Ecom EN2-F User manual

Version 1.9.2

Operating Instructions

Page 2

Page 3

Table of Contents Page

EN2F Design & How It Works

i. Important Tips 4

1. Instrument Design 6

2. Accessories 7

3. Remote display (ECOM-R) 8

4. Gas Cooler 10

5. Power Supply 11

6. Data Logging onto Memory Card 11

Testing Emissions with the EN2F

7. Analyzer startup 13

7.1 Carrying case & cooler 13

7.2 Sample line & probe 13

7.3 Analyzer startup 14

8. Gas Analysis

8.1. Gas analysis display screen 15

8.2 Inserting the probe 16

8.3 Calculations: CO2, Efficiency, Losses, Excess Air, Dew Point 17

8.4. Taking a measurement : Ramp-up, Measure, Purge 17

8.5. Printing 18

8.6 O2 Correction/Reference O2 18

9. Draft/Pressure 19

10. Soot test 19

11. Averaging Tests 20

Settings, Service Tips, and Technical Data

12. Adjustments 21

13. Control 25

14. Data Processing 26

15. Delta-T Measurement (option) 27

16. Maintenance Tips 28

17. Technical Data 31

18. FAQ 32

19. Calibration Procedure 34

20. Memory Card Data 36

Page 4

i. Important Tips

The ecom-EN2-F meets the requirements for

CTM 030, CTM 034, and ASTM D6522.

In order to get correct measurement values:

- allow 1 min. for auto-zero in fresh air

- allow at least 2 min. for stable readings before

taking measurement

The following substances impair the instrment´s

operation:

- cleaning agents

- degreasers

- wax polishes

- adhesives

- anything containing formaldehyde

Adjustments at burners and boilers

should be made only by specialists

who are familiar with these installations.

1. Charge the internal battery regularly.

(an unused analyser should be charged at least 1 x per month)!

2. Never store the unit with a discharged battery!

To control for thermal drift, start the analyzer and let it

acclimate to ambient temperature for 15-30 minutes,

then restart the analyzer before testing.

Page 5

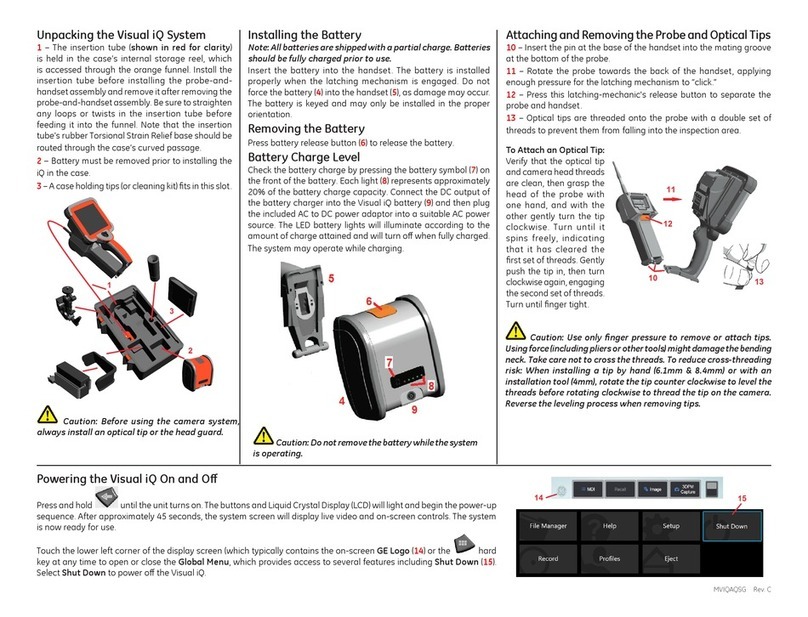

i. Important Tips (continued)

Before begining with measurements, please set up

condensation trap as follows:

- pull knob out to unlock

- swing the condensation trap a full

90deg up until it locks into place

- Unblocking pin must be

engaged before pump will start

Do not block fresh air opening

for fresh air pump!

Fresh air opening

Page 6

1. Instrument Design

Connection air

temperature

Slot for multi-

media card

Connections

Pa pressure

sensor

Connection

gas

temperature

Connection

via USB

Connection

gas

Connection

draft

Connection

pressure

Connec

tion

AUX

Integral

printer

Sensors com-

partment

Graphic

display

Optical flow

control

Battery com-

partment

Peltier cooler w/ con-

densate drain and

particulate filter

Bluetooth

Antenna

AC

connection

Charging

indicator

light

Page 7

Keyboard

2. Accessories

ESC key

(quit/

escape menu)

In the input mode, the keys are

used for numerical inputs

Enter key

(confirm

selection)

Cursor keys

(Up/Down/Right/

Left/Scroll)

Save snapshot to

internal memory

Access printing

menus (press F2

to quick print)

ON / OFF

key

Info key

(access to

control menu)

F1: Standby –pump shuts off

F2: Quick print

F3: CO purge pump on/off

F4: Edit line items on screen

Page 8

3. Remote display (ECOM-R)

Connection with ECOM analyzer

(the ecom-R connects with only 1 analyzer at a time)

Unpair Bluetooth Connection

- Hold the red key (approx. 5 sec.) until “Unpair:”appears

- When “Unpair: OK”is shown, the connection is deleted

Analyzer must have Bluetooth option!

(wireless range is approx. 10 m)

Setup Bluetooth Connection

-Ensure there is only one instrument with Bluetooth near the ecom-R

- Turn on the analyzer

-Go to Adjustments Internal Bluetooth and select Protocol-

Enhanced

-Turn on ecom-R & wait while the Bluetooth connection is made

automatically

*Change display:

Choose line

Adjust line

Set adjustment

Exit adjustment

Change display* (see below)

Start printout

(4 displays)

Choose display screen

Switch on/off ecom-R

(hold approx. 1 sec.)

READY = Connection is active

CALIB = Analyzer in calibration phase

WAIT = Searching for connection

Battery voltage

Page 9

3. Remote display (continued)

Changing out the batteries

-open battery compartment door

-take out used batteries

-put in new batteries (with correct polarity)

-close battery compartment door

Important: Always dispose of used batteries in official recycling con-

tainers only (e.g. in battery shops).

Model with integrated air temperature sensor

If there is no air temperature sensor connected at the ecom-

EN2, then the air temperature sensor of the ecom-R supplies the

measured values.

Battery compartment

Batteries 1.5 V AA (2)

Unlocking

Air temperature sensor

Page 10

4. Gas Cooler

Exhaust gas with a temperature above the steam dew point (35 -

65 °C) is introduced into a long spiralling gas path with a surface

coated metal body with good thermal conductivity. The gas radiates

its heat to this metal body. A Peltier element (semi-conductor cooling

element) powered by a continuous current is thermally connected

with this body and with a second metal body with cooling ribs and

ventilation slots.

The flow thru the Peltier element creates a heat transfer from

WARM to COLD, drains the heat of the metal body flown by gas and

conveys it to the outer cooling body. This heat is conveyed to the

surrounding air with the aid of a fan.

The condensation formed by the heat loss of the gas drops in a re-

ceptacle and is pumped out automatically via a peristaltic pump.

On battery operation alone, the Peltier cooler can be switched off

to save battery power. In the Gas Analysis menu press <Enter>,

select Peltier I/0 and press <Enter>. To switch the Peltier cooler

back on, repeat these steps.

Fan

WARM

COLD

Peltier

element

Gas

outlet

Gas inlet

Level

monitoring

Condensate

evacuation

The Peltier cooler consumes a lot of

power so the cooling efficiency

may be reduced if the analyzer is

running on battery power alone!

Page 11

5. Power Supply

The EN2-F is recommended to be powered by AC power when

available. The analyzer can also be powered using the internal bat-

tery for a while (6 V; 3.8 Ah). The battery should be recharged when

the analyzer starts beeping or an alert message appears. The bat-

tery life can be checked by looking at the voltage indication on the

display in the Control menu. The low battery warning is activated

when the value “Batt” falls below 5.7 V. When the analyser is con-

nected to AC power, the voltage will read as dashes “—.—“ Unplug

the power cord to read the battery voltage.

When the battery voltage falls below 5.4 V, the instrument must

be connected to AC power to retain power.

6. Data Logging onto Memory Card

The multi-media card enables the storage of data records on a re-

movable SD card. The data fields on the csv file are listed at the end

of this manual. The following conditions must be fulfilled for using a

multi-media card:

- minimal card volume 32 MB - max. 2 GB

- card formatted on 16 bit FAT

Insert Memory Card

Insert the multi-media card as shown.

Take care that the card inserts smoothly

and that you do not jam it in.

Used batteries can be brought to recycling stations or

public waste disposal companies!

Never pull out cards during data recording

as this may cause a loss of data and/or

damage to the memory card itself.

Page 12

6. Data Logging onto Memory Card (continued)

Memory card must be 32MB to 2GB!

To log data using the memory card, follow these steps:

-insert the memory card –on the main menu a new option “Data

processing” will appear

-go to Data Processing –press enter

-scroll down to Datalogger –press enter

-scroll to Save to MMC –press enter

-using the numerical buttons, enter the data logging interval in

seconds (min 1 sec, max 255 sec) –press enter

(i.e. 15 sec will give you 4 data points per minute)

-scroll to Datalogger –press enter –press F1 to confirm

-a blinking disk will appear in the upper right corner indicating that

the analyzer is currently logging data

-go back to Gas Analysis to start the pump (if not already running)

and view the data

-when you are finished with your test, go back to the Datalogger

screen (ESC - Data processing –Datalogger)

-go to Datalogger –press enter –press F1 to confirm to stop the test

The data file will be saved as a csv file (J2KDL-00.csv). Take out the

memory card and insert into a computer to view in Excel. Edit the

spreadsheet as necessary. The data fields on the csv file are listed

at the end of this manual.

In addition to data logger recordings the data could be transferred

online with USB cable (USB Driver / 1200 Baud / Protocol DAS) to

the software “DASNT”. The software “DASNT” and the USB Driver

are available free of charge from www.ecomusa.com.

Page 13

7. Analyzer startup

7.1 Carrying case & cooler

When opening the case, make

sure to pull out and up on the

two tabs on the front.

After the case is opened, unlock

the cooler by pulling out on the

knob and swinging the cooler

90deg upward. The cooler must

be unlocked before the pump

engages.

7.2 Sample line & probe

Connect gas sample line, pressure line, and thermocouple as pictured:

The fittings are sized so that you cannot switch the gas and pressure lines.

Page 14

7.3 Analyzer startup

Press the red power button to turn on

the analyzer. The main menu is dis-

played with 6 (or 7) menu options:

- Gas analysis : Perform gas analysis

(see Chapter 8)

- Averaging : Perform averaging test

(see Chapter 11)

- Soot test : Perform soot test/smoke dot test

(see Chapter 10)

- Data processing : Save snapshots to internal memory or perform

data logging (only displays if MM card is inserted)

(see Chapters 6 & 14)

- Adjustments : Modify instrument settings

(see Chapter 12)

- Control : Check operation state of instrument

(see Chapter 13)

- Diagnostics : Only used with ECOM AK tool

To perform measurements, select Gas analysis and confirm with

<Enter>. The instruments starts a 1- minute auto-zero phase and the

fuel types selection list is displayed. The following fuel types are

available:

Natural gas Propane

Butane Number 2 oil

Number 4 oil Number 6 oil

Coal Wood

North sea gas Diesel oil

Fuel type

Natural gas

CO2max A1 B

11.7 0.37 0.009

Select:

Gas analysis

Averaging

Soot Test

Data Processing

Adjustments

Control

The probe must be in fresh air

when you start the analyzer!

Page 15

8. Gas Analysis

8.1. Gas analysis display screen

After the 1-minute auto-zero phase, the instrument switches over to

the measurement mode. The gas measurement values can be

viewed on 4 display pages. Press up/down to scroll between the

pages.

Note: To view readings with O2 correction, see Chapter 8.6 for in-

structions on how to change the units to O2-corrected values.

Pressing <F1> goes to “Standby“ mode which turns the pump off. If

you want to change the F1 key, go to Adjustments->Internal->F1

Hotkey. You can set the F1 key to: Soot test, Data processing, View

memory, Display values, Fuel type, Efficiency (K), Internal, Adjust-

ments.

Press <F2> to print out the values simultaneously to their recording

in the intermediate memory.

Press <F3> to start the CO purge pump. This dashes out the CO

reading on the display and introduces fresh air to the CO sensor to

protect it from over ranging Note: The CO purge pump automati-

cally activates when the CO ppm limit is exceeded –usually set

at 4000ppm.

Standby

<F1>

Edit line

items on

display

<F4>

Print

values

<F2>

CO purge

pump on/off

<F3>

Peltier

cooler

ON/OFF

O2 3.2

%

CO2

13.1 %

T.Gas

184 °C

T.Air 20

°C

BImSchV

Page 16

8.1. Gas analysis display screen (continued)

Pressing <F4> goes to “Edit” mode which allows the user to change

the line items on the display screen.

In “Edit” mode, the values on the screen can be changed to what the

user wants to see. To change these values, press F4 and you should

see the 1st line start blinking:

- select line you would like to change with Up/Down –it will blink

- select parameter you would like to see with Right/Left

- repeat until the display screen shows what you want it to

- press F4 to accept changes

8.2 Inserting the probe

Connect the sampling tubing on the instrument to the sample gas

inlet. Position the sampling probe in the exhaust channel, so that the

thermocouple is fully surrounded with the gas (see below).

Core stream search

Gas stream

Thermocouple hook

Probe tip

O2 3.2 %

CO2 13.1 %

CO 0 ppm

Eff. 92.5 %

Losses 7.5 %

Exc. air

1.18

T.Gas 184 °C

T.Air 20 °C

BImSchV

To control for thermal drift, start the analyzer and let it

acclimate to ambient temperature for 15-30 minutes,

then restart the analyzer before testing.

Page 17

8.2 Inserting the probe (continued)

Perform the measurement in the core stream of the exhaust gas

channel (probe placed in the hottest gas temperature area). A trend

indication for T.Gas lets you know whether the temperature is in-

creasing or decreasing so that you can find the core stream. As long

as the display shows an up arrow, it means the probe tip is moving

towards the core stream center. If a down arrow is shown, it means

you have moved the probe away from the core stream and the tem-

perature is decreasing. If no temperature change is shown for at

least 3 seconds, the trend indication will disappear.

8.3 Calculations:

CO2, Efficiency, Losses, Excess air, & Dew point

CO2, efficiency, losses, excess air and dew point are calculated val-

ues. They can only be calculated if realistic values for the basic pa-

rameters like O2and the temperatures are available. In order for the

calculations to appear, the O2 must be below 20.5% and the differ-

ence in gas temp and ambient temp must be at least 5°:

O2< 20.5 % and T.Gas - T.Air > + 5 °C

The dew point can only be calculated accurately if, in the menu "Ad-

justments", the current barometric air pressure value has been

inputed. If the gas temperature falls below the dew point (between 25

and 65 °C), the efficiency will be calculated with condensation. In this

case a (K) is displayed after „Efficiency“.

8.4 Taking a measurement:

Ramp up, measure, & purge

The analyzer takes a little time to ramp up, which allows for gas

transport time and the build-up of a stable electrochemical reaction

on the sensors. This time period lasts approx. 1 to 1.5 minute. Be

sure to wait until the values are stable. If deviations higher than 2

ppm still occur by the gas values, they can be due to unstable pres-

sure conditions in the exhaust channel.

Page 18

If the measurement values are stable, press the Save Button (num-

ber 6) to transfer the values in the internal memory or F2 to print.

8.5. Printing

Press F2 to print the values on the screen.

To use the Printer button (number 6 on the keypad), you have to

press the Save button (number 7 on the keypad) before pressing

the Printer button.

Inserting Text onto the Printout

If you want to insert text onto the printout, press Enter while in Gas

Analysis, select Insert Text, press up/down to select the line, and

press Enter again to start entering text.

When done, press F1 to accept the text, then press ESC until you

are back in Gas Analysis.

Each time you print from now on, the text will appear on the printout.

To delete the text, press Enter while in Gas Analysis, select Insert

Text, press up/down to select the line, and press Enter again to start

editing the text. Press F4 to get the cursor up to the text line, scroll

right until the blinking cursor is beyond the last character, then press

F2 until all characters are cleared.

When done, press F1 to accept the text, then press ESC until you

are back in Gas Analysis. No text will print out until the next time you

insert text.

8.6 O2 Correction/Reference O2

O2 correction is commonly used by regulatory agencies to normalize

CO and NOx values to a specific O2 percent (usually 3% or 15%).

This allows for an “apples to apples” comparison when looking at

emissions data from many different pieces of equipment with many

different excess air values.

Go to Adjustments -> Ref. O2 and enter the desired O2 correction

value using the numbered buttons.

Measurement stored in

intermediate memory

Page 19

Now go to Adjustments -> Units and press up/down or right/left to

change the unit to %O2 undiluted. Your units have been changed

and you can return to Gas Analysis to view the corrected readings.

9. Draft/Pressure

A trend indication for the draft/pressure conditions in the exhaust

channel can be viewed during the gas analysis. However, the

draft/pressure value will not be on the printout until you zero the sen-

sor. To record a pressure measurement, follow these steps:

While in Gas Analysis, scroll through the pages until you get to this

one shown below. The pump will turn off.

Disconnect the draft hose from the in-

strument and press F4 to zero the pres-

sure sensor. The sensor is now cali-

brated. Reattach the draft hose, wait for

the reading to appear, and press the

Save button (number 6) to record the

measurement. Now when you press F2

(whether in this menu or within other

Gas Analysis pages), you will see the

draft print out along with the gas read-

ings.

10. Soot test

The Soot test allows you to enter up to

3 soot test measurements.

You must first turn on the probe heater so that the sample is main-

tained above dew point, preventing any condensation in the probe

which can affect the filter paper. The filter paper slot is heated up to

approx. 70 °C. Go to Adjustments / Internal / Probe heating / F1.

-Return to Soot test.

-Insert a filter paper in the paper slot.

Pressure

Draught -0.12 hPa

Recorded value:

--.-- hPa

Soot test

Select :

Boiler temp. : 66°C

1.Soot meas. : -.-

2.Soot meas. : -.-

3.Soot meas. : -.-

Oil trace : ----

Page 20

-Select the line „1st. Soot meas.“.

-Press <Enter> to start the measurement. The analyzer will pull 1.63

liters of sample gas.

-Release the filter paper from the probe slot.

10. Soot test (continued)

-Compare the greyness to your soot test chart (0-9).

-Input the result using the numerical keys and press <Enter>.

-Repeat this procedure until all 3 soot tests are completed. The av-

erage value will be calculated and automatically stored.

-Go back to Gas Analysis and press F2 to print off soot test results.

-Go to Adjustments / Internal / Probe heating / F4 to turn off the

probe heater.

You do not need to input Boiler temp. or oil trace if not needed.

11. Averaging

The averaging feature allows you to collect snapshots in a timed

interval and calculates the average over a set time period. For in-

stance, if you want to take 1 measurement per minute over a 5 mi-

nute period, you can set up the Averaging test to automate this.

1.Select Averaging within the main menu

2.Select Meas. Time

Input total measuring time in minutes or

seconds (for seconds, press decimal 1st)

3.Select Scanning

Input interval time (for seconds, press

decimal 1st)

For example: If the Meas. Time is 5 minutes and the Scanning time

is 60 seconds or 1 minute, the mean value will take into account 5

scans and find the average.

Start measurement

Measurement time

Scanning

Printer

Store

Mean values

Select :

Let the probe cool down before putting

back into the carrying case.

Other manuals for EN2-F

1

Table of contents