EcoSpeed Electric Mountain Drive Guide

ElectricMountainDriveComponents

DriveUnit

(connectorsmaydiffer

dependingonmotor)

FreewheelingCrankset

(tripleshown)

MotorChainAd-

justPlate

Frame Collar

ReturnSideIdlerMounting

Holes

Motor/Gearbox

Unit

PhaseCon-

nectors

EcoSpeedMotor

Controller

OtherParts

ElectricMountainDriveComponents

PhaseLeads

ThrottleLead

HallSenseLeads

PowerLead

EcoSpeed’sDigital

MotorController

ReturnChain

Idler WaxLube Throttle MotorChain

AdjustCup

LockRing

Adjust

Cup Insert

Tool

Possible

Clamp-sets

Congratulations onyourpurchaseofEcoSpeed’s ElectricMountainDrive, Type2.TheType2Electric

MountainDriveis theworld’sbestmulti-speed,throttleoperated,electric-assistconversionandtheonly

electric-assistdesigned specificallyforthepower needs of shortwheelbaserecumbentbikes andtadpole

trikes.

Theseinstructions will guideyoustepbystepthroughwhatwehopewill bea simpleand painless instal-

lationof yourEMtnD.Themechanicalskills involved aremodestand,wegiveyouhints andtips atevery

stepthatreflectwhata professionalmechanicknows.Ifatanytimeyouhaveproblems,call us at1-866-

EcoSpeed (866-326-7733)forfriendlytechnicalassistanceore-mailus at support@ecospeed.com.

A word onhowtheseinstructions areorganized: Eachstepis under a majorheading–Step1:,Step2:,

etc.Ifyou’veinstalled anEMtnDbefore,youcanjustread themajorheadings and ignore theexplana-

torytext.Beloweachmajorheadingis a listofsub-steps.Theimportantinformationineachsub-stepis

inbold text.Ifyou’re a competentbikemechanic,youcanjustread theboldtextand safelyignore the

rest.Theremainingtextisthere toclarifythingsfornon-mechanics. We’vealsoincluded tips andhints

inItalics.

SincetheEMtnD2 will fitbothbikes andtrikes,forsimplicitywewill justrefer tothemall as bikes

unless weare pointingoutsomethingthatapplies onlytotrikes.Inthis firstversionof theEMtnD2 man-

ual,mostphotos showtheEMtnD1onanuprightbike. Theinstallations steps arethesameexceptthe

unitclampstothefrontboomrather thanthedowntubeas showninthephotos.

Beforegettingstartedcheckthatall thepiecesneededwereincludedinyourshipment:

Checkthepackinglistincludedwithyourshipment.

Youwill also needthefollowingtools:

1)2.5mm,3mm,4mm,5mm,and8mmhex(orAllen)wrenches. (Thestandard “L”shaped

hexwrenches sold atbikeshops andhardwarestores.Getlonghandled versions ifpossible.)

2)10mmbox oropenendwrench.

3)8mmand10mmnutdriversorsockets.Also14mmifyourbottombracketusesthissize

bolt.

4)Wireclippersorscissors.

5)Small screwdriver. (Foradjustingfrontderailleur.)

6)Needlenosepliers.

7)Crankpullertool. TheParkToolCWP-6would beanexampleofthis (Standard bikerepairtool.

Availablefromalmostanybikeshop.)

8)Bottom brackettool. Suchas ShimanoTL-UN74. (Standard bikerepairtool.Availablefromal-

mostanybikeshop.)

9)15mmpedalwrench. TheParkToolPW-5wouldbeanexampleof this (Standard bikerepairtool.

Availablefromalmostanybikeshop.)

10)Torquewrench(optional). A small one, readingininch-pounds.

11)PinSpanners. Boththered and greenhandledParktoolpinspanners. Onceyouhaveall theparts

and toolsyouneed,it’stimetoclear a nicespacetowork,find severalof hours time, and gettoit!

Ifyouhaven’thad yourbiketunedupbyyourlocal

bikeshopina while, nowwouldbea good time.

InstallingtheEMtnDwill placeextra stress onyour

bikesoit’s importantthatitbeintopcondition.

Step 1:Findawayto secureyourbikewhile

working. (photo 1)

Trikes cansimplyberested onallthree wheels.

Placingthetrikeonlargetabletopcanmakeiteas-

iertoworkon.

Notethatthefollowingtwo stepswould takeany

competentbikeshopabout5 minutes todo.Ifyou

would rathernot hasslewiththem,takeyourbike

to yourlocal bikeshopand havethemremovethe

cranksetand bottombracket.Thenstartatstep4.

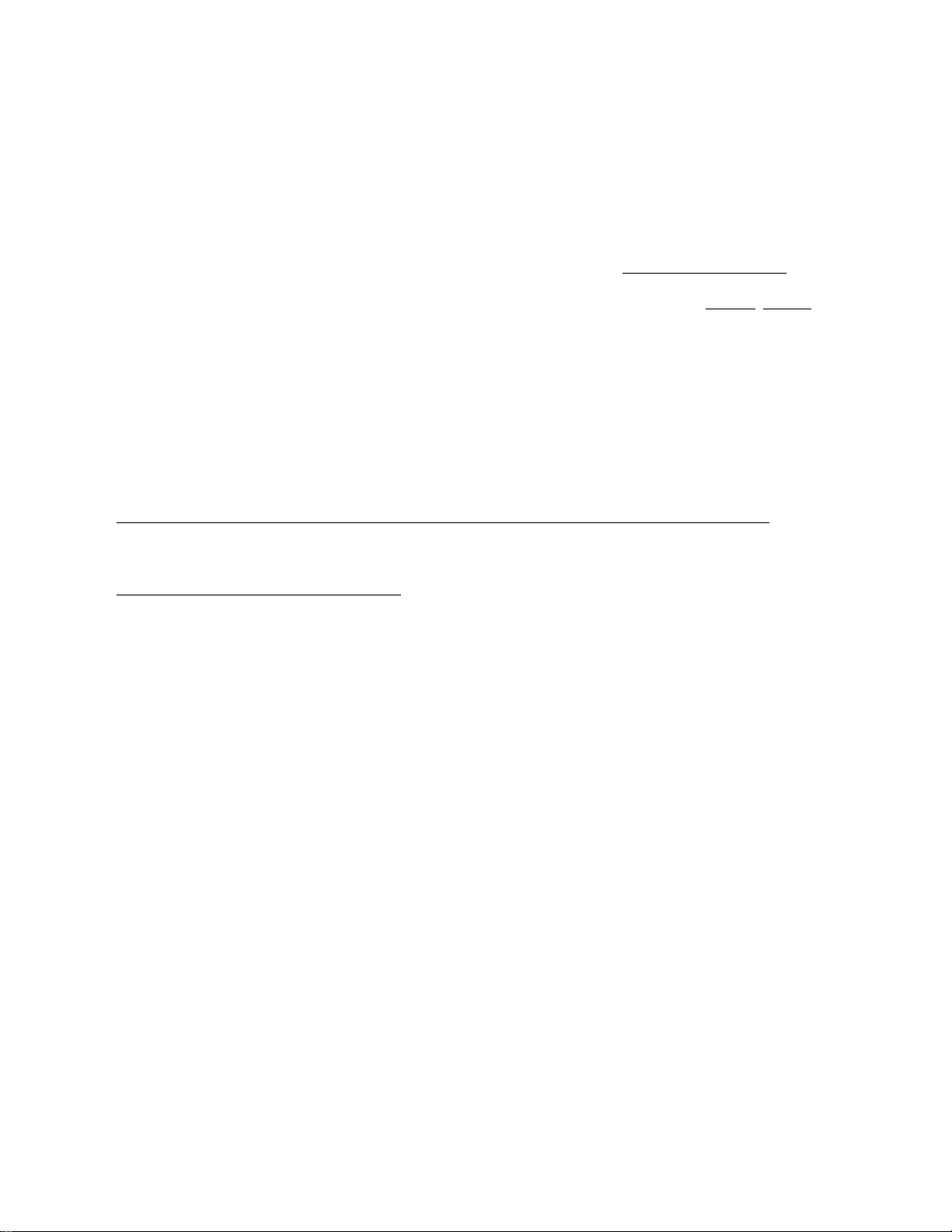

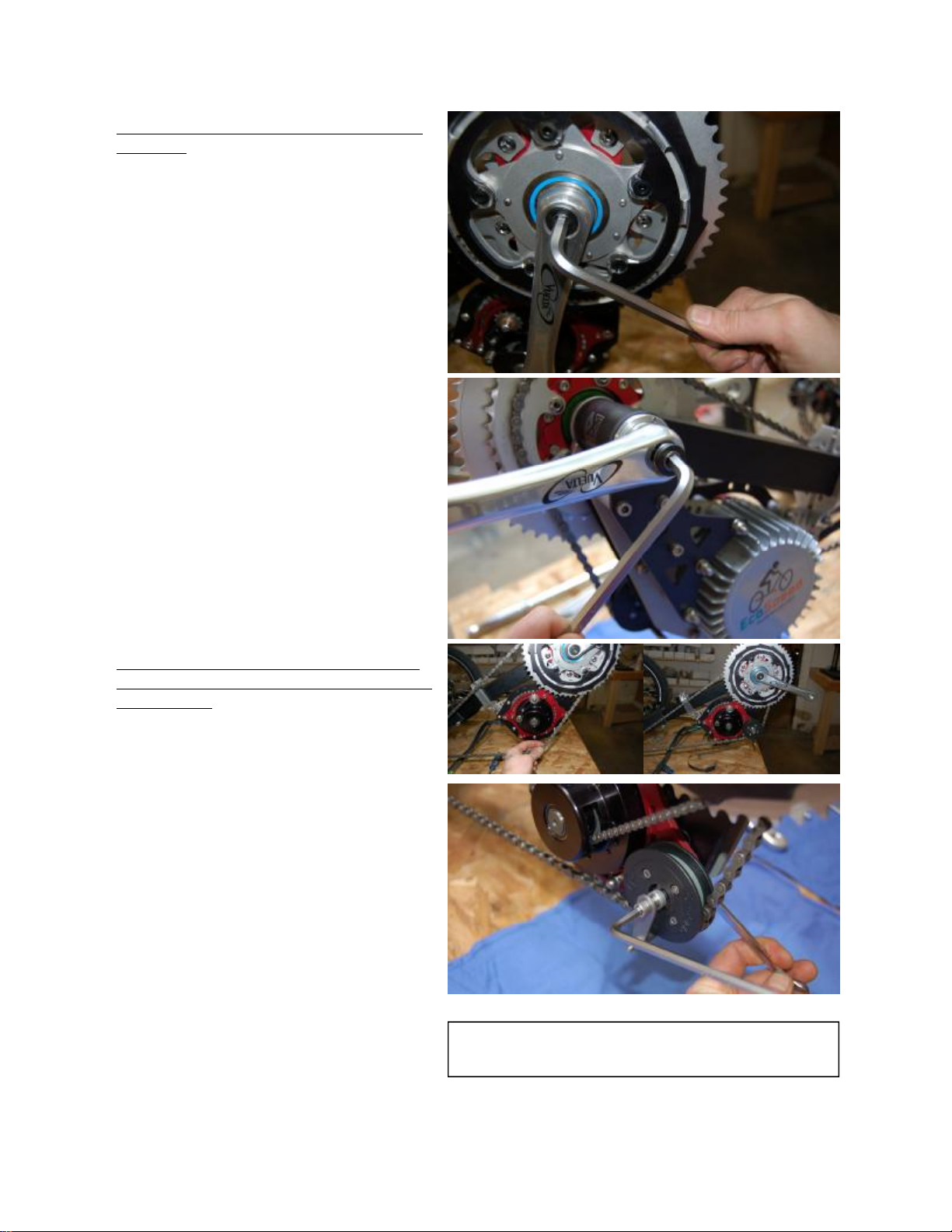

Step 2:Removecrankset.

Removethecranksetincludingtheleftarm.

Leavechainhangingfromfrontderailleur.

Thetoolsinvolvedwill differbetweencrank

modelsandbrands.

Thecranks areheld inplacebybolts,sometimes

concealedunder caps.Removeusinga socketor

hex wrench. Oncethebolts areout,useyourcrank

puller tooltopull thecranks off of thebottom

bracketaxle(photo2).

Step 3: Removebottombracket.

TheEMtnD isdesignedtoworkwithframes

thattakestandard1.37”x24tpi,68mm wide

bottom brackets.Ifyours is not,youwill need

tofind a compatiblewidebottombrackettouse

with theEMtnD.Thesupplied oneuses a 127mm

squaretaper axle. There is quitea bitofadjustabil-

itybuiltintotheEMtnD,soa similar oneshould

workfine.

There are differentbottombrackettools,soyou

will need tousetheoneappropriateforyourbike.

Photo3 shows thetoolusedforShimanocartridge

bottombracketnuts suchas theonesupplied with

theEMtnD.

Notethatthe right nutis left-handthreaded,i. e. it

tightens byturningleftand loosens byturningto

theright(clockwise).The left nutuses standard

right handthreads (loosens counterclockwise).

Removetheleftnutfirst.Thecartridgewill comeoutalongwiththeright nut.

(1)BikeonWorkTable

(2)RemovingCrankwithCrankPuller

(3)RemoveBottom Bracket

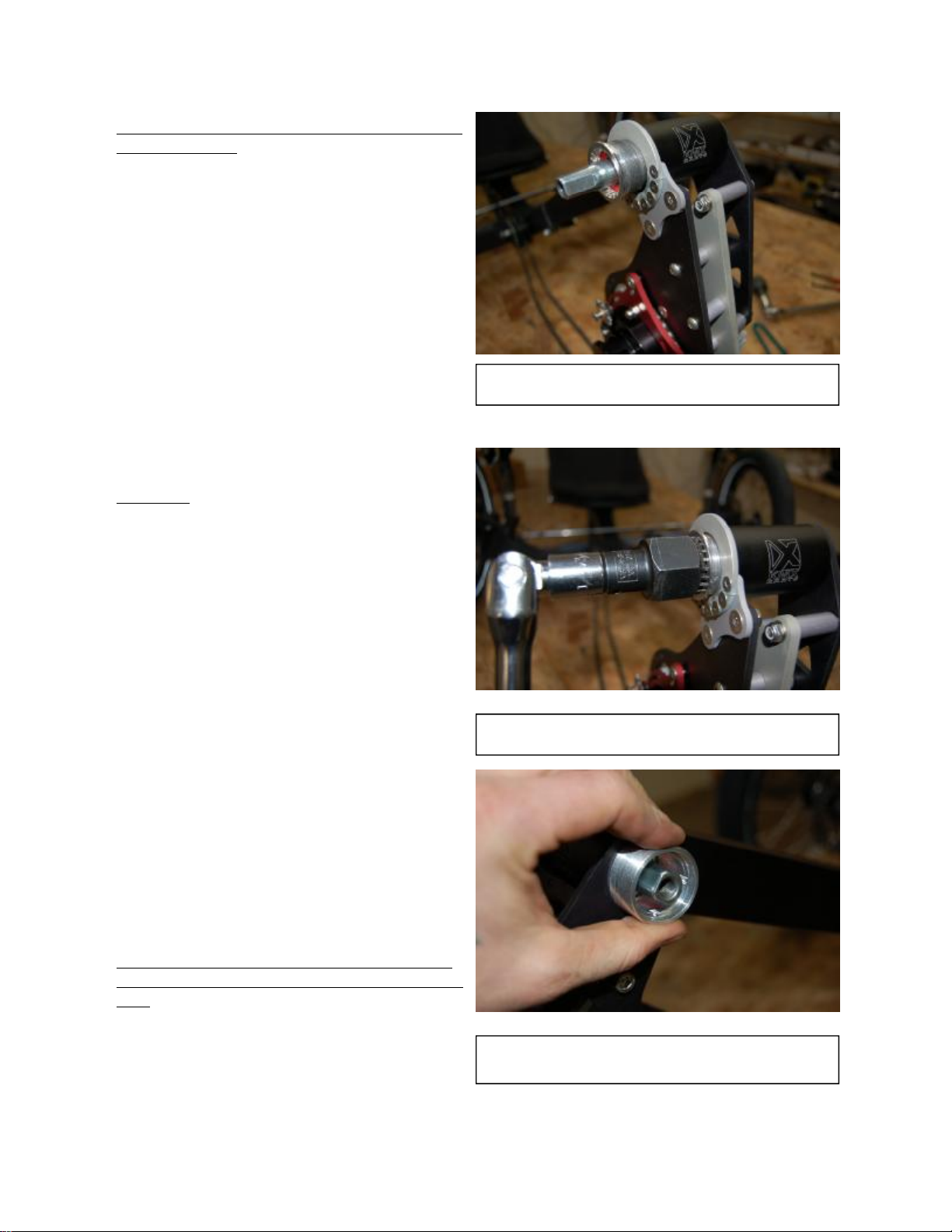

Step 4:Install thenewbottombracketandat-

tachtheEMtnD

Slip the BB cartridgeandrightsidenut

throughthe collaron the EMtnD.Sup-

portthe weight ofthe EMtnD,soasnot

to damagethe threads,andscrewin the

right sideBBnut.(Photo 4A+B)

Youmaywantto havean assistantholdthe

unitwhile youperformthisstep.Thethreads

ontheBB nuts arefragile aluminum,so be

verycareful when first engagingthethreads.

Rememberthattherightnutislefthand

threadedso turnitcounterclockwiseto engage

thethreads.

(Trick:toavoidcross threading, gentlypress

thenutintothebikeframewhileturning

clockwise.Youwill feel aperiodicclickasthe

endof thethreaddropsintothegroovein the

framethreads.When youfeel theclick,stop

turningclockwiseandturn counterclockwise

toengagethethreads.)

ScrewintherightsidenutuntiltheEMtnD

collarispressedagainst thebikeframebutdo

not tighten.(Photo 4B)

Screw in the leftsidenutthroughthe

lefthandcollar,don’ttighten.Thisin-

volvesthe useofaproprietarytool

madeto fit ourspecialleftsidecup.

(Photo 4C+D)

Youuseastandardpinspanner,insert its ends

into thespecial tool,andusethisto threadin

theleftsidecup.Youcan then threadonthe

lockring, whichwill not betightenedyet.

When you’redone,theEMtnDwill behanging

off ofthebottombracketbythecollars as

showninPhoto6.

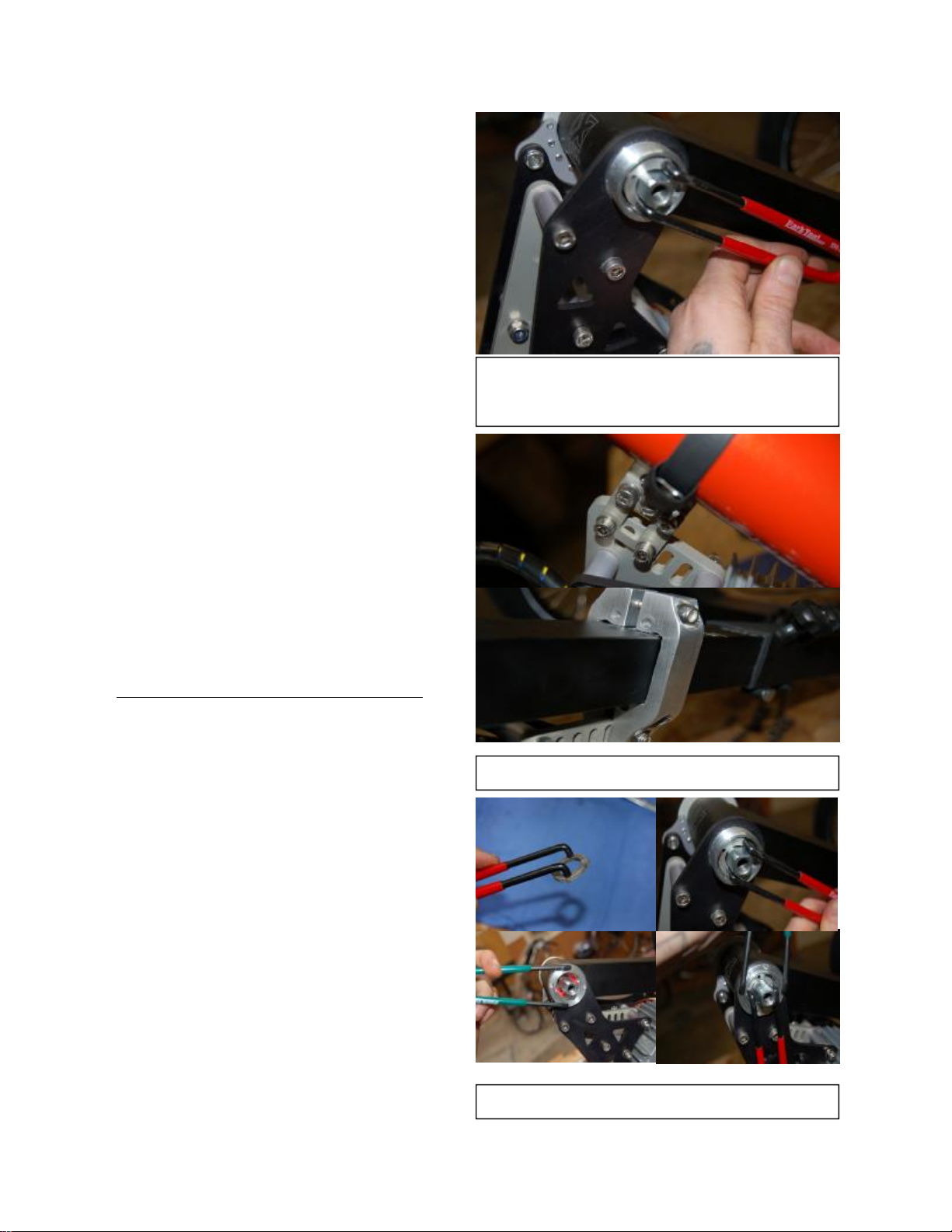

Step 5:SwingtheEMtnDupagainst thebot-

tomofthetrike’sboomtubeandinstall clamp

sets.

Iftheclamps interfere withexposed cables,they

canbeenclosed ina shortlengthof cablesleeve

and routed aroundtheclamps. (4C)LeftSideBB NutPartly Installed

(4B)UsingaPark Tool

(4A)InstallingNewBottom Bracket

Most kits will havean adjustable strap system

thatattachesthefrontoftheEMtnDto the

frame.Theprimarymotor platehascutouts to

accommodatetheheadoftheclamp,allowing

itto beoutofthewayandstreamlined.

Tighten theclampuntil thereissignificant

tensionholdingthemotor tothedowntube.

As youdothis,feedtheemergingclamptail

into thesuppliedpieceofshrinkwrap,thiswill

preventanyexposededges.When clampis

tight,shrinkthiswithaheatgun,blow-dryer,

pen torch,or lighter.If usingflame,besure

not to burnthebikeor yourself!(Photo 5)

If youhaveamachinedclampfor yourappli-

cation,therewill be2M5bolts holdingitto

themotor frame,and1M6boltholdingthe

halvestogetherabovethebike’sboom.

Oncebothhalvesareinstalled, tighten theM5

bolts andnuts holdingtheclampstheEMtnD

unit.Next,tighten theM6boltandnut.If you

haveatorquewrench,tighten themto 90inch-

lbs(10N-m).Otherwisetighten firmlybutnot

so muchastoclosethegap between theclamp

topmorethan acouple ofmm.

Step 6:FinishattachingtheEMtnDunit.

Makesureall clampboltsorstrapistight.

Tightenbothbottom bracketnuts.

Tighten thebottombracketinall thewaybe-

forescrewingtheadjust cupin,leavingjust

enoughthreadsfor thelockring. Useyourpin

spanners,andwhen thecupisinall theway,

holditinplaceandtighten thelockringup

against thecollar.

Itmaytakesometimeto getthehangofusing

thespannerwiththeEcoSpeedtool,just take

yourtimeanditwill come.Donot losethespe-

cial tool,asyouwill needitto changebottom

brackets,or removethemotor incaseyou

changetrikes,etc.(Photo 6)

(4D)EMtnDHangingfromCollaron

Bottom Bracket,UsingProprietary

Tool.

(6)AdjustCupandLock-ringInstall

(5)ClampsInstalledOn Frame

Step 7:Install thefreewheelingcrankset.

(photo 7)

Install theleftsidecrankarm andthe

freewheelingcrankandchainringas-

semblyontheright.Tighten boltsfirmly

sothatbotharmsarepressedontothe

bottom bracketaxleasfarastheywill

go.

It’s importantthattheright sidecrankarmis

firmlyseatedontotheBB axleforcorrectalign-

mentof themotordrivechain.

This stepinvolves puttingthedrivechainonto

thesmall chainring, and installingtheReturn

ChainIdler inoneofthetwooptionalplace-

ments.Thepurposeof theidler is toroutethe

returnsideof thebikechainaroundthegear-

box.Inthephotoshowntheidler is inthefor-

ward position.This is thedesired position,but

dependingonthebikeyoumayhaveshifting

problems and needtoplacetheidler inthe

rearward position.

As itwill behard totellwhichpositionwill

workbestduringinstallation,putitinthefor-

ward positiontostartwith,andthenchangeit

ifthere are problems.

Step 8: Install themotor chainandalign

thegearboxsprocketto thechainringmo-

tor sprocket.

Install themotorchainusingneedle

nosepliers.

Thegear boxrolls easilyinonedirection,insert

thechainand roll itaround thesprocketand

throughtotheother side. Nowwrapitaround

themotorsprocketandbringtheends together

with pliers as shown.(Photo8)

Theends attachbyinsertingthe2pinned link,

coveringitwith thesmall plate, andthencon-

nectingthemwiththeclipthatshould seat

firmlyintothepin’s slots.(Photo8)

Alignthemotorchain.

Sightdownthelineof themotorchain,anduse

theredtertiaryplates’setscrews and adjust-

mentboltstostraightenouttheline, where itis

notgoingtorubagainsteither chain-ring

guards,and will givethebestpower transfer possible. Youmaywanttousea thinstraight edge, suchas a

(7)InstallingCrankset,DriveChain,and

Return Chain Idler

metalruler, tohelp yousight downthechain-line

tocheckalignmentofthegearboxsprocketwith

thechain-ringmotorsprocket.(Photo8)

Thesetscrews cangoina littlemore thanhalf

wayintotheplateifneeded forproper alignment.

Whenthedesired chainlineis found,tightenthe

pinchbolts nexttothesetscrews.Itis possibleto

putexcessiveforceontheplate,a good guideline

is totightendownuntilyousee thered tertiary

platestarttobend slightly,and thenleaveitright

there.

Step 9: Installall wiring

Whilewiringupthesystem,donotsecure anyof

thewires totheframeuntileverythingis inplace

and tested.This will insure thateverythingis

workingand routed mostefficientlybefore using

theincluded zipties.

Install thethrottle

Ifyourbikehastwistshifters,remove

rightsidegripandshifterandinstall the

thumbthrottlebetweenshifterandbrake

asshowninphoto 9A.

Youmayneed tomovetherightbrakelever to

thelefttomakeroomforthethrottle. Thethrot-

tleslides ontoyourhandlebar and locks inplace

with a setscrewvisibleonthebottomofthe

throttlebody.

Reinstall thetwistshifter makingsure there is

enoughclearancetoallowfree movementofthe

throttlelever.

Ifyourbikehasthumbshifters:Install

accessorymountonleft handside,and

placethethrottleonitsoitisabovethe

bars.Photo 9B

Ifyoudon’t havethecorrectthrottletoworkwith

yourbar and shifter setup,contactEcoSpeed for

adviceand/ora differentthrottle.

Bothrightand lefthand mountingare possible. It

is uptoyourcomponentset-up,and whichyou

prefer.

Routethethrottlewiresothat itdoesn’timpairturningthebars,won’tsnagonanything,

andreachesthethrottleconnectoronthemotor.

(9A+B)LeftandRight ThrottlePositions

(8)InstallingChain,andAlign UsingSet

Screws

If youhaveaCycle Analyst for yourkit,install

itNow

TheCycleAnalyst will haveawheelsensor

andaconnectionbetween thebattery and

controller. Itis importanttomountitnow,as the

throttleand analystwires will followsomeofthe

samepaths.

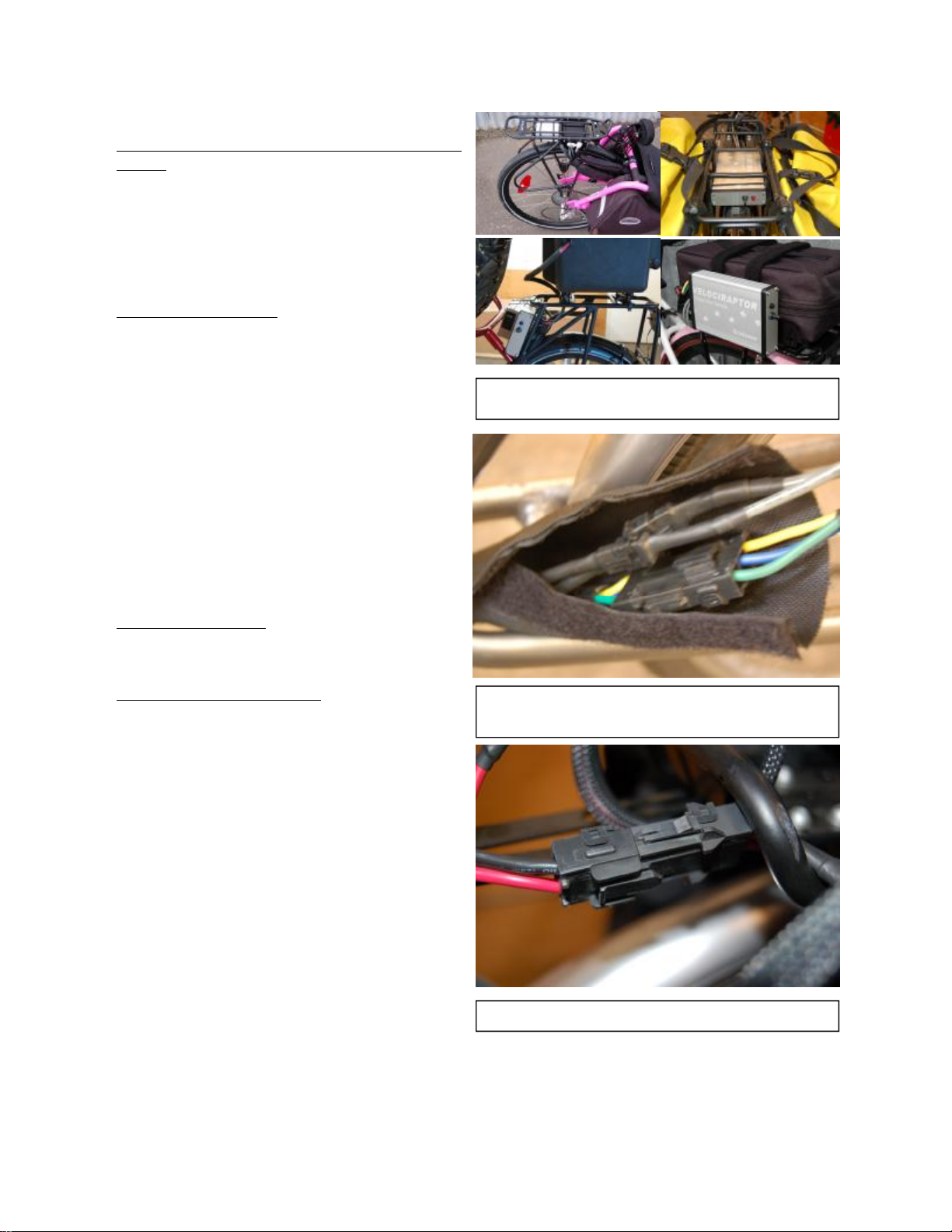

MounttheController

Attachthe controllerto yourbikeusing

the includedadhesivefoam andcable

ties.Photo 9C showspossiblemounting

locations.

Thecontrollerisan electronicdevicethat

regulatesmotor speedandpowerlevelsinre-

sponseto asignal fromthethrottle.Itissmall

andlightandso maybemountedinanynum-

berofplaces.Theimportantconsiderations

arecooling—thecontrollershouldbeinopen

airandnot enclosed, andlocatingitso that

cablesfromthemotor andthrottle will reach.

MountyourBattery

See theincludedseparateinstructionsfor

yourtypeofbatterysystem.

Step 10:Connect all cables

Connectthefollowingcables:

1) Throttle. Black4-circuitJSTconnectoron

throttleplugs intomatchingconnectoron

throttle. Becarefulwhenpluggingintoavoid

bendingconnectorpins.(Photo10A)

2) 3Motorphasewires. Thesecanhavevari-

ous connectortypes dependingonthemotor

and controller combination.Thephasewires

are thethree heavycolored wires comingoutof

themotor.Connectthemtothematchingcon-

nectoronthecontroller. Ifthephasewires have

individualconnectors,matchthemaccording

tocolor.(Photo10A)

3) MotorHall SenseCable. A graycablecom-

ingoutof themotorendingina blackJSTcon-

nectorwith5 or6circuits.Plugintothecorre-

spondingconnectoronthecontroller. Becare-

fulwhenpluggingintoavoid bendingconnectorpins.(Photo10A)

4) MainPowerConnection. Theheavycablefromthebatterytothecontroller terminatingina gray

2-circuitMiniFitSrconnector.(Photo10B)

(10A)OptionalWireWrap,Enclosing

Connectors

(9C)PossibleControllerLocations

(10B)Main PowerConnector

WARNING: Donot route the phase

wires(2above)andthe Hall sensecable

(3 above)nextto eachotherovertheir

entirelength.Spacethem atleastan

inch(25mm)apartovermostoftheir

length.The highcurrentsin the phase

wirescan interferewith the low voltage

signalsinthe Hall cableanddestroythe

controller.

Step 11:CheckfrontDerailleurAdjustment

Triplechainringversiononly:Testfrontde-

railleuradjustmentandadjustasneeded.

It’sespecially importanttoadjust thederail-

leurso it doesn’tovershiftonthebigringanddropthebikechainontothemotorchain.

Ifyoudon’t knowhowtoadjustyourderailleuryoucanaskyourlocalbikeshoptodoit,orgoto:

http://www.parktool.com/repair/readhowto.asp?id=75

ontheParkToolCompanywebsiteforanexcellenthow-toarticleonfrontderailleuradjustment.

Singlechainringversiononly:Ifswitchingfrom atriplechainringtosinglechainring,

leavethefrontderailleurinplaceandadjustitso thatthebikechainiscenteredinthe

cage.

This will provideextra protectiontokeepthechainfromcomingoffthefrontsprocketonsharpbumps.

Step 12:FinishupandTest.

1)Withtherearwheelsuspendedoffoftheground,turnonthebatterypackswitchand

pressthethrottleto testthesystem.Runthebikethroughall ofthegearstomakesurethe

derailleurisproperly adjusted. Lookat themotorchainandverify that itisrunning

smoothly.Makesurethatall wiresareout ofthewayofall movingparts.Makesureaxle

boltsorskewersaretight

2)Onceyou’resatisfiedthat everythingisoperatingcorrectly,neatlytieall wiresout of

theway ofmovingpartsusingtheincludedcableties.

Proper adjustmentofthegears and makingsure thattherear cassetteandbearings areingood shapeis

especiallycriticalgiventheextra load thedrivetrainwillbesubjected to.Also,checkthattherear axle

skewer orbolts arefullytightened.Axlebolts shouldbetorqued toabout20ft-lbs (28Nm).Skewers

shouldbeas tight as youcancomfortablymakethem.Itis possibleforthemotortopull theaxleright

outof thedropouts iftheyare loose.

3)Roadtest. Runthroughall thegears makingsure theyare shiftingsmoothly.Usefull throttleineach

gear tocheckforskippingofthedrivechain.Keepspeeds lowatfirstuntilyou’re sure thateverythingis

functioningproperlyand youbecomefamiliar withridingwiththemotorassist.

Congratulations! Yourinstall iscomplete!

(11)AdjustingFrontDerailleur

Table of contents

Other EcoSpeed Bicycle manuals