

Seaward

Seaward PAC3760 operating instructions