EDELRID FLEX LITE User manual

FLEX LITE

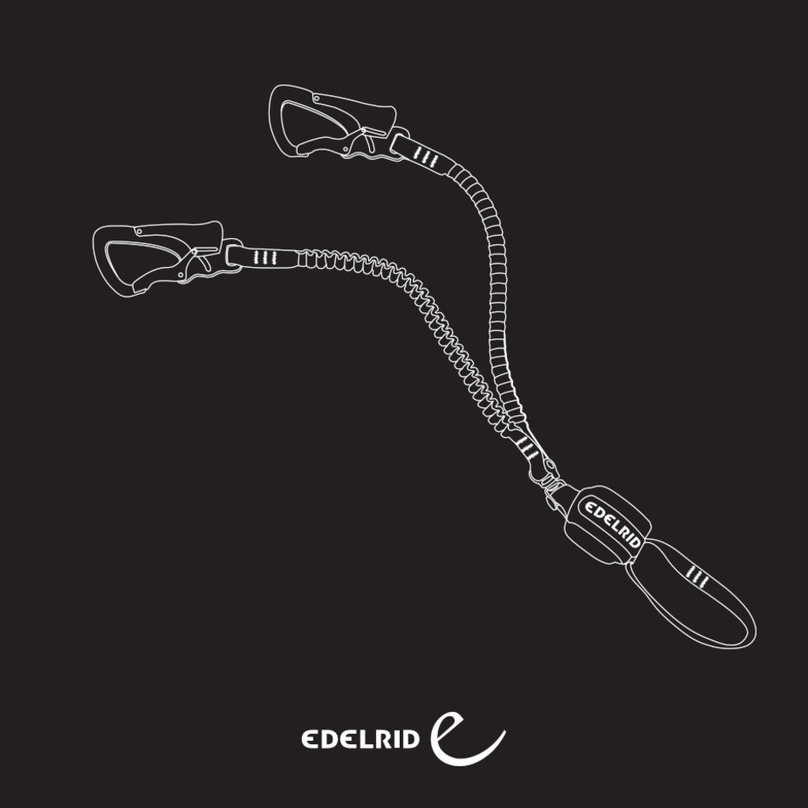

Abb. / fig. / ill. / afb. / fig. / rys.

1a C

D

H

A

E

E

F

H

I

K

J

B

G

1b

2a

3a

2b

3b

2c

3c

4a

4b

5a 5b 5c

5d 5e

6a 6b

6c 6d 6e

5 min

5 min

7a 7b

A

EN 361:

2002

A/2

EN 361:

2002

8b8a

9a 9b 9c

8c 8d 8e

40°C 40°C

10a

11

10b

max. +55 °C

min. –20 °C

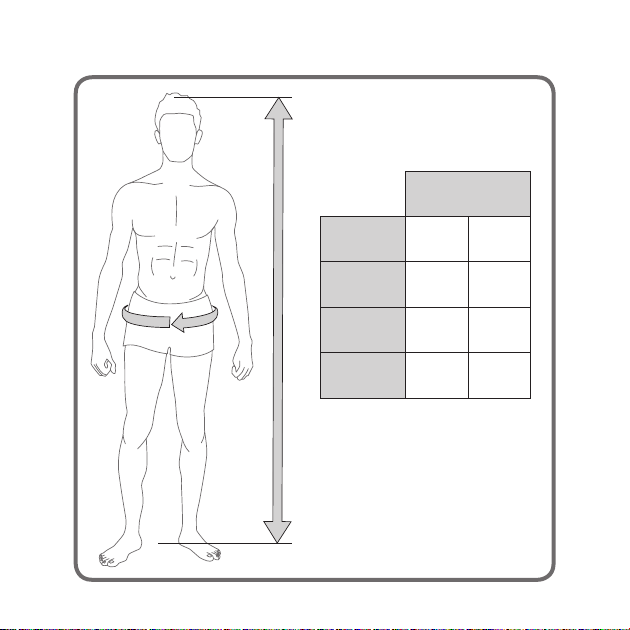

Flex Lite

Zertifizierung

Certification EN 361 EN 361

Größe

Size S – M L – XL

Gewicht

Weight 1.100 g 1.190 g

Körpergröße

Body Size 155 – 180 cm 175 – 205 cm

12

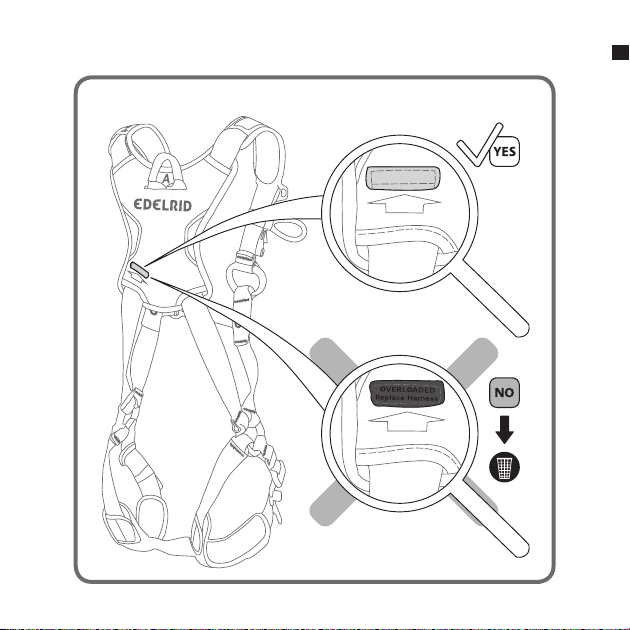

13

FALL INDICATOR

FALL INDICATOR

DE

Flex Lite

Fall Arrest Harness according to EN 361, ANSI/

ASSE Z359.11-2014

INSTRUCTIONS FOR USAGE, SAFETY,

LIFESPAN, STORAGE AND CARE

This product is part of personal protective equipment

for protection (PPE) against falls from heights and

should be allocated to one individual.

These instructions for use contain important notes,

a control card and a proof of inspection (test book).

Before using this product, all documents must have

been read and their content understood. This

document must be provided to the user by the

retailer in the respective country’s language and

must be kept with the equipment while it is in use.

INSTRUCTIONS FOR USE

These instructions must be carefully read and

followed. This product especially manufactured

for working at great heights or depths does not

release users from the risk borne personally.

Work and sporting activities carried out at great

heights or depths are potentially dangerous. Errors

and carelessness can lead to serious injuries or

even to death. Experience is required in order to

select the correct equipment. Equipment may only

be used by trained and experienced persons or

under instruction and supervision. Users must be

aware that poor physical and/or mental health can

jeopardise safety under normal conditions and in

emergencies. The manufacturer cannot be held

liable if the equipment has been abused or used

incorrectly. In all cases, the users or the persons

responsible bear the responsibility and the risk.

When using this product in the areas of rescuing

and personal protective equipment, we recommend

that the relevant national regulations be observed.

EN

Before using the equipment, the user must

ensure that, in the event of falling into the

PPE-system, the person caught can be rescued

immediately, safely and effectively. Motionless

suspension in a harness may cause severe injury

and even death (suspension trauma) Personal

protection equipment products may only be

used to belay people.

Product specific notes

Fig. 1a/b designations of relevant elements:

A Sternal catch eye EN 361

B Dorsal catch eye EN 361

C Adjustable shoulder straps/Easy Glider buckle

D Tear-off/freely positionable equipment

attachment loop up to max. 5 kg

E Triple Lock buckle

F Removable leg cushion

G Fall indicator

H Elastic keepers

I Individual labelling field

J Bag for RFID (chip)

K Labelling

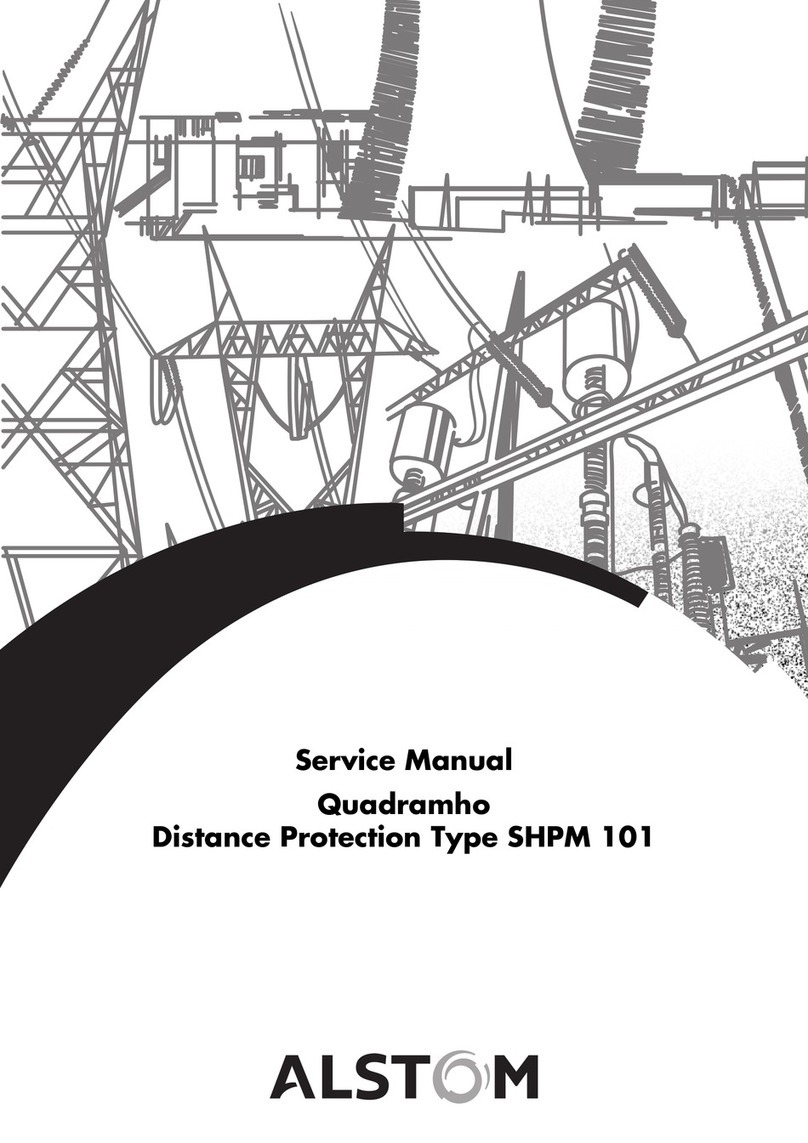

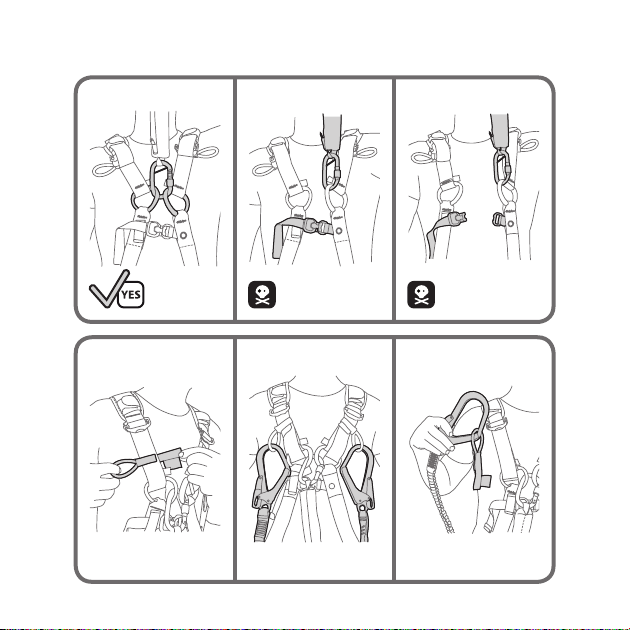

Application to EN 361 (Fig. 8a – e):

The harness is safely connected to a rescue or fall

arrest system at the catch eyes (A or A/2); the

connectors employed (karabiners should

withstand a lateral force of ≥ 15 kN) must

conform to EN 362 and are fastened to the catch

eyes (marked A or A/2). When using the front

catch eyes A/2 both eyes must be attached to the

connector conforming to EN 362. Catch systems

may be used with or without energy absorbing

elements. In case of a fall, the fall arrest systems

must reduce the fall arresting force to a value

that can be born by the human body (6 kN).

EN

Only one fall arrest harness to EN 361 may be

used in each fall arrest system! Before using a

fall arrest system, ensure that sufficient free

room for a fall from the work position is

available below the user.

Free room for fall below the user

The elongation (Hs) of the harness upon a fall

load is max. 27 cm. Observe the corresponding

instructions supplied with the lanyard (energy

absorbing lanyards, height securing devices,

guided-type fall arresters on movable or

stationary guide) as well as those of other

components that may be used.

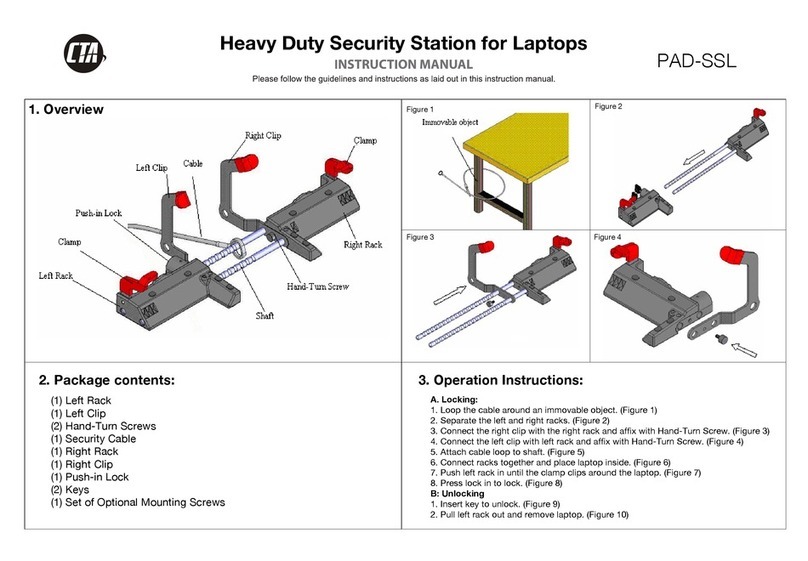

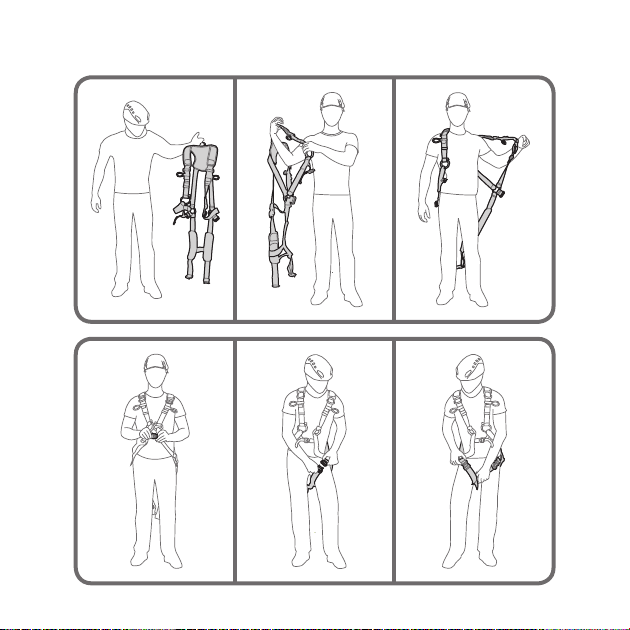

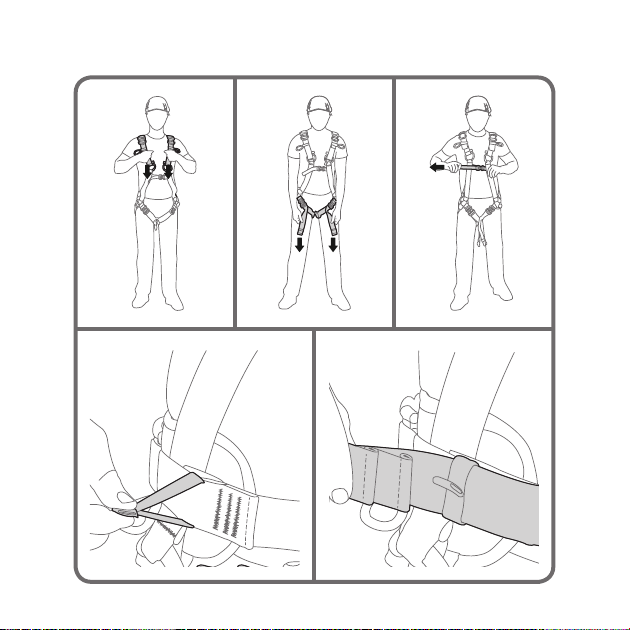

Fig. 2 Putting on of the harness

2a Aligning the harness to the shoulder cushion

2b – c Putting the harness on laterally (like a

jacket)

Fig. 3a – c When closing the Triple Lock buckles

on the legs and the hip be sure to assign them

correctly. Note the marking! (Legs – left & right)

Fig. 4 Use of different buckle types

4a On TripleLock buckles flip the frame up to

attach it to the hook. To loosen the buckle, force

the frame into the buckle housing and lift the

buckle up at the same time.

4b To loosen EasyGlider buckles flip them up.

To close, pull the outbound webbing. Pull the

covers over the buckles upon closing.

Fig. 5 a – c Tightening the shoulder, leg and

breast straps

Fig. 5 d – e Stowing the excess strapping in the

strap keeper

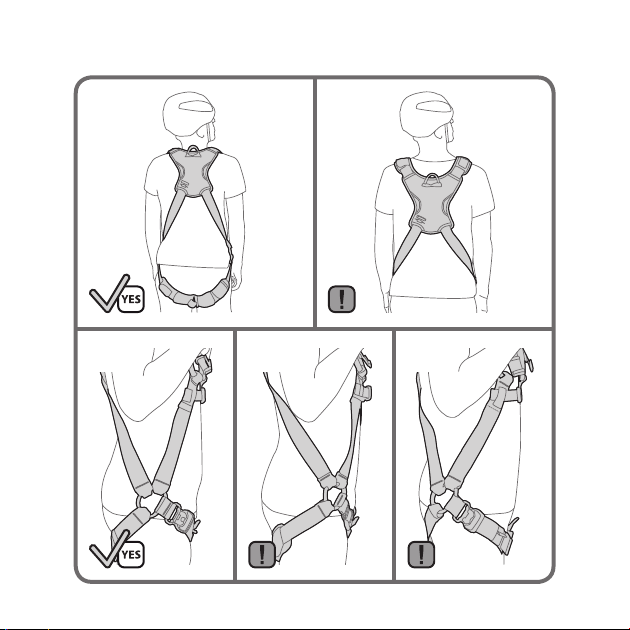

Fig. 6

6a The shoulder cushion should align flush with

the nape of the neck.

6b Shoulder cushion too low

6c – e Position of the textile hip joint

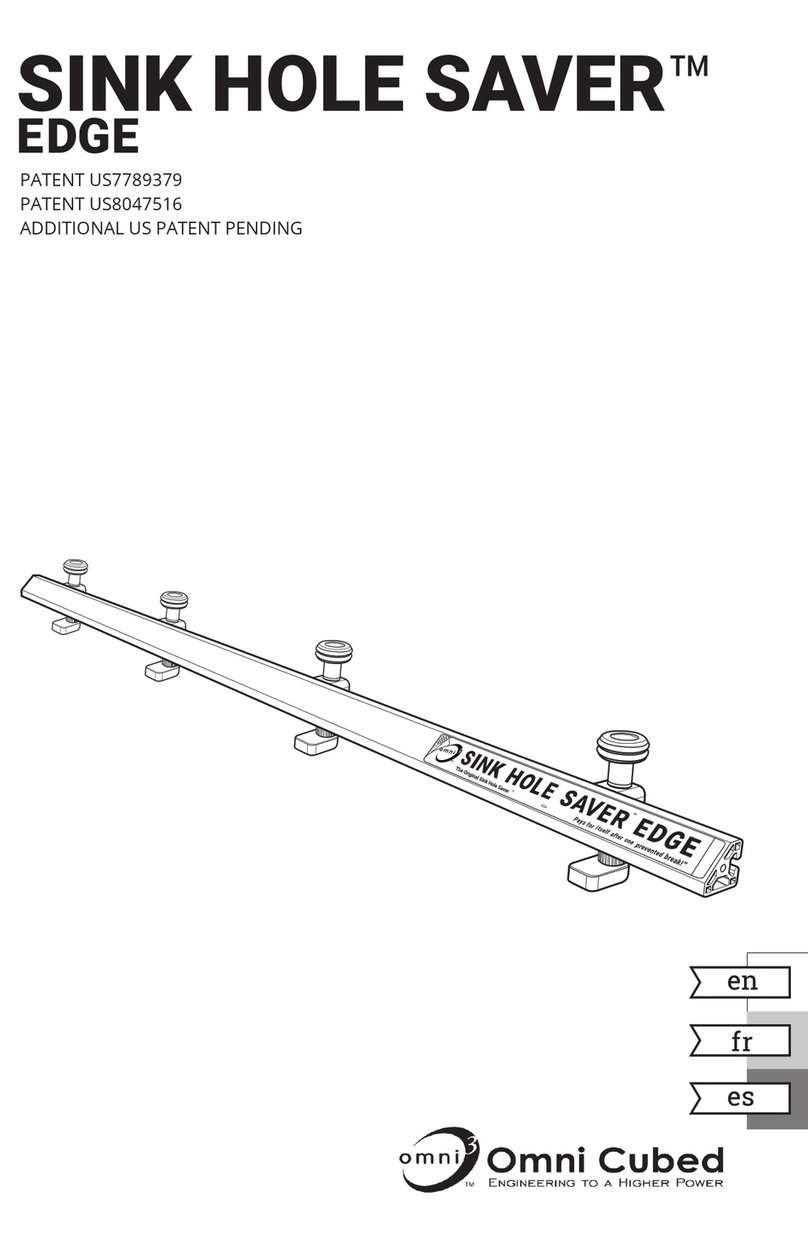

Fig. 9 Equipment attachment loops

9a Free positioning

9b Stowage for lanyards to EN 354, EN 355

9c Detach if the load exceeds 5 kg

Fig. 7 Upon adjustment but before using the

harness you should try being suspended in it for

at least 5 minutes in the planned usage situation.

The harness must fit comfortably. When

properly selected (Fig. 12 size table) and

adjusted the suspension test must not result in

hindered breathing and/or pain. When the

harness has been applied, its metal parts should

not contact genitals or arm pits. Free suspension

in the harness must not lead to excessive arching

of the back, tensioning of the body, pressure on

the genitals, loins or arm pits. Women's

lymphatic vessels of the breast should not be

constricted if at all possible.

ANCHOR POINT

In order to avoid high loads and swinging falls

in the event of a fall, anchor points for belay

purposes must always be as vertical as possible

above the person to be belayed. The lanyard/

anchor device from the anchor point to the

person secured should always be kept as taut as

possible. Slack ropes must be avoided! The

anchor point must be designed in such a way

that, when fixing the PPE, no effects can occur

which reduce the stability and it is not damaged

during use.

Sharp edges, ridges and crushing can

seriously impair the stability. These should be

covered, where necessary, using suitable

auxiliary equipment. The anchor point and the

anchoring must be able to withstand the

expected loads in a worst-case scenario. Even if

energy absorbers (to EN 355) are used, the

anchor points must be specified for a fall

arresting force of up to 10 kN, also refer to EN

795

When using a lanyard (fall arrest system), please

note that the maximum overall length of the

lanyard including shock absorbers and

connecting components must not exceed 2.0m.

SAFETY NOTICES

When combining this product with other

components, the safety aspects of the

products may interfere with each other.

If this product is used in combination with

other components of a rescue/fall arrest

system, users must acquaint themselves with

the enclosed recommendations, notes and

instructions for these components prior to

use and comply with them. This equipment

should only be used in connection with parts

of personal protective equipment (PPE)

bearing the CE-symbol to protect individuals

against falls from heights.

If original components are modified or

removed from the product, its safety aspects may

be restricted. The equipment should not be

modified in any way or altered to allow

attachment of additional parts without the

manufacturer’s written recom-mendation.

The equipment must be checked for possible

damage before and after each use. It must be

ensured that the equipment is serviceable and

fully functional.

The equipment must be discarded immediately

if there is even the slightest doubt as to its

serviceability.

WARNING! The products must be kept away

from damaging environments. This includes

contact with abrasive and aggressive

substances (e.g. acids (battery acid!), alkalis,

soldering water, oils, cleaning agents), as well

as extreme temperatures and flying sparks.

In addition, sharp edges, wetness and especially

icing-up can diminish the stability of textiles.

CLIMATE REQUIREMENTS Fig. 10b

The permanent use temperature of the product

(in dry condition) ranges from approx. -20°C to

+55°C.

LIFESPAN AND REPLACEMENT

The lifespan of the product mainly depends

mainly on the way and frequency in which it

is used and external influences.

Products made from synthetic fibre (polyamide,

polyester, dyneema) are subject to a certain

ageing process even if they are not used. This is

caused by the intensivity of UV-rays and

environmental influences.

The maximum service life at optimum storage

conditions (see item Storage) and with no use is

12 years.

The maximum service life (commercial/non-

commercial use) assuming proper use, no visible

signs of wear, and at optimum storage

conditions is 10 years.

PPE showing signs of wear must be replaced, for

instance, if the edges of webbing and straps are

damaged, if fibres have come off the webbing, if

seams are damaged or show signs of wear, or if the

equipment has come in contact with chemicals.

Watch out for sharp burrs or signs of corrosion on

metal parts of the equipment. Repairs may only be

performed as outlined in the instructions of the

manufacturer.

In case of extreme use (extreme signs of wear), for

instance, upon strain by a fall or when damage is

visible, immediately remove the PPE from use and

turn it over to the manufacturer or a competent

person for inspection and/or repair; be sure to

request a written confirmation for the work done

(Fig. 13).

Repairs may only be performed as outlined in the

instructions of the manufacturer.

INSPECTION

The product must be checked and, if necessary,

maintained whenever this is necessary but at least

yearly by the manufacturer, an expert or an

authorised testing centre.

In the process, it must be ensured among other

things that the product labelling is legible.

When the maximum service life of 10 years has been

reached, the PPE must be removed from further use.

STORAGE, TRANSPORT AND CARE

Storage

Store in a cool, dry, dark place outside transport

containers. Avoid contact with chemicals (caution:

battery acid!) Store without mechanical stress

caused by jamming, pressure or tension.

Transport

The product must be kept away from direct sunlight,

chemicals, dirt and mechanical damage. For this

purpose, a protective bag or special storage and

transport containers should be used.

purpose, a protective bag or special storage

and transport containers should be used.

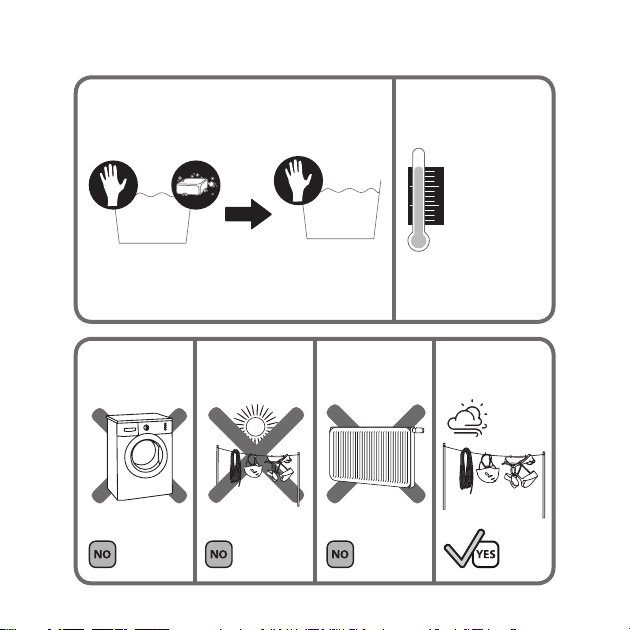

Cleaning Fig. 10a and 11

Clean soiled products in luke-warm water (if

neces-sary, use pH-neutral soap). Rinse well. Dry

at room temperature, never use a tumble drier or

dry close to radiators! If required, halogen-free

commercial disin-fectants may be used.

If required, hinges of metal parts may be oiled

after cleaning.

WARNING! Failure to follow these

instructions may endanger life!

Material:

- Polyamide

- Polyester

- Aluminium

- Steel

INFORMATION ON THE PRODUCT:

Manufacturer: EDELRID

Product description:

Fall arrest harness according to EN 361,

ANSI/ASSE Z359.11

Model: Flex Lite

Size

Maximum user load

YYYY MM: Year and month of manufacture

Lot number: GV xxx xxxx

Identification: (to be entered by the user him/

herself if appropriate)

CE 0123: certification body monitoring the PPE

production

i-Symbol: Warning notices and instructions

must be read and observed

Fall arrest harness to EN 361: Marking A and

A/2 (A/2 + A/2 = A ): catch eye

Declaration of Conformity:

EDELRID GmbH & Co. KG herewith declares that the

article is in conformity with the applicable pertinent

requirements and regulations of the EU Directive

89/686 applicable until 20 April 2018 and of the EU

Regulation 2016/425 applicable as off 21 April 2018.

The original declaration of conformity may be

downloaded from the following website:

http://www.edelrid.de/...

Remarks

Instructions for use: CE XXXX: Notified body responsible

for issuing of the EC Type Approval Certificate of the

product.

Our products are manufactured with the utmost care.

However, should any of our products give cause for a

justified complaint, please advise us of the lot number.

We reserve the right to make technical amendments.

ANSI additional information

- The Instructions for Use must be provided to the user

of this equipment.

- The Instructions for Use for each item of equipment

used in conjunction with this product must be followed.

- Rescue plan: You must have a rescue plan and the

means to rapidly implement it in case of difficulties

encountered while using this equipment.

- WARNING: when using multiple items of equipment, a

dangerous situation can arise in which the safety function

of an item of equipment can be af-fected by the safety

function of another item of equipment.

- WARNING: chemicals, heat, corrosion and ultravio-let

light can damage your harness. Contact Edelrid if there is

any doubt about the condition of this product.

- Be vigilant when working near sources of

electricity, moving machinery or abrasive or sharp

surfaces.

Appendix A – ANSI/ ASSE Z359.11

ANSI/ASSE Z359 Requirements for proper use and

maintenance of full body harnesses

Note: these are general requirements and

information provided by ANSI/ASSE Z359; The

manufacturer of this equipment may impose more

stringent restrictions on the use of the products they

manufacture, see the manufacturer’s instructions.

1. It is essential that the users of this type of

equipment receive proper training and instruction,

including detailed procedures for the safe use of

such equipment in their work application. ANSI/

ASSE Z359.2, minimum requirements for a

managed fall protection program, establishes

guidelines and requirements for an employer’s

managed fall protection program, including policies,

duties and training, fall protection procedures,

eliminating and controlling fall hazards, rescue

procedures, incident investigations and evaluating

program effectiveness.

2. Correct fit of a full body harness is essential to

proper performance. Users must be trained to select

the size and maintain the fit of their full body

harness.

3. Users must follow manufacturer’s instructions for

proper fit and sizing, paying particular attention to

ensure that buckles are connected and aligned

correctly, leg straps and shoulder straps are kept

snug at all times, chest straps are located in the

middle chest area, and leg straps are positioned and

snug to avoid contact with the genitalia should a fall

occur.

4. Full body harnesses which meet ANSI/ASSE

Z359.11 are intended to be used with other

components of a personal fall arrest system that limit

maximum arrest forces to 1800 pounds (8 kN) or less.

5. Suspension intolerance, also called suspension

trauma or orthostatic intolerance, is a serious condi-

tion that can be controlled with good harness design,

prompt rescue, and post fall suspension relief devices.

A conscious user may deploy a suspension relief

device allowing the user to remove tension from

around the legs, freeing blood flow, which can delay

the onset of suspension intolerance. An attachment

element extender is not intended to be attached

directly to an anchorage or anchorage connector for

fall arrest. An energy absorber must be used to limit

maximum arrest forces to 1800 pounds (8 kN). The

length of the attachment element extender may

affect free fall distances and free fall clearance cal-

culations.

6. Full body harness (FBH) stretch, the amount the

FBH component of a personal fall arrest system will

stretch and deform during a fall, can contribute to

the overall elongation of the system in stopping a fall. It

is important to include the increase in fall distance

created by FBH stretch, as well as the FBH connector

length, the settling of the user’s body in the FBH, and

all other contributing factors when calculating total

clearance required for a particular fall arrest system.

7. When not in use, unused lanyard legs that are still

attached to a full body harness D-ring should not be

attached to a work positioning element or any other

structural element on the full body harness unless

deemed acceptable by the competent person and

manufacturer of the lanyard. This is especially im-

portant when using some types of Y-style lanyards, as

some [dangerous shock] load may be transmitted to

the user through the unused lanyard leg if it is not

able to release from the harness. The lanyard parking

attachment is generally located in the sternal area to help

reduce tripping and entanglement hazards.

8. Loose ends of straps can get caught in machinery or cause

accidental disengagement of an adjuster. All full body

harnesses shall include keepers or other components which

serve to control the loose ends of straps.

9. Due to the nature of soft loop connections, it is

recommended that soft loop attachments only be used to

connect with other soft loops or carabiners. Snap hooks

should not be used unless approved for the application by

the manufacturer. Sections 10-16 provide additional

information concerning the location and use of various

attachments that may be provided on this FBH.

10. Dorsal

The dorsal attachment element shall be used as the primary

fall arrest attachment, unless the application allows the use of

an alternate attachment. The dorsal attachment may also be

used for travel restraint or rescue. When supported by the

dorsal attachment during a fall, the design of the full body

harness shall direct load through the shoulder straps

supporting the user, and around the thighs. Supporting the

user, post fall, by the dorsal attachment will result in an

upright body position with a slight lean to the front with

some slight pressure to the lower chest. Considerations

should be made when choosing a sliding versus fixed

dorsal attachment element. Sliding dorsal attachments are

generally easier to adjust to different user sizes, and allow a

more vertical rest position post fall, but can increase FBH

stretch.

11. Sternal

The sternal attachment may be used as an alternative fall

arrest attachment in applications where the dorsal

attachment is determined to be inappropriate by a

competent person, and where there is no chance to fall in

a direction other than feet first.

Accepted practical uses for a sternal attachment

include, but are not limited to, ladder climbing with a

guided type fall arrestor, ladder climbing with an

overhead self-retracting lifeline for fall arrest, work

positioning, and rope access. The sternal attachment

may also be used for travel restraint or rescue. When

supported by the sternal attachment during a fall, the

design of the full body harness shall direct load

through the shoulder straps supporting the user, and

around the thighs. Supporting the user, post fall, by

the sternal attachment will result in roughly a sitting

or cradled body position with weight concentrated on

the thighs, buttocks and lower back. Supporting the

user during work positioning by the sternal

attachment will result in an approximate upright body

position. If the sternal attachment is used for fall

arrest, the competent person evaluating the

application should take measures to ensure that a fall

can only occur feet first. This may include limiting the

allowable free fall distance. It may be possible for a

sternal attachment incorporated into an adjustable

style chest strap to cause the chest strap to slide up

and possibly choke the user during a fall, extraction,

suspension... The competent person should consider

full body harness models with a fixed sternal

attachment for these applications.

12. Frontal

The frontal attachment serves as a ladder climbing

connection for guided type fall arrestors where there is

no chance to fall in a direction other than feet first, or

may be used for work positioning. Supporting the

user, post fall or during work positioning, by the

frontal attachment will result in a sitting body

position, with the upper torso upright, with weight

concentrated on the thighs and buttocks. When

supported by the frontal attachment, the design of the

full body harness shall direct load directly around the

thighs

and under the buttocks by means of the subpelvic

strap. If the frontal attachment is used for fall

arrest, the competent person evaluating the

application should take measures to ensure that a

fall can only occur feet first. This may include

limiting the allowable free fall distance.

13. Shoulder: The shoulder attachment elements

shall be used as a pair, and are an acceptable attach-

ment for rescue, and entry/retrieval. The shoulder

attachment elements shall not be used for fall arrest.

It is recommended that the shoulder attachment

elements be used in conjunction with a yoke

which incorporates a spreader element to keep

the full body harness shoulder straps separated.

14. Waist, rear: The waist, rear attachment shall

be used solely for travel restraint. The waist, rear

attachment element shall not be used for fall arrest.

Under no circumstances is it acceptable to use the

waist, rear attachment for purposes other than

travel restraint. The waist, rear attachment shall

only be subjected to minimal loading through the

waist of the user, and shall never be used to

support the full weight of the user.

15. Hip: The hip attachment elements shall be

used as a pair, and shall be used solely for work

positioning. The hip attachment elements shall not

be used for fall arrest. Hip attachments are often

used for work positioning by arborists, utility

workers climbing poles, and construction workers

tying rebar and climbing on form walls. Users are

cautioned against using the hip attachment

elements (or any other rigid point on the full body

harness) to store the unused end of a fall arrest

lanyard, as this may cause a tripping hazard, or, in

the case of a multiple-leg lanyard, could cause

adverse loading to the full body harness and the

wearer through the unused portion of the

lanyard.

16. Suspension seat: The suspension seat attachment

elements shall be used as a pair, and shall be used

solely for work positioning. The suspension seat

attachment elements shall not be used for fall arrest.

Suspension seat attachments are often used for

prolonged work activities where the user is

suspended, allowing the user to sit on the suspension

seat formed between the two attachment elements. An

example of this use would be window washers on

large buildings.

USER INSPECTION, MAINTENANCE AND

STOR-AGE OF EQUIPMENT

Users of personal fall arrest systems shall, at a

minimum, comply with all manufacturer instructions

regarding the inspection, maintenance and storage of

the equipment. The user’s organization shall retain

the manufacturer’s instructions and make them

readily available to all users. See ANSI/ASSE

Z359.2, Minimum requirements for a managed fall

protection program regarding user inspection,

maintenance and storage of equipment.

1. In addition to the inspection requirements set forth

in the manufacturer’s instructions, the equipment

shall be inspected by the user before each use and,

additionally, by a competent person, other than the

user, at interval of no more than one year for:

- absence or illegibility of markings

- absence of any elements affecting the equipment

form, fit or function

- evidence of defects in or damage to hardware

elements including cracks, sharp edges, deformation,

corrosion, chemical attack, excessive heating, al-

teration and excessive wear

- evidence of defects in or damage to strap or ropes

including fraying, unsplicing, unlaying, kinking,

knotting, roping, broken or pulled stitches, excessive

elongation, chemical attack, excessive soiling,

abrasion, alteration, needed or excessive lubrication,

excessive aging and excessive wear

2. Inspection criteria for the equipment shall be set

by the user’s organization. Such criteria for the

equipment shall equal or exceed the criteria

established by this standard or the manufacturer’s

instructions, whichever is greater.

3. When inspection reveals defects in, damage to, or

inadequate maintenance of equipment, the

equipment shall be permanently removed from

service or undergo adequate corrective

maintenance, by the original equipment

manufacturer or their designate, before return to

service.

Maintenance and storage

1. Maintenance and storage of equipment shall be

conducted by the user’s organization in accordance

with the manufacturer’s instructions. Unique issues,

which may arise due to conditions of use, shall be

addressed with the manufacturer.

4. Equipment which is in need of, or scheduled for

maintenance shall be tagged as “unusable” and

removed from service.

5. Equipment shall be stored in a manner as to

preclude damage from environmental factors such as

temperature, light, UV, excessive moisture, oil,

chemicals and their vapors or other degrading

elements.

Table of contents

Languages:

Other EDELRID Protection Device manuals

Popular Protection Device manuals by other brands

Val-Matic

Val-Matic VentSafe Security Cage Operation, maintenance and installation manual

ABB

ABB RET630 Product guide

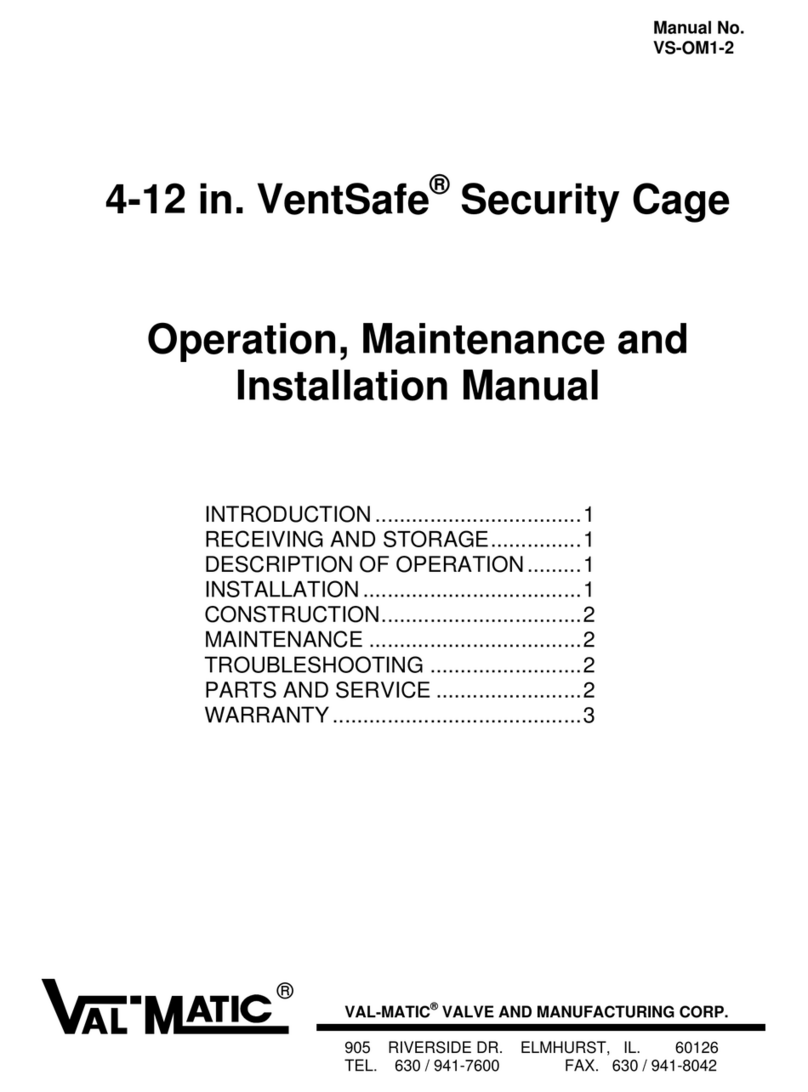

ELAC

ELAC PB62-W Setup guide

Husqvarna

Husqvarna HP500BT-01 Operator's manual

Max-Air Systems

Max-Air Systems ME G Series Installation, operation and maintenance instructions

PSP

PSP ZAP Light Extreme quick start guide