Scotchman PRESSPRO 176MT User manual

www.scotchman.com

PRESSPRO

MODEL 176MT

SCOTCHMAN IND. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844

VERSION 2 - January 2022

MOVABLE TABLE

PAGE 2

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844

1 General information and specifications ...................................................................5

1.1 Technical data ......................................................................................................5

2 Safety advice ..........................................................................................................6

2.1 Users responsibility...............................................................................................6

2.2 Basic safety advice ..............................................................................................6

2.3 Out of use ............................................................................................................7

3 Installation ...............................................................................................................8

3.1 Deliver condition ..................................................................................................8

3.2 Transport ..............................................................................................................8

3.3 Environmental conditions .....................................................................................8

3.4 Bolting the machine to the floor............................................................................8

3.5 Installation of the hydraulic unit ............................................................................9

3.5.1 Connecting hydraulic hoses ..............................................................................9

3.6 Oil tank filling .......................................................................................................10

3.7 Electrical connection .............................................................................................11

4 Functions of the press .............................................................................................11

4.1 Hydraulic unit .......................................................................................................12

4.1.1 On / Off switch ..................................................................................................12

4.1.2 Emergency button ............................................................................................12

4.1.3 Direction control valve ......................................................................................12

4.1.4 Pressure gauge ................................................................................................13

4.1.5 Pressure regulation valve .................................................................................13

4.1.6 Speed setting valve...........................................................................................13

4.1.7 Hand pump .......................................................................................................13

5 Getting started ........................................................................................................14

5.1 De-aerating the press ..........................................................................................14

5.2 De-aerating the hand pump .................................................................................14

5.3 Positioning of cylinder ..........................................................................................14

Introduction

TABLE OF CONTENTS

PAGE 3

SCOTCHMAN IND. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844

5.4 Regular use .........................................................................................................15

5.5 Working period ....................................................................................................16

5.6 Adjusting press cylinder/table position ................................................................16

6 Servicing and maintenance ....................................................................................17

6.1 Oil tank draining....................................................................................................17

6.2 Contact your supplier ...........................................................................................17

7 Appendixes .............................................................................................................18

7.1 Appendix I: Electric scheme for a press with a manual operated hydraulic unit ...........18

7.2 Appendix II: Hydraulic schemes ..........................................................................19

7.3 Appendix III: Spare parts .....................................................................................21

Fig. 1 Technical specifications PressPro Model 176 MT ..........................................5

Fig. 2 Bolting the machine to the floor........................................................................8

Fig. 3 Installation of the hydraulic unit .......................................................................9

Fig. 4 Securing Hydraulic Unit ...................................................................................9

Fig. 5 Hydraulic Hoses & attachment locations..........................................................9

Fig. 6 Fixing hose clamps ..........................................................................................10

Fig. 7 Overview of controls ........................................................................................11

Fig. 8 On / Off switch .................................................................................................12

Fig. 9 Emergency switch ...........................................................................................12

Fig.10 Directional control valve .................................................................................12

Fig. 11 Pressure regulation .......................................................................................13

Fig. 12 Speed setting valve .......................................................................................13

Fig. 13 Hand pump ....................................................................................................13

Fig. 14 Moving the cylinder ........................................................................................15

Fig. 15 Adjusting press/cylinder position.....................................................................16

Fig. 16 Examples of type labels...................................................................................17

PAGE 4

INTRODUCTION

This manual helps you to install, operate and maintain your press. Always read this manual

before you start working with the machine. If you have any questions, please contact your

supplier. The manual gives safety instructions where necessary to assure a safe use of the

machine. These safety instructions are clearly marked with the following symbol:

Always follow the instructions mentioned with this symbol to prevent damages to the machine

or injury to the operator. In case of doubt, please contact your local supplier.

The supplier of the press can not be held responsible for any

damages or injuries when the machine is modified by a third

party or when maintenance is done by unqualified persons.

If you want to contact your local supplier about your press, always mention its serial number

on the machine label. This label is located on the right side of the head of the press. When

you have questions about the hydraulic unit, also mention this serial number. The label is

located on the back of the hydraulic tank.

PAGE 5

SCOTCHMAN IND. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844

1. General information and specifications

This hydraulic portal press is designed for:

bending and straightening of large sheets, beams, profiles, pivots, shafts etc.

(dis)assembly of bearings, bushings or pivots

stamping, punching, forming of a wide range of materials

This machine can be used in repair shops, work shops, etc. To enable more options, the machine can

be equipped with a flat lower table for example.

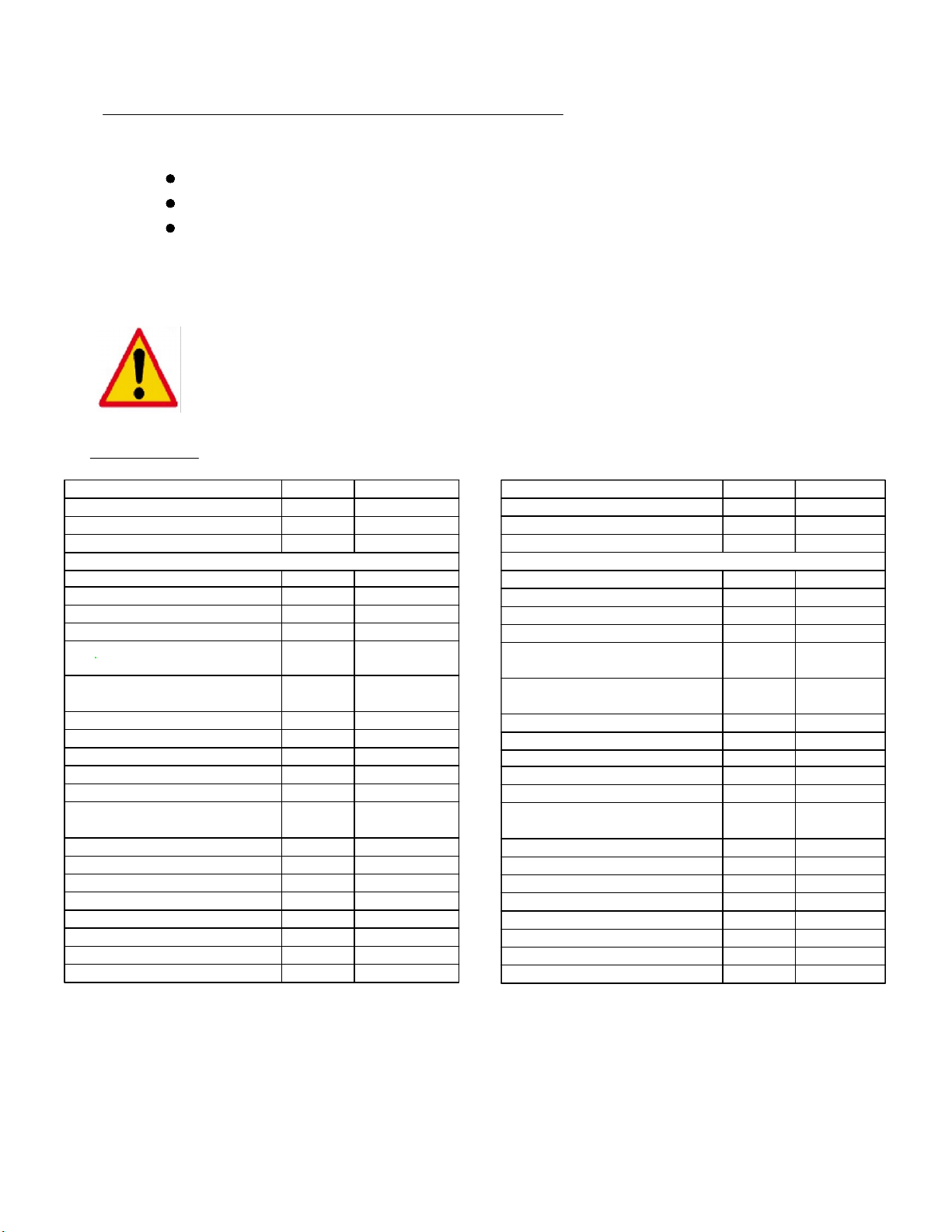

1.1 Technical data

Fig. 1 Technical specifications Scotchman PressPro Model 176 MT

The given parameters of the piston movements are maximum values and can be up to 25% lower.

Parameters are valid with minimum oil temperature of 86°F (30°C).

Pressure force

Maximum pressure

Cylinder stroke

Oil delivery

Total oil capacity

(tank and cylinder capacity)

Oil type (See Pg. 13)

Press speed

Approach speed

Return speed

Motor

Voltage

Frequency

Revolutions per minute

Insulation protection

Insulation classification

Weight

Diameter cylinder

Diameter piston rod

Diameter piston head

kW/hp

V

Hz

rpm

IP

-

pounds

in.

in.

in.

I

4hp

176

176

3698.5

15-3/4

1.875/

27.6

15

HL46

.094

.29

.37

50/60

3000

54

5000

11.02

4.92

6.3

USA STANDARD

US tons

psi

in.

gal/min

in/sec

in/sec

in/sec

(delivered with an extra cylinder extension to reach the table)

Vertical light

Table size ( L x W) in.

in.

Table height / Working height

Working Width in.

in.

68.5 x 39.25

27-1/2

43 5/16

29-15/16

220 or 440

Three Phase

TONS

gallons

Pressure force

Maximum pressure

Cylinder stroke

Oil delivery

Total oil capacity

(tank and cylinder capacity)

Oil type

Press speed

Approach speed

Return speed

Motor

Voltage

Frequency

Revolutions per minute

Insulation protection

Insulation classification

Weight

Diameter cylinder

Diameter piston rod

Diameter piston head

kN

bar

mm

ltr/min

liter

-

mm/sec

mm/sec

mm/sec

kW

V

Hz

rpm

IP

-

kg

mm

mm

mm

220 or 440

I

3

160

1570

255

400

7.1/

27.6

57

HL46

54

2265

280

125

160

TONS M E T R I C

Three Phase

50/60

3000

7.48

9.35

2.40

(delivered with an extra cylinder extension to reach the table)

Table height / Working height

Working Width

Vertical light

Table size ( L x W) mm 1740 x 996

mm 700

mm 1100

mm 760

Warning: proper use of the machine is necessary at all times, to prevent

damages to the machine and injury of the operator. Therefore operation

of the press is only allowed by persons who have read, understood and

follow this manual.

PAGE 6

2. Safety advice

2.1 Users responsibility

Safe use of the hydraulic press can be achieved in daily work when all the necessary

precautions are taken. It is the responsibility of the user to ensure that:

· the machine is used as directed;

· the machine is used in perfect working condition and the safety installations are checked

regularly;

· none of the safety and warning instructions are removed from the machine and these

remain legible;

· all regular maintenance operations are conducted as prescribed;

· only original spare parts are used;

· the direction valve seal is not removed.

2.2 Basic safety advice

Before starting work, inspect the machine carefully. Replace all worn or defective parts immediately.

Keep all parts in good condition and secured in place. Tighten nuts, bolts and screws to keep the

equipment in good working condition.

Note: the supplier of the press can not be held responsible for any

damages or injuries when the machine is modified or when maintenance

is done by unqualified personnel.

Warning: do not put your hands into the working area when the piston is

moving. Hands or any other part of the body in this danger zone can get

smashed by the piston. The danger zone is clearly marked on the left and

right side with the following symbol:

Warning: never turn off the machine when pressing force is being applied to

the work piece. Unexpected force expansion when restarting, can damage

the machine or injure the operator. Therefore always release the force from

the object, move the piston upwards and then safely turn off the press.

Warning: always wear safety shoes, safety glasses, ear protection and

body fitting clothes to prevent injuries to any part of the body.

PAGE 7

Note: do not use the machine in the following conditions:

· explosion hazard zones;

· outdoors;

· extreme temperatures +5°C < > +50°C

Note: maximum pressing force can be exerted for a short time only.

Caution: any welding operations on the press table are prohibited. This can

damage the machine or the operator can get dangerously injured.

2.3 Out of use

Do not use the machine when:

· The operator has not read or not understood the manual.

· Maintenance has not been done by qualified personnel.

· The press is not complete or non-original spare parts have been used.

· Any worn parts are visible.

· The specifications of the power supply are not conform the information stated at the motor plate +/-10%.

· The power supply plug is not equipped with a protection circuit.

· Unprotected bystanders are present.

Note: the machine MUST be bolted to the floor - see Chapter 3 Installation .

Never use a machine unless it's bolted to the floor. It can tip over if heavy

parts are loaded on the table. This can cause severe injury or death!! Use

the press in the vertical position ONLY .

www.scotchman.com

PAGE 8

SCOTCHMAN IND. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Phone: 1-800-843-8844

3. Installation

3.1 Deliver condition

The press is delivered in the following condition:

· Hydraulic unit not installed to the frame. It is delivered packed on the table or separately.

· Cylinder fixed in the middle of the press.

· Hydraulic unit without oil.

3.2 Transport

3.3 Environmental conditions

The machine should be placed in:

· A clean- dry- and dust free room.

· A surrounding temperature of +5°C < > +50°C.

· A maximum humidity of 90%, not condensing.

· An area with enough working light.

· An area with a flat, hard floor, where good fixing of the press is possible.

3.4 Bolting the machine to the floor

Note: When press is delivered, check for freight damage before

signing anything. If you later find anything damaged while unpacking

or setting up the press STOP and contact Scotchman Ind.

In all cases of transporting the press, take care of the following precautions:

Mount the hydraulic unit on the inside of the frame on the table - Not on the outside!

Fix the cylinder in the middle of the press.

Fasten the frame properly to avoid abrupt movements.

PRESS IS TOP HEAVY!!

BOLT PRESS TO THE FLOOR!!

When the machine is positioned in the desired

location, it should be bolted to a concrete floor as

shown with (4) 10 mm (3/8") screws and plugs

(not included). The press is made with a hole in

each of the (4) table-legs for this purpose .

Fig. 2 Bolting Scotchman PressPro Model 176 MT to the floor.

PAGE 9

3.5 Installation of the hydraulic unit

Hyd. Power

Unit is

shipped as

shown.

It must be

bolted to the

angle iron

mounts &

the hoses

need to be

connected to

the press.

Remove the back

bolt & loosen the bolt

on the angle iron.

Rotate the angle iron

to horizontal and

install the back bolt.

Tighten both bolts.

This must be done

on both sides.

Fig. 3 Hydraulic Unit and mounting brackets as shipped from the factory

3.5.1 Connecting hydraulic hoses

Fig. 5 Hydraulic hoses and attachment locations

Once the hydraulic unit is mounted, the hoses must be attached. The caps in

the hose and fitting are color coded. In the example shown below:

Yellow hose to Yellow fitting & Red hose to Red fitting

Tip: the hydraulic unit weighs about 110 lbs!!

When placing the unit in the correct position, make

sure to use enough man or machine power to lift

the unit.

Hydraulic Unit is bolted to the brackets with (4) M10 bolts on the bottom.

Also See Fig. 6 on the next page for overall view.

(4) M10 bolts

secure Hyd. Unit

Hyd. Unit in place

Fig. 4 Securing

Hydraulic Unit

PAGE 10

3.6 Oil tank filling

The press is delivered without oil. Before starting up, the tank needs to be filled.

Mobile DTE 10 Excel 46 or Mobile DTE 25 or similar hydraulic oil is recommended.

Bring the piston into its upper position.

Remove the filler plug on top of the hydraulic unit.

Replace the filler plug.

Start the hydraulic unit.

De-aerate the press: Lower the piston (with the direction control valve / joystick) 4 in. and

bring the piston back to its upper position. Then lower the piston 8 in. and bring it back

to the upper position. Then lower the piston 12 in. and then back to the upper position.

Then move the piston down again to 15 to 15-3/4 in. and bring it back up to the upper

position.

Turn off the hydraulic unit.

Remove the filler plug again and check oil level.

If needed, add more hydraulic oil to the tank.

Replace the filler plug.

To properly fill the oil tank:

On top of the cylinder there are (2) threaded holes. The centered hole is for the large

diameter (18mm) hose from the reservoir. The other hole is for the small diameter

(5mm) pressure gauge hose.

Top of cylinder

Fig. 6 Keep hoses straight - no sharp bends

MAKE SURE ALL HOSES ARE TIGHTENED SECURELY AND CONNECTED IN THE

CORRECT LOCATION BEFORE FILLING RESERVOIR AND OPERATING THE PRESS

Make sure there are no sharp bends in the hoses between the clamps and connections

to the hydraulic unit as shown above.

Fill the tank with a sufficient amount of oil. The total capacity of this press including

the reservoir and cylinder is 15 gal. (57 liters).

PAGE 11

Note: never run the press when its low on oil. This will damage the hydraulic

unit and cause the press to malfunction.

The machine must be connected to 220V 3ph or 440V 3ph power.

The electric circuit must be protected by a fuse or circuit breaker with an adequate rating.

The motor direction can be changed by swapping (2) of the incoming phases (SEE BELOW).

NOTE: check if the turning direction of the motor is in the direction of the arrow,

looking at the motor from above. THE WRONG DIRECTION CAN DAMAGE THE

MACHINE IN A VERY SHORT TIME!!

3.7 Electrical connection

PAGE 11

4. Functions of the press

Fig. 7 Overview of controls

4.1.1

On / Off

Switch

4.1.2

Emergency

Button

4.1.5

Pressure

Regulation

Valve

Oil Filler

Plug

4.1.3

Direction Control

Valve / Joystick

4.1.6

Speed Setting

Valve

4.1.7

Hand Pump

PAGE 12

4.1 Hydraulic unit

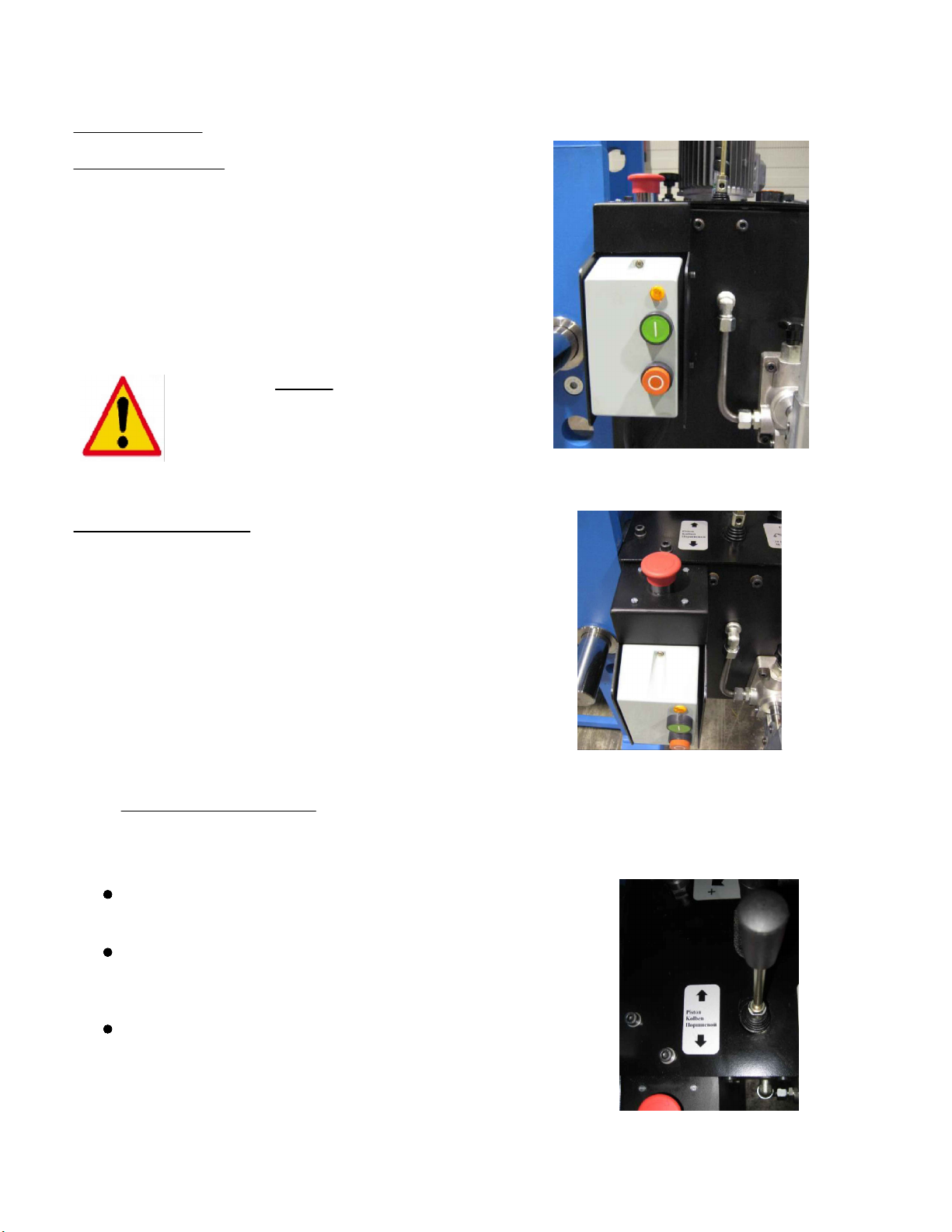

4.1.1 On / Off switch

The on / off switch is situated at the front of the hydraulic tank.

· Pushing the green button will start the motor of the

hydraulic unit.

· Pushing the red button will stop the motor of the hydraulic

unit immediately. All parts will stay in the position where

they are at that moment

Fig. 8 On / Off switch

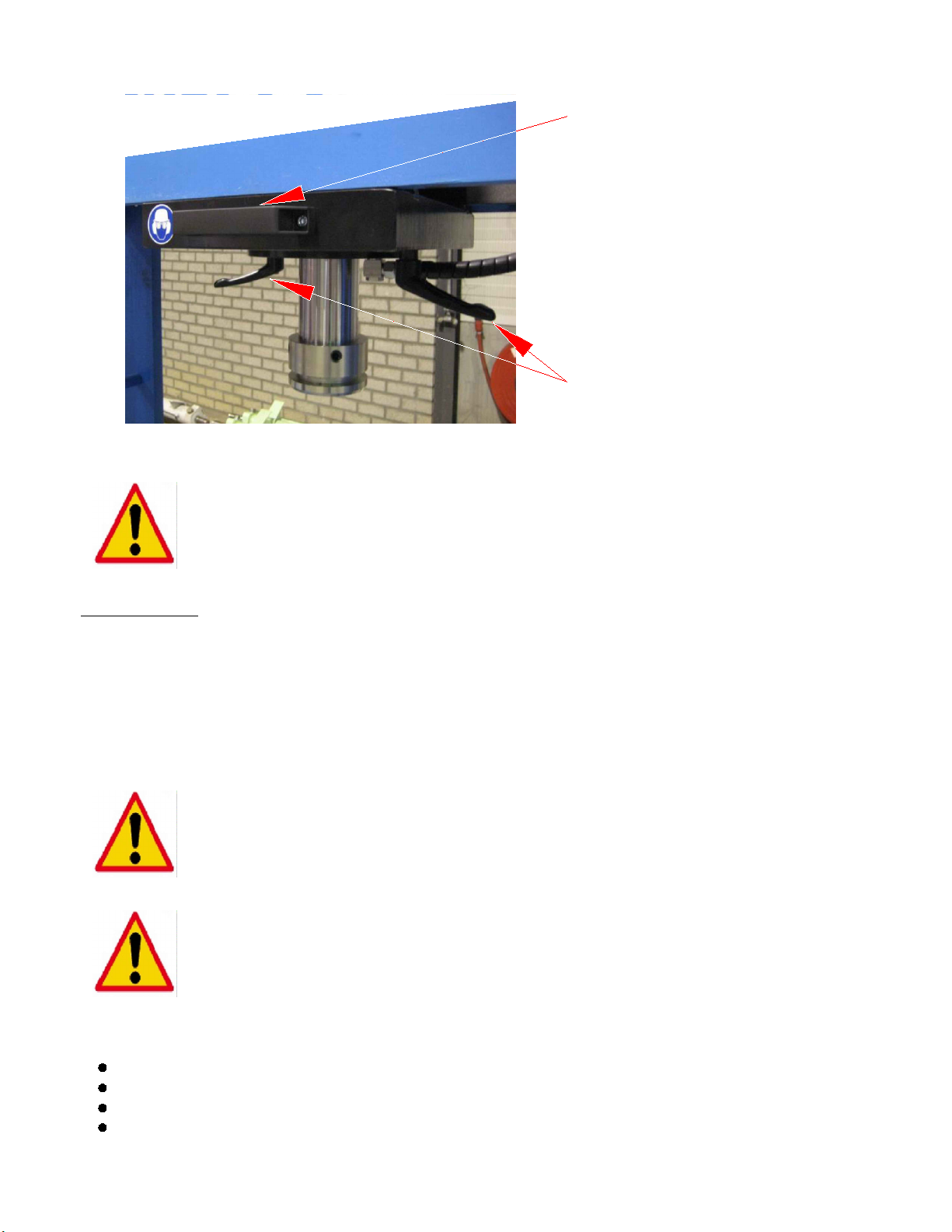

4.1.3 Direction control valve

The direction control valve / joystick is located in the top cover of the hydraulic unit.

The valve has 3 lever positions:

Fig. 10 Directional control valve

Middle position: if the lever has not been operated, the valve

will always return to this position. There is no movement of the

press ram.

Upper position: if the lever is positioned upwards, the press ram

of the cylinder will move upwards. As long as the valve is

operated, the press ram will move. When the lever is released,

the press ram will stop and stay in this position.

Lower position: if the lever is positioned downwards, the press

ram of the cylinder will move downwards. As long as the valve

is operated, the press ram will move. When the lever is

released, the press ram will stop and stay in this position. If

the press ram reaches its lowest position (end of the cylinder

stroke) the pressure of the cylinder will automatically drop to

almost zero, to prevent damages to the press ram head.

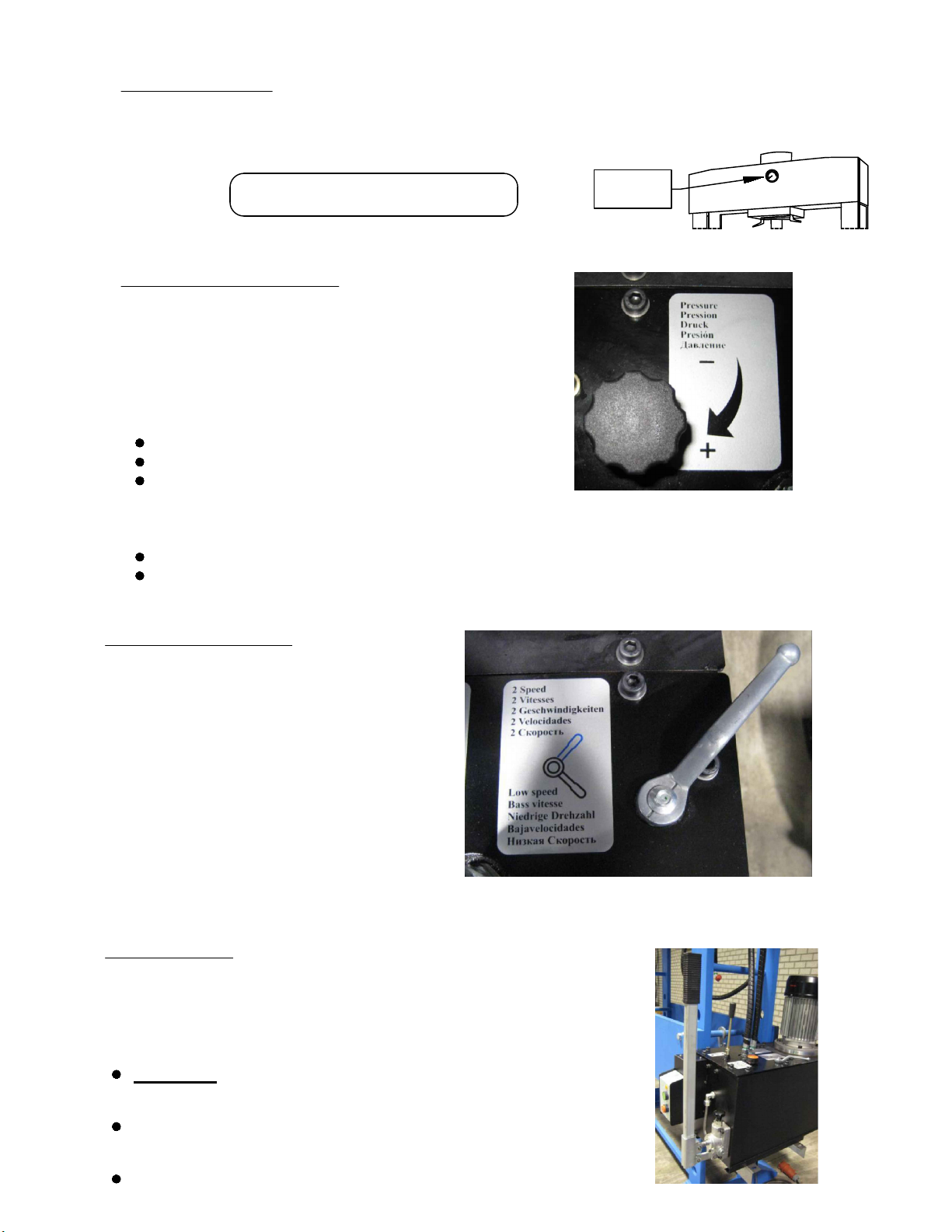

4.1.2 Emergency button

The emergency button is located on top of the on / off switch.

Pushing the red emergency button in case of emergency will

stop the electric motor of the hydraulic unit immediately. All other

parts will stay in the same position they are at that moment.

To restart the hydraulic unit again:

· Make sure that the dangerous situation is solved.

· Reset the red emergency button by turning it counter

clockwise, the button will pop-up again.

· Push the green button from the on / off switch again.

Fig. 9 Emergency switch

WARNING: NEVER turn off the machine

when pressing force is being applied to the

work piece. Unexpected force expansion

when restarting, can damage the machine

or injure the operator.

PAGE 13

4.1.4 Pressure gauge

4.1.6 Speed setting valve

The speed setting valve is located in the top

cover of the hydraulic unit.

If the lever is in the lower position, the piston

will move with low speed when the directional

control valve is activated. If the lever is in the

upper position, the piston will move with high

speed when the direction control valve is

activated. When the piston is reaching the

work piece with high speed, it will

automatically switch to low speed as soon as

it feels counter pressure. This has no

influence on the maximum working pressure

or working force. Fig. 12 Speed setting valve

The pressure gauge is located in the head (in front toward the top) of the press. The gauge shows

the pressure in psi & bars. For this press the maximum pressure is as follows:

If this maximum pressure is reached, the maximum capacity of the press is reached as well.

4.1.5 Pressure regulation valve

Fig. 11 Pressure regulation

Adjusting the pressure:

Start the hydraulic unit.

Raise the press ram so no force is applied.

Turn the knob on the pressure control valve

counter clockwise to lower the pressure.

Do not remove the knob!!

Note that it can be turned far enough to unscrew from the pressure control valve.

Lower the press ram to the work piece and keep force applied with the joystick.

Slowly turn the knob on the pressure control valve clockwise & carefully raise the

pressure while watching the pressure gauge.

The pressure regulation valve is located in the top cover of the

hydraulic unit. With this valve the maximum pressure, referring

to the maximum press capacity, can be changed. Turning the

knob clockwise will increase the pressure, turning the knob

counter clockwise will reduce the pressure.

4.1.7 Hand pump

The press is equipped with a hand pump, located on the front panel of

the hydraulic unit. This pump can be used for manual pressing

functions or when accurate force setting is necessary.

To use the hand pump:

Fig. 13 Hand pump

TURN OFF the hydraulic unit by pushing the red button of the

on/ off switch.

Set the directional control valve in the required position

(up- or downwards).

Start pumping the hand pump with its lever.

PRESSURE

GAUGE

PressPro 176MT: 3700psi (255 bar)

PAGE 14

5. Getting started

5.1 De-aerating the press

5.2 De-aerating the hand pump

5.3 Positioning of cylinder

To start the press for the first time, make sure:

The press is installed correctly (see former paragraphs).

The oil tank is filled with a sufficient amount of oil.

The hydraulic hoses are tightened correctly to the cylinder and to the hydraulic unit.

The machine is connected to the correct voltage & grounded per local code.

When starting up for the first time or when the hydraulic hoses have been disconnected from the

hydraulic unit or cylinder, the system need to be de-aerated. To do this:

Start with the piston in the upper position (as delivered condition).

Make sure there is no work piece on the table.

Start the hydraulic unit.

Move the piston to the down position by activating the directional control valve.

Move the piston back to the up position by activating the direction control valve.

Repeat this complete cycle at least 6 times to ensure that all the air is out of the system.

Note: incorrect de-aerating can cause unexpected movements of the piston and

cause the press to malfunction.

When starting up for the first time or when maintenance of the hydraulic unit is performed, the hand

pump needs to be de-aerated. To do this:

Start with the piston in the upper position.

Make sure there is no work piece on the table.

Turn off the hydraulic unit by pushing the red button at the on / off switch.

Set the directional control valve in the downwards position.

Start pumping the hand pump with its lever until the piston reaches the lower position.

Set the directional control valve in the upwards position.

Start pumping the hand pump with its lever until the piston reaches the upper position.

Repeat this complete cycle at least 3 times to be sure all air is out of the hand pump.

Note: incorrect de-aerating can cause unexpected movements of the piston and

cause the press to malfunction.

Move the complete cylinder to the left or right by means of the bow grip (handle).

Tighten the levers again when the cylinder is in the right position. Manual tightening is enough.

Do not use a wrench - Do not over-tighten the levers.

When your work with the press is finished, move the cylinder back in its center position.

Turn both levers two turns counter clockwise to loosen.

DO NOT COMPLETELY REMOVE THE LEVERS!!

All presses are equipped with a movable cylinder which makes it possible to correctly align

the press ram with the work piece. To move the cylinder side to side:

PAGE 15

bow grip

levers

Fig. 14 Moving the cylinder

5.4 Regular use

Place the work piece on the table in alignment with the piston rod. If this is not possible, reposition the

cylinder and portal to achieve the best alignment.

Take caution when performing operation on elements that are likely to fly off, break (especially casting

element and hardened elements) or bounce up as a result of the applied force. In this case, a cover

must be installed around the work piece or the operator should stand at a safe distance.

After correct placement of the work piece, pressing force can be applied as described in the previous

chapters.

When pressing operations are finished:

Return the piston back to its outer upper position.

Position the cylinder back to the centre of the machine.

Turn off the hydraulic unit.

Clean the machine and working area.

Tip: working with the cylinder in the outer left or outer right position, will

shorten the durability of the press. Working in the centre of the press is

preferable.

Warning: always wear safety shoes, safety glasses, ear protection and

body fitting clothes to prevent injuries to any part of the body.

Note: upward movement of the piston is only allowed for returning the

piston to its start position. Any other use of the return stroke (e.g.

stretching) can result in broken parts and de-function of the press.

PAGE 16

The machine is not designed for continuous operation.

Maximum cycle intensity is 2 per minute.

Maximum 10 minutes working time with maximum cycle intensity.

Note: when you do not take the maximum working period into account, it can

result in overheating the hydraulic oil and heating up the hydraulic unit. The

machine can get damaged and the operator may suffers burns.

5.5 Working period

5.6 Adjusting press cylinder/table position

Section 5.3 explains how to change the position of the cylinder from side to side. The cylinder on

the PressPro 176 MT can be moved front to back as well. This is done by anchoring the four legs

on the table (1) solidly to the floor, and then moving the press head back and forth to wherever it is

needed. When the desired position is achieved simply lock the press head into place and begin use.

In Figure 15 below, the dotted lines (2) represent the parts of the press that actually move. On both

sides, the rollers (3) ride on a ledge (4) that is welded to the table.

1.

Fig. 15 Moving the cylinder front-to-back.

2.

3.

4.

4.

PAGE 17

6. Servicing and maintenance

Note: replacing parts, electrical, mechanical or hydraulic, can only be done by

qualified personnel. Your supplier can not be held responsible for damages or

injuries as result of inappropriate servicing.

Daily

Remove dust and dirt

from the table and

around the press.

Check the press for

visible damages.

Weekly

Check oil level of the

hydraulic unit.

Check electrical

connections.

Half-yearly

Inspect all hydraulic

fittings and hoses and

tighten any loose

connections.

Inspect and tighten all

loose fixing bolts.

In case of leakages, damaged parts or bare electric cables; do not use the machine before it is

repaired.

Always use original spare parts.

Note: when starting with maintenance, always unplug the electrical connection

and make sure there is no hydraulic pressure on the system. Both can result in

injuries to the maintenance operator.

6.1 Oil tank draining

Replace the hydraulic oil at least once a year. A drain plug is located at the bottom of the oil tank. If

the inside of the tank is not clean, remove the top cover of the tank and clean the tank from the inside.

Check if the drained oil has a gray color or if there are metal particles visible in the oil. This can

indicate worn out parts in the cylinder or the hydraulic unit.

You have to prevent spilling dirt and water inside the oil tank.

6.2 Contact your supplier

If there are any questions, please contact your supplier.

Always mention the serial number on the machine label. This label is located at the frame of the press

(front right side). When you have questions about the hydraulic unit, also mention its serial number.

The label is located on the back of the hydraulic tank.

Yearly

Replace the hydraulic

oil of the unit. See

instruction below.

Fig. 16 Examples of type labels

SCOTCHMAN IND.

HYDRAULIC PRESS

MODEL

PRESSPRO 176MT

S/N 10061N120001

FRAME HYDRAULIC TANK

PAGE 18

7. Appendixes

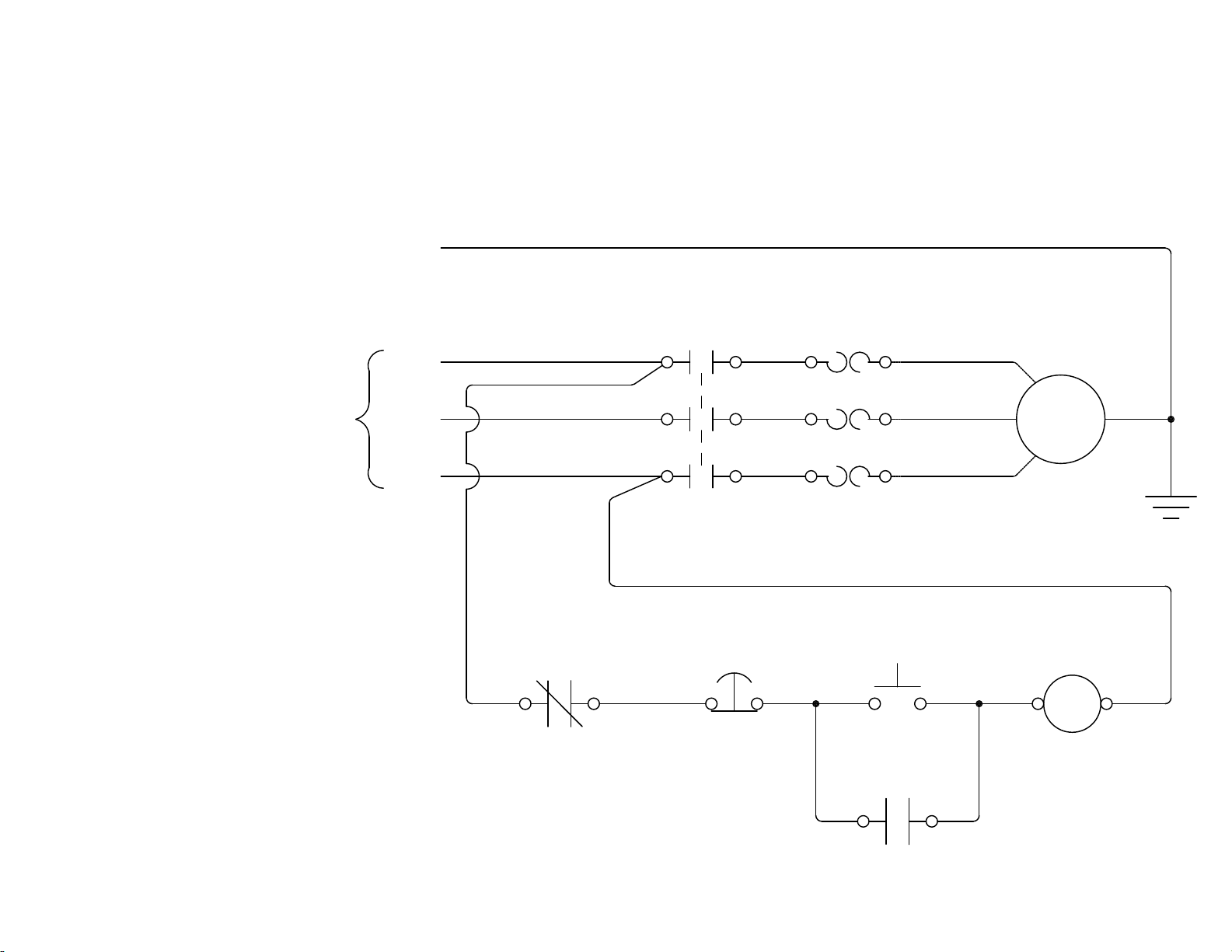

7.1 Appendix I: Electric schematic for a press with a manual operated hydraulic unit

230V 460V

Brown

Black

Blue

4

3

LC1DXX

SCHNEIDER

LRDXX

SCHNEIDER

LINE POWER

START

BUTTON

Brown

Black

Blue

* Follow Instruction

Sheet In Motor Box

If Provided

Brown

TO MOTOR*

SET OVERLOAD TO

FLA SHOWN ON

SERIAL NO. PLATE

W2

U2

V2

U1

V1

W1

W2

U2

V2

U1

V1

W1

NOTE: Swap (2)

Incoming

Power Wires to

change Rotation

21

L1 L2 L3

13 21 A1

14 22

A2

97 98 95 96

T1 T2 T3

EMERGENCY

STOP

L3

L2

L1 T1

T3

MTR

1M 1OL

T2

INCOMING SUPPLY

(BY CUSTOMER)

PROVIDE MAXIMUM

UPSTREAM

PROTECTION PER N.E.C.

CODE 430-52 AND TABLE

430-152.

GND

95 96

1OL E-STOP

1 2

1PB

START

3

4

2PB

A2

1M

A1

1M

1314

L1

L3

L2

SEE MOTOR TAG

FOR DETAILS

PAGE 19

PAGE 20

Table of contents

Other Scotchman Industrial Equipment manuals

Scotchman

Scotchman PRESSPRO 66 User manual

Scotchman

Scotchman DO-150-24M User manual

Scotchman

Scotchman GAA-600-90 CNC User manual

Scotchman

Scotchman IRONWORKER 6509-24M User manual

Scotchman

Scotchman CPO-315-RFA-BL User manual

Scotchman

Scotchman GAA-500-90 CNC DT20 User manual

Scotchman

Scotchman 6509-24FF User manual