1

ITEM DESCRIPTION MATERIAL

1 Body PVC

2 Screen, 20 Mesh 304 Stainless Steel

3 Cage, 2 Mesh 304 Stainless Steel

4-12 in. VentSafe®Security Cage

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information to

properly install, maintain and ensure a long service

life for the VentSafe®. The VentSafe®is to be

installed in vent pipes used to vent vaults, reservoirs

and air valves to prevent the entrance of foreign

objects and to provide a barrier against the

intentional introduction of liquids into the vent pipe

(see figure 1).

RECEIVING AND STORAGE

Inspect the VentSafe®upon receipt for damage in

shipment. Unload all devices carefully to the ground

without dropping.

The devices should remain boxed, clean and dry

until installed to prevent weather related damage.

DESCRIPTION OF OPERATION

The VentSafe®is a wafer-style, screened cage to

deter unauthorized access and to prevent foreign

objects from entering the valve, vault or reservoir

vent, but still allow the vent to perform its function of

admitting and expelling air under normal operating

conditions.

INSTALLATION

The installation of the VentSafe®is important for its

proper operation. The VentSafe®can be installed in

the vertical or horizontal position between typical

ANSI Class 125 flanges using standard connection

practices. The VentSafe®Security Cage can be

located above ground as shown in Figure 2. The

device can also be placed in series at both locations

for added protection. When installed at the end of

the vent pipe a ring-type flange is needed on the end

of the pipe to secure the device in place,

Flanged connections should only be mated with flat-

faced pipe flanges. The bolts should be tightened in

gradual steps using the crossover method.

Recommended torque values are given in Table 1.

The VentSafe®can be used with or without flange

gaskets since the vent piping is not pressurized.

TABLE 1. FLANGE BOLT TORQUES

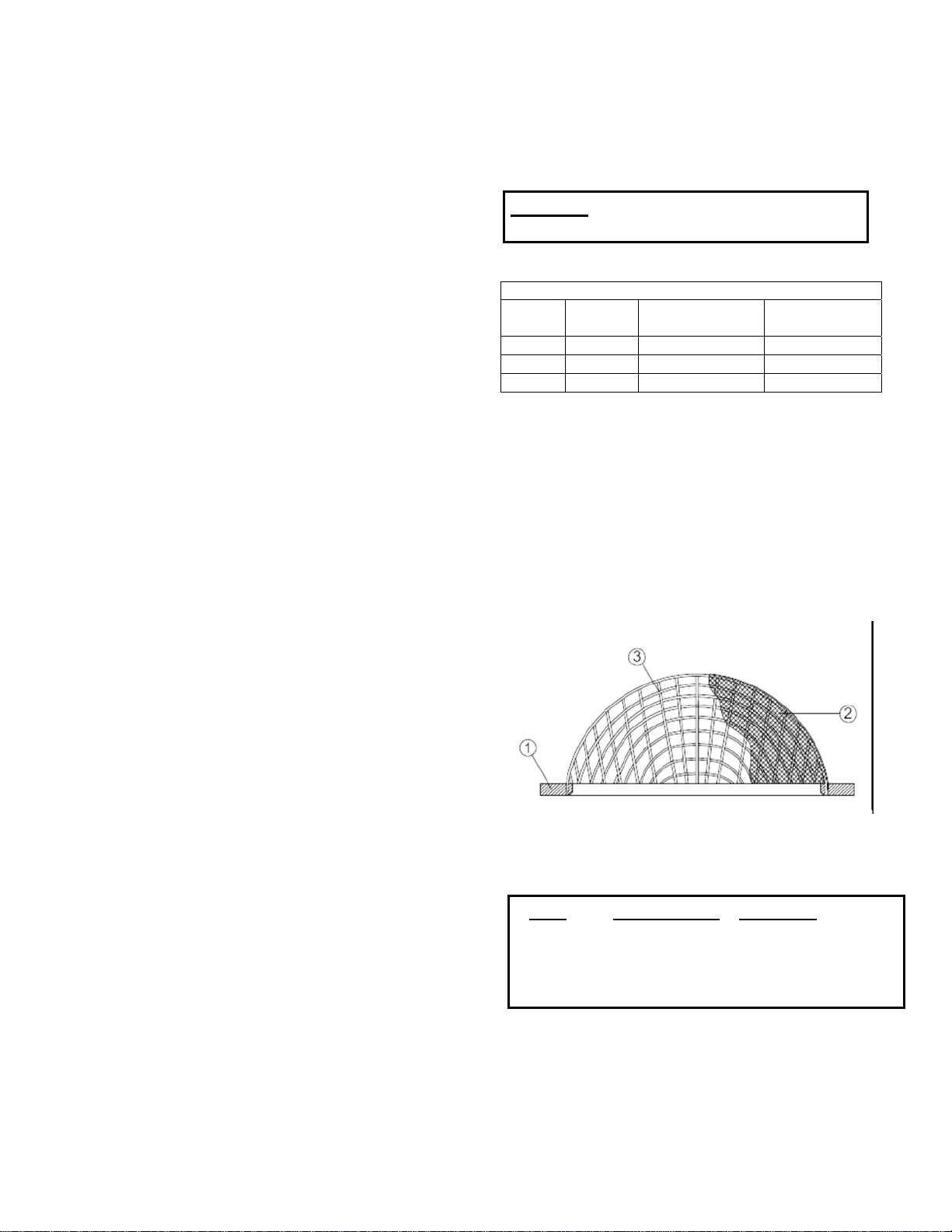

VENTSAFE®CONSTRUCTION

The standard VentSafe®is constructed of quality

corrosion resistant materials including polyvinyl

chloride (PVC) and stainless steel type 304. The

general details of construction are illustrated in

Figure 1 and identified in Table 2.

Figure 1: VentSafe®Cross Section of

Components

Table 2: VentSafe®Parts List

Mounting Flange Bolts

Device

Size Bolt

Size Recommended

Torque (ft-lbs) Maximum

Torque (ft-lbs)

4 5/8” 20 30

8 3/4” 30 40

12 7/8" 60 70

CAUTION: The use of excessive bolt torque

may damage the device.