Eding CNC CPU5A4E User manual

CPU5A

Card size 100x100mm

3 or 4 axes interpolation, 125 KHz step frequency.

Standard CNC outputs (TOOL, TOOL SPEED: PWM / 0-10V, Flood coolant, Mist coolant, AUX1, Watchdog)

Standard CNC inputs (4 Home inputs, Probe, Spindle sensor, Run, Pause, E-Stop, Hand wheel)

Powered by USB or +5V external.

4 Axes + USB + Ethernet (USBCNC_CPU5A4E)

3 Axes + USB (USBCNC_CPU_5A3) ... 4 Axes + USB (USBCNC_CPU_5A4)

Connector

Signal

Connector

Signal

X1

25P SUBD - FEMALE

1: OUT TOOL

2: OUT DIR1

3: OUT STEP1

4: OUT DIR2

5: OUT STEP2

6: OUT DIR3

7: OUT STEP3

8: OUT DIR4

9: OUT STEP4

10: IN HOME3

11: IN ESTOP

12: IN HOME2

13: IN HOME1

14: OUT FLOOD

15: IN HOME4

16: OUT WATCHDOG

17: PWM or 0..10V

(JUMPER)

18: PROBE

19: SPINDEL-PULSE

20: +5V (Solder jumper)

21: +5V (Solder jumper)

22: GND

23: GND

24: GND

25: GND

S: SHIELD

X2

9P-SUBD-FEMAILE

1: IN RUN

2: IN PAUSE

3: OUT MIST

4: OUT AUX1

5: IN HANDWHEEL A

6: IN HANDWHEEL B

7: +5V

8: GND

9: GND

S: SHIELD

74HCT14 outputs for step/direction

15 mA per output source or sink.

Other outputs are open collector transistor outputs

E-Stop input

Other inputs are 74HCT14 inputs.

Pull-up to +5V with 10K

Filtered with R/C filter

100 mA max current.

PWM frequency 5 Khz

Charge pump frequency 10 Hz (LED4)

See also the manual about how to use an open

collector output.

0..10 Volt output

10 mA for VFD control

Jumper settings

Jumpers

The yellow marked jumpers are the only ones

interesting to you. The others should be left

untouched.

Lower left (USBPWR) is set if the board is powered by

the USB voltage.

Remove if you want to power externally.

External POWER can be applied on the SUBD 25

connector (PIN 20-21, 22-25). And also on the SUBD 9

connector (PIN 7, 8-9), see table above.

(*)

These power lines can also be used to drive the

step/dir/amp-enable inputs of your drive of needed.

When using the supply lines on the SUBD 25 the

solder jumpers on the bottom side must be

connected.

They are not standard connected because of

compatibility with other parallel port based CNC

controls where these pins are connected to GND.

This jumper selects the signal on PIN 17 of the DB25.

Jumper to the right => PWM out.

Jumper to the left => 0-10 Volt out.

This jumper controls the watchdog output at PIN 16

of the SUBD 25.

The upper jumper controls the output being NPN or

PNP.

The lower jumper controls the output polarity.

The details of the watchdog output configuration

jumpers.

Upper jumper to the right => Open Collector NPN.

Use with external supply.

Upper jumper to the left => Open Collector PNP (+5V)

output. Use with internal +5V supply.

Lower jumper to the right =>NPN Active SAFE.

PNP Active NOTSAFE.

Lower jumper to the left=>NPN Active NOT SAFE.

PNP Active SAFE.

This GREEN LED shows the state of the Watchdog.

ON => Safe

OFF => Not Safe

Connection to the stepper motor or servomotor drive

EXAMPLE1 - USE WATCHDOG TO AMPENABLE FOR LEADSHINE DRIVE (POSITIVE PULSE CONNECTION)

The Leadshine drives are OFF when the input is driven, it is opposite of what most of us expect.

Upper jumper to the left (PNP), Lower to the right (ON-SAFE)

Positive pulse connection does not need the +5V, that is the difference with negative pulse connection.

Pulse Inversion

CPU to drive connections

EXAMPLE2 - USE WATCHDOG TO AMPENABLE FOR LEADSHINE DRIVE (NEGATIVE PULSE CONNECTION)

Upper jumper to the right (NPN). Lower jumper to the left (OFF-NOTSAFE)

Negative pulse connection is the standard way to connect this type of drive.

It needs the 5 Volt connection terminal.

See also(*) above.

Pulse Inversion

CPU to drive connections

REMARK

By connecting a drive to the wrong pulse polarity does not harm anything. Nothing will be damaged.

The difference is the speed that you will get on the motor. Just try out by inverting the Pulse inversion in the

software what gives the highest motor speed.

Where is X, Y, Z connected to?

USBCNC allows variable configurations.

Some customers have X Y Z A

Some have X Y Z C

Some have X Z A B

So the first selected axis in the setup is connected to STEP1/DIR1 the next to STEP2/DIR2 etc.

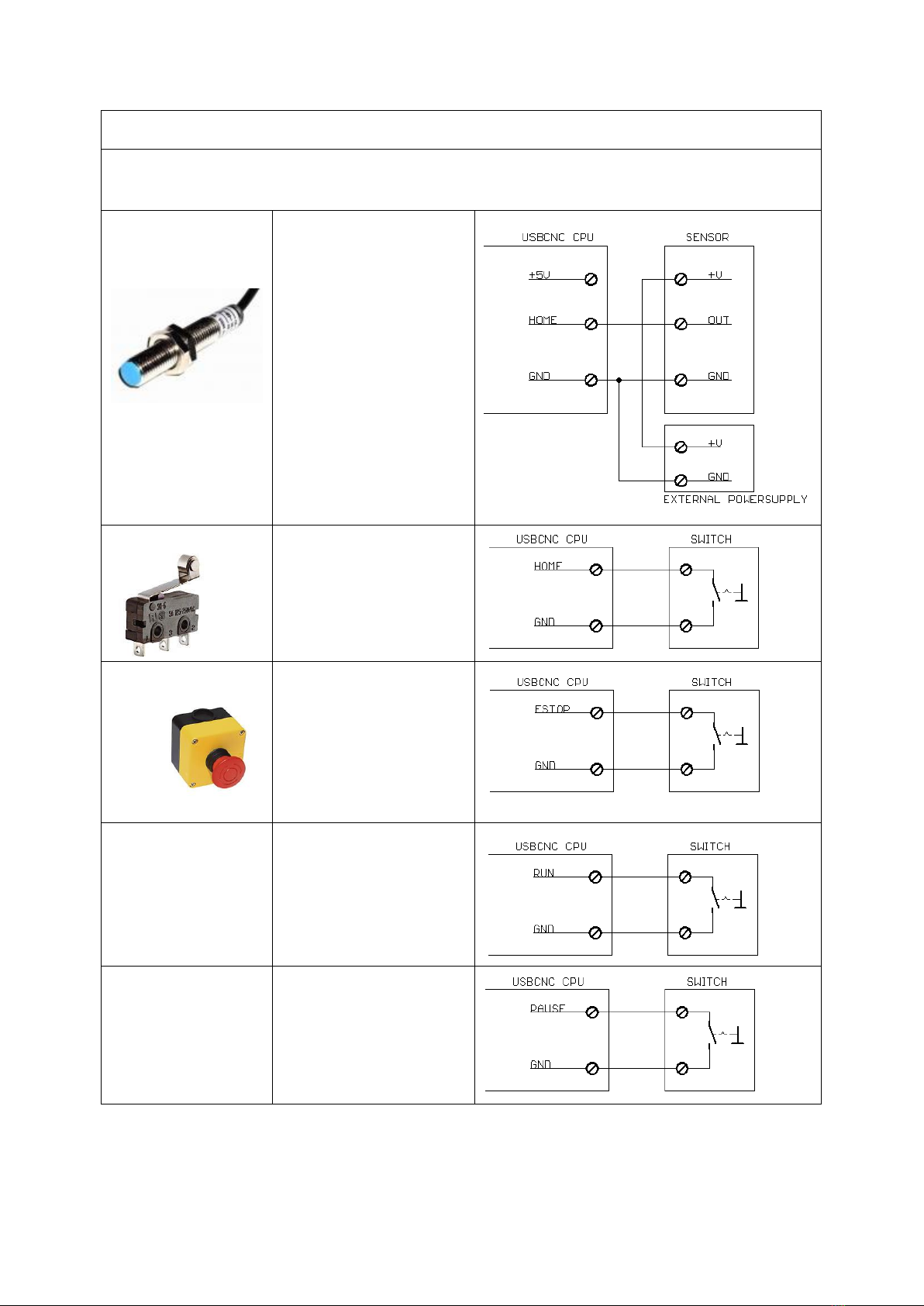

Connection of the inputs

HOME - ESTOP - PAUSE - RUN - HANDWHEEL - SPINDLE-SENSOR

INDUCTIVE HOME

SENSORS

NPN Type

SIMPLE HOME SWITCH

Normally Open Type

HomeInputSenseLevel = 0

Normally Closed Type

HomeInputSenseLevel = 1

ESTOP

SWITCH

Normally Open

EStopInputSenseLevel = 0

Normally Closed

EStopInputSenseLevel = 1

RUN SWITCH

Any push button switch

Auto detect

PAUSE SWITCH

Any push button switch

Normally closed

Handwheel

+5 Volt handwheel

Spindle sensor

This is required for

Lathe Thread cutting

Ask your dealer

Probe

A probe can be a normally

open or normally closed

switch.

Connection of the outputs

TOOL (Kress) - VFD - FLOOD - MIST -AUX1

TOOL FLOOD MIST AUX

SOLID STATE RELAY

This is the way I recommend,

Use a solid state relay.

A solid state relay causes no

sparks, very little EMV noise.

TOOL FLOOD MIST AUX

RELAY

Standard relays cause a lot of

EMV noise.

EMV noise can disturb the

USB communication.

I recommend to use

standard relay's only for low

power.

Never for get to apply a anti

parallel diode of 100 - 200

volt / 1 - 2 Amp.

Without this diode the CPU

may be damaged.

HF Spindle wit VFD

You can use the 0 - 10 volt

output together with the

tool output to control the

VFD.

Ask your VFD supplier how to make the connections

exactly.

LEDS

LED's from left to right

BOOTLOADER MODE

CNC MODE

Blue

+5 Volt and CPU 3.3Volt present.

Red

Error during programming.

Watchdog reset signal, 10

Hz pulse.

Yellow

Alternating flash indicate

boot loader active and

communication with USB

working.

FLASH=> ETHERNET ACTIVE

Green

FLASH => USB ACTIVE

Orange

Capture status, if on boot

loader remains active.

See also CPU5 configurator

tool.

10 pulses at startup to show

CNC firmware starting.

On if E-Stop activated.

Off if no E-Stop activated.

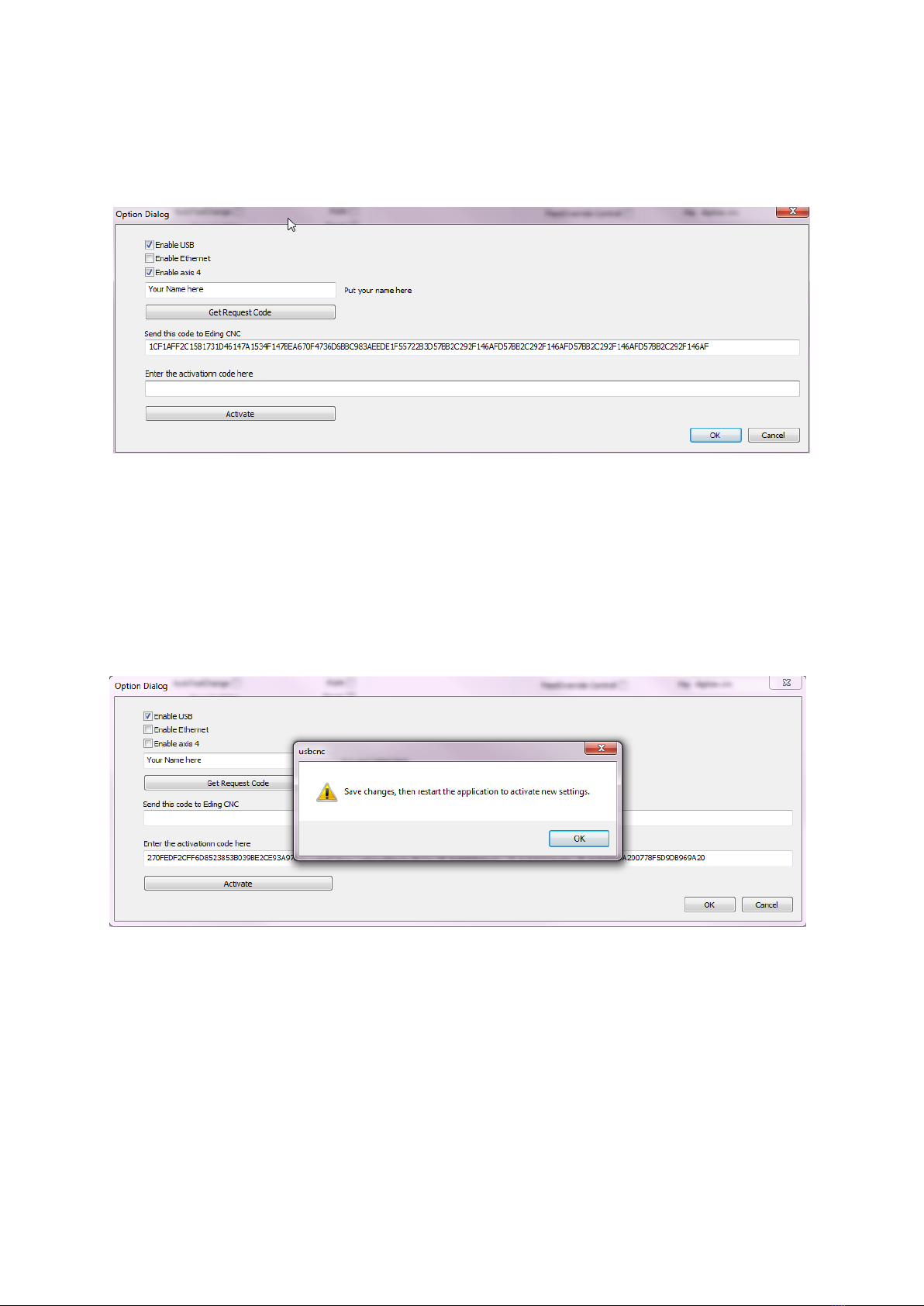

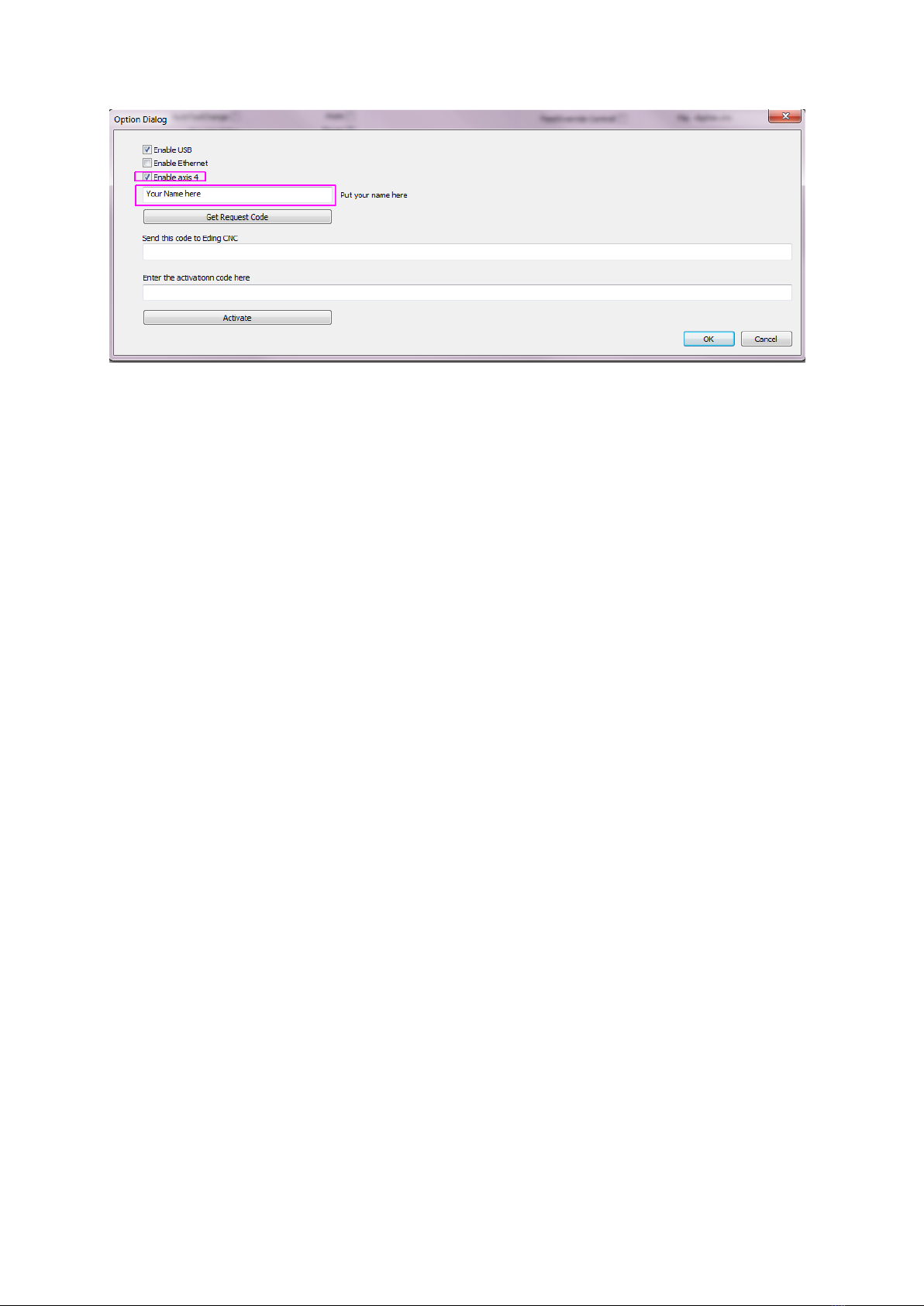

Upgrading USBCNC_CPU5A3 to USBCNC_CPU5A4

If you have bought a CPU5A3 and want to use the 4th axis, it is possible to upgrade. Via the 2nd setup page in

the USBCNC software, see explanation below:

CPUOPT: This is special for CPU5A.

This button allows to add the 4th axis function on a CPU5A3. So it upgrades

from 5A3 to 5A4.

These are the steps to follow:

In the dialog check the "enable axis 4" checkbox, enter tour name and press

get request code:

Send the request code to the supplier.

Copy and paste it into an email and send it to your USBCNC supplier.

To do this double click the code, press ctrl-c, in your e-mail press control-v.

Your suplier will send you a activation code.

Copy and paste this into the activation code area. then press activate.

Do what the dialog tells you, press ok twice, press save changes. and restart.

When you press the CPU-OPT button again, you will see that the 4th

axis is enabled and that it is registered with your name.

Table of contents

Other Eding CNC Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs IDENTControl IC-KP2-2HB18-2V1 manual

Rockwell Automation

Rockwell Automation AB Quality Allen-Bradley MicroLogix... user manual

Selah Effects

Selah Effects Quartz Timer V2 user manual

epiphan video

epiphan video AV.io HD user guide

DINUY

DINUY KNX EM KNT 002 Installation and commissioning

MGS

MGS Maya M24 manual