EDMA EDMAPLAC MEGA Instruction Manual

Ref. 267455

BOARD LIFTER

INSTRUCTION AND SECURITY

MANUAL

• Respect the safety instructions in order to avoid injuries or damages on surrounding elements.

• Follow the operating instructions to avoid damaging the tool.

READ THIS MANUAL CAREFULLY BEFORE THE FIRST USE

HANDLE

STEERING WHEEL

POWER DRILL

SUPPORT BASE

MAIN BRAKE LEVER

HANDLE TO ANGLE

THE TOP RACK

WOODEN PLATFORM

Reference : 267455

Maximum loading weight : 80 kg (175 lbs)

Maximum board dimensions : 1,20 x 6.00 m (3,94 x 19,69 Ft)

Minimum board dimensions : 0.15 x 0.60 m (0.49 x 1.97 Ft)

Maximum height with extension part : 4,50 m (14,76 Ft)

Maximum height without extension part : 3,50 m (11,48 Ft)

Minimum height : 161 cm (5,28 Ft)

Maximum vertical lifting height with 2,50 m (8,2 Ft) height board :5,75 m (18,86 Ft)

Board loading height : 80 cm (2,62 Ft) without extension

Minimum width in moving/storage position : 63 cm (243/4”)

Total gross weight: 68.5 kg (151 lbs)

SPARE PARTS

WEAR PARTS

SPECIFICATIONS

- Ref 526732 - Hex bit for using with power drill

- Ref 526761 - Steering wheel central screw

- Ref 526735 - Top rack retractable stopper

- Ref 526756 - Steering wheel

- Ref 526740 - Steering wheel handle

- Ref 526746 - Main brake lever

- Ref 526747- Removable pin

- Ref 526741 - Balance bar with wheels

- Ref 526742 - Power drill support base

- Ref 526737 - Middle foot

- Ref 526744 - Side foot with brake

- Ref 526743 - Side foot without brake

- Ref 526763 - Top rack

- Ref 526764 - Right arm

- Ref 526765 - Left arm

- Ref 526766 - T-arm tube

- Ref 526757 - Extension tube

- Ref 526758 - Internal tube

- Ref 526736 - Wooden platform

- Ref 526754 - 43 mm (13/4’’) screw + nut

- Ref 526753 - 58 mm (21/4’’) screw + nut

- Ref 526751 - 68 mm (25/8’’) screw + nut

- Ref 526750 - 78 mm (31/8’’) screw + nut

- Ref 526755 - Nut

Ref 526730 - Brake lining

Ref 526731 - Metallic cable

Ref 526733 - Wheel with brake

Ref 526734 - Wheel without brake

SAFETY BRAKE

LEVER

REMOVABLE

PIN

CLAMPING

SCREW

NECESSARY TOOLS : 13 mm (1/2”) flat wrench, 6 mm (1/4”) hex wrench

HORIZONTAL CEILING SETTING

AND SLOPING CEILING

12

VERTICAL SETTING STORAGE/MOVING POSITION

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

EDMAPLAC MEGA ASSEMBLY INSTRUCTIONS

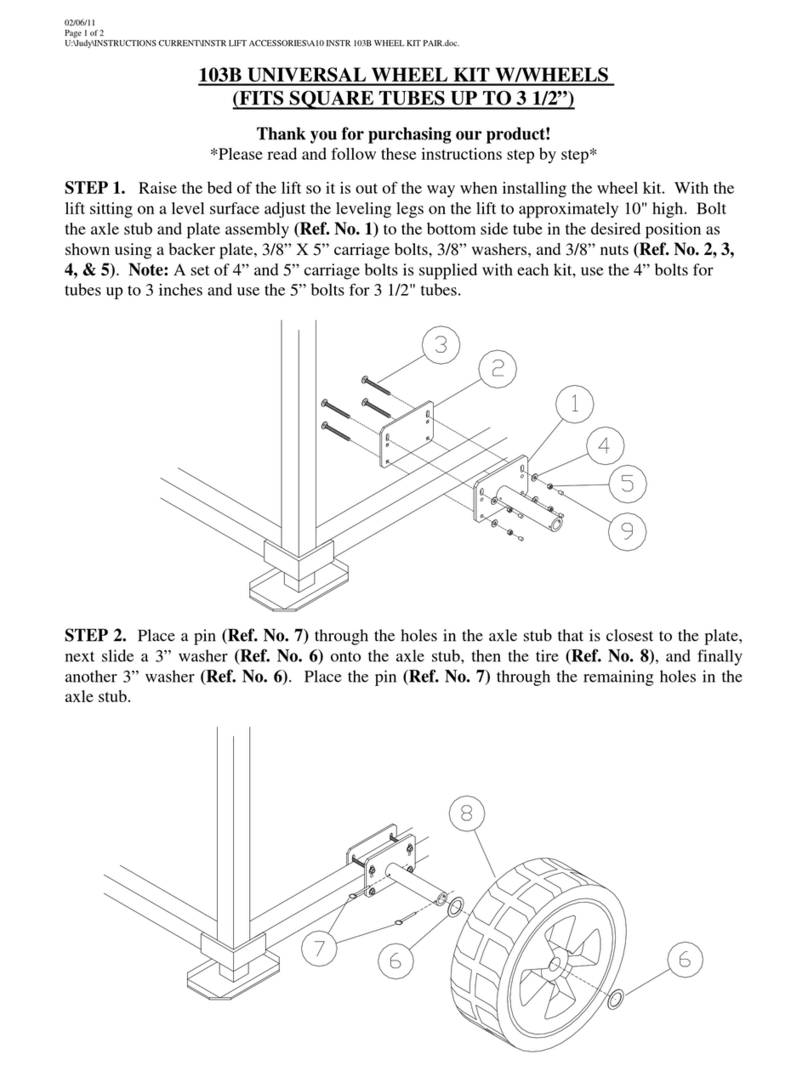

Fix the balance bar with wheels to the main

body with the two 78 mm (31/8’’) screws and nuts.

Use a 13 mm (1/2”) at wrench and a 6 mm (1/4”)

hex wrench.

Fix the lateral and central feet to

the base frame with the six 58 mm

(21/4’’) screws and nuts. Use a 13

mm (1/2”) at wrench and a 6 mm

(1/4”) hex wrench.

Position the side feet with brake

on the same side than the security

and main brake levers.

The central foot is the shortest

foot. The central foot nuts have

to be rmly tightened because it

doesn’t rotate like the side feet.

Open the 2 side feet and insert the removable pin in the base frame hole following the selected conguration.

11 nuts

Middle foot

Support base for

power drill

Main body

Top rack

T-Arms tubes

Arms

Integrated extension

Side feet

Two 43 mm (13/4’’) screws

Six 58 mm (21/4’’)screws

One 68 mm (25/8’’) screw

Two 78 mm (31/8’’) screws

Balance bar wheels

3

Ref. 267455

Wooden platform

The top rack must be in low position while changing the feet position.

®

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

Insert the 1 m (3,28 Ft) extension in the frame and lock it in the selected hole with the

removable pin.

The extension has 3 different height positions : 3,50 m (11,48 Ft), 4 m (13,12 Ft) and

4,50 m (14,76 Ft).

Insert the top rack in the extension base and

x it with the 68 mm (25/8’’)screw and nut.

Assemble the arms with

the two 43 mm (13/4’’)

screws and nuts, using a

13 mm (1/2”) at wrench

and a 6 mm (1/4”) hex

wrench. Make the arms

marks match :

R with R and L with L.

Insert the arms in the top rack according to the position

selected. When you are in front of the steering wheel, put the

R arm on your right and the L arm on your left. The retractable

pins must be locked in the corresponding holes.

Follow the marks on the arms to select the appropriate width :

Mark 1 (without T-arms tubes) – Distance between axes : 2.3 m (7.55 Ft).

Mark 2 (with T-arms tubes) – Distance between axes : 2.8 m (9.19 Ft).

Mark 3 (with T-arms tubes) – Distance between axes : 3.6 m (11.81 Ft).

Mark 4 (with T-arms tubes) – Distance between axes : 4.3 m (14.11 Ft).

Mark 5 (with T-arms tubes) – Distance between axes : 4.88 m (16.01 Ft).

There are 5 different positions to adjust the arms width.

Distance between axes

Fix the power drill support base to the main body with the 2

provided screws and tighten the wing nuts to lock the support

base.

3,50 m (11,48 Ft) 4 m (13,12 Ft) 4,50 m (14,76 Ft)

4

5

6

7

8

Ref. 267455

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

OPERATING INSTRUCTIONS

1Lift the latch to unlock the top rack and tilt it completely.

Insert the arms in the tube according to the selected setting, the retractable pin must be locked in the hole.

Block the 2 wheel brakes, then load the board.

Pull the handle to position the board on the chosen conguration.

2

3

4

Ref. 267455

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

OPERATING INSTRUCTIONS

Ref. 267455

5Unlock the 2 wheel brakes and turn the steering wheel while pushing

the main brake lever to lift the board.

Once the board touches the ceiling, position

the board perfectly and lock the wheel

brakes while screwing the board.

Push the brake lever while lifting the safety brake latch, to lower the top rack. If you have to lower the top rack

loaded, pay attention to control the descent by pushing slightly on the main brake lever.

In case of a main brake default, release immediately the safety brake lever in order to stop the descent right

away.

6

7

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

LOADING CONFIGURATIONS

HORIZONTAL CEILING - SLOPING CEILING AND HORIZONTAL WALL SETTING

Open the feet as much as possible and insert

each removable pin in the 3rd hole of the

base frame.

Insert the arms in the

horizontal tubes, the

retractable pin must be

locked in the selected hole.

Turn the steering wheel while pushing the main brake lever to lift the board up to the ceiling.

Once the board loaded(*), position the EDMAPLAC® MEGA along the wall. Pull out the removable pin from the

top rack in order to angle the board completely, while pushing the EDMAPLAC® MEGA along the wall thanks to

the top rack handle. Lock the 2 wheel brakes. We advise to not exceed a loading weight of 32 kg (71 lbs) for

this setting.

(*)Always ensure that board is correctly centered on the panel lifter head.

Once the board loaded(*), pull the

top rack handle to put the board in

horizontal position.

Position the panel lifter with the

steering wheel in front of the wall

to lift the board along the wall.

(*)Always ensure that board is

correctly centered on the panel

lifter head.

Once the board loaded(*),

pull out the removable pin to

unlock the top rack, then pull

the handle to angle the board.

Insert the removable pin in the

sloping ceiling position hole (45°

position). The top rack position is

adjusted according to the ceiling

angle while the board is touching

the ceiling.

(*)Always ensure that board is

correctly centered on the panel

lifter head.

1

2

3a

3b

4

5

CEILING SETTING

HORIZONTAL SLOPING CEILING

HORIZONTAL WALL SETTING

Ref. 267455

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

LOADING CONFIGURATIONS

VERTICAL LIFTING AND VERTICAL SLOPING CEILING SETTING

Insert the arms in the vertical tubes, the

retractable pin must be locked in the

selected hole according to the board

dimensions.

- 1st hole for vertical sloping ceiling

- 2nd hole (with “vertical position”

marking) for vertical lifting

Once the board loaded(*), pull out the

removable pin to unlock the top rack,

then pull the handle to angle the

board and insert the removable pin in

the sloping ceiling position hole (45°

position).

The top rack position is adjusted

according to the ceiling angle while

the board is touching the ceiling.

(*)Always ensure that board is

correctly centered on the panel lifter

head.

Once the board loaded(*), position the

EDMAPLAC® MEGA along the vertical

wall. Pull out the removable pins from

the 2 lateral feet and open them up to

the 2nd hole of the frame base. Insert

the removable pins to lock the feet. Pull

out the removable pin from the top rack

in order to angle the board completely

on vertical position, while pushing the

EDMAPLAC® MEGA along the wall thanks

to the top rack handle. Lock the 2 wheel

brakes.

(*)Always ensure that board is correctly

centered on the panel lifter head.

Turn the steering wheel while

pushing the main brake lever to

lift the board.

1

2a

2b

3

VERTICAL SLOPING CEILING

VERTICAL lifting

Ref. 267455

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

AUTOMATIC USE ASSISTED BY POWER DRILL

1First of all, you must use the power drill support base for safety reason. Then, set up the EDMAPLAC®MEGA

according to the selected setting conguration.

Insert the hex bit in the

power drill chuck

Adjust the power drill

support base according to

the power drill dimensions.

Insert the hex bit xed to the power drill, in the hex hole located in the

middle of the steering wheel. Turn the power drill to block it against the

power drill support base. Set the power drill on “maximum torque - low

speed”, rotating on clockwise direction.

Pull the power drill trigger to lift the board.

To lower the top rack, remove the power drill rst, then push the main brake lever while lifting

up the safety brake latch.

23

4

5

6

Ref. 267455

POWER DRILL MINI 14.4 VOLTS - 3 Ah

powerdrill

DIRECTIONOF

ROTATION

MAXIMUM TORQUE

LOW SPEED

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

SAFETY INSTRUCTIONS

PRECAUTIONS BEFORE USE

• Make sure all the parts are perfectly well assembled

• Make sure all the nuts are well tight and the removable pins are in position.

• Remove the dust from the gear as well as the rack and pinion.

• Make sure the retractable pins are well locked in their holes.

• Before each use, make a general operational checking.

• Make sure the cable is in good condition. Do not hesitate to change it as soon as the tiniest imperfection

is visible : crushing, pinching, wire breaking.

• Make sure the main brake is in good condition and well adjusted. Once the board lifted at the required

height, it has to stay in position when the safety brake is unlocked. If the top rack goes down, tighten the

main brake by turning the knurled nut clockwise direction.

General safety warnings

• This tool is exclusively dedicated to the plasterboard setting.

• The maximum loading weight is 80 kg (175 lbs). Do not exceed the maximum weight in order to avoid a premature wear.

• Do not use EDMAPLAC®MEGA as a freight elevator or person elevator.

• Do not grease or oil the rack and pinion as well as the gear.

• The top rack must be in low position while changing the feet position.

• Do not use the tool carrier wooden board as a working platform. Use a stepladder or a regulatory working platform to

screw the board onto the ceiling.

• Do not hinder the wheels while using. It may cause a failover of the device.

• Do not clutter up the working area in order to move the EDMAPLAC®MEGA easier.

• Do not put your hand through the steering wheel while the top rack is lowering. It may cause hand or nger injuries.

• Do not let children use the EDMAPLAC®MEGA.

• Do not erase the EDMAPLAC®MEGA warning markings.

• Any modications on the tool are not allowed.

• Once the board lifted at the required height, it has to stay in position when the safety brake is unlocked. If the board goes

down, tighten the main brake by turning the knurled nut clockwise direction. If the board is heavier than a standard board

(more than 25 kg), turn the knurled nut clockwise direction to increase the spring power. If the board still goes down even

with the knurled nut at its tightest, change the brake lining.

• Use the EDMAPLAC® MEGA on a rm and stable surface which can support the weight of the tool and plasterboard.

• Lock the 2 wheel brakes while lifting a board.

• The user has to ensure his own safety as well as the safety of the other people around the EDMAPLAC®MEGA.

• In order to avoid collision with the top rack during its descent, use the main brake to regulate the speed. In case of a main

brake default, release immediately the safety brake lever in order to stop the descent right away.

• Wearing a helmet : follow the current legislation

• Have the device checked regularly by a control agency (decree of 1st march 2004).

Ref. 267455

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

CABLE REPLACEMENT

a

b

1

1

35

3

2

2

4

45

Unscrew the axis maintaining the pulley and remove

it with a 17 mm (11/16”) at wrench and an 8 mm

(5/16”) hex wrench.

Put the axis through the cable loop to x it to the

internal tube.

Remove the pulley. Unscrew the screw from the

main body with a 5 mm (3/16”)

hex wrench, in order to

remove the cable completely.

Put the pulley back to its location.

Pull the internal tube out.

Fix the opposite cable loop to the main body with

the provided screw.

Unscrew

the nut from

the axis

maintaining

the cable to

the main body.

Use a 10 mm

(3/8”) at

wrench and a 5

mm (3/16”) hex

wrench.

Put the principal tube back in the main

body.

Put the axis maintaining the pulley back

and tighten the nut on the axis with a

17 mm (11/16”) at wrench and an 8 mm

(5/16”) hex wrench.

For this step, the internal tube must not

be completely inserted in the frame.

NECESSARY TOOLS : 10 (3/8”) and 17 mm (11/16”) flat wrench, 5 (3/16”) and 8 mm (5/16”) hex wrench

WITHDRAWAL OF USED CABLE

NEW CABLE INSTALLATION

Ref. 267455

INSTRUCTION AND

SECURITY MANUAL

MAJ - 05/18

BRAKE LINING REPLACEMENT

1

1

2

3

4

3

2

4

Unscrew the central axis of the steering

wheel with a 6 mm (1/4”) hex wrench.

Insert the brake lining in its location.

Put the steering wheel on the main axis and make sure that the small key is in its location.

Replace the spring.

Screw the steering wheel central axis.

Pull the steering wheel to remove it from the

axis. Be careful not to lose the small key while

pulling the steering wheel.

Remove the spring by lifting the main

brake lever.

Pull the brake lining to remove it from its

location.

NECESSARY TOOLS : 6 mm (1/4”) hex wrench

WITHDRAWAL OF BRAKE LINING

NEW BRAKE LINING INSTALLATION

a

b

Ref. 267455

EDMA S.A.S

TECHNOPARC EPSILON 1

616, Rue Isaac Newton

83700 SAINT-RAPHAËL

FRANCE

Tel. : +33 (0)4 94 44 70 70

Fax : +33 (0)4 94 44 70 71

Internet : www.edma.fr

* 1 year warranty in case of manufacturing defects under normal use. This warranty does not take into account wear parts : brake lining, cable,

wheels, top rack retractable stops.

YEAR

In conformity with European directive ‘‘MACHINERY’’ 2006/42/CE.

Approved by the VERITAS conformity report # 628 8214-1.

R

e

p

o

r

t

N

o

6

2

8

8

2

1

4

-

1

A

P

P

R

O

V

E

D

B

Y

V

E

R

I

T

A

S

This manual suits for next models

1

Table of contents

Other EDMA Lifting System manuals

Popular Lifting System manuals by other brands

Mortuary Lift

Mortuary Lift ULTIMATE 1000 Installation Suggestions

Granberg

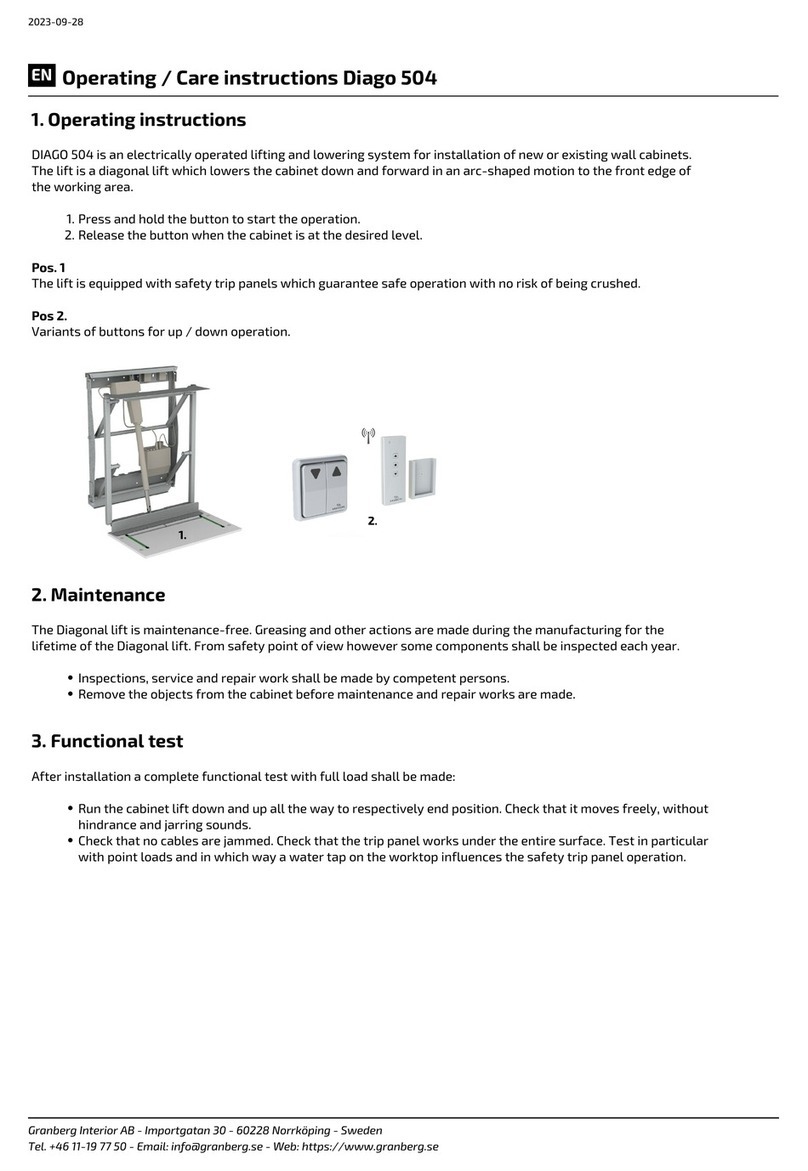

Granberg Diago 504 Operating and care instructions

Southern States

Southern States EV installation instructions

Sealey

Sealey MC454E instructions

Porta-Dock

Porta-Dock 103B quick guide

TECHNOLIFT

TECHNOLIFT SL-9L Installation, operation & maintenance manual

ATN

ATN Zebra 12 Operator’s and Safety Handbook

ThyssenKrupp

ThyssenKrupp Flow2 user manual

ACCO Brands

ACCO Brands ACCOLIFT series instruction manual

Halfen

Halfen DEHA KKT-U Assembly instructions

CHIEF

CHIEF CM2L40 installation instructions

Terex

Terex Genie Lift Tools Expo Installer Z-45/25 Operator's manual supplement