8000 Platform - Quick Card “Fiber Characterization Script” – V1.3 - September 2011 – Ref.: E8000M02QCFC1 - Copyright 2011 JDSU. All rights reserved

1

1

1

2

3

1

2

3

4

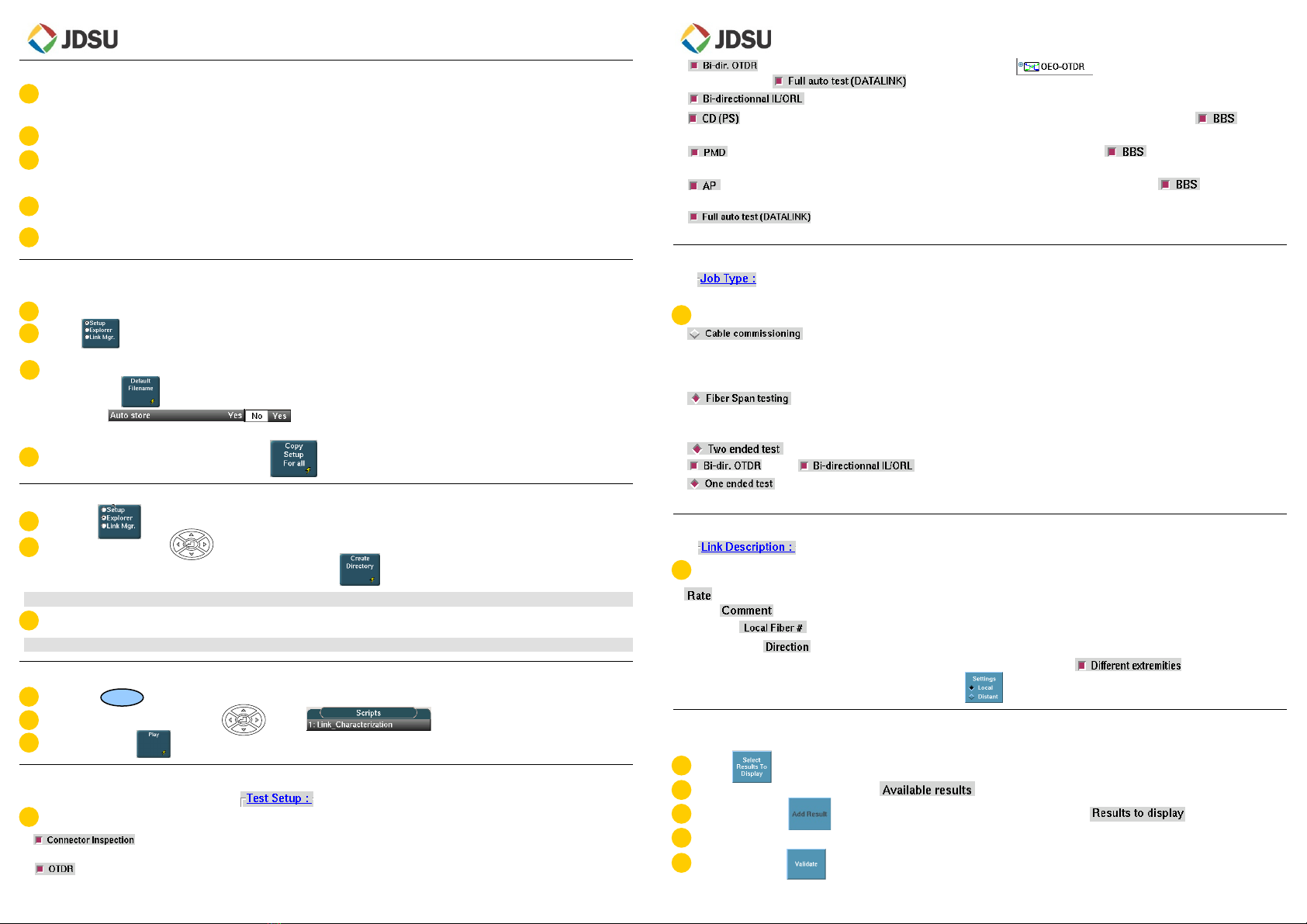

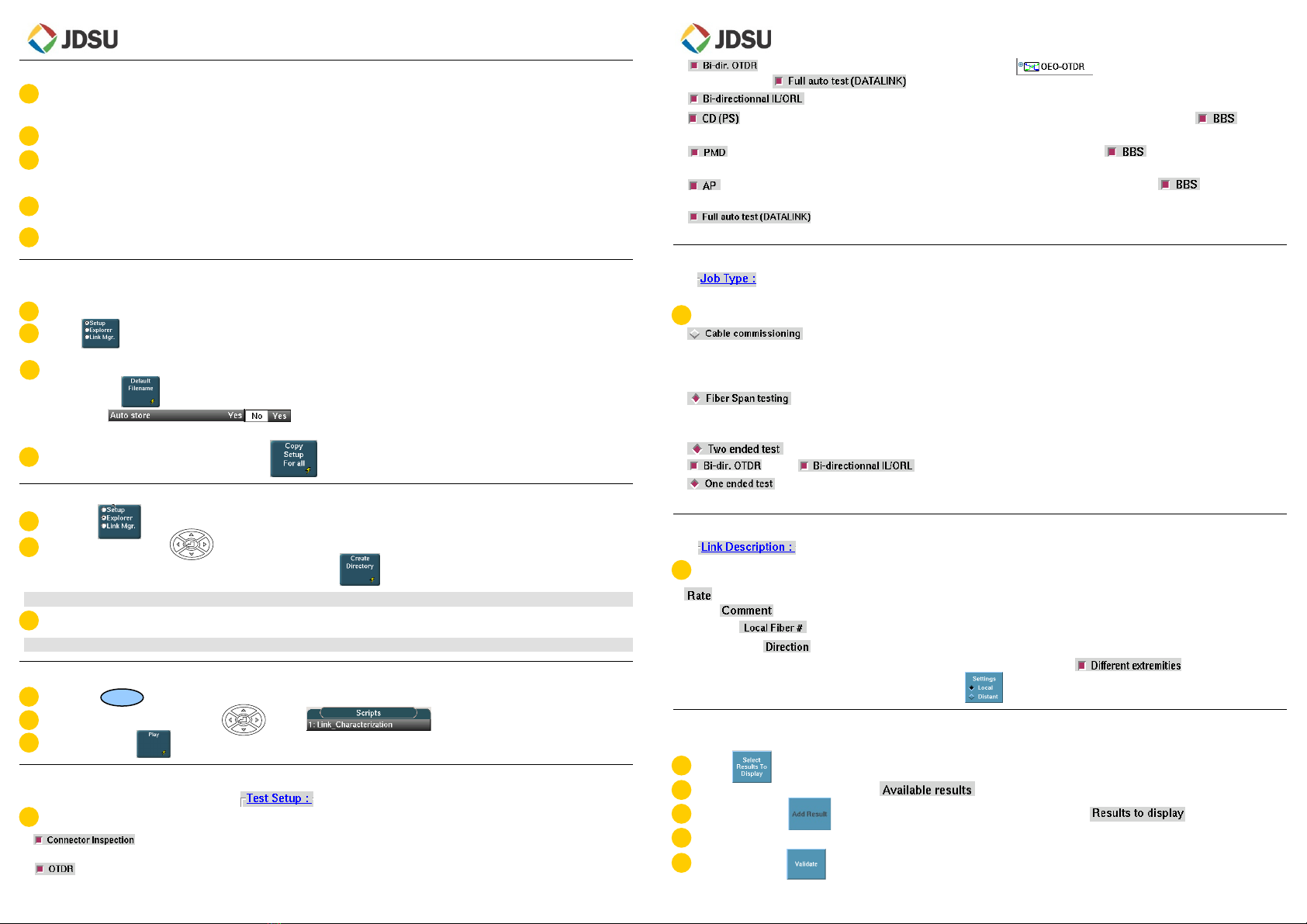

Check List

Check that OEO OTDR settings on each unit (for bidirectional solutions) are identical; or that SM OTDR settings on each unit

are identical. Note: You can press the Test Auto and Factory Defaults soft keys to get a set of default settings to work from.

Check that units are correctly set, typically Km.

Set the IL/ORL (FOX) wavelengths to be consistent with OTDR in case the OFI module is used.

Ensure that the Acquisition Band for CD and AP is appropriate to your Broadband Source. For handheld OBS 500/550 use

SCL; for BBS2A module use OESCL. When you switch acquisition band, you must check that a valid reference exists for that

band, the reference S/N should match the S/N of your source.

Check that Length is set to “Known Length” = Yes, for PMD, CD and AP testing. This will allow the Script to auto populate the

length field using the OTDR results.

Check that PMD, CD and AP Length units are consistent with OTDR settings.

Setup File Parameters

This paragraph provides a set of instructions for selecting typical File Storage options for Fiber Characterization test results.

Press the FILE Hard Key of the mainframe

Press softkey until the Setup radio button is selected. It is recommended you accomplish this on one of the OTDR tabs

(SM OTDR or OEO OTDR).

Select the following parameters starting from the top of the menu to the bottom.

a. Press the softkey

b. Select

c. For File type user preference, typically one OEO file or Single SOR files

After all the File parameters are selected, press , softkey

Select storage directory

Press the softkey once to select the “Explorer” page.

Using the navigation keys , on the left side of the screen, select the main or sub directory where you wish to store files,

typically the “Hard Disk”. After highlighting this Directory, press softkey to create a new subdirectory where you wish

your files to store.

It is not mandatory to create a subdirectory as the script automatically creates one at the start of the test sequence.

Use the pop-up keyboard to enter the directory name.

Move the pointer on the left to highlight the new directory so that files will store there.

Getting started with the “Link Characterization” Script

Press the hard key.

Drop down using the navigation keys or touch to select the “Link characterization” script.

Press the soft key to launch the script process.

Define the Test Setup

The available test functions are listed in black in window.

Check marked the square button for each test function to be added in the test sequence. (Button becoming red).

-: Available if video inspection scope is connected to the mainframe. The script will open up the connector

image viewer.

-: The script will use the wavelengths defined in the OTDR test Setup and measurements will be performed using Automatic

configuration.

SCRIPT

3

1

2

2

3

4

5

-: Automated bi-directional OTDR measurement using the . It will require the use of the optical talk

set and will select automatically.

-: Automated bi-directional Loss test set, using the OFI module (Fox port).

-: Chromatic Dispersion measurement. It requires the use of the OBS handheld or the selection of the on the

other T-BERD 8000 script configuration menu.

-PMD measurement. It requires the use of the OBS handheld or the selection of the on the other T-BERD 800

script configuration menu.

-Attenuation Profile measurement. It requires the use of the OBS handheld or the selection of the on the other T-

BERD 8000 script configuration menu.

-It enables communication between 2 T-BERD 8000 running the script in order to perform bi-directional

OTDR measurement and automate the BBS mode selection.

Define the Job Type

The enables to define how the product is going to organize the results and what type of characterization test sequence is

performed.

Check marked the square button for each type (button becoming red).

1

-is used for testing an entire cable. The script will save all the test results and the summary report into one

directory, and for all the fibers. The directory will be created using the Cable ID as the name. This directory will be located under the

current selected directory. Make sure the selected directory is the root hard disk or a well known one. Press the System hard key

and the File hard key to get access to the Explorer in order to change the directory selection.

-is used for few fiber testing. The script will save the test results of one fiber and the report summary into one

directory. Each fiber will have its own directory. The directory will be created using the FiberID and the Fiber #, as the name. This

directory will be located under the current selected directory.

-defines the script sequence and synchronization between the 2x T-BERD 8000. It is required when

and/or test parameters are selected.

-defines the script sequence when only one T-BERD 8000 is used in conjunction with a handheld OBS 5x0 at the

far end.

Define the Link Description

The enables to document the information, related to the link being tested.

Fill-in all the information using the USB key board: Local Cable Id / Local Fiber Id / Origin & End Location / Job Ticket

-: select the expected bit rate in the drop down menu. This will pre-define the alarm thresholds for CD and PMD testing.

-Add a which will be loaded into each test application and save with each test results.

-Define the of your fiber under test.

a. Set the of the measurement between O->E and E->O (Origin and End).

b. If the Origin fiber number or cable Id is different from the far end, check mark in order to have

access to the local and distant information using the soft key.

Configuring the "Results" Summary table

This summary table enables to review selected values at the end of the test sequence. A pass/Fail status is associated to the table.

1

Press to access the selection list.

2

Highlight one parameter in the column .

3

Press the soft key in order to select the parameter and see it in the column .

4

Repeat steps 1 to 3 until you have selected all the parameters. Maximum 7.

Press the soft key in order to acknowledge the selection.

5

1

8000 Platform - Quick Card “Fiber Characterization Script” – V1.3 - September 2011 – Ref.: E8000M02QCFC1 - Copyright 2011 JDSU. All rights reserved