MHS Boilers Aqua Line T1 User manual

Aqua Line

Installation Guide

Hot water radiant panels

5

FIVE YEAR

WARRANTY

2

Read this document before

installing the appliance

Warning

Incorrect installation, adjustment, alteration, repair or maintenance work may lead to material

damage or injury. All work must be carried out by certied, qualied professionals. If the

appliance is not positioned in accordance with the instructions, the warranty shall be rendered

void. This appliance is not intended for use by children or persons with a physical, sensory or

mental handicap, or who lack the required experience or expertise, unless they are supervised

or have been instructed in the use of the appliance by somebody who is responsible for their

safety. Children must be supervised to ensure that they do not play with the appliance.

If the manual refers to an image or table, a number will be shown between square brackets, for

example [3]. The number refers to images and tables at the back of the manual with the stated

number.

1.0 General

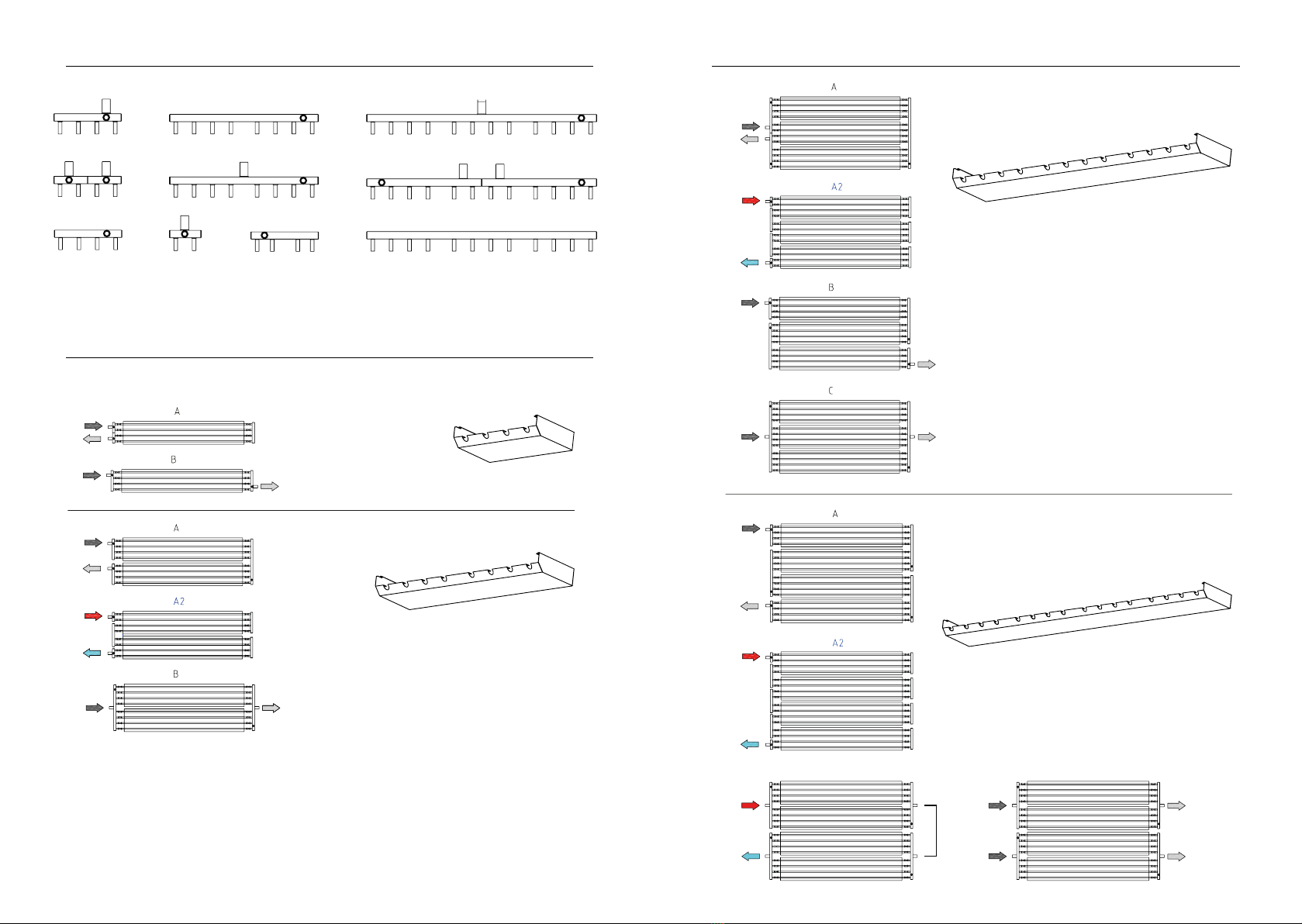

[1] Panel dimensions [6] Heat delivery table

[2] Overview, water side connection [7] Minimum mass ow

[3] Panel structure [8] Transporting the panel

[4] Overview, covers [9]/[10] Mounting instructions

[5] Selection and design advice [11] Mounting to the ceiling

1.1 Application

The Aqua Line heats a room by means of radiant heat. Warm water is pumped through the

pipes in the radiant panels. This makes the panel warm and heat is then radiated. The Aqua Line

can also be used for cooling: cooled water is pumped through the pipes making the panel

cold and cooling the environment. Condensation must be prevented from forming. The minimum

water temperature therefore depends on the level of atmospheric humidity in the room.

Subject to change

The manufacturer is committed to constantly improving its products and reserves the right to

make changes in the specications without prior notice. The technical details are considered

correct but do not form the basis for a contract or warranty. All orders are accepted according

to the standard terms of our general sales and delivery conditions (available upon request).

Key table [6]

T = type of panel

K = medium upper temperature

P = number of pipes per distributor

3

EN

Twi + Twu

K = ————— – T omg

2

Key table [7]

TR = water return temperature in °C

W = minimum mass ow of water per pipe in kg/h

Key table [9]

LB = section length

U = section expansion in mm

Tgem = average water temperature.

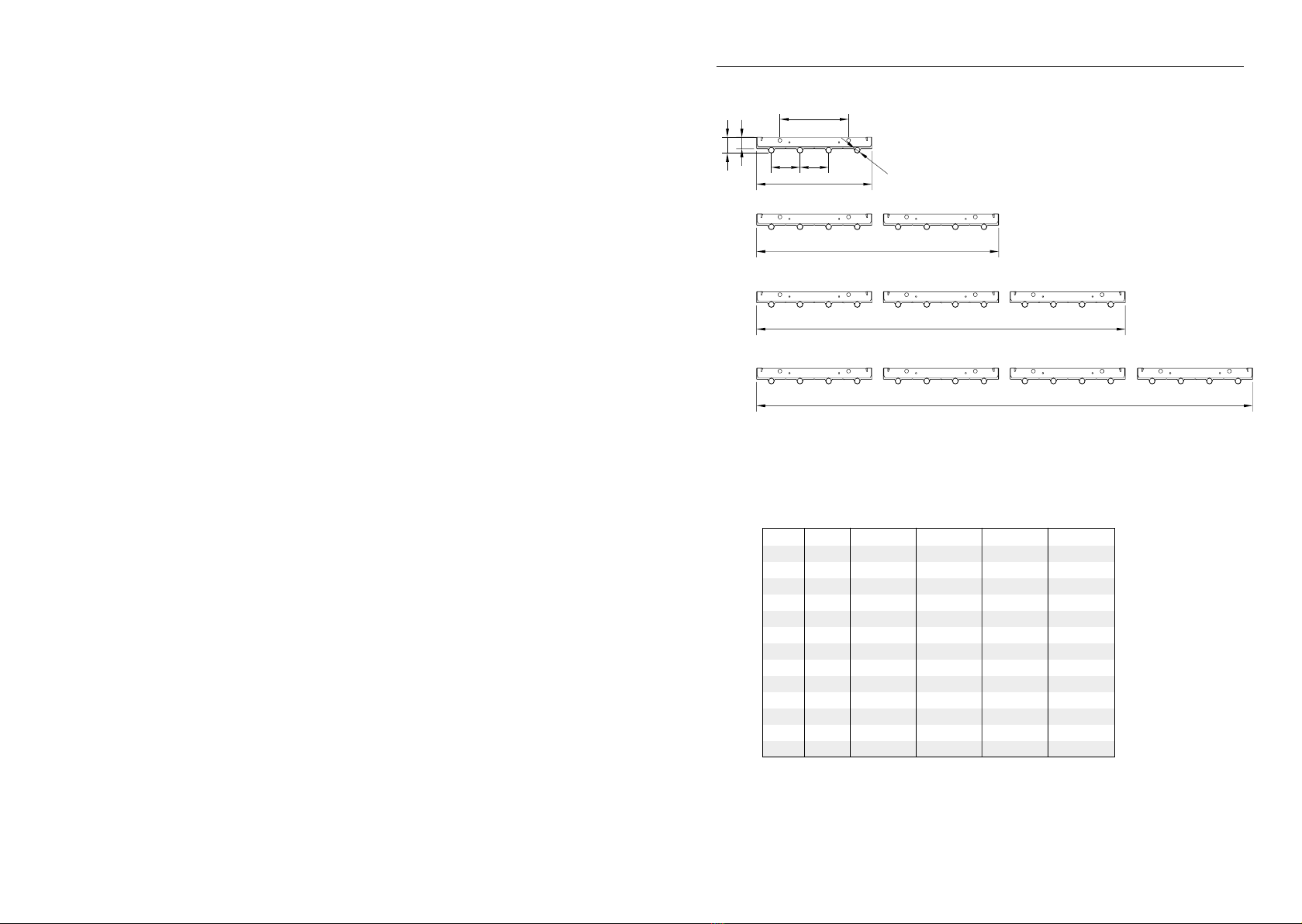

1.2 Panel type + dimensions: [1]

T Type G Thicknesses of material

A Length H Weight per 4m (empty)

B Width I Weight per 6m (empty)

C Number of pipes J Water content per 4m

D Pipe diameter K Water content per 6m

E Thickness of pipe wall L Max. temperature

F Height of radiation hood (radiation panel) M Max. operating pressure

1.3 General warnings

Incorrect installation, adjustment, alteration, maintenance activity or repair may lead to material

or environmental damage and/or injuries. The appliance should therefore be installed, adapted or

converted by a skilled and qualied installer, taking into account national and international

regulations. A faulty installation, adjustment, alteration, maintenance activity or repair shall render

the warranty void.

1.4 Description of the Aqua Line panel [3]

A radiation panel is made up of multiples of four pipes attached to a proled steel plate. Because

the pipes are actually located within the prole of the steel plate, there is a large contact area.

This also benets the delivery capacity. The top of the radiation panel should be insulated on the

upper side using the loose insulating material supplied (to be tted by you). This will restrict

undesirable upward radiation. The insulation strips must be cut to length manually.

1.5 Construction of the panel [3]

1 Reector

2 Water-carrying pipe

3 Distributor

4 1” connections, water side

5 Mounting set (prole and carbine hooks)

6 Push-on connectors (optional)

7 Insulating material

8 De-aeration connection ½” (de-aeration nipple is not included in MHS’s scope of supply)

The panels are delivered in standard lengths of 4 or 6 metres. Longer lengths can also be created

by joining the panels together using the push-on connectors [3]. Note the water ow in this case.

In addition to the length, the width can also be adjusted. The distributors are also installed using

the push-on connectors. If required, the push-on connectors can be concealed using a reector

concealing cover to create a neat nish [4].

4

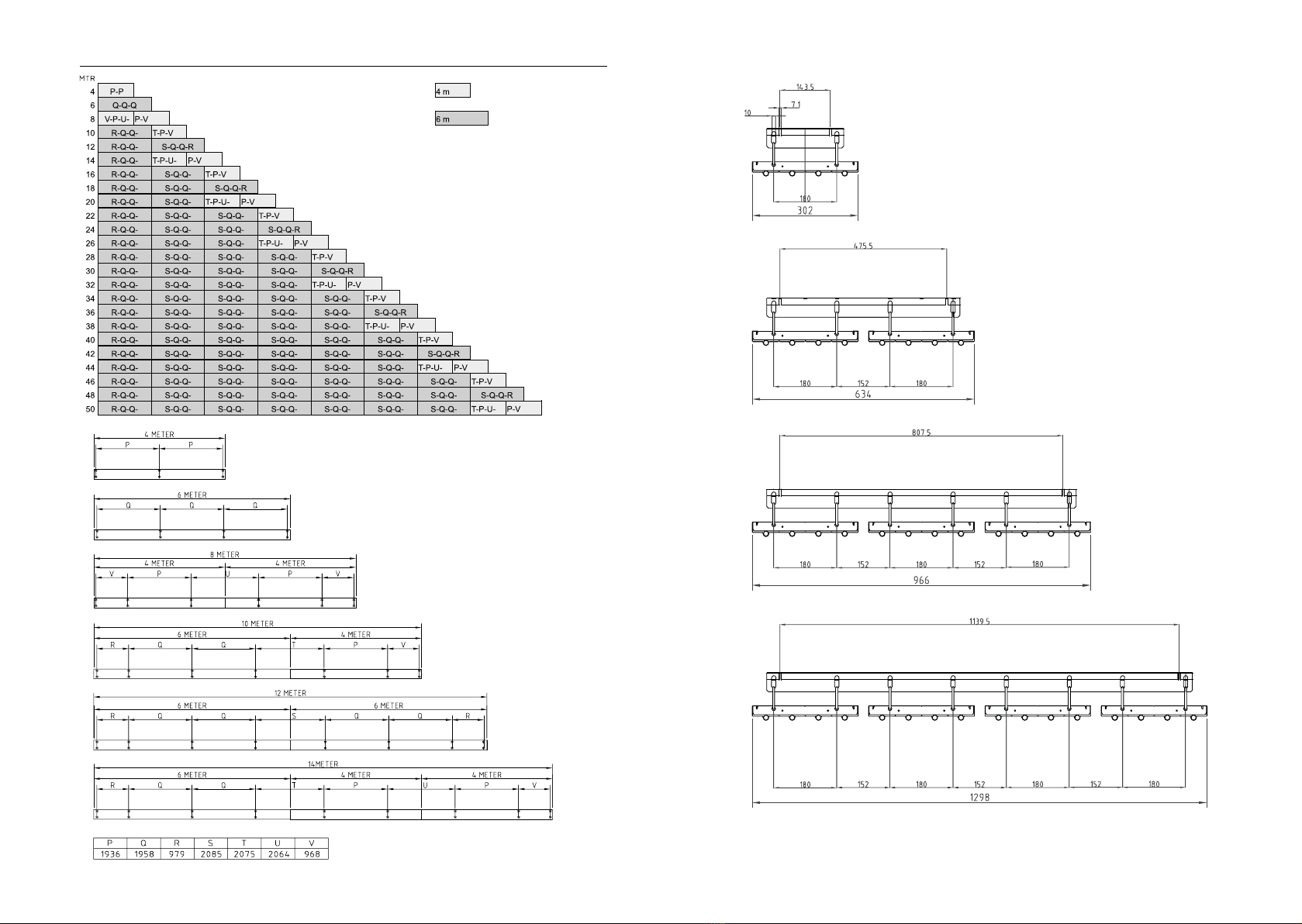

2.0 Selection and design advice [5]

In order to heat the room evenly, it is important to follow the steps below. These calculations

determine the type of panel, the panel length, distributors and the pressure drop. In connection

with the water side pressure drop and panel expansion, we advise you to keep the maximum

section length below 46 metres.

2.1 Signs and symbols

B = Width of the room q = Panel heat output per section length

H = Height of the room Q = Heating requirement

Hm = Installation height Tomg = Ambient temperature

K = Upper temperature Twi = Water temperature in (feed)

L = Length of the room Twu = Water temperature out (return)

LB = Section length ∆T = Temperature variation

Ltot = Total section length Qpp = Heat capacity per panel (table) [6]

nsp = Number of radiation sections npp = Number of panel lengths needed

n = Number of pipes per group R = Pressure drop per pipe per metre of panel

mpb = Mass ow per pipe Z = Distributor pressure drop

m = Mass ow per panel length

2.2 Steps to be followed

1. Determine the width, height and type of panel for the space. [5]

Twi = 65ºC

Twu = 50ºC

Tomg = 18ºC (Temp. in the room)

2. Determine the section length: [5]

LB = L – 3m

L

B = 45 – 3 = 42m

NOTE!

Only 4 or 6 metre panels may be used.

42m is divisible by 6. This results in 7 panels, each 6 metres in length

See table [9]

3. Determine the installation height:

Hm= H – 0.5m

Hm = 5 – 0.5 = 4.5m

This is also the optimal distance from the centre point of each panel. [5]

5

EN

4. Determine the upper temperature:

Twi + Twu

k = ————— – T omg

2

65 + 50

k = ————— – 18 = 39 Kelvin

2

This value can be used to look up the heat capacity of the panel in the table (heat delivery

table) [6] (type 1,2,3 and 4). This is the value Qpp.

(T=1) Qpp = 132 W/m (heat output table) [6]

5. Determine the heat delivery for a single length:

q = LB x Qpp

q = 42 x 132 = 5544 W/section

6. Determine the temperature variation of the water:

∆T = Twi – Twu

∆T = 65 – 50 = 15 K

7. Determine the mass ow of the liquid in one panel length:

m = (q/∆T ) x 0.86

5544

m = ———— x 0,86 = 318 kg/h

15

8. Determine the mass ow per pipe:

mpb = m / n

1 section consisting of a Type 1 panel. [2]

Flow may take place through 4 pipes or 2 pipes. The mass ow must be calculated for these

two situations in order to connect the panel on the water side.

mpb = 318 / 4 = 79,5 kg/h (B)

318 / 2 = 159 kg/h (A)

9. Check the minimum mass ow using the appropriate table [7] (68 kg/h). The calculated value

must be higher in order to achieve turbulent ow through the pipes. This then gives the

correct number of distributors [2].

6

10. Determine the pressure drop on the water side [2]:

T1 Single side Sit.A ∆P = (Lb x R1) + (Lb x R2) + Z

T2 Single side Sit.A ∆P = (Lb x R1) + (Lb x R2) + Z

T3 Single side Sit.A ∆P = (Lb x R1) + (Lb x R2) + Z

T4 Single side Sit.A ∆P = (Lb x R1) + (Lb x R2)+ (Lb x R3) (Lb x R4)+ Z

T1 Alternating sides Sit.B ∆P = (Lb x R1) + Z

T2 Alternating sides Sit.B ∆P = (Lb x R1) + Z

T3 Alternating sides Sit.B ∆P = (Lb x R1) + (Lb x R2)+ (Lb x R3) + Z

T3 Alternating sides Sit.C ∆P = (Lb x R1) + Z

R = Water resistance per panel length in Pa/m

Z = water resistance in Pa for both distributors

R = x 196

Calculation example: T=1 , 79,5 kg/h (B)

∆P = LB x R +Z

R = 41 Pa Z = 202 Pa

Determine the pressure drop for both panel groups:

∆P = 42 x 41 + 202 = 1924 Pa

3.0 Transport

Leave the panels on the pallet for as long as possible.

Ensure the pallet does not bend too much (do not move the pallet using a pallet truck).

To prevent bending, move the panel rotated/turned by 90º [8].

Panels must be stored in a dry environment.

4.0 Mounting panels [9][10]

4.1 Mounting instructions [9]

– The panel must be placed at a minimum height of 2m above the oor.

– The measurement from the centre point of the panels must not be greater than the height

above the oor. [5]

– Distance between the installation proles max. 2 metres [9].

– Suspend the panels in such a way that they can expand freely lengthways [9][10].

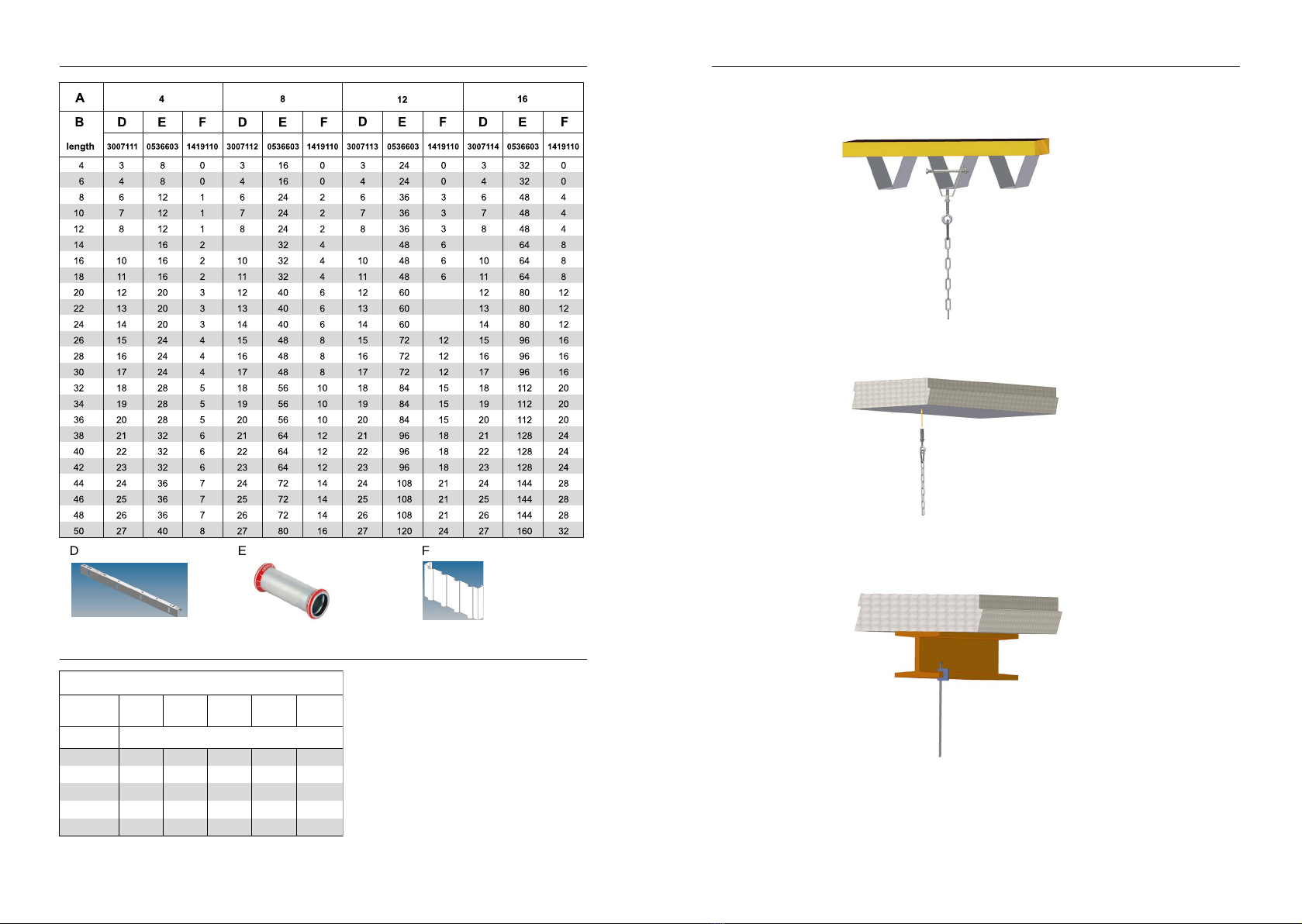

Key table [10]

A = Number of tubes

B = Section length

D = Number of brackets

E = Number of press links

F = Cover between panels

m

Z = x 2000

1000

(

(

2

m

pipes

173

(

(

2

7

EN

l2 = Expansion in mm

l1 = Section length mm

α = Linear expansion coefcient of steel => 11.7x10-6

Tw gem = Average water temperature.

Tomg = Temperature in the room.

Determine the expansion of 1 section length:

l2= l1 x (1 + α x (Tw gem – Tomg)

l2 = 42000 x (1 + 11.7x10-6 (57.5 – 0))

l2 = 42028.3mm

Expansion U = 28.3mm

Expansion table [11].

4.2 Order of installation. [4]

– Fit the suspension points [9][10]

– The panels can be mounted directly to threaded rod or hung from chains [12].

– Join the panels together using the push-on ttings.

– Install the distributors [3].

– Add the insulation.

– Place covers, if required, on the panel connections and distributors [4].

5.0 Start-up

Fill the installation with water, bleed the pipes and rinse through to remove any contamination.

Adjust any ow controls. Ensure that the water mass ow does not fall below that indicated in the

table [7]. If the water mass ow is lower, output cannot be guaranteed.

Key table [7]

TR = water return temperature in °C

W = minimum mass ow of water per pipe in kg/h

6.0 Maintenance

Clean the panels regularly, check them for leaks and check the suspension points. If applicable, ask

a qualied installer for maintenance advice.

8 9

1298

966

634

302

ø15

180

aa

42

30

[1]

T 1 2 3 4

A m 4/6 4/6 4/6 4/6

B mm 305 636 968 1300

C n 4 8 12 16

D mm 15 15 15 15

E mm 1,0 1,0 1,0 1,0

F mm 42 42 42 42

G mm 0,5 0,5 0,5 0,5

H kg 12,2 24,4 36,6 49,2

I kg 18,2 36,4 54,6 72,8

J dm3 2,12 4,24 6,36 8,48

K dm3 3,19 6,38 9,57 12,76

L ºC 120 120 120 120

M bar 8 8 8 8

1110

[1]

[2]

0650265 0650273 0650285

0650267 0650275 0650287

0650263 0650252 0650261 0650283

1419111

1419112

1419113

1419114

BC

[2]

1419111

1419112

1419113

1419114

BC

[5][3]

7

[4]

1 8 4

3

6

2

5

12 13

[7]

[8]

56

TR W

°Ckg/h

30 99

35 88

40 81

45 73

50 68

55 61

60 58

65 53

70 50

75 47

80 44

85 41

90 39

95 37

100 35

[6]

Watt/m to EN 14037 1-3

Me dium TMe dium P

overtem

p

overtem

p

K1234 K48 12 16

1154769521428 1904 115165330494659

110451 90313541806110 156312 468624

1054278551282 1709 105147295442590

100403 80712101613 100139 278417 556

95 3807591139 1518 95 131261392522

90 356712 1068 1424 90 122244 367489

85 3336669981331 85 114228342456

80 310619 9291239 80 106212 318423

75 2875748611148 75 98 196293391

70 264529 7931058 70 90 180270 360

69 2605207801040 69 88 177265353

68 256511 7671022 68 87 174260 347

67 2515027531004 67 85 170256341

66 247493 7409876684167 251335

65 24248572796965 82 164246329

64 238476 7149516481161 242322

63 23346770093463 79 158237316

62 229458 6879166278155 233310

61 22544967489961 76 152228304

60 220441 6618816074149 223298

59 21643264886459 73 146219292

58 212423 6358475871143 214286

57 20741562283057 70 140210280

56 203406 6098125668137 205274

55 19939859679555 67 134201268

54 195389 5847785466131 197262

53 19038157176153 64 128192256

52 186372 5587445263125 188250

51 18236454572751 61 122183244

50 178355 5337105060119 179239

49 17334752069449 58 116175233

48 169338 5086774857113 170227

47 16533049566047 55 111166221

46 161322 4836444654108 162215

45 15731447062745 52 105157210

44 153305 4586114451102 153204

43 14929744659443 50 99 149198

42 144289 433578424896145 193

41 14028142156241 47 94 140187

40 136273 409546404591136 182

39 13226539752939 44 88 132176

38 128257 385513384385128 171

37 12424937349737 41 83 124165

36 120241 361482364080120 160

35 11623334946635 39 77 116154

30 97 194291 38830326496128

25 78 15623531325 26 51 77 102

20 60 120180 2402019395878

15 43 85 12817115 14 27 41 55

14 15

[9]

16 17

19

[12]

18

[10]

[11]

999

9

9

9

9

U(mm)

LB(mm) 10.000 20.000 30.000 40.000 50.000

Tgem (˚C)

30 3,5 7,0 10,5 14,0 17,6

50 5,9 11,7 17,6 23,4 29,3

70 8,2 16,4 24,6 32,8 40,9

80 9,4 18,7 28,1 37,4 46,8

90 10,5 21,1 31,6 42,1 52,7

RC/0119/7371RC

SALES OFFICE - 0345 521 5666

MHS Radiators Limited, 3 Juniper West, Fenton Way, Southfields Business Park, Basildon, Essex SS15 6SJ

Tel: 0345 521 5666 Fax: 01268 888260

This manual suits for next models

3

Table of contents

Other MHS Boilers Heater manuals