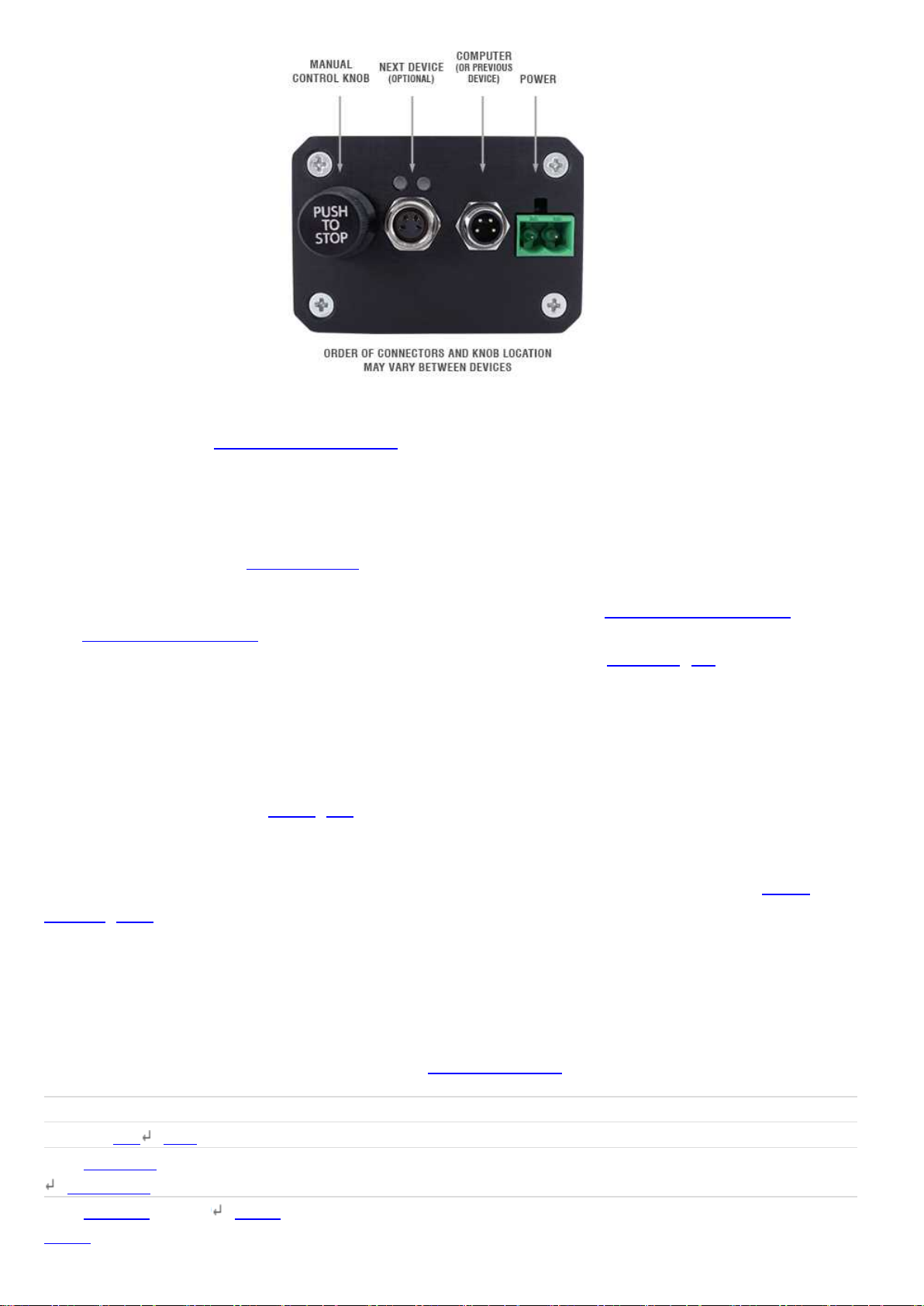

movement modes available: Velocity and Displacement. Switch between these modes by holding

down the knob for 1 second or by configuring the knob.mode (T:109) setting.

On power-up, many devices will only travel towards the motor from their start-up positions until the

home position is reached. Once the device has been homed, the full range of travel becomes

available.

Velocity Mode

Turn the knob clockwise to move the device in the positive direction (extend) or counter-clockwise for

negative direction (retract). Each detent of the knob increases the speed of the carriage.

There are 16 speeds in each direction. The velocity profile and maximum speed can be configured

via the knob.speedprofile (T:112) and knob.maxspeed (T:111) settings. The device stops and resets

the knob upon arriving at the end of travel.

Displacement Mode

Turn the knob clockwise to move the device in the positive direction (extend), counter-clockwise for

negative direction (retract). Each detent of the knob moves the device a fixed number of microsteps,

specified by the knob.distance (T:110) setting. If knob.distance (T:110) is set to 0, each detent of the

knob will move to the next index position, similar to move index (T:78) movements. The device

moves at the speed specified by the maxspeed (T:42) setting, or the slower of maxspeed (T:42)

and limit.approach.maxspeed (T:41) if the device has not been homed. If there are fewer

than knob.distance (T:110) microsteps to the end of travel and another move is requested, the device

will move to the end of travel and then stop.

Summary of knob functionality

Turning the knob:

Moves the device in the direction of knob turn.

Pressing the knob:

Decelerates and stops the device (identical to a stop (T:23) command).

Instantly stops the device, if the device is already decelerating.

Warning: Stopping instantly may result in damage to the product and reduced lifespan. Use sparingly if

the axis is under heavy load.

Pressing and holding the knob for 1 second:

Toggles between Velocity Mode and Displacement Mode.

Trajectory Control and Behaviour

This section describes the behaviour of the device trajectory when a movement command is issued.

Software Position Limits

The travel range of the device is limited by the Minimum Position and Maximum Position settings.

The factory settings for the devices are configured to match the physical travel range. If a customized