EcoPower SBP-XFMR Series Guide

Installation and User Instructions

SBP-XFMR Series

2

March 2022

Version 1.0

DISCLAIMER

Eco Power Equipment Ltd. makes no representations or warranties with respect to this manual and, to

the maximum extent permitted by law, expressly limits its liability for breach of any warranty that may be

implied to the replacement of this manual with another. Furthermore, Eco Power Equipment Ltd.

reserves the right to revise this publication at any time without incurring an obligation to notify any

person of the revision.

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not intended

as a substitute for and is not to be used for determining suitability or reliability of these products for

specific user applications. It is the duty of any such user or integrator to perform the appropriate and

complete risk analysis, evaluation and testing of the products with respect to the relevant specific

application or use thereof. Neither Eco Power Equipment Ltd. nor any of its affiliates or subsidiaries shall

be responsible or liable for misuse of the information that is contained herein. If you have any

suggestions for improvements or amendments or have found errors in this publication, please notify us.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product.

When devices are used for applications with technical safety requirements, the relevant instructions

must be followed.

Failure to observe this information can result in injury or equipment damage.

Copyright © 2019 by Eco Power Equipment Ltd.

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any

form or by any means, including photocopying, recording, or other electronic or mechanical methods,

without the prior written permission of the publisher. For permission requests, write to the publisher,

addressed “Attention: Permissions Coordinator,” at the address below.

Eco Power Equipment Ltd.

8, 26004 TWP 544, Sturgeon County, AB, T8T 0B6, Phone: 1-888-483-4843

3

TRADEMARKS

Eco Power Equipment Ltd. has made every effort to supply trademark information about company

names, products, and services mentioned in this manual. Trademarks shown below were derived from

various sources. All trademarks are the property of their respective owners.

General Notice: Some product names used in this manual are used for identification purposes only and

may be the trademarks of their respective companies.

Product Modifications

Year

Type

Modifications

2022

1

SBP-XFMR V1

Document Revisions

Date

Version Number

Document Changes

4

Table of Contents

1. PREFACE 7

Description of the User 7

Conventions Used in This Manual 7

Explanation of Safety Warnings 8

Retaining Instructions 8

Obtaining Documentation and Information 9

Internet 9

Ordering Documentation 9

Other languages 9

Documentation Feedback 9

Support and service 9

Description of the product 10

Intended Use and Reasonably Foreseeable Misuse 10

Setup Process 12

Connecting 14

Disconnecting 14

Replacement parts of HUBBELL®SINGLE POLE DEVICES 14

How to Use the Product 16

Safety information 16

Technical life span 20

Personal Protective Equipment 20

Inspection Tasks 21

Before use inspection tasks (never open a live panel, see above safety recommendations) 21

Quarterly Inspection tasks 21

5

1. PREFACE

1.1 Description of the User

This manual is intended to support end users of the Eco Power Equipment SBP power distribution products. Our

products are designed and intended to provide site power solutions for temporary and prime rated power on a variety of

applications including construction job site, oil, and gas job sites, pipelines, events, security, and government or military

operations.

The user will deploy and set up the SBP and should be qualified and follow all instructions contained in this operating

manual.

1.2 Conventions Used in This Manual

The following style conventions are used in this document:

Bold

Names of product elements, commands, options, programs, processes, services, and utilities Names of interface

elements (such windows, dialog boxes, buttons, fields, and menus)

Interface elements the user selects, clicks, presses, or types

Italic

Publication titles referenced in text

Emphasis (for example a new term)

Variables

Courier

System output, such as an error message or script

URLs, complete paths, filenames, prompts, and syntax

User input variables

< > Angle brackets surround user-supplied values

[ ] Square brackets surround optional items

| Vertical bar indicates alternate selections - the bar means “or”

6

1.3 Explanation of Safety Warnings

Danger indicates a hazard with a high level of risk which, if not avoided, will result in death or serious injury

Warning indicates a hazard with a medium level of risk which, if not avoided, could result in death or serious injury.

Caution indicates a hazard with a low level of risk which, if not avoided, could result in minor or moderate injury.

Indicates information considered important, but not hazard-related.

1.4 Retaining Instructions

Read and understand this manual and its safety instructions before using this product. Failure to do so can result in

serious injury or death.

Follow all the instructions. This will avoid fire, explosions, electric shocks or other hazards that may result in damage to

property and/or severe or fatal injuries.

The product shall only be used by persons who have fully read and understand the contents of this user manual and

understand the safe operation of the machine.

Ensure that each person who uses the product has read these warnings and instructions and follows them.

Keep all safety information and instructions for future reference and pass them on to subsequent users of the product.

The manufacturer is not liable for cases of material damage or personal injury caused by incorrect handling or

non-compliance with the safety instructions. In such cases, the warranty will be voided.

7

1.5 Obtaining Documentation and Information

1.5.1 Internet

The latest version of the documentation is available at the following address: http://www.ecopowerequip.com

1.5.2 Ordering Documentation

Documentation, user instructions and technical information can be ordered by calling Eco Power Equipment Ltd. at

1-888-483-4843

1.5.3 Other languages

This is the English user manual. Manuals in other languages are available upon request. Not all languages are covered.

1.5.4 Documentation Feedback

If you are reading Eco Power Equipment Ltd. product documentation on the internet, any comments can be submitted on

the support website. Comments can also be sent to support@ecopowerequip.com

We appreciate your comments.

1.5.5 Support and service

For information about special tools and materials please contact:

Eco Power Equipment

Address: #8, 26004 TWP 544, Sturgeon County, AB, T8T 0B6

Phone: 1-844-332-0924

Web: www.ecopowerequip.ca

For other questions, information, technical assistance, ordering user instructions, and service related information please

contact the manufacturer:

Eco Power Equipment Ltd.

Address: #8, 26004 TWP 544, Sturgeon County, AB, T8T 0B6

Phone: 1-888-483-4843

Web: www.ecopowerequip.com

8

2 Description of the product

2.1 Intended Use and Reasonably Foreseeable Misuse

The machine is a mobile, skid-mounted transformer with ineghrated power distribution panel board and receptacle

outlets. This system is designed to support power distribution application. The Eco Power Equipment SBP unit consists of

a skid with power distribution equipment mounted within a NEMA 3R tested sheet metal enclosure.

This machine is intended for prime rated power requirements and has been designed to operate 24/7. This equipment is

also intended for the purpose of supplying electrical power to connected loads. Refer to the product rating plate for the

output voltage and frequency of the unit, and for the maximum output power limit of the panel.

This machine has been designed and built strictly for the intended use described above. Using the machine for any other

purpose could permanently damage the machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following are some examples of misuse:

Connecting a load that has voltage and frequency requirements that are incompatible with the rating

Overloading the machine with a device that draws excessive power during either continuous running or start-up

Operating the device in a manner that is inconsistent with all federal, provincial and local codes and regulations

Operating the machine outside of factory specifications

Operating the machine in a manner inconsistent with all warnings found on the machine and in the Operator’s Manual

This machine has been designed and built in accordance with the latest Canadian safety standards. It has been

engineered to eliminate hazards as far as practicable and to increase operator safety through protective guards and

labeling. However, some risks may remain even after protective measures have been taken. They are called residual risks.

On this machine, they may include exposure to:

Electric shock and arc flash

To protect yourself and others, make sure you thoroughly read and understand the safety information presented in this

manual before operating the machine

9

Follow safe Electrical Work Practices:

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

●Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E,

CSA Z462.

●This equipment must only be installed and serviced by qualified electrical personnel.

●Turn off all power supplying this equipment before working on or inside the equipment.

●Always use a properly rated voltage sensing device to confirm all power is off.

●Read and understand this entire instruction bulletin and the latest edition of the included NEMA PB 1.1

standards publication before installing, operating, or maintaining this equipment.

●Local codes vary, but are adopted and enforced to promote safe electrical installations. A permit may be needed

to do electrical work, and some codes may require an inspection of the electrical work.

●Replace all devices, doors, and covers before turning on power to this equipment.

Failure to follow these instructions will result in death or serious injury.

10

2.2 Maintenance

Eco Power Equipment Recommends all customers integrate a routine maintenance for all mobile power distribution

equipment. This equipment has been designed to provide mobile power distribution and as such we recommend our

customer implement a routine maintenance program:

1. Torque Check Procedure: All mobile power distribution should undergo regular torquing procedures before use.

This procedure should be developed based on the movement and usage of the equipment. With regular

checking and verification of critical connection points, here are some examples:

a. Hubbell Bus Tab Connection Points: 107-inch lb (9 ft-lb)

b. MCCB Tab to Breaker Bolts: 288 in-lbs (24 ft-lb)

c. MCCB and other items have torque ratings directly labelled on the device

2. Thermal Inspection: Abnormal heating associated with high resistance or excessive current flow is the main

cause of many problems in electrical systems. Infrared thermography allows us to see these invisible thermal

signatures of impending damage before the damage occurs. When current flows through an electric circuit, part

of the electrical energy is converted into heat energy. This is normal. But, if there is an abnormally high

resistance in the circuit or abnormally high current flow, abnormally high heat is generated which is wasteful,

potentially damaging and not normal.

2.3 Setup Process

The setup and deployment process involved for the SBP-XFMR series power distribution panel involves locating the unit

on a level, suitable terrain, connecting earth ground, and connecting electrical distribution.

Before using the unit, be sure to read and understand all of the instructions. This equipment was designed for specific

applications; DO NOT modify or use this equipment for any application other than which it was designed for.

Equipment operated improperly or by untrained personnel can be dangerous.

Before using a unit visually inspect the unit for damage. A complete visual inspection of all power distribution

connections.

Equipment Spacing:

Eco Power Equipment recommends that SBP-XFMR type power transformers be mounted so that there is an air space of

no less than 305 mm (12”) between the enclosure and any adjacent wall unless otherwise marked. Furthermore, it is

recommended that a minimum air space of 610 mm (24”) be allowed above the transformer for adequate cooling. A

minimum working space of 762 mm (30”) is recommended for all removable access panels that provide access to

connections, and any renewable or adjustable parts / accessories. If the transformer must be located near a combustible

surface / wall, the minimum clearance established by the Local Electrical Code and Fire Marshal should be maintained.

11

Location and Enviroment

Dry type transformers should be located such that they comply with all applicable local safety and electrical codes. It

should not interfere with the normal movement of personnel, equipment and material and should not expose the

transformer to potential damage from cranes or other moving equipment.

Enclosures are intended for use in secured areas, generally not accessible to unauthorized or untrained persons.

Transformers with open bottom enclosures, or with bottom ventilation openings should not be installed on or over

combustible surfaces.

Outdoor ventilated units should ideally be located such that nearby buildings or landscape features can help reduce

windblown dust, rain or snow from entering the enclosure.

Transformers to be installed at altitudes greater than 1,000 m (3,300 ft.) above sea leave, or in ambient temperatures

exceeding a maximum average of 30 ⁰C and a maximum peak temperature of 40⁰C must be specifically designed for these

environmental conditions to operate correctly

Setup Guide:

1. Inspect the unit, before connecting it to a load.

2. Check that all safety guards are in their correct position and secure.

3. Read and understand ALL safety sections at the beginning of this manual.

4. Ensure all maintenance procedures are up to date.

5. Ensure the unit is set up on firm and level ground, with the area around the unit clean, and setback space as

outlined in this manual

6. Ground unit in accordance with local grounding requirements, the green cam locks are bonded to the enclosure,

there is also a mechanical lug provided on the chassis for bonding purposes.

7. Warn personnel on site of pending startup.

8. Connect primary side de-energized camlocks (Alternativly a qualified electrician an configure the primary size

connection via direct hard wire, connect via gland with appropriately rated connector to maintain enclosure

compliance)

9. Ensure main breakers are in the OFF / Green position

10. Inspect all electrical connections; repair or replace any that are cut, worn, or bare. This includes inspecting cords

external to the panel to the load-use safe electrical practices in accordance with local guidelines and best

practices

11. This unit is equipped with primary and secondary transformer protection and uses adjustable MCCB(s), the user

must adjust to local code requirements (600V applications require the breakers to be adjusted down in certain

cases, typically to a 0.9-0.8 - see the unit rating plate)

12. Verify voltage and frequency are correct before turning on the main circuit breaker, this machine is designed to

operate at multiple voltages and phases

13. Turn on secondary main MCCB,

14. Turn on secondar branch circuits

12

15. It is advised that the loading is increased gradually such that the circulating current begins from 10% of the rated

amperage, and increase in 10% -15% increments every 10 minutes until it reaches 50% – 75% of the rated

current.

WARNING:

It is the operator’s responsibility to ensure that the panel is properly and safely positioned at the location. This includes

setting MCCB dials properly for your application.

DANGER:

Entering the electrical compartment while equipment is in operation can result in death or serious injury.

Safety Instructions

Read and understand this manual and its safety instructions before using this product. Failure to do so can result in

serious injury or death.

PROPER MATING of HUBBELL®SINGLE POLE DEVICES

Connecting

1. Align large arrows, & insert female into male device.

2. Push together & bottomed, 50 lb (222 N) maximum, with gap between shoulders.

3. Twist clockwise by hand in the direction of the arrow, locking between 30º and 180º.

Disconnecting

1. Twist counter clockwise by hand, until large arrows are aligned.

2. Pull devices apart.

WARNING: Use only replacement part Cat. No. HBLMBXX or HBLFBXX series with Attachment Plug or Cord connector Cat

Nos. HBL300MXX, HBL400MXX or HBL300FXX, HBL400FXX series only. WARNING: Risk of Fire or Electric Shock. Do not

use this replacement enclosure housing (plug body) with any attachment plug or cord connector, (as appropriate), other

than the one specified on the replacement mark packaging and in these instructions.

13

2.4 How to Use the Product

2.4.1 Safety information

●Only qualified technicians should attempt to work on electrical equipment.

●Always wear protective clothing and footwear when working on or around the transformer.

●Any person with a pacemaker, metal implant, or jewelry should not come within 10 feet of the transformer

enclosure while it is in operation.

●The use of electrical safety, arc flash safety grounding, and lockout/tagout procedures should always be

followed to ensure personal safety when installing, servicing and uninstalling electrical equipment.

●Never energize a transformer if it appears to be damaged.

●Never lift anything over head or over top of other persons.

●Generally, the voltage required will be the rated voltage times the per unit impedance time the percentage

of current required. The winding temperature should not be allowed to exceed the average winding

temperature rise or 100 ⁰C, whichever is lower. Refer to ANSI/IEEE C57.94

●In the event of a fire, do not use water to extinguish the flames. Use a suitable quenching agent such as,

CO2.

●Terminals are for electrical loading only. Wherever possible, use flexible connectors to avoid mechanical

strain on terminal pads.

●Always inspect the unit to ensure that nothing has entered the enclosure or unit that might create a safety

hazard such as debris, rodents, animals, etc. This is more likely to occur if the transformer has been stored

for any length of time.

●Make sure all power supplies are disconnected and properly grounded before attempting to work on the

transformer or inside of the control box.

●Do not make any connections that are not authorized by the nameplate or the connection diagram.

●Do not enter the cabinet or stick objects into the unit when energized. This could result in injury or death.

●High voltage is present in the system while on, never attempt to service the electrical system while the

engine is on, or the system is on - qualified technicians should only setup this equipment

●Do not a unit if there are signs of wear or damage

●Never permit anyone to operate the unit without proper training

●No supply cables should come in contact with the core or any live part except the terminal that it is intended

for. Ensure that minimum electrical clearances are maintained. (Refer to Table 1, Section 7.4)

●Never modify equipment without the written consent of Eco Power Equipment

Transformer Specific Details

●User installed cables must be kept as far away from coils and top clamps as possible. Refer to the Table 1

below for recommended minimum electrical clearance when performing final check. You should only make

those connections specified by the nameplate or connection diagram. Be sure to check all tap jumpers for

correct location and torque.

●Some tap connections and other joints involve bare aluminum or copper. If it is necessary to change taps or

assemble a joint of bare aluminum or copper, lightly clean the contact surfaces. Once the contact areas have

14

been abraded, assemble the parts and tighten securely. Always use two wrenches when breaking or making

joints to prevent damage to parts.

Table 2 below summarizes the recommended torque values for the different types of bolted electrical connections found

on dry-type transformers. All electrical connections should be checked prior to the energization of a unit.

Tap connections are typically provided to adjust for difference between nominal and tested incoming voltage values.

Standard units have taps located on the face of each phase coil (See figure 9). Unless specifically instructed otherwise,

transformer are shipped with the tap connection made for the nominal voltage. The taps are marked with letters or

numbers which correspond to the markings on the nameplate schematic. When changing taps, the following instructions

should be followed:

1. De-energize the transformer.

2. Short-circuit and ground the HV and LV terminals.

3. Locate the tap jumpers.

4. Loosen the hardware on the tap jumpers.

5. Remove the tap jumper and move the connection to the desired tap on each phase. (All coils must have identical tap

setting).

15

6. Verify all coils are connected at identical taps.

7. Torque the taps connections to the recommended values per Table 2, Section 7.5.

8. Remove the shorting connection on the HV and LV terminals.

9. Inspect the transformer to ensure that no tools or other objects have been left in the vicinity of the transformer

10. Replace all access panels, and re-energize the transformer

When cable connections are required, conductors suitable for at least 90⁰C should be used. Connections should be made

and supported such that they do not stress the terminals with the weight of the cables while still allowing for expansion

and contraction. The minimum electrical clearances to the core & coil per Table 1 in Section 7.4 should be maintained

and all connections should be torqued to the recommended values per Table 2 in Section 7.5.

Note: Top cable entry is not permitted in the main transformer compartment in accordance with CSA C22.2 No.47. If the

enclosure is fitted with air terminal chambers barriered off from the main compartment, then cables may be brought

into the top of these terminal chambers. Please contact Rex Power Magnetics or refer to the outline drawings supplied at

the order stage for instructions on appropriate cable entry locations.

Anti-vibration Pads

Dry type power transformers supplied as core & coils, or installed in an open bottom enclosure are supplied with

standard neoprene anti-vibration pads to be positioned underneath the core and coil base channel assembly. These

anti-vibration pads reduce the transfer or vibration and noise from the transformer core to the mounting surface. Refer

to figure 6 for proper location of these

pads.

16

Loading:

When energizing a transformer from a cold start, it is preferable to slowly increase the load while monitoring current,

voltage and load levels. If this is not possible, full load may be applied with caution. Note: When energizing a dry type

transformer for the first time, some smoke and vapor may appear during the first few hours of operation. This is normal,

and should dissipate within a few hours.

Parallel Operation:

Transformer may be operated in parallel to supply larger load as long as their polarity/phase shift, rated voltage,

frequency, impedance and turns ratios are the same. If these parameters differ, circulating currents will flow in the circuit

loop between the parallel units. The greater the difference between these parameters, the larger the magnitude of the

circulating current. The difference in impedance should not exceed 10% and the remaining parameters should be

identical. When specifying a transformer to be operated in parallel with an existing unit, the precise parameters of the

existing units need to be noted.

Voltage Selector Switch

●Always set to the appropriate voltage for your application, these units have been factory set to 480V and 600V

tap positions - review on each installation and commissioning

●Note the this is a multie tap transformer, so it is possible to fine tune output voltage if your applications requires

changes

17

Panel Board Specific Details

See Panel board manufacturers documention for completed details.

For QOB Circuit Breakers:

Push inward until the circuit breaker connector is centered on

the branch connector mounting hole. Engage the screw into

the branch connector hole and tighten it to the torque values

shown on the interior wiring and torque diagram.

6. Install the load wire.

7. Reinstall the deadfront.

8. Install a filler plate in all branch circuit breaker spaces not used.

QO and QOB Circuit Breaker Removal

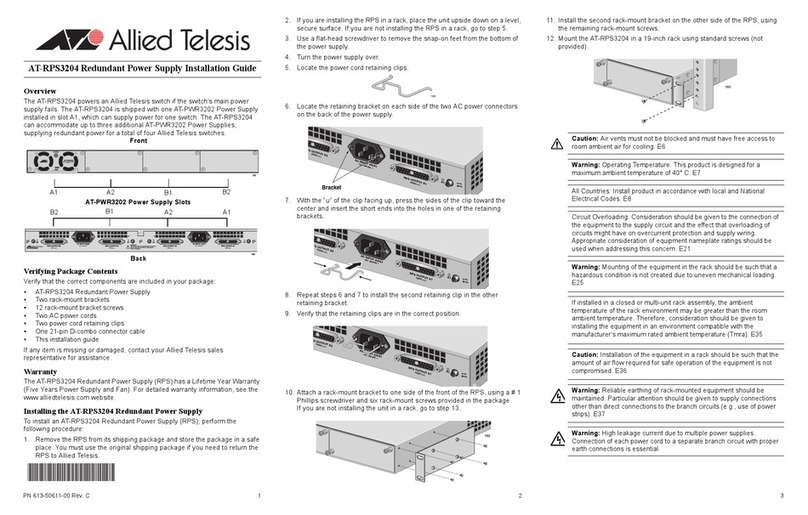

Refer to Figure 4, QO and QOB Circuit Breaker Installation and Removal, on page 15, for the following instructions:

1. Turn OFF all power to the panelboard.

2. Remove the deadfront.

3. Remove the load wire.

4. Disengage the branch connector. For QO Circuit Breakers: Pull outward until the plug-on jaws fully disengage the

branch connector. For QOB Circuit Breakers: Loosen the screw in the circuit breaker connector and pull the circuit

breaker off of the branch connector. 80043-712-06 Rev. 06 NQ/NQM Panelboards and QONQ Load Centers 07/2021

Installation 15 ENGLISH

5. Snap the wire terminal end of the circuit breaker off of the mounting rail.

6. Reinstall the deadfront.

7. Install a filler plate in all branch circuit breaker spaces not used.

18

Figure 4: QO and QOB Circuit Breaker Installation and Removal

19

2.4.2 Technical life span

●Unit Lift Span: 5+ Years in mobile applications

●Eco Power recommends that our customers implement an inspection process regularly on equipment to

ensure long life and successful operation: regular torque procedures on mobile equipment are required for

long term success, either with a regular schedule torque between maintenance, or advising customer to

torque check before each application setup

2.4.3 Personal Protective Equipment

●Always wear personal protective equipment: follow CSA Z462& NFPA 70E for guidelines

20

Table of contents

Other EcoPower Power Supply manuals