Cosmo LS-R700 User manual

Interface

Installation

Manual

Installation

10

11

1

2

3

4

5

6

7

8

9

Introduction

Interface

Operations

Listed by Purpose

Screen List

Setup

Basic Operations

Troubleshooting

Specifications

Reference

Operation

Manual

Specifications

&

References

Maintenance

Manual

Operation Manual

Installation Manual

Operation Manual

Maintenance Manual

Specifications & References

AIR LEAK TESTER

LS-R700

No.LS-R700-941B1-D

Table of Contents 1

TABLE OF CONTENTS

INSTALLATION MANUAL

1

1Introduction ..................................................................................................................7

1Introduction.........................................................................................................................................8

2Safety Precautions.............................................................................................................................8

3Notes....................................................................................................................................................9

2

2Installation and Setup................................................................................................11

1Unpacking .........................................................................................................................................12

1.1 Accessories ....................................................................................................................................12

1.2 Items to Be Prepared By the Customer.........................................................................................12

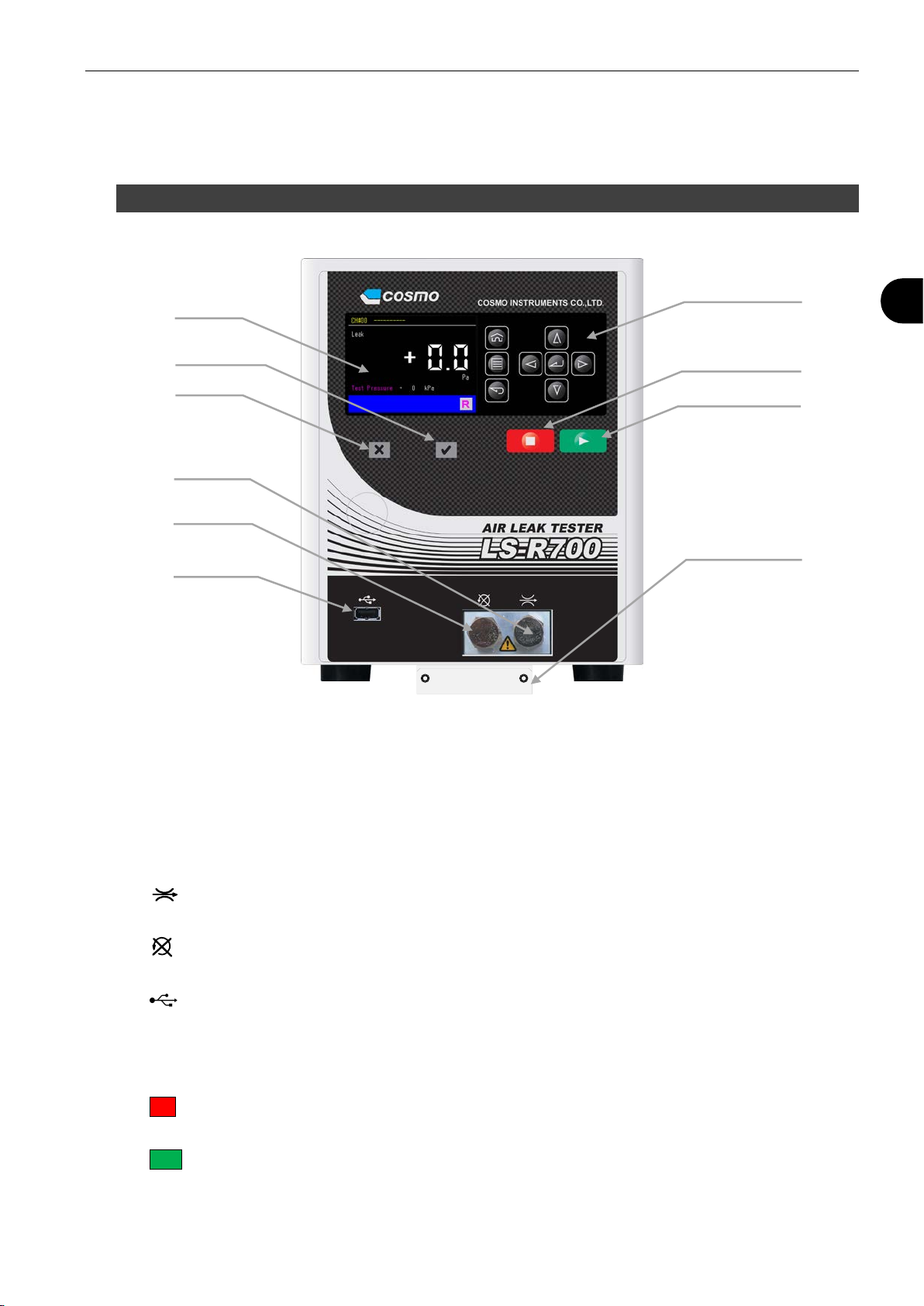

2Part Identifications...........................................................................................................................13

2.1 Front Panel.....................................................................................................................................13

2.2 Rear Panel......................................................................................................................................14

2.3 Operation Keys...............................................................................................................................15

3Installation.........................................................................................................................................16

3.1 Environment of Leak Tester and Leak Test Stand .........................................................................16

3.2 Installation of LS-R700 with Quick Mounting Brackets..................................................................16

3.3 Pneumatic Hookups .......................................................................................................................18

3.4 Tubing for Tested part (Work) and Master .....................................................................................20

3.5 Power Source.................................................................................................................................20

3.6 Control I/O Connector ....................................................................................................................21

4Turning on Power for the First Time..............................................................................................22

3

3Interface ......................................................................................................................23

1Control I/O Port.................................................................................................................................24

1.1 Standard Control I/O Port: Phoenix Contact ...............................................................................24

1.2 Control I/O Port D-SUB Connector (Special Spec.) .................................................................25

1.3 Input Specifications ........................................................................................................................26

1.4 Output Specifications......................................................................................................................26

1.5 Typical PLC Connection.................................................................................................................28

1.6 Channel Code.................................................................................................................................29

1.7 Stage Number Output.....................................................................................................................29

1.8 Signal Timing Charts ......................................................................................................................30

1.9 Checking Wiring with I/O Monitor...................................................................................................31

2RS-232C Serial Interface Port.........................................................................................................32

2.1 RS-232C Interface..........................................................................................................................32

2.2 Interface Cable Wiring Example.....................................................................................................32

2.3 Formats of RS-232C Output...........................................................................................................33

2.4 Data Format....................................................................................................................................33

2.5 Checksum.......................................................................................................................................38

2.6 Printer .............................................................................................................................................38

3USB Port............................................................................................................................................40

Table of Contents

2

OPERATION MANUAL

4

4Basic Touch Screen Operations ...............................................................................41

1Turn On Power................................................................................................................................. 42

2Go to Sub Menus and Items........................................................................................................... 42

3Go Back to the Previous Page....................................................................................................... 42

4Switch Pages ................................................................................................................................... 42

5Settings Lock / Unlock.................................................................................................................... 43

5.1 Lock / Unlock Settings................................................................................................................... 43

5.2 Set a Passcode.............................................................................................................................. 44

6Switch the Operation mode between Remote and Manual ........................................................ 44

7Go to Home Screen......................................................................................................................... 44

8Go to Main Menu.............................................................................................................................. 45

9Settings Operations........................................................................................................................ 45

9.1 Change channels........................................................................................................................... 45

9.2 Select an Option From Multiple Selections................................................................................... 45

9.3 Enter a value.................................................................................................................................. 45

5

5Screen List..................................................................................................................47

1Main Menu........................................................................................................................................ 48

2Measurement Screen Menu............................................................................................................ 48

2.1 Measurement Screens (Remote).................................................................................................. 48

2.2 Measurement Screen Description: Standard (Manual).............................................................. 49

2.3 Measurement Screen Description: Advanced (Manual)............................................................. 50

2.4 Measurement Screen Description: Waveform (Manual)............................................................ 50

3Settings Menu.................................................................................................................................. 51

3.1 Basic Settings................................................................................................................................ 51

3.2 Advanced Setting........................................................................................................................... 52

3.3 Common Settings.......................................................................................................................... 54

3.4 Copy Settings ................................................................................................................................ 55

3.5 Initialize to Default......................................................................................................................... 55

3.6 Backup/Restore............................................................................................................................. 55

3.7 CSV Copy to USB.......................................................................................................................... 55

4System Menu ................................................................................................................................... 56

4.1 System Settings............................................................................................................................. 56

4.2 Data to Store in USB ..................................................................................................................... 57

4.3 Test Data Update Time.................................................................................................................. 57

4.4 System Backup/Restore................................................................................................................ 57

5K(Ve) Menu....................................................................................................................................... 58

5.1 K(Ve) Settings................................................................................................................................ 58

5.2 K(Ve) Automatic Setup .................................................................................................................. 59

5.3 K(Ve) Check................................................................................................................................... 59

6Comp. (Compensation) Menu........................................................................................................ 60

6.1 Mastering Settings......................................................................................................................... 60

6.2 Mastering Display.......................................................................................................................... 61

6.3 Drift Comp Settings ....................................................................................................................... 61

6.4 Drift Comp Display......................................................................................................................... 61

6.5 Fixed Comp Settings..................................................................................................................... 61

7Analysis Menu ................................................................................................................................. 62

7.1 Counter .......................................................................................................................................... 62

7.2 X-Chart/List.................................................................................................................................... 62

8Maint. (Maintenance) Menu ............................................................................................................ 62

8.1 Battery Replacement..................................................................................................................... 63

Table of Contents 3

8.2 Error Log.........................................................................................................................................63

8.3 I/O Monitor......................................................................................................................................63

8.4 Inspection .......................................................................................................................................63

8.5 Calibration Reminder......................................................................................................................64

8.6 Inspection Items .............................................................................................................................64

9Language Menu................................................................................................................................64

10 Troubleshooting Menu.....................................................................................................................64

10.1 Error List .........................................................................................................................................65

10.2 Large Leak List...............................................................................................................................65

10.3 Frequent (+) Fails...........................................................................................................................65

10.4 Frequent (-) Fails............................................................................................................................65

11 Misc. (Miscellaneous) Menu............................................................................................................65

11.1 System Version...............................................................................................................................65

6

6Setup ...........................................................................................................................67

1Initial Setups .....................................................................................................................................68

1.1 Operation Mode when the power turns on.....................................................................................68

1.2 Home Screen..................................................................................................................................68

1.3 Set Date..........................................................................................................................................68

1.4 Set Time..........................................................................................................................................68

2Perform a Simple Air Leak Test......................................................................................................69

2.1 Test Parameter Entry......................................................................................................................69

2.2 Timer...............................................................................................................................................69

2.3 Test Pressure..................................................................................................................................69

2.4 Leak Limit .......................................................................................................................................70

2.5 K(Ve)...............................................................................................................................................70

3Flow for Initial Adjustment..............................................................................................................71

4Initial Test Parameter Backup.........................................................................................................73

4.1 System Backup...............................................................................................................................73

5Notation of Air Leak Tests stages and Limits...............................................................................74

6Air Leak Test Result List .................................................................................................................74

7

7Operations Listed By Purposes................................................................................75

1Display Measured Differential Pressure in a Leak Rate Unit......................................................76

1.1 K(Ve) Automatic Setup...................................................................................................................76

1.2 Manual Entry of K(Ve) Value (Leak Coefficient) ............................................................................78

2Reducing Cycle Time.......................................................................................................................78

2.1 Setting Mastering Compensation...................................................................................................78

2.2 Bypass Charge (Option).................................................................................................................80

3Enhance Test Result Reliability......................................................................................................81

3.1 Setting Mastering Compensation...................................................................................................81

3.2 Setting Drift Compensation ............................................................................................................81

3.3 Setting Fixed Compensation..........................................................................................................82

3.4 Use Mastering Comp with Drift Compensation..............................................................................82

3.5 Setting Noise Reduction.................................................................................................................82

3.6 Setting Exhaust Interference Prevention.......................................................................................83

4Enhance Test Reliability..................................................................................................................84

4.1 Setting Idle ΔP Check (Self Check) ...............................................................................................84

5Managing Data on Computer..........................................................................................................84

5.1 Program RS-232C Settings............................................................................................................84

5.2 Collecting Data in USB Memory.....................................................................................................85

5.3 Copy Test Parameters to UBS Memory.........................................................................................87

6Programming Parameters for the Similar Tested Parts...............................................................89

6.1 Copy Settings .................................................................................................................................89

6.2 Initialize to Default..........................................................................................................................89

Table of Contents

4

7Analyze Measured Data .................................................................................................................. 90

7.1 Use X-Chart................................................................................................................................... 90

8Backup and Restore........................................................................................................................ 91

8.1 Restoring Test Parameters............................................................................................................ 91

8.2 Preparing for Replacing LS-R700 ................................................................................................. 92

9Other Settings.................................................................................................................................. 93

9.1 Name Channels............................................................................................................................. 93

10 Other Features................................................................................................................................. 94

10.1 Backlight Auto-off........................................................................................................................... 94

10.2 Select a Language......................................................................................................................... 94

11 For Maintaining Reliable Test Results .......................................................................................... 94

11.1 Daily Inspection Points.................................................................................................................. 94

11.2 K(Ve) Check................................................................................................................................... 95

12 Updating Software........................................................................................................................... 95

Table of Contents 5

MAINTENANCE MANUAL

8

8Maintenance ...............................................................................................................97

1Daily Inspection Points....................................................................................................................98

2Monthly Inspection Points ..............................................................................................................98

3Annual Inspection Points................................................................................................................99

4Features for Maintenance................................................................................................................99

4.1 K(Ve) Check....................................................................................................................................99

4.2 No-Leak Check............................................................................................................................ 100

4.3 DPS Offset Adjustment................................................................................................................ 100

4.4 DPS Span Check......................................................................................................................... 101

4.5 PS Offset Adjustment .................................................................................................................. 101

4.6 PS Span Check............................................................................................................................ 101

5Battery Replacement .................................................................................................................... 102

5.1 Battery Replacement Procedure................................................................................................. 102

5.2 About ERROR 51: Lo Battery SRAM.......................................................................................... 104

5.3 How to Troubleshoot ERROR 51................................................................................................ 105

5.4 If ERROR 51 Occurs Right After Replacing Battery................................................................... 105

6Initializing Memory........................................................................................................................ 105

9

9Troubleshooting.......................................................................................................107

1When an Error Occurred .............................................................................................................. 108

2Error List ........................................................................................................................................ 108

3Error Messages and Treatments ................................................................................................. 109

3.1 ERROR 1 PS Offset Error ........................................................................................................ 109

3.2 ERROR 2 PS Out of Range...................................................................................................... 109

3.3 ERROR 3 Test Pressure Error...................................................................................................110

3.4 ERROR 4 BAL1 Lost Test Pressure..........................................................................................111

3.5 ERROR 10 DPS Offset Error.....................................................................................................111

3.6 ERROR 11 Air Operated Valve Error 1 .....................................................................................112

3.7 ERROR 12 Air Operated Valve Error 2.....................................................................................113

3.8 ERROR 14 Air Operated Valve Error 4.....................................................................................114

3.9 ERROR 15 Air Operated Valve Error 5.....................................................................................115

3.10 ERROR 16 Air Operated Valve Error 6.....................................................................................116

3.11 ERROR 21 DPS Stopped Oscillating........................................................................................117

3.12 ERROR 22 Stop Valves Closed.................................................................................................117

3.13 ERROR 23 Mastering Error.......................................................................................................118

3.14 ERROR 24 K(Ve) Value Out of Range......................................................................................119

3.15 ERROR 25 Leak Limit Out of Range.........................................................................................119

3.16 ERROR 51~ERROR 61 System Errors..................................................................................... 120

4Large Leak List.............................................................................................................................. 121

4.1 Output Signal Timing Charts for Large Leak Timing................................................................... 122

5Frequent (+) Fails.......................................................................................................................... 124

6Frequent (-) Fails........................................................................................................................... 126

Table of Contents

6

SPECIFICATIONS/REFERENCE

1

10

0Specifications...........................................................................................................127

1Primary Specifications.................................................................................................................. 128

2Model Classifications.................................................................................................................... 129

1

11

1Reference..................................................................................................................131

1Leak Testing Overview.................................................................................................................. 132

1.1 Stage Summary........................................................................................................................... 132

1.2 Internal Pressure Changes of the WORK And MASTER ........................................................... 133

1.3 Leak Rate Conversion................................................................................................................. 133

2External Appearance..................................................................................................................... 135

3Pneumatic Circuit.......................................................................................................................... 136

4Pressure Unit Conversion Table.................................................................................................. 138

5Flow Unit Conversion Table......................................................................................................... 138

6Leak Unit Description ................................................................................................................... 138

7CE Marking..................................................................................................................................... 139

8Information to Users (FCC Rules)............................................................................................... 139

9Common Peripherals.................................................................................................................... 140

9.1 External Exhaust Valve (Separately Sold).................................................................................. 140

9.2 Bypass Circuit Unit...................................................................................................................... 140

1 Introduction 7

1

1

1

INTRODUCTION

1Introduction..............................................................................................................8

2Safety Precautions..................................................................................................8

3Notes.........................................................................................................................9

INSTALLATION MANUAL

8 1 Introduction

1

1

1

I

In

nt

tr

ro

od

du

uc

ct

ti

io

on

n

Thank you for purchasing the Air Leak Tester LS-R700 Series.

LS-R700 is a differential pressure decay air leak tester designed for industrial use.

This manual provides installation, operating and maintenance instructions for LS-R700 Series.

Read this operation manual carefully before using this product, and retain it for future reference.

2

2

S

Sa

af

fe

et

ty

y

P

Pr

re

ec

ca

au

ut

ti

io

on

ns

s

This section provides how to use the product safely and avoid injuries to the operators or damages to your assets. Please

handle the product according to these instructions and observe the following symbols that appear in this manual:

[Explanations of the signs]

Symbol Explanation

Failure to take or avoid a specific action could result in death or serious physical harm to the

user.

Failure to take or avoid a specific action could result in minor physical harm to the user, or in

property damage.

[Explanations of the symbols]

ΔThis symbol denotes a warning/caution to alert the users. Aspecific explanation of the potential danger and what must be

done to avoid it follows. (Example: Electrical shock hazard)

1) Ground the product before plugging it into a power

source. Neglecting it could result in electrical shock

hazards. Do not ground the product to a gas pipe. It

could result in fires or electrical shock hazards.

2) If the metal part of the power plug or surrounding area

is dusty, clean it thoroughly with a dry cloth.

Neglecting it could result in fires or electrical shock

hazards.

3) Do not use voltages other than those for which the

product is rated. It could result in fires or electrical

shock hazards.

4) If the product has been dropped or damaged, switch it

off and disconnect the power plug from the outlet.

Neglecting it could result in fires or electrical shock

hazards.

5) Do not apply air pressure in excess of the pressure

rating of the product. Excessive pressure input could

cause major component failure and/or injury.

6) Should foreign matter such as water or oil get inside

the product, switch off the power immediately and

unplug it from the outlet. Neglecting it could result in

fires or electrical shock hazards. Use extra caution

when installing the product in an environment where

water or oil exists nearby.

7) This product is not customer-serviceable. Customer

servicing could result in fires or electrical shock

hazards.

8) Replace a fuse after turning off the power of the main

unit and disconnecting the power plug from the outlet.

Use a fuse equivalent to the current one for

replacement. Using a different fuse could result in

fires or electrical shock hazards.

9) Discontinue using the product immediately under the

following circumstances:

• The product smokes.

• The product emits abnormal noises.

• The product has developed problems not

covered in the Operation Manual.

• The product cannot be operated as indicated

in the Operation Manual.

To avoid electrical shock hazards or physical

harm, disconnect the power cable and remove

the pressure source from the instrument. Not

doing so could result in fires or electrical shock

hazards.

WARNING

CAUTION

WARNING

1 Introduction 9

1

1) Do not use the product in places that are damp, that

are exposed to direct sunlight or that are outside the

temperature range of 5°C to 40°C. Using the product

in such environments could result in malfunctions or

failures.

2) To avoid damage to the power cable, which could

result in fires or electrical shock hazards, observe

these precautions:

• Do not damage, modify or apply undue force

to the power cable.

• Before servicing the product, disconnect the

power plug from the outlet.

• Do not handle the power plug with wet hands.

• When disconnecting the power plug, do not

pull on the power cable.

3) Mount the product securely on a structure with enough

load capacity. Do not install the product on the

insecure foundation or in places with vibration to avoid

overturns and injuries.

4) Ensure the correct cable connection. Incorrectly

connected cables could result in damage to the

product and surrounding hardware.

5) Do not step on top of the product or place containers

filled with liquids, oil or soapy water, or the like on it.

Spills may result, causing physical harm, electrical

shock hazard, rust or other damage.

6) Should the LCD become damaged, avoid skin contact

with the liquid contained inside. It could cause

inflammation. Wash with running water in case of

skin contact.

7) Do not disassemble the product other than replacing

the designated consumable parts. The product could

malfunction, resulting in physical harm or electrical

shock hazards..

8) Do not install or remove the tubing with the product

connected to an air pressure source. It could result in

physical harm.

Wear a safety goggle to protect your eyes.

9) When a leak test has been completed, unclamp the

tested part only after all pressure has been released

from the product. Residual pressure could result in

physical harm.

10) Hold its bottom to keep it from dropping when

transferring the product. Do not lift the product by

gripping its components on the rear panel such as the

stop valves.

11) Put on steel-toe boots when transferring the product

for shipping, installation, dismantling. Neglecting it

could result in physical harm by dropping the product..

12) Wipe out the product lightly with a dry and soft cloth for

maintenance. When the product is with heavy dirt,

dilute the neutral detergent with water, soak the cloth in

the detergent, squeeze the cloth, and wipe the dirt out.

Do not use organic solvent.

13) Handle the product according to the instructions in this

operation manual or the protection feature equipped

with the product will be compromised.

3

3

N

No

ot

te

es

s

1) The information in this document is subject to change without notice to allow for performance or feature upgrades.

2) This document may not be reproduced in whole or in part without prior approval of the publisher.

3) We are not responsible for the items tested using the product or for any consequences resulting from the tests.

4) This product comes with the self-check feature to detect certain improper settings and/or operations, and any

malfunctions of components to minimize incorrect pass/fail judgment. However the scope of monitoring by

self-checking, however, is limited.

5) This product is a differential pressure decay air leak tester adopting the master comparison method. Please note that

when using the product in an inappropriate environment, there are risks of incorrect fail judgments due to various effect

such as leakage from the sealing fixture, part deformation, temperature changes in the part and/or fixture.

6) The user is encouraged to consult your local Cosmo representative directly for any questions regarding the use of this

product.

CAUTION

2 Installation and Setup 11

2

2

2

INSTALLATION AND SETUP

1Unpacking ..............................................................................................................12

1.1 Accessories.................................................................................................................12

1.2 Items to Be Prepared By the Customer.......................................................................12

2Part Identifications................................................................................................13

2.1 Front Panel..................................................................................................................13

2.2 Rear Panel...................................................................................................................14

2.3 Operation Keys............................................................................................................15

3Installation..............................................................................................................16

3.1 Environment of Leak Tester and Leak Test Stand........................................................16

3.2 Installation of LS-R700 with Quick Mounting Brackets ................................................16

3.3 Pneumatic Hookups.....................................................................................................18

3.4 Tubing for Tested part (Work) and Master ...................................................................20

3.5 Power Source..............................................................................................................20

3.6 Control I/O Connector..................................................................................................21

4Turning on Power for the First Time....................................................................22

12 2 Installation and Setup

2

1

1

U

Un

np

pa

ac

ck

ki

in

ng

g

When you receive the LS-R700, unpack and check for the transport damage.

1.1 Accessories

Power cord 1

Control I/O connector: MSTB 2,5 / 16-STF-5,08 (Phoenix Contact) 2

Inspection record / Traceability related documents 1 each

Operation manual CD

(Installation manual / Operation manual / Maintenance manual / Specifications & References) 1

1.2 Items to Be Prepared By the Customer

For installation:

For mounting LS-R700 with Quick mounting bracket: M4 screws (4)

Tube for pneumatic connection

Tube for connecting the tested part and reference master to LS-R700

For external device connection:

Control I/O cable

DCV24 Power source

For storing leak test data and/or test parameters:

USB memory

Computer

RS-232C serial communication cable

2 Installation and Setup 13

2

2

2

P

Pa

ar

rt

t

I

Id

de

en

nt

ti

if

fi

ic

ca

at

ti

io

on

ns

s

2.1 Front Panel

A Color LCD:

B Pass lamp:

Lights when the test result is “Pass”.

C Fail lamp:

Lights when the test result is “Fail”.

D (Calibration port):

Connect a Leak Master to this port for daily maintenance.

E (Maintenance port):

Do not remove the plug when

F (USB port):

Test Data, Waveform Data and Mastering Data are output in CVS format.

Software can be upgraded using this port.

G Operation keys

H ■key:

Used to stop a measurement in manual mode.

I ►key:

Used to start a measurement in manual mode.

J Quick Mounting Bracket:

Using this bracket, LS-R700 can be installed and removed easily with two M4 screws.

B

D

H

G

A

C

E

F

J

I

14 2 Installation and Setup

2

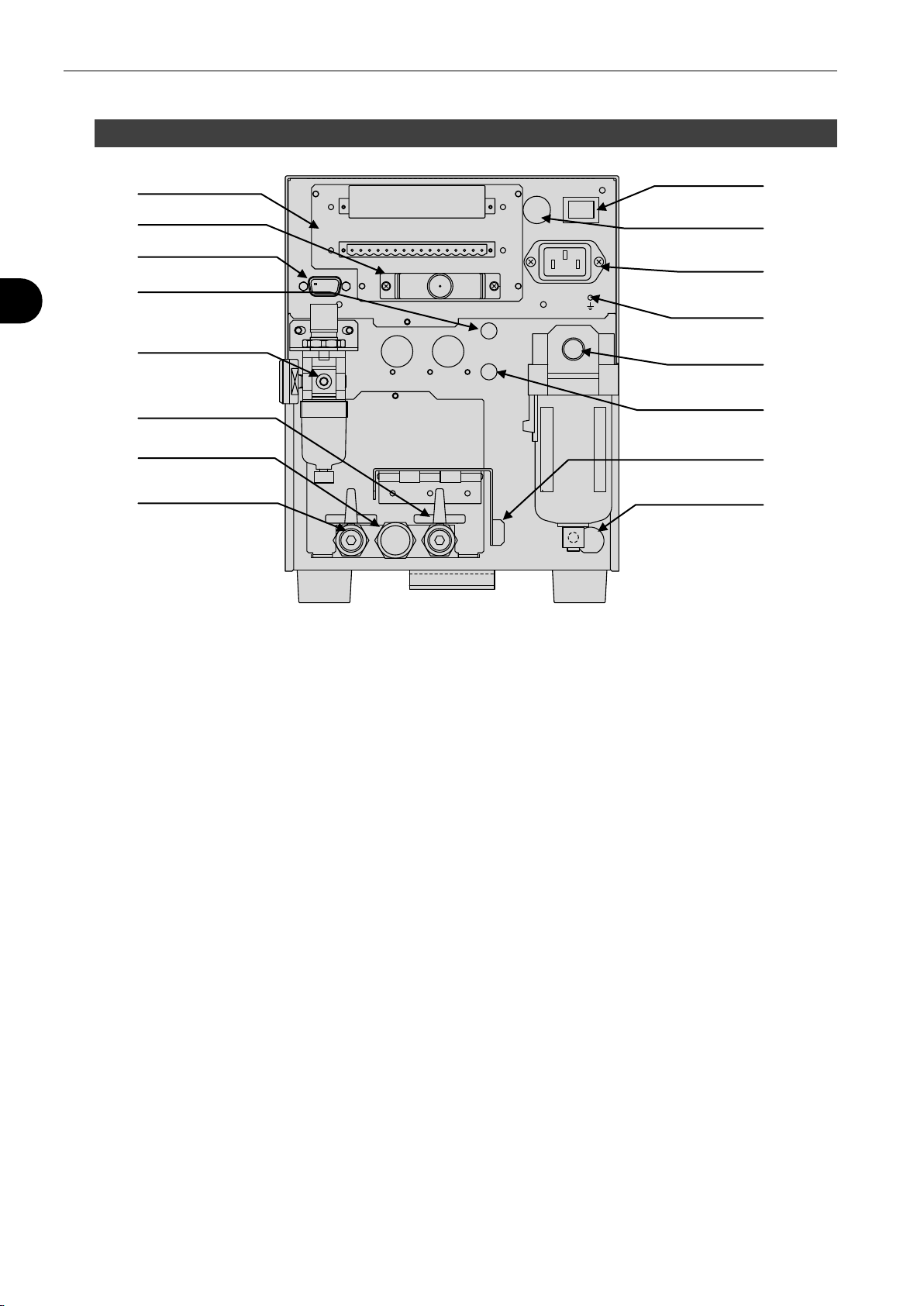

2.2 Rear Panel

A CONTROL I/O (Phoenix contact):

External device is connected to control

LS-R700 externally.

Upper: Input ALower: Output B

B CONTROL I/O (Special specification):

D-sub connector

C COM 1:

Serial communication port.

Data is output in the designated format.

(RS-232C 9-pin male)

D G3:

Pilot pressure port for External Exhaust valve

(Push-to-connect fitting 4mm)

E PILOT PRESSURE:

Pilot pressure port

Connect clean air regulated from 400 to 700

kPa

F MASTER:

MASTER-side stop valve.

A port to connect a reference (Master).

Leave the valve opened except for

maintenance.

G EXHAUST:

Silencer for exhaust

Air is exhausted from this port after a leak test.

H WORK:

WORK-side stop valve

A port to connect a tested part (Work).

Leave the valve opened except for

maintenance.

I POWER: Power switch

J FUSE: Fuse (T2.5A 250V)

K 100 - 240 VAC~:Power inlet

L FG: Grounding

M TEST PRESSURE:

Test pressure port

(Push-to-connect fitting 4mm)

N BYPASS FILL (Option):

Pilot pressure port for fill valve for Bypass

circuit unit

O Stop Valve Monitoring Switch with a valve

cover (Option):

When the valve(s) is open, the cover won’t

close and the switch is not pressed.

This is to prevent leak testing with the stop

valves closed.

P EP REGULATOR (Option):

Electro-Pneumatic regulator connector

WORK

COSMO INSTURUMENTS CO., LTD

MADE IN JAPAN

MASTEREXHAUST

G3

T2.5A–250V

100-240VAC~50/60Hz

100VA MAX.1ph

POWER

COM1

BYPASS

FILL

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

2 Installation 15

2

2.3 Operation Keys

A Home key:Used to open a measurement screen programmed to be the Home screen.

B Menu key:Used to open the main menu

C Back key:Used to back to the previous screen.

D Enter key:Used to complete the selection or numeric entry.

E Cursor keys: Used to move the cursor within a page or program numbers.

A

B

C

D

E

16 2 Installation

2

3

3

I

In

ns

st

ta

al

ll

la

at

ti

io

on

n

3.1 Environment of Leak Tester and Leak Test Stand

Location of Leak Tester to Avoid Temperature Fluctuation

• Avoid direct sunlight.

• Avoid direct wind due to doors opening and closing.

• Avoid direct wind from heating and cooling vents.

When above cannot be avoided, use a curtain. However, it’s not good to cover the whole test stand area

completely because of temperature fluctuations that could occur in the tested parts. Therefore, partial

covering will give better result.

Effects of Plant Temperature on Leak Testing

• Do not put the leak test station right after heating, cooling welding or washing processes.

• If the temperature of the floor and test bench are different, and the tested parts are taken from the floor,

heat transfer will take place between the parts and the fixture. This will cause an error. The tested

parts should be stored at the same level as the test bench in order to keep the temperature the same.

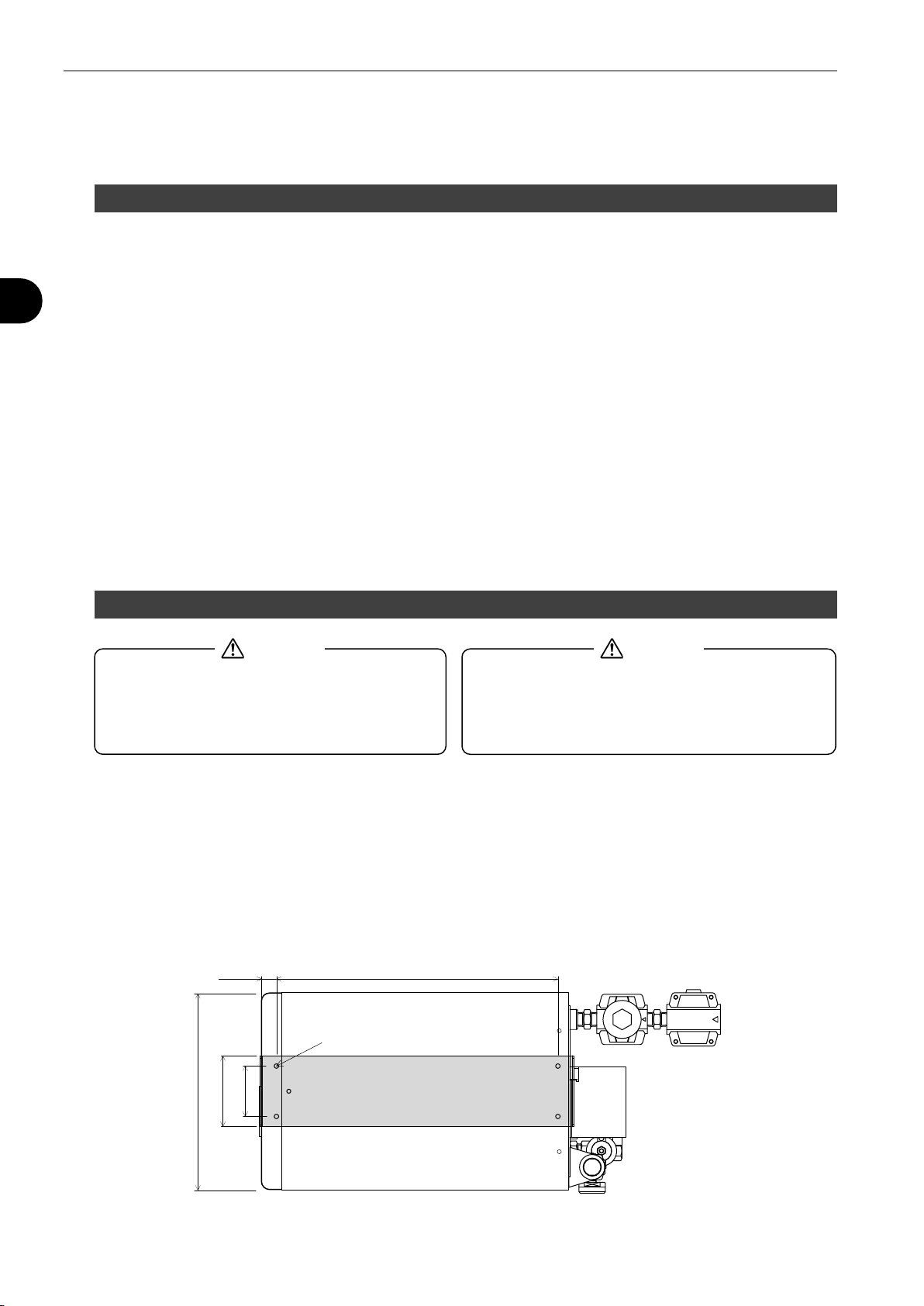

3.2 Installation of LS-R700 with Quick Mounting Brackets

LS-R700 comes with a mounting bracket that can be install/remove from the base with two screws.

Mounting Base

This base is loosely attached to the bottom of LS-R700. Remove it from the tester and mount it on the leak

test stand where LS-R700 is to be mounted with four M4 screws. The mounting surface has to be flat and

smooth.

Mount the mounting base on the test bench as shown below. M4 screws are not enclosed with LS-R700.

Hold its bottom to keep it from dropping when

transferring the product. Do not lift the product by

gripping its components on the rear panel such as

the stop valves.

CAUTION

Mount the product securely on a structure with enough

load capacity. Do not install the product on the insecure

foundation or in places with vibration to avoid overturns

and injuries.

CAUTION

Mounting Base

Top of LS-R700

50

70

17.8 275

195

Φ4.5 mounting holes (4)

Front

side Rear

side

2 Installation 17

2

How to Mount

Two mounting brackets are attached to the bottom of the LS-R700, A in front and B in back.

Mount as the following procedure:

Place the LS-R700 with the

Brackets Aand Battached a

little toward the front of where

the LS-R700 is to be

mounted.

Insert the bracket B to the rear

latch of the mounting base

while lifting the front of the

LS-R700.

Lower the LS-R700 where the

Bracket A gets behind the

front latch of the mounting

base and align the screw

holes.

Mount the LS-R700 with two

M4 screws.

Mount the “Mounting Base” on

a leak test stand.

Mounting Bracket A Mounting Bracket B

Mounting Base

18 2 Installation

2

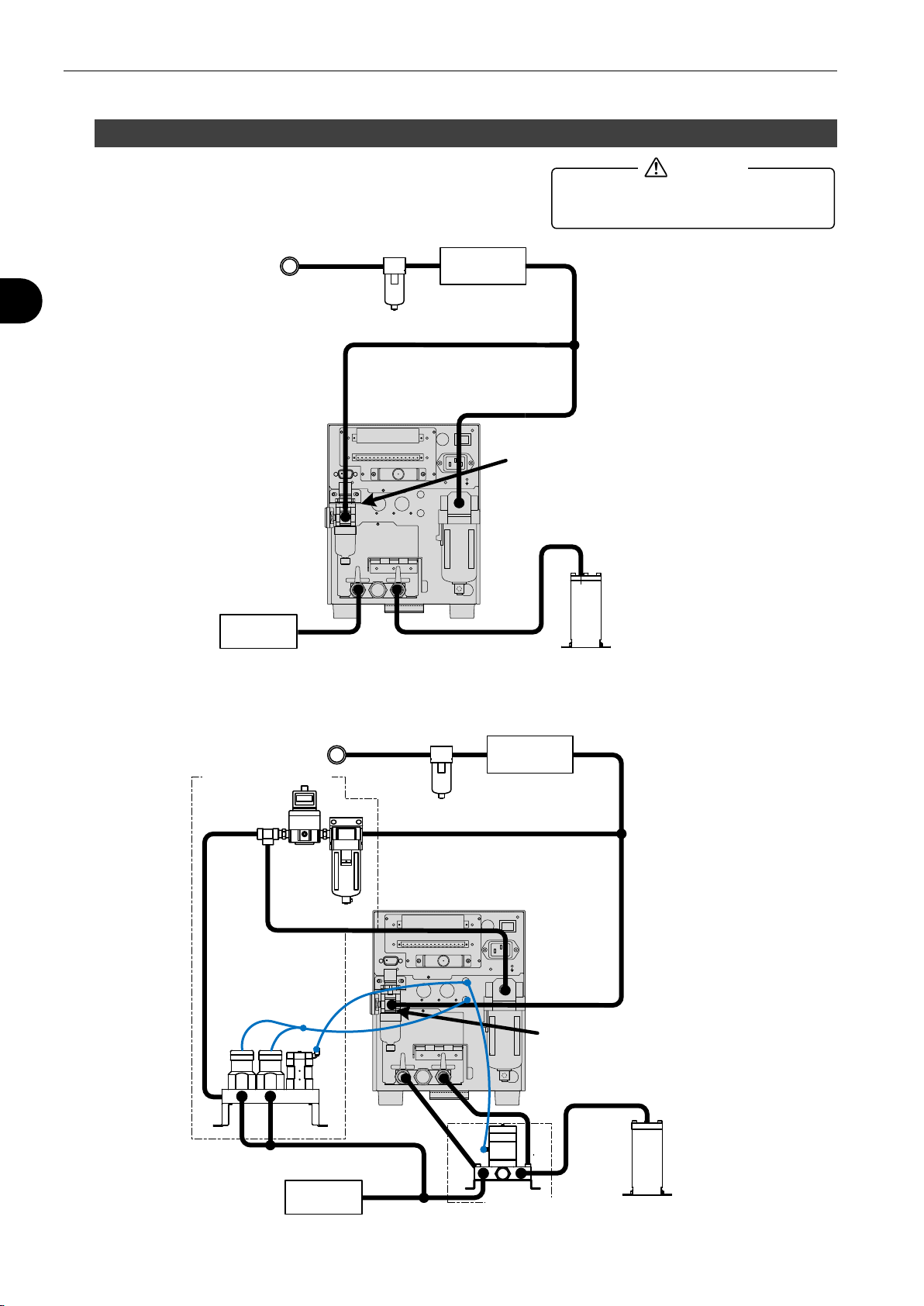

3.3 Pneumatic Hookups

Standard Connection Example

Optional Equipment Connection

WORK

COSMO INSTURUMENTS CO., LTD

MADE IN JAPAN

MASTEREXHAUST

G3

T2.5A–250V

100-240VAC~50/60Hz

100VA MAX.1ph

POWER

COM1

BYPASS

FILL

Tested Part

Test Pressure

Air Dryer

Drain

Pilot pressure

Regulated between 400 and 700kPa.

Master Chamber

(Sold Separately)

Be sure to shut off the pressure source

before connection/disconnection.

CAUTION

WORK

COSMO INSTURUMENTS CO., LTD

MADE IN JAPAN

MASTEREXHAUST

G3

T2.5A–250V

100-240VAC~50/60Hz

100VA MAX.1ph

POWER

COM1

BYPASS

FILL

Air Dryer

Test Pressure

Drain

Bypass Circuit Unit

Pilot pressure

Regulated between 400 and 700kPa.

Tested Part External Exhaust Vavle

G3-ME

Master Chamber

(Sold Separately)

Table of contents

Other Cosmo Test Equipment manuals