Ecom ECD2800 User manual

ECD2800 /ECD2600

ECOM spol. s r.o., Trebonicka 239, 252 19 Chrastany u Prahy, Czech Republic

IČO: 411 92 192, DIČ: CZ411 92 192

User’s Guide

ECD2800 /ECD2600

UV-VIS DETECTOR

ECD2800 /ECD2600

2 / 47

Document properties

File:

Manual-ECD2000-en-03

Number of pages:

47

File size:

5729 kB

Last save:

11/6/2019 8:59:00 AM Dominika Pavlová

Ver.

Date

Author

Approved by

Description

00

01.09.2013

Jaroslav Formánek

Jaroslav Formánek

First issue.

01

15.04.2015

Jaroslav Formánek

Jaroslav Formánek

Second issue.

02

11.09.2017

Kateřina Kněžourková

Jaroslav Formánek

Third issue.

03

16.01.2018

Kateřina Kněžourková

Jaroslav Formánek

Update chapter 15, 16, 17.

03

01.06.2018

Michaela Čamborová

Jaroslav Formánek

New photo on first page

03

6.11.2019

Dominika Pavlová

Jaroslav Formánek

Address change in chapter 13, 19 and in the

footer of the first page.

04

8.03.2021

Dominika Pavlová

Jaroslav Formánek

Addition of cable image for analog outputs

(see 6.4.4).

Related documents

Manual-Ethernet_devices

ECD2800 /ECD2600

3 / 47

CONTENT:

1. GENERAL INFORMATION.................................................................................................... 6

1.1. Product Function................................................................................................................................6

1.2. Produced Fersions .............................................................................................................................6

1.3. Accessories ........................................................................................................................................6

2. GENERAL OPERATING INSTRUCTIONS ................................................................................. 8

2.1. Safety Symbols on Unit .....................................................................................................................8

3. DESCRIPTION ................................................................................................................... 9

4. INSTALLATION AND BASIC CONTROL USING KEYBOARD ...................................................... 11

4.1. Cell Connection ................................................................................................................................11

4.2. Door Installation ...............................................................................................................................12

4.3. Connection to Power Supply and Connection of Communication Cables ................................12

4.4. Start of the Unit.................................................................................................................................12

4.5. Basic Control by Keyboard .............................................................................................................13

4.6. Description of Symbols on the Screen ..........................................................................................14

5. CONTROL FROM PC........................................................................................................ 14

6. WORKING WITH MENU .................................................................................................... 14

6.1. Parameters ........................................................................................................................................15

6.1.1. Wavelength.................................................................................................................................15

6.1.2. Time Constant ............................................................................................................................15

6.1.3. Sample Rate...............................................................................................................................16

6.1.4. Thresholds..................................................................................................................................16

6.2. Preferences .......................................................................................................................................17

6.2.1. Lamp...........................................................................................................................................17

6.2.2. Cell Temp ...................................................................................................................................17

6.2.3. Display........................................................................................................................................17

6.2.4. Sound .........................................................................................................................................17

6.2.5. Cooling .......................................................................................................................................18

6.2.6. Opti Filter ....................................................................................................................................19

6.2.7. Leakage......................................................................................................................................19

6.2.8. Signal..........................................................................................................................................19

6.3. Control...............................................................................................................................................20

6.3.1. Optical Recalib ...........................................................................................................................20

6.4. IO Config............................................................................................................................................20

6.4.1. Ethernet ......................................................................................................................................20

6.4.2. Remote Keylock .........................................................................................................................21

6.4.3. Interface......................................................................................................................................22

6.4.4. Analog Output ............................................................................................................................24

ECD2800 /ECD2600

4 / 47

6.5. Info .....................................................................................................................................................25

6.5.1. Device.........................................................................................................................................25

6.5.2. Boards ........................................................................................................................................25

6.5.3. Ethernet ......................................................................................................................................25

6.5.4. User text .....................................................................................................................................25

6.5.5. Lamps.........................................................................................................................................26

6.5.6. Cell .............................................................................................................................................26

6.6. Diagnostic .........................................................................................................................................26

6.6.1. Errors..........................................................................................................................................26

6.6.2. Warnings ....................................................................................................................................26

6.6.3. Power .........................................................................................................................................26

6.6.4. Cooling .......................................................................................................................................27

6.6.5. Interface......................................................................................................................................27

6.6.6. Cell Temp ...................................................................................................................................27

6.6.7. Opti Calib....................................................................................................................................27

6.6.8. Tests...........................................................................................................................................28

6.7. Service...............................................................................................................................................28

6.7.1. Parts Replacement.....................................................................................................................28

7. WORKING MODES .......................................................................................................... 31

8. RS232.......................................................................................................................... 32

9. REPLACEMENT OF LINE FUSE.......................................................................................... 33

10. TROUBLESHOOTING...................................................................................................... 33

11. MAINTENANCE ............................................................................................................. 34

11.1. Cleaning and Decontamination.....................................................................................................34

11.2. Control of Tubing and Cell Connection .......................................................................................34

11.3. Lamp Control ..................................................................................................................................34

11.4. Operational Qualification...............................................................................................................34

12. SPARE PARTS .............................................................................................................. 35

13. WARRANTY AND POST-WARRANTY REPAIRS.................................................................. 36

14. CELLS ......................................................................................................................... 36

14.1. Order of Cell Components.............................................................................................................37

14.2. Control of Cell Purity and Absorbing Mobile Phase...................................................................37

14.3. Replacement of Cell Windows ......................................................................................................38

14.4. Cleaning Cell Windows ..................................................................................................................38

15. TECHNICAL PARAMETERS ............................................................................................. 39

16. APPENDIX 1–ECD2600 CE /ECD2800 CE FOR CAPILLARY ELECTROPHORESIS ............ 40

ECD2800 /ECD2600

5 / 47

17. APPENDIX 2–ECD2600 EX /ECD2800 EX WITH OPTICAL CONNECTORS ....................... 43

18. APPENDIX 3–ES DECLARATION OF CONFORMITY .......................................................... 46

ECD2800 /ECD2600

6 / 47

1. GENERAL INFORMATION

This unit is designed for use in laboratories in systems of liquid chromatography as

UV-VIS detector.

1.1. Product Function

The detector measures changes in absorption of light in liquids passing through a cell on

selected wavelength in the range of 190 up to 800 nm (600 nm). As a light source is used

deuterium lamp combined with tungsten lamp.

1.2. Produced Fersions

ECD2800 UV - VIS Detector Cat.: ADA0000X

ECD2600 UV - VIS Detector Cat.: ADB0000X

ECD2800 CE UV-VIS Detector Cat.: ADACE00X

ECD2600 CE UV-VIS Detector Cat.: ADBCE00X

ECD2800 EX UV-VIS Detector Cat.: ADAEX00X

ECD2600 EX UV-VIS Detector Cat.: ADBEX00X

ECD2600 is not equipped with tungsten lamp as a secondary light source.

1.3. Accessories

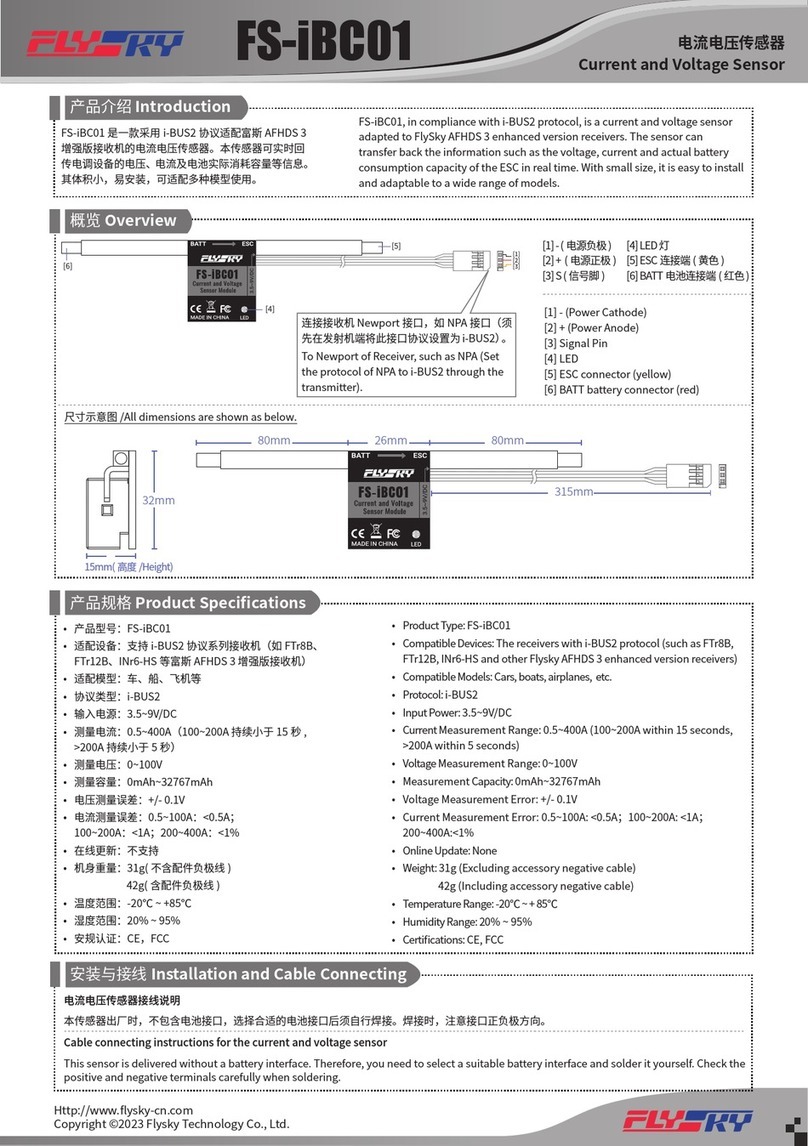

BASIC ACCESSORIES

P/N

Qty

Picture

Description

23984000

1

Tube fuse T - 2.5A/250V, CSA

EKAB-011

1

Mains cable 10A-250V 1.5 m

00051478

1

Terminal block 3 pins green

EKAB-040

1

LAN cable 1 m

K0310000

1

Analog output

ADA99100

1

Capillary 0.25 mm 300 mm ECD with fittings

ECD2800 /ECD2600

7 / 47

P/N

Qty

Picture

Description

ADA99200

1

Capillary 0.25 mm 300 mm ECD

ADA99400

1

Hydrodynamic resistor with fittings

ADA99900

1

Waste set ECD2600/2800

00000121

1

PEEK One-Piece Handtight Nut 1/16", 10-32

ADA40000

1

Test cell TC01

18329000

1

Screwdriver Torx T10

99040300

1

Open End Wrench 7-5.5 mm

00016000

1

Door 2000

DOC00001

1

-

User’s guide

DOC00002

1

-

Production protocol

Spare parts and selectable accessories see 12. Spare parts

Cell specified in purchase order is inserted in the detector.

ECD2800 /ECD2600

8 / 47

2. GENERAL OPERATING INSTRUCTIONS

Caution: The unit may not be used, if it is leaking.

Caution: Do not place unit or any other equipment so that disconnecting power cord

is difficult.

Caution: Never manipulate with the unit, if the door is mounted. There is a danger of

its damage.

Caution: UV light is dangerous for eyes. During regular operation of the detector is UV

light perfectly shielded. While exchanging the cell, never look in the cell area.

Always put in at least test cell. Exchange of deuterium lamp must be carried out

with disconnected power cord.

Caution: Never dismount unit cover. There is nothing needing customer service or

maintenance.

2.1. Safety Symbols on Unit

UV light is dangerous for your eyes. If the flow-cell is installed in unit

then UV light is perfectly shielded. In case of any manipulation with

flow-cell is very important to protect eyes with glasses absorbing UV

light.

Electrical device! Disconnect power cord before servicing.

Electrical device! Disconnect power cord before servicing. Read the

operational guide before replacing fuse!

ECD2800 /ECD2600

9 / 47

3. DESCRIPTION

FRONT VIEW

No.

Description

1

Front switch.

2

Keyboard.

3

Cell compartment.

4

Drain from cell compartment.

5

Leakage sensor.

6

Drain channel with cone for connecting waste system.

7

Door hinges.

8

Slots for tubing and capillaries.

9

Display.

10

Status LED lights:

LAMP (green) indicates light sources (deuterium lamp and tungsten lamp). It blinks

during lamp turning on/off and lights when a lamp is turned on.

RMT (yellow) indicates status of unit remote control. It lights when the unit is

communicating through interface ETHERNET or RS232.

ERR (red) indicates error status of the unit. It lights, if an error is indicated and blinks, if

a fatal error is indicated, when unit status has been changed.

ECD2800 /ECD2600

10 / 47

KEYBOARD KEYS AND THEIR FUNCTIONS

Symbol

Description

MENU

Enter to unit MENU, fast exit from MENU.

LAMP

Turn on/off light source. Autozero is performed after turned on.

WL

Setting the wavelength.

ZERO

Zeroing.

ENTER

Confirm the entry to the selected MENU item, confirm the new set value of

the parameter, invoking the QUICK DIAGNOSTICS screen.

ESC

Return one step without saving changes.

Directional key.

The value of the setting parameters are increased/decreased with

the up/down arrows and the wavelength value is increased/decreased

directly on the main screen.

REAR VIEW

No.

Description

1

Combined power socket with main switch and main fuse.

2

Connector Ethernet/LAN.

3

Connector RS232.

4

Connector IO Interface.

5

Analogue output.

ECD2800 /ECD2600

11 / 47

4. INSTALLATION AND BASIC CONTROL USING KEYBOARD

Place the unit in a suitable location that satisfies the following conditions:

•Horizontal place.

•Keep at least 10 cm space behind the rear of the unit.

•Keep away from equipment generating strong magnetic field.

•Equipment is intended for use in regular laboratory environment only - see Technical

parameters –operating environment conditions.

4.1. Cell Connection

Unscrew black dummy screws.

Connect the inlet of the cell (below, marked as IN) to the

column, using capillary and PEEK screw.

Connect hydrodynamic resistor to the cell outlet (OUT, above)

to restrain bubbles forming in the cell.

Check the tightness of cell during mobile phase flow.

Caution: Never look inside opened cell compartment if the lamp is on. Never leave

the cell compartment opened and always place at least test cell in. Never

put inside the cell compartment anything else then the flow-cell.

ECD2800 /ECD2600

12 / 47

Note: Side and top slots in front panel of the unit are designed for tubing and capillaries

accommodation. FEP tubing with outer diameter 1/8” are fitted by pressing into

the slot. Capillaries and tubing with outer diameter 1/16” are fitted using short

FEP tubing with outer diameter 1/8” and inner diameter 1/6”, threaded on the

capillary. A tubing threaded this way cannot be pressed in and it is fitted by

inserting from the side into the slot.

4.2. Door Installation

In order to prevent damage of door hinges, the door is supplied apart. The door should be

slipped on the hinges in opened position, see pictures below.

Door mounting must be easy, no strength needed, otherwise the hinges may get damaged.

4.3. Connection to Power Supply and Connection of Communication

Cables

Plug the power supply cord into the instrument socket on the rear panel. Connect PC via

Ethernet or using RS232. If you are connecting whole system, connect in the same manner also

other units.

4.4. Start of the Unit

Use a switch on the rear panel of the detector for connecting to mains voltage, then switch

on the unit using push button on the front panel. The push button glows red, if power source is off

and green, if power source is on. If power supply is disconnected, the unit remembers last status of

this push button and after power supply reconnection it restores the last status. This can be used

for automatic start in the system with a common switch of power source for whole system of liquid

chromatograph (for example using a multiple socket-outlet with a switch).

ECD2800 /ECD2600

13 / 47

4.5. Basic Control by Keyboard

After unit start (Mode START) display shows

unit type

Then the unit turns to mode IDLE, where the

lamps are off.

After pushing key LAMP the light sources are

turning on in mode LAMPS UPDATE, which is

signalized by flashing of lamp symbol and

green LED diode LAMP on the right next to the

display.

Then follows mode LAMP PREEHEATING

This mode is followed by calibration of

wavelengths in mode OPTICAL CALIBRATION,

using maximum of zero order and spectral line

of hydrogen at 656 and 486 nanometers. Status

of this process is signalized on the screen

After successful calibration the main screen

displays absorbance measurement. MEASURE

ABSORBACE (ABS)

Now you can set wavelength by pressing key

WL. Keys with arrows left and right move with

cursor and up and down change the value.

Pressing ENTER confirms selected wavelength,

it is set and zeroed (Autozero). Now let the unit

to stabilize.

ECD2800 /ECD2600

14 / 47

4.6. Description of Symbols on the Screen

10 Hz *)

Sampling rate.

1s *)

Time constant for signal filtering.

R52% a S53%

Light intensity in reference and measuring channel on set wavelength. If S value

is significantly lower, it shows dirty cell or absorbing mobile phase.

254 nm *)

Set wavelength.

-0.000052AU

Actual value of absorbance in AU units.

ABS

Actual detector mode.

Symbol of switched on deuterium lamp (if it is off, symbol does not contain the

filament in the center).

Symbol of switched on tungsten lamp (if it is off, symbol does not contain the

filament in the center).

Symbol of successfully executed wavelength calibration (empty box means that

calibration has not been performed).

Unsuccessful wavelength calibration, initial calibration constants are used.

Unsuccessful Autozero process.

Leakage sensor is activated.

*) Values marked with this symbol may be changed in menu

5. CONTROL FROM PC

During unit control from PC communication proceeds through serial line RS232 or through

LAN. Communication protocol can be supplied upon request.

Unit may be controlled with SW Clarity and ECOMAC.

6. WORKING WITH MENU

Menu enables setting all parameters and functions of the unit, its diagnostics and service.

MAIN MENU is entered by pushing key MENU. In the menu you can move using arrows,

ENTER and ESC. Any part of the menu can be abandoned by pressing key MENU.

ECD2800 /ECD2600

15 / 47

MENU FLOW DIAGRAM

6.1. Parameters

Here can be set basic parameters of the detector.

6.1.1. Wavelength

This screen is identical to the screen displayed after pressing key WL. Wavelength can be

set in the range of 190-800(600) nm. Keys with arrows left and right move with cursor and up and

down change value. Press ENTER for confirmation of selected wavelength, it will initiate

wavelength setup. Automatic zeroing (Autozero) is only performed when ENABLE is set in

Menu/Preferences/Signal/Autozero After WL Change.

6.1.2. Time Constant

Time constant represents level of signal filtering and is counted for level 63.5 %. Preset value

is used for both digital and analogue output. Slower (longer) time constant improves overall noise

of the detector output at the price of decreasing response speed. Low values decrease response

speed (response delay –time lag) and change the shape of peaks (they are wider and lower).

Time constant does not have an influence on the peak area size, even if low value widens and

lowers the peek.

RECOMMENDED TIME CONSTANT SETTINGS

Time Constant

[s]

Peak half width for narrowest

expected peek in analysis

[s]

0.02

0.1

0.05

0.2

0.1

0.4

ECD2800 /ECD2600

16 / 47

Time Constant

[s]

Peak half width for narrowest

expected peek in analysis

[s]

0,2

0,9

0.5

2.2

1 default

5

2

10

5

24

10

45

Example: narrowest expected peak half width in analysis is 8 s and therefore recommended time constant

is 1 s

For standard chromatographic analysis is usually suitable default value of time constant 1 s.

But it is necessary to reset it for UHPLC applications, where is commonly suggested value 0.05 s.

6.1.3. Sample Rate

This setting determines, how many times per second will be measured signal. Its value is

selected according to speed of running analysis.

RECOMMENDED MINIMAL SAMPLING RATES

Sampling

Rate

[sps]

Peak width for narrowest

expected peak in analysis

[s]

Peak half width for narrowest

expected peak in analysis

[s]

1

20

12

2

10

6

5

4

2.4

10 default

2

1.2

20

1

0.6

50

0.4

0.2

100

0.2

0.1

for 20 points per peak; coefficient 1.7 was used for conversion of width and half width

Example.: narrowest expected peak half width in analysis is 11 s and therefore minimal recommended

sampling rate is 2 sps (samples per second)

For standard chromatographic analysis is usually suitable default value of sampling rate

10 sps (samples per second). But it is necessary to reset it for UHPLC applications.

Setting high sampling rate results in large data files. Contrariwise too low sampling rate

destroys peak shape and puts inexact its area and height. Recommended setting ensures at least

20-40 data points (samples) per narrowest peak.

6.1.4. Thresholds

Detector enables to do certain actions based on absorbance signal and setting of threshold

values. It is possible to set two values, THRESHOLD A and THRESHOLD B in the range

1 up to 4 AU.

Actions performed based on set threshold values can be set for external interface

in Menu/IO config/Interface.

ECD2800 /ECD2600

17 / 47

6.2. Preferences

Here can be optimized detector functions to satisfy any user needs.

6.2.1. Lamp

In each sub menu can be set used lamps, method of their start and eventual preheating.

6.2.1.1. Lamps Use

The unit can be set (only model ECD2800) so, that BOTH LAMPS (deuterium and tungsten

lamp) are always on, or only deuterium lamp (ONLY DEUTERIUM (D2)) and/or only tungsten

lamp (ONLY TUNGSTEN (W)).

6.2.1.2. Preheat Time

Preheating of lamp is performed at first start of light sources after unit start, because of

highest possible accuracy of followed first optical calibration of the unit. Default value is 10 s.

The preheat time can also be used for enforcement of general stabilization of the unit before

measurement. It is not possible to perform measuring before lamp is preheated. Preheating can be

skipped using key ESC.

6.2.1.3. Auto Turn On Mode

The unit can be set in a mode that immediately after unit start the light sources are

automatically turned on. In mode OFF the lamps are not turned on after unit start, in mode ON the

lamps are started automatically. Default value is OFF.

6.2.2. Cell Temp

This mode is not used so far.

6.2.3. Display

6.2.3.1. Brightness

The display brightness can be set in eight levels, where value 8 is maximum brightness.

6.2.3.2. ABS Units

Units displayed can be set to AU, mAU and mAU without initial digits (mAU ZEROS

SUPPRESSION). This setting does not influence analogue nor digital output.

Absorbance is measured in relative absorbance units. It does not refer to 1 cm optical path

length. Absorbance measuring range is <−0.2; 4.0> AU for negative dynamic range NORMAL and

<−0.8; 3.0> AU for negative dynamic range HIGHER. It can be set in Menu/Preferences/signal.

6.2.3.3. ABS Precision

For setting number of displayed digits of absorbance.

6.2.4. Sound

Sound signals of the unit can be set as follows:

ECD2800 /ECD2600

18 / 47

SOUND SETTING

Setting

Description

KEYBOARD

At each touch of button will be generated short beep when

the key does not have any significance at the moment, mid-

length beep for value change and moving in menu and longer

beep for confirmation of value changes.

ERRORS

At error occurrence will be generated sound signal of the

error. Three consecutive longer beeps in case of an error and

in case of a fatal error with repetition every 5 s. Repetition

can be interrupted by pressing any key.

WARNINGS

At warning occurrence will be generated sound signal of

warning. Three consecutive shorter beeps.

OPERATIONS

During operation will be generated longer beep and for long

operations may be this beep generated at the beginning and

at the end of an operation.

6.2.5. Cooling

Setting method of cooling is essential for detector drift and less essential for its noise. Final

result of its behavior is always dependent on surroundings and therefore needs experimental

attestation for given environment. It is necessary only for reaching the best result in highly sensitive

applications. For common use, the default setting is sufficient.

Lower rotation speed of fans decreases the noise (sound) level in laboratory, but increases

working temperature of illuminator. The lower the illuminator temperature is, the better is the

stability and working parameters of the unit. Recommended range of working temperature is

30-50 °C.

Diagnostics of cooling status is done in Menu/Diagnostic/Cooling, where are displayed actual

measured values of cooling system.

6.2.5.1. Fans Mode

Here can be set method of optical block cooling using fans. Selectable options are OFF,

CONSTANT VOLTAGE, CONSTANT SPEED and CONSTANT TEMPERATURE.

Mode OFF Total shutoff is not recommended. Setting of these modes is preceded in further

points.

6.2.5.2. Fans Voltage

Fans are controlled by constant adjustable voltage (default value is 8 V). Suitable for air-

conditioned laboratories, most stable fans run, but it is impossible to reach lowest rotation speed.

Default mode is cooling.

6.2.5.3. Fans Speed

Here can be set constant speed of fans (default value is 4000 rpm). Setting is a sum of

rotation speed of both fans. Suitable for reaching very low rotation speed. Speed control can cause

slightly unstable run.

6.2.5.4. Illuminator Temp

Constant illuminator temperature is maintained by variable rotation speed of fans. However,

they can cause higher detector noise, which can slightly react to rotation speed regulation. For not

ECD2800 /ECD2600

19 / 47

air-conditioned laboratories the best solution (default value is 40 °C). Recommended setting for

surrounding temperature under 25 °C is 36 °C, and 40 °C for surrounding temperature over 25°C.

Best method to find suitable temperature is to set constant voltage to default value (8 V) and add

2°C to measured temperature after stabilization. Great influence on illuminator temperature has

turned on/off halogen light.

6.2.6. Opti Filter

Optical filters are placed at the front of monochromator before diffraction grating. They are

used to suppress second order on the grating, where for example when setting wavelength 400 nm

grating generates second order of wavelength 200 nm. This wavelength is in automatic mode

filtered by white cut-of filter, which absorbs all wavelengths lower than 340 nm.

SETTING OF OPTICAL FILTERS

Setting

Description

AUTOMATIC

Setting without filter is used for wavelengths under 360 nm,

white filter (WHITE) is used for wavelengths in range of

361-580 nm. Yellow filter (YELLOW) is used for wavelengths

over 581 nm. At this setting is not inserted any filter for test

scans. Recommended and default setting.

NONE

None filter is inserted. All light goes through.

WHITE

White filter is inserted. It absorbs wavelengths under 300 nm.

YELLOW

Yellow filter is inserted. It absorbs wavelengths under

480 nm.

Standardly is set automatic mode. Others are used only during diagnostics.

6.2.7. Leakage

Leakage sensor contains reference and measuring sensor. If the measuring sensor is

immersed in liquid, sensor generates a signal. Signal processing is depending on actual setting.

SETTING OF LEAKAGE SENSOR BEHAVIOR

Setting

Behavior

OFF

Signal is ignored.

AS WARNING

Warning is displayed. Default setting.

AS ERROR

Invokes fatal error, when light sources turn off and unit goes to initial idle

state.

For termination of leakage signalization, it is necessary to remove the source of liquid leak

6.2.8. Signal

6.2.8.1. Negative Dynamic Range

Setting negative dynamic range influences range of absorbance measuring.

SETTING OF NEGATIVE DYNAMIC RANGE

Setting

Description

NORMAL

<−0.2; 4.0> AU. Default value.

HIGHER

<−0.8; 3.0> AU.

ECD2800 /ECD2600

20 / 47

6.2.8.2. Autozero After WL Change

Here can be set autozero after change of wavelength by key WL or

in Menu/Parameters/Wavelength. ENABLE is set (Autozero is allowed) or DISABLE is set

(Autozero is not allowed). Default setting is ENABLE.

Autozero is not performed after change of wavelength with up/down arrows when ENABLE

is set.

6.3. Control

6.3.1. Optical Recalib

Calibration of optical unit is runs over after first start of light sources after unit switch-on, or it

can be initiated from this menu. If light sources are off and consequently turned on without unit

shutoff, optical unit calibration is not undertaken.

During optical unit calibration is set and controlled spectral setting of detector (wavelength).

Calibration of wavelength is based on spectral lines of hydrogen (656 nm and 486 nm) produced

by emission of deuterium lamp. First point of calibration (0 nm) is finding maximum light on zero

order (grating works as a mirror). Subsequently is found maximum light on spectral line 656 nm

and thereby is the detector calibrated. Verification of setting is done on spectral line 486 nm and if

it is not correct, detector displays a warning. At the end of calibration is performed autozero and

eventual deuterium lamp turnoff. If the use of tungsten light is set in detector menu

(Menu/Preferences/Lamps/Lamps use) than even in spite of that deuterium lamp is turned on

during optical unit calibration and turned off afterwards.

6.4. IO Config

6.4.1. Ethernet

In menu parts can be set possibilities of ethernet connection.

Note: Prior to connecting the unit to corporate network, always contact local

network administrator and consult with him connecting parameters. This

way you will avoid network collision. For more information and

troubleshooting with ethernet devices connection, read document Manual-

Ethernet_devices, which is available upon request.

Ethernet interface supports communication speed 10/100 Mb/s. For connection can be used

common UTP cable (Cat 5e). Main communication proceeds on port 10001 and function of

automatic look up uses port 30718. The unit further supports the following services: DHCP client

(automatic IP address allocation), AUTOIP [automatic IP address 169.254.x.y. (x.y. …random

generated numbers), when there is no available DHCP server in the network], web server (port 80)

and ICMP protocol (for connection test use tool PING).

This manual suits for next models

1

Table of contents

Popular Security Sensor manuals by other brands

ObboMed

ObboMed HO-2200 quick start guide

Hellermann Tyton

Hellermann Tyton TopTronic T175HP manual

TECHNO-AC

TECHNO-AC Success AT-107N Technical Description, Operating Instructions

Green Brook

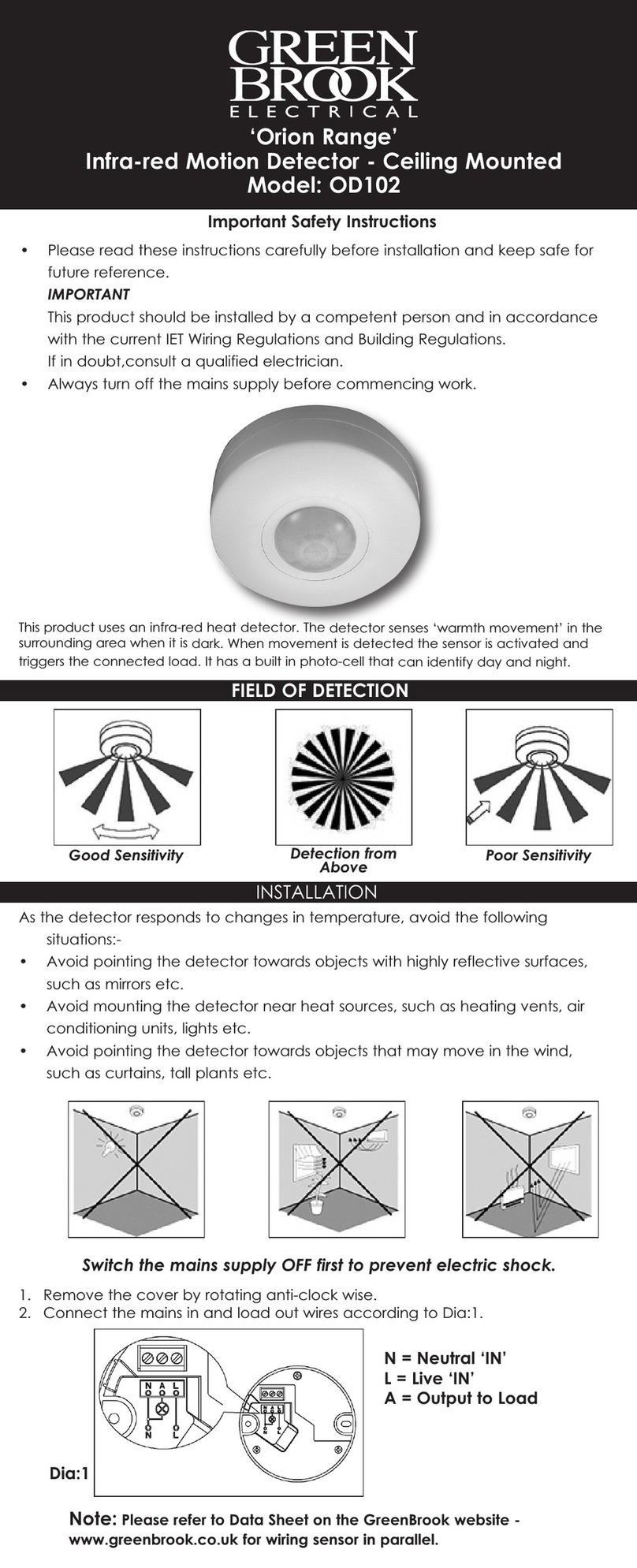

Green Brook Orion Range OD102 Important safety instructions

HIK VISION

HIK VISION Pyronix XDH10TT-WE quick start guide

C.P. Electronics

C.P. Electronics MWS6-PRM-VFC-NC installation guide