♦Most Likely •Less Likely ♣Least Likely

Symptom Cause Remedy

1. Heater shuts

o

♦Manual reset ♦Requiring manual restart by reset button on.

2. Loss

o

prime overnight ♦Vacuum air leak i

n

uel line ♦Check all

uel connections. Tight

en

ittings.

W

on

t hold vacuum ♣Plugged pump screen ♣Check pump screen, may need cleaning-to access, remove pump cover

IS TANK EM

P

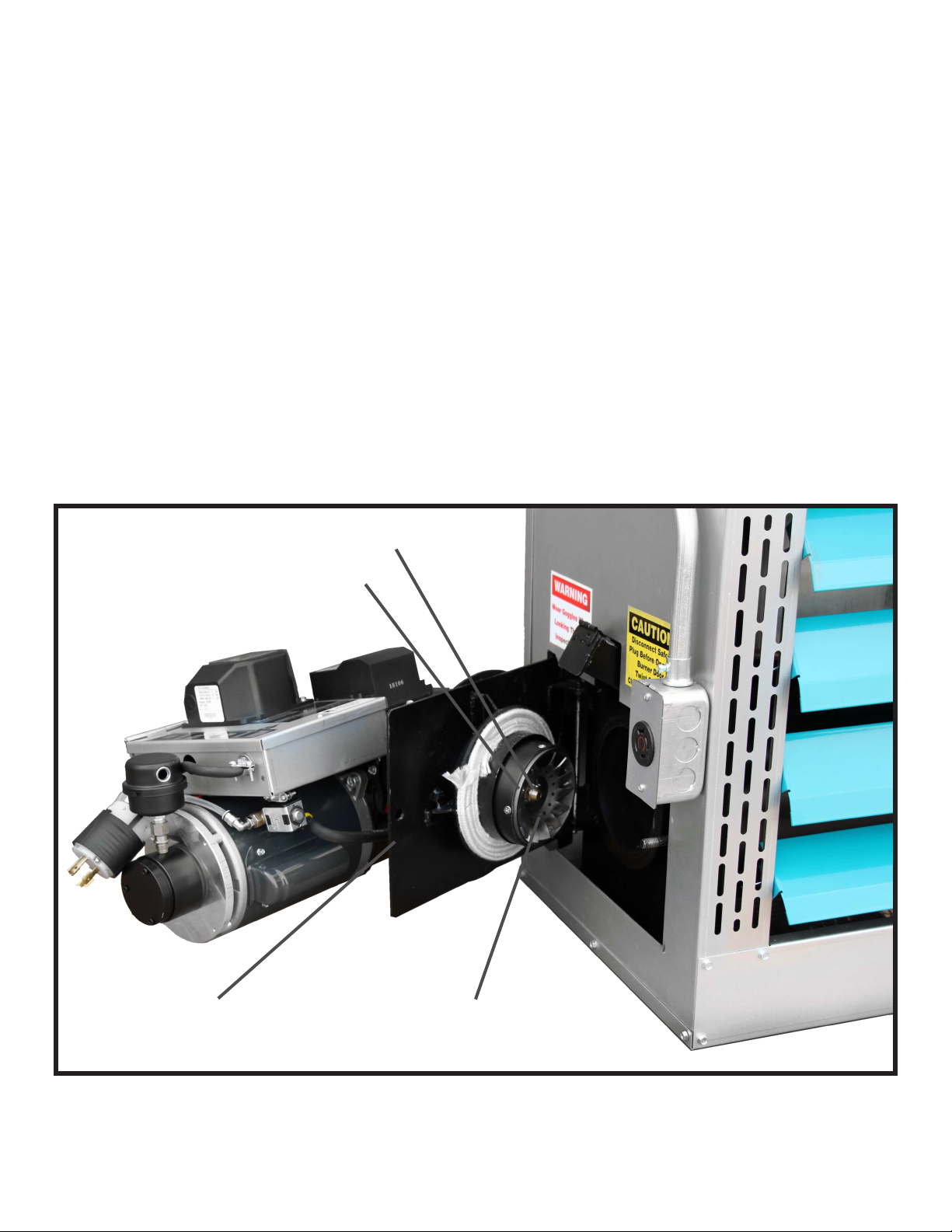

•Plugged

e

r or tank oil empty •Clean

ilter. Using vent port, reprime pump

(

Figures 6 & 7).

3. Fails to start. ♦Vacuum Leak ♦Open bleeder port i

air present. Check and tighten

ittings.

♦Inadequate Fuel Supply ♦Clean

ilter. Check all

uel connections. Tighten

ittings.

•No Pressure •Check, may need cleaning—to access, remove pump cover.

•Using vent port, reprime pump

(

Figures 6 & 7).

•No Pre-heat •Be sure all wiring to pre-heater is tight-no loose connections.

•B

a

irerod

replace; continuity at terminals.

•Auto start circuit not

unctioning •Check circuit control board and replace i

necessary

(

all

actory).

•Check continuity at terminals

o

irerod limit snap switch.

Replace i

needed.

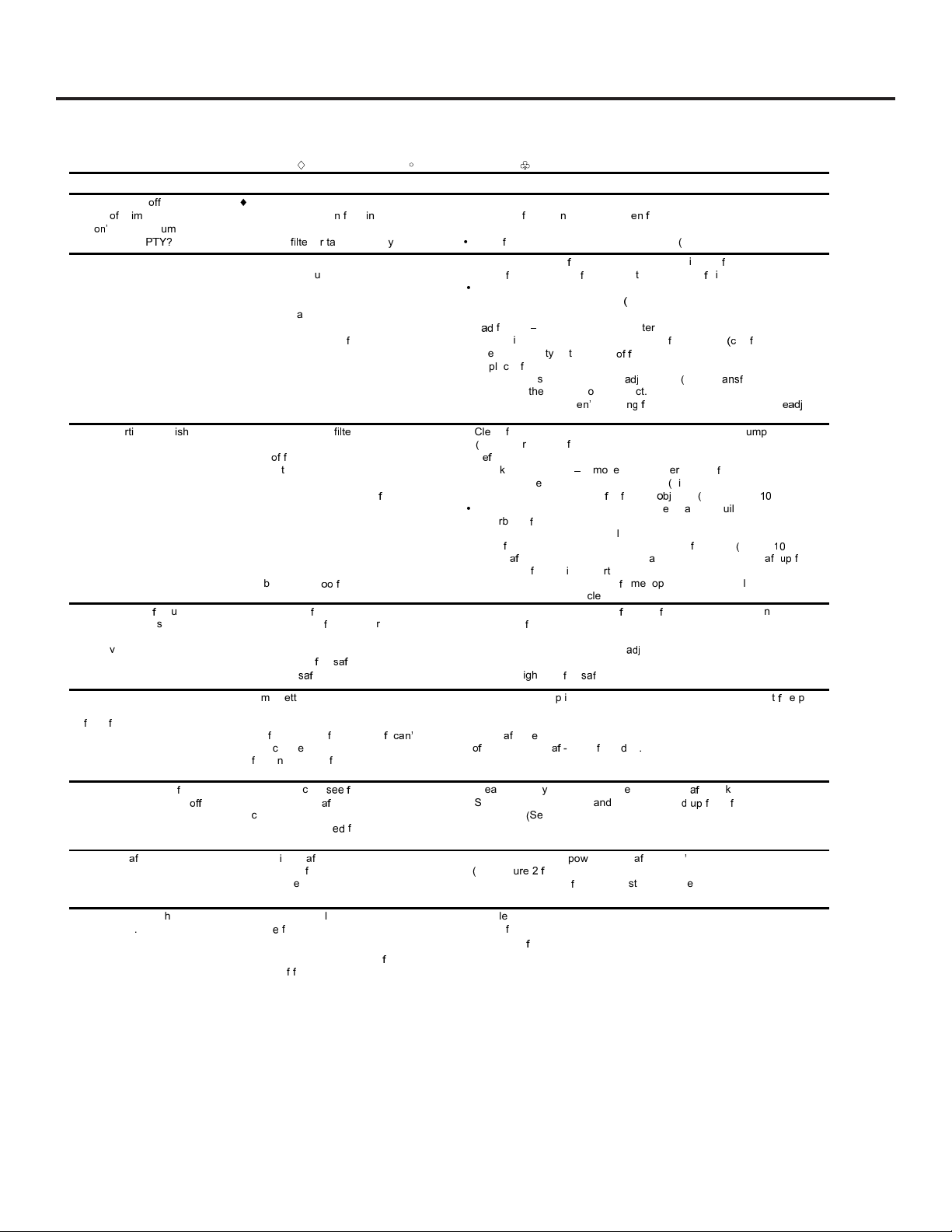

•No Arc •Check springs to electrode rod

a

ustment

(

under tr

a

n

ormer)

make sure they make good contact. Open burner door and make

sure electrode tips ar

en

t touchi

n

lame cone or one another. R

e

a

ust.

4. Hard starting diminished ♦Partially plugged

e

r. ♦Clean

ilter. Using vent bleeder port on pump, re-prime pump

(

See Figure 6 & 7)

lame.

♣Out

o

uel ♣R

e

ill Storage.

♣No oil to burner ♣Check pump screen

remove pump cover; clean i

needed.

Using vent bleeder port, re-prime pump.

(

Figures 6 & 7)

•Inadequate combustion air

rom burner •Remove nozzle and check

or

oreign

o

ects.

(

Figures 9 &

1

)

•Aluminum Block Pre-heater inside burner may not build

up carbon. I

carbon is present, thermocouple heat sensor wire could

have open circuit. Heat control board may have blown circuit and circuit

board

use.

Inspect both and replace either i

needed

(

Figure

1

).

Back dr

a

t in combustion chamber may be present. Check dr

a

t

lue

pipe & over

ire at vision port.

•Air band open t

oo

ar •Close air band—while viewing

lame; open air band slowly until

combustion chamber is clear, not orange.

5. Heater cycles

requently, ♦Heater over

iring, Inadequate ♦Investigate and locate reason

or over

iring. Check and clean end cone

without thermostat combustion air

rom burner turbulator i

needed.

temperature setting being

achieved in area to be ♣Temperature setting wrong ♣Check temperature setting and

a

ust as necessary.

heated. On high limit

an

a

ety switch

•High limit

a

ety switch bad •Replace high limit

an

a

ety switch.

6. Heater rumbles and ♦Pump setting wrong ♣Clean ash buildup in combustion chamber, exchange and vent

lue pipe.

excessive heat blow back

rom

lame vision port.

♣Dra

t incorrect. I

proper dra

t

a

n

t♣Set dr

a

t. Clean out combustion chamber and exchangers

be achieved, consider any exhaust

o

ash. Check dr

a

t-reset i

needed.

ans in building i

added since initial install.

7. Heater establishes

lame ♦Photo eye cant

ee

lame. ♦Clean photo eye which is clouded by back dr

a

t smoke.

but locks out or shuts

o

.♣Due to back dr

a

t. Flame end ♣Swing open burner door and clean ash buil

rom

lame

Need to reset primary. cone may have ash. end cone.

(

See Figure 5 & 8).

•Bad or uncontroll

e

lame due to

nozzle erosion •Replace nozzle

8. Proper dr

a

t setting ♦Negative dr

a

t in building ♦May need to install power vent/dr

a

t inducer

s in stack.

cannot be achieved or exhaust

ans present.

(

See Figur

e

or wiring).

♣Excessive ash buildup/Heater ♣Clean ash and soot

rom combustion chamber and heat

exchangers.

9. Poor or reduced heat ♦Flame too small ♦Nozzle or preheater block may be plugged with carbon debris.

production. ♣Entir

e

uel supply may be plugged. ♣Clean

ilter both, oil strainer and check oil pump screen.

•

Excessive ash buildup exchangers •Clean ash

rom combustion chamber and exchangers.

•

Through vision port, check

lame

to see i

lame is smaller than usual

or too large and uncontrolled.