ECRM Mako 8 CTP Manual

MAKO 8 CTP/

Operator Guide

NEWS extra

Mako 8 CTP / NEWS extra

Operator Guide

This guide reflects Mako 8 CTP/NEWS extra systems as of March 2005

© copyright ECRM Incorporated 2005

For additional copies of this guide contact:

ECRM Order Processing

554 Clark Road

Tewksbury, MA 01876

Phone No. (US) - (+1) 978-851-0207 — Fax (US) - (+1) 978-851-7016

Phone No. (UK) - (+44) 1923-218255 — Fax (UK) (+44) 1923-218256

Phone No. (Hong Kong) - (+852) 2-564-8989

Fax (Hong Kong) (+852) 2-564-8821

Visit our Web site: www.ecrm.com

Proprietary Notice

The information in this publication is the sole property of ECRM. It cannot be

reproduced, in whole or in part, without the express written consent of ECRM. The

information is believed to be accurate as of the publication date, but it is subject to

change without notice due to continuing product development.

ECRM®, Mako8 CTP®, and NEWS extra® are trademarks of ECRM Imaging

Systems. Other brand and product names are trademarks or registered trademarks of

their respective owners.

AG114123 Rev. 2 iii

Table of Contents

Preface vii

Scope of this Guide vii

Organization of this Guide vii

Not Covered in this Guide viii

Requirements and Safety 1

Introduction to the System 1

System Requirements 1

Laser Safety 2

Regulatory Information 3

System Operation 5

Introduction 5

Platesetter Parts 7

Starting Up the System 9

Shutting Down the System 9

Using the Platesetter Control Panel 10

Menu Selection 12

User Preferences Menu 13

User Maintenance Menu 17

Test Patterns Menu 19

Running a Step Wedge Test Pattern 23

Status Messages 25

Error Messages 26

System Configuration Display 27

AG114123 Rev. 2 v

Preface

Scope of this Guide

This guide provides instructions for the operating and maintaining a

Mako 8 CTP/NEWS extra platesetter. This guide describes all

aspects of the operation of the system, from the loading of media, to

the delivery of exposed media to an on-line processor.

The Mako 8 CTP/NEWS extra employs a Class 3B laser. This

guide contains important safety information and regulatory

information about the laser. You should read this information

thoroughly before operating the system or performing the

procedures described in this guide.

This guide assumes the system is properly installed and plugged

into the system power conditioner. It also assumes that the system

has been calibrated and tested for proper operation and acceptable

output.

Organization of this Guide

Chapter 1: Requirements and Safety

This chapter includes system operating requirements and

information about laser safety.

Chapter 2: System Operation

This chapter discusses all operational features and provides

complete listings of system operational messages. All of the system

menus are described in detail. All of the menu items are mapped in

flow diagrams.

vi AG114123 Rev. 2

Chapter 3: Media Handling

This chapter provides instructional information on how to load

media. Guidelines for handling media are also provided.

Chapter 4: General Maintenance and Troubleshooting

This chapter covers general maintenance items that can be

performed by the operator. This chapter includes troubleshooting

tips and a procedure for re-locating or moving the system.

Not Covered in this Guide

System set-up and installation

Engineering specifications

Alignment and calibration

Field service information

1

AG114123 Rev. 2 1

Requirements

and Safety

Introduction to the System

Plates are loaded by manually positioning the plate against the pin

bar registration system. When sensors determine the plate is

properly positioned, the plate is automatically moved into the

imaging unit and imaged. After that, the exposed plate is moved

onto the media transport, which feeds the plate into a customer-

supplied plate processor.

System Requirements

System Power and Heat Dissipation

Power (maximum) 100 - 240 Volts; 3 Amps

50/60Hz, single phase.

Heat Dissipation 850 BTU/hour

Environmental Requirements

Temperature- 62 - 86 degrees F (17 - 30 degrees C)

Humidity 45 - 65%, non-condensing.

Note: Operating the system outside the ranges specified above

may affect performance.

2 AG114123 Rev. 2

Laser Safety

Laser Product Classification

The system is classified as a Class one (I) laser product which

contains a Class 3B (IIIb) laser System. This classification means

that the operator is exposed to no hazardous laser light during

operation and maintenance. The laser itself, however, is a Class 3B

(IIIb) laser device, and emits visible laser light which is considered

hazardous by FDA published limits.

IMPORTANT WARNING

Use of controls or adjustments or performance

of procedures other than those specified in this

guide may result in hazardous laser light

exposure.

System Laser Wavelength Identification Label

The system contains a laser that emits visible laser light. The

identification label is located on the optics assembly. The label is

shown in Figure 1-1.

Figure 1-1 Media Sensitivity Label

MEDIA SENSITIVITY

405 nm VISIBLE

AG114123 Rev. 2 3

Regulatory Information

Electromagnetic Emissions

DOC - Canada

The Canadian Department of Communications requires compliance

with the Radio Interference Regulations, ICES -003.

This digital apparatus does not exceed the Class A limits for radio

noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of

Communications.

EMC Directive - Europe

Complies with EN 55011: 1998

This is a Class A product. In a domestic environment this product

may cause radio interference in which case the user may be

required to take adequate measures.

FCC - USA

The standards for electromagnetic emissions are Part 15, Subpart J

of the FCC rules. The system was tested to Class A limits. The

following statements are required by the FCC:

Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void your authority to

operate the equipment.

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction guide, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

4 AG114123 Rev. 2

case the user will be required to correct the interference at his or her

own expense.

Compliance with applicable regulations depends on the use of

shielded cables, which the user is responsible for procuring.

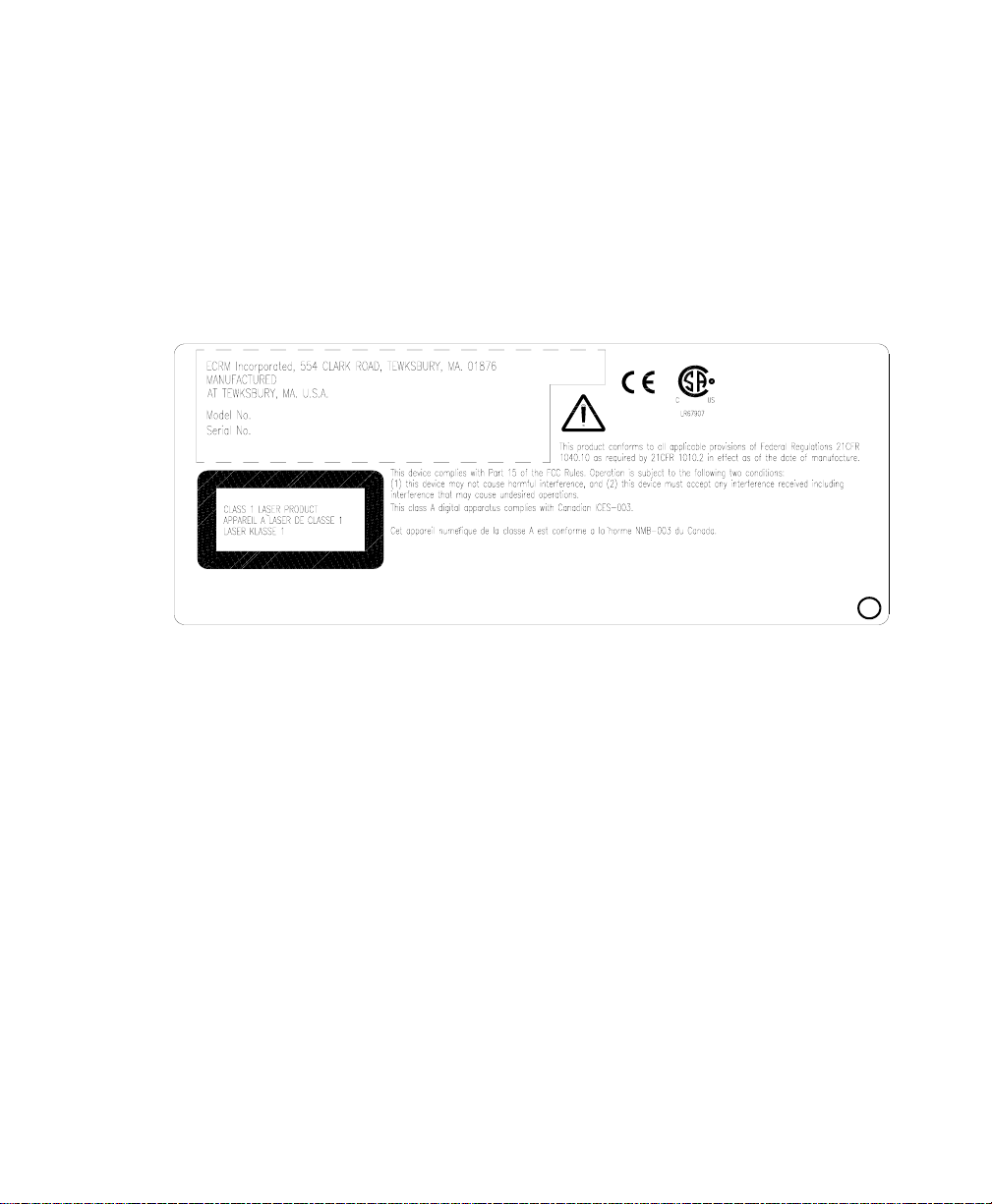

Identification and Certification Label (ratings plate)

The identification and certification label is attached to the back of

the unit, above the pinch rollers.

Figure 1-2 Identification and Certification Label

2

AG114123 Rev. 2 5

System

Operation

Introduction

A complete Mako 8 CTP / NEWS extra system includes a control

workstation, CtServer software, the platesetter, and a power

conditioner.

Workstation

The control workstation connects directly to the platesetter and runs

the CtServer software. Operating instructions for the workstation are

provided with the workstation.

The operator makes frequent use of the workstation. For that reason,

the workstation should be set up next to the platesetter.

CtServer Software

CtServer is used to send jobs to the platesetter. It is also used to

define the plate and pin bar requirements for jobs and communicate

that information to the platesetter, which displays the information on

the control panel LCD. The use and operation of CtServer is

documented in the CtServer User’s Guide.

Mako 8/NEWS extra Platesetter

The platesetter is the output device that images the plates.

6 AG114123 Rev. 2

Power Conditioner

The system power conditioner protects the system against power

quality problems like brownouts, surges, over-voltage, sags, voltage

imbalance, and line noise.

The platesetter, the workstation, and the workstation monitor all

must be plugged into the power conditioner.

Figure 2-1 AC Power and I/O Connections

AC MAINS

POWER

AC OUTLETS

PLATESETTER PC MONITOR

AC INLET

AC Power

AC Power

RS-232*

SCSI Monitor

(CtServer)

CONDITIONER

AC INLET

AC INLET

AC

INLET

Plate Line IF

AC Power

AC Power

MAKO 8/NEWS extra System

* Used by service personnel to run diagnostic programs.

PROCESSOR

AG114123 Rev. 2 7

Platesetter Parts

The main parts of the platesetter are shown and described below

Figure 2-2 External View of the Platesetter

Power Cord Receptacle

The power cord receptacle is located on the right side of the system,

as shown in Figure 2-2.

Note: In order for the system to work properly, the platesetter,

the CtServer computer, and the computer monitor must all

be plugged into the system power conditioner. Be advised

that if the devices are not plugged into the power condi-

tioner, damage resulting from voltage spikes, brownouts,

etc., will NOT be covered by the warranty.

PEDESTAL

INPUT TRAY

MEDIA

TRANSPORT

CONTROL PANEL

PIN BAR

FAN FILTER

10

POWER SWITCH

POWER CORD

RECEPTICAL

8 AG114123 Rev. 2

Power Switch

The power switch controls ac power to the system. To start up the

system, turn on the power switch located on the rear right side of the

machine. Depress zero (0) to turn OFF, depress one (1) to turn ON.

See Figure 2-2.

Note: It is recommended that the system be powered on for a 1-

hour warm-up period prior to imaging.

Pin Bar

The pin bar is used for plate registration. There are two types of pin

bars: press notch registered and edge registered.

Up to two pin bars come with the system as standard equipment.

Additional pin bars can be ordered as an option. Exposing sets of

plates with different registration notch requirements is easily

accomplished by changing the pin bar.

Control Panel

The control panel allows you to interact with the platesetter.

Commands and menu selections are controlled through this device.

Input Tray

The input tray is used to position the plate for exposing. The plate is

placed on the input tray and gently pushed against the registration

pins.

A new plate cannot be loaded until the previous plate has been

completed.

Media Transport

The media transport provides for automated delivery of media to a

customer-supplied online processor.

AG114123 Rev. 2 9

Pedestal

The pedestal is a specially designed base for the platesetter.

Fan Filters

The platesetter has several fan filters. For details about the filters,

see Chapter 4.

Starting Up the System

Turn on the power switch located on the rear right side of the

machine. Depress one (1) to turn the power ON. When the system

completes its initialization, a message appears on the display

indicating ONLINE. When ONLINE appears, the host computer

can be powered on. Once the host computer is powered on and

running CtServer or the RIP, and the Mako CTP is ONLINE,the

system is ready to expose images.

Shutting Down the System

To shut down the system, turn off the power switch located on the

lower right side of the machine. Depress zero (0) to turn the power

OFF. Shut down the system only when the display reads ONLINE,

and the second line is blank. (No operational message visible).

Once the machine is turned off, the host computer will have to be

rebooted after the machine is turned back on in order to establish

communication.

10 AG114123 Rev. 2

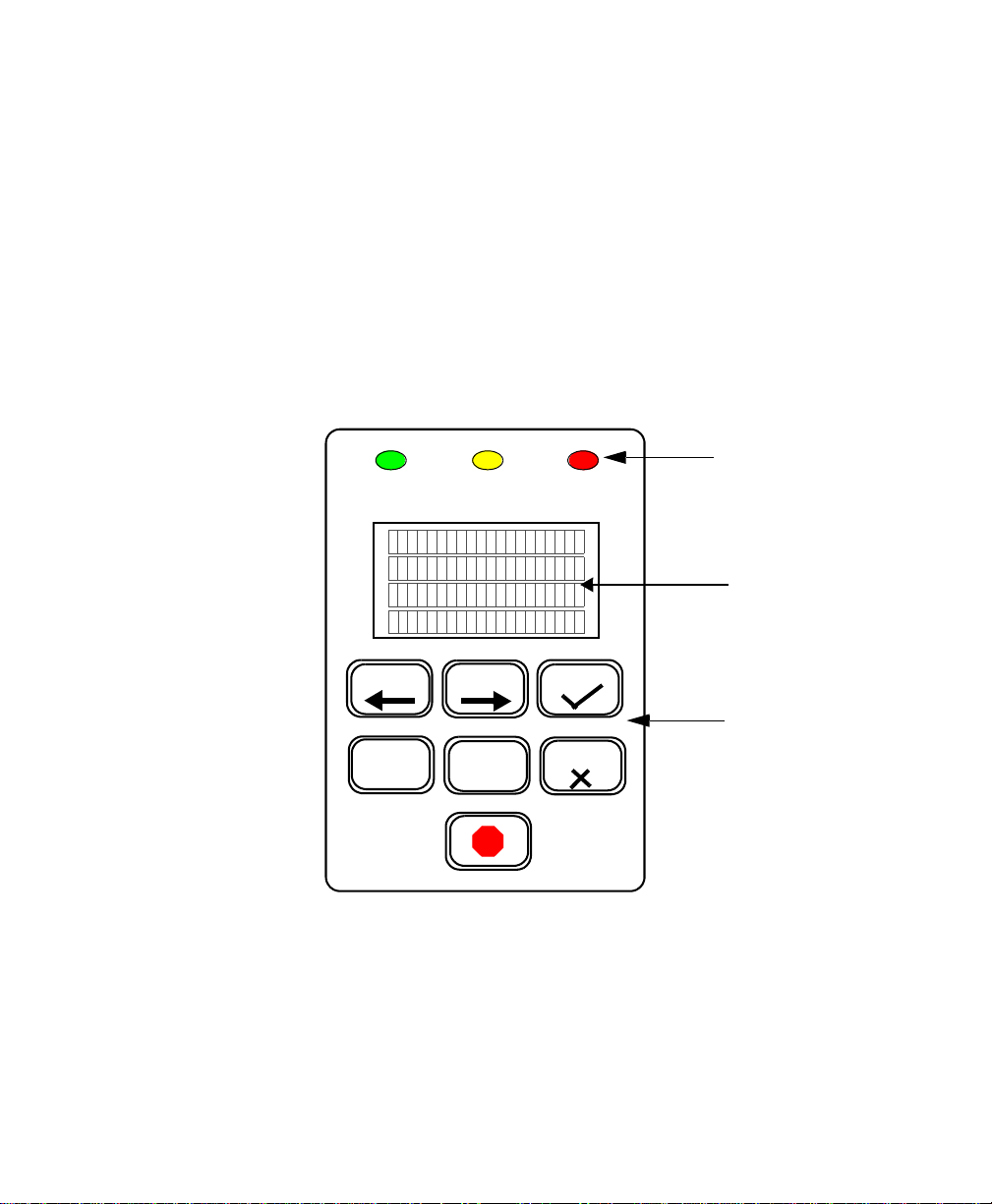

Using the Platesetter Control Panel

The first time you use your new system, you should review and set

all the menu parameters. Advance through the menu items and

verify or change them as needed. When you finish, the system is

ready for use.

Using the Control Panel to Access Menus

The system control panel is used to access the menus. The main

parts of the control panel are shown and described below.

Figure 2-3 Control Panel

PREV NEXT

MENU SELECT

LCD

OK

CANCEL

KEYPAD

EXPOSE ERRORATTENTION

LEDS

AG114123 Rev. 2 11

Keys

Moves you backward within the menu or moves the

cursor backward within the current menu item.

Enter or exit the menu sub-system by pressing MENU

from the ONLINE or the OFFLINE state.

Moves you forward within the menu or moves the cursor

forward within the current menu item.

Increments the numeric digit under which the cursor is

positioned or scrolls through the options available for the

current menu item.

Start exposing the loaded plate. Also, from anywhere in a

numeric field, causes the next menu item to be displayed.

In the last item of a menu, causes a return to the first item

of the menu.

Cancels a pending “load plate” request, but does not stop a

job that is in progress.

The Emergency stop button. This button will stop all

moving parts of the platesetter.

LEDs

Green LED that indicates the plate is being exposed when

it is flashing. Additionally, indicates registration pin

contact when loading a plate.

Yellow LED that indicates there is a condition that

requires operator attention. The LCD display indicates

what needs to be done.

Red LED that indicates a platesetter error condition. The

LCD display indicates what the error is.

PREV

MENU

NEXT

SELECT

OK

CANCEL

EXPOSE

ATTENTION

ERROR

12 AG114123 Rev. 2

Menu Selection

There are three operator menus:

• User Preference Menu (See page 13).

• User Maintenance Menu (See page 17.)

• Test Pattern Menu (See page 19.)

To select and set parameters in any menu:

Step 1. Press MENU to enter the user menu system.

Step 2. Press SELECT until the menu you want displays on the LCD.

Step 3. Press NEXT to enter the menu.

Step 4. Set the parameter to what you want. Press SELECT to change the

value.

Step 5. Press Next to go to the next parameter until you have completed

your selections.

Step 6. Repeat steps 4 and 5 until all changes are made.

Step 7. Press MENU to exit the user menu system.

Figure 2-4 The User Menus

Preferences Test

Patterns

SELECT

NEXT

User

Preferences

User

Maintenance

Test

Patterns

Test

Patterns

SELECT SELECT

ONLINE

MENU

User Menus

NEXT NEXT

AG114123 Rev. 2 13

User Preferences Menu

UNITS OF MEASURE

OPTIONS ENGLISH (inches) or METRIC (millimeters)

The selected units of measure apply to all numeric measurement

values in various menus.

AUDIO ALERTS

OPTIONS ENABLED or DISABLED

This menu item allows you to disable or to enable the audible

alarms for the following conditions:

Error conditions, Power-up, Image complete

HORIZONTAL MAGNIFICATION

LIMITS 85.00% to 110.00%

Sets the size of the image in the horizontal direction from 85% to

110% of nominal.

VERTICAL MAGNIFICATION

LIMITS 85.00% to 110.00%

Sets the size of the image in the vertical direction from 85% to

110% of nominal.

IMAGE OFFSET

LIMITS -0.300” to +0.300” (-7.62mm to +7.62mm)

The image may be shifted to the left with a negative (-) value, or to

the right with a positive (+) value by up to 0.300 inches. Press

PREV to access the (+) and (-) sign.

14 AG114123 Rev. 2

Figure 2-5 User Preferences Menu Map

Preferences Test

Patterns

Units of

Audio Alerts

User Preferences

SELECT

Measure

Horizontal

Vertical

Image

Magnification

Magnification

Offset

PREV NEXT

MENU SELECT

OK

CANCEL

EXPOSE ERRORATTENTION

Ignore Laser

Temp. Errors

Ignore The

Processor

Processor

Speed

NEXT

Overlap

Outputting &

Imaging

User

Preferences

User

Maintenance

Test

Patterns

Test

Patterns

SELECT SELECT

MENU

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

User Menus

MENU

Only 1 Pin Bar

in Use

NEXT

Automatically Begin

NEXT

Imaging After

Pinching

These options are disabled when the

Output Device option is set for Tray.

ONLINE

ONLINE

Use the

NEXT

Plate Line Interface

Use the Transport

as an Output Tray

NEXT

NEXT

Registration Delay

Before Pinching

Plate

This manual suits for next models

1

Table of contents