EDRO DYNATROL HMI User manual

The EDRO Corporation

P.O. Box 308

East Berlin, CT 06023 U.S.A. July, 2009

www.edrodynawash.com

PROGRAMMING – OPERATION

PARTS REFERENCE MANUAL

DYNATROL HMI

TOUCH SCREEN CONTROL

For DynaWash Washer-Extractors

Includes DynOzone Programming and Operation

HMI Code 1.00

Technical specifications are based on the latest information available

at the time of printing and are subject to change without notice.

DynaTrol HMI Touch Screen Control

Page 1

TABLE OF CONTENTS

Page

Machine Configuration 2

Motor Setup 4

Water Level Setup 4

Ozone/Signal Setup 5

Timers Setup 5

Miscellaneous Configurable Parameters 6

Language Setup 6

Programming 7

Wash/Rinse Step 8

Drain Step 10

Extract Step 10

Pause Step 11

Link Program 11

End Program 11

Operation 12

Load and Start a Program 12

AutoStart 13

Wash Screen 13

Override Mode 14

Drain Screen 14

Extract Screen 15

Program Complete 15

Alarms and Warnings 16

Reports 17

Alarms 18

Counters 19

Program History 20

Technical Information 21

On Screen Control Manual 21

Debug Screens 22

Settings 24

Passwords 24

Copy Program 25

Reset Factory Programs 25

Clear Program Names 25

Transfer Programs 26

Default Factory Programs 26

HMI System 27

Set System Time 27

Calibrate Screen 27

Download Port 27

Backlight 27

HMI Configuration Settings 27

Parts Reference 28

DynaTrol HMI Touch Screen Control

Page 2

The DynaTrol touch screen control features the latest HMI (Human Machine Interface)

control technology. It is based on a Programmable Logic Controller using ladder logic

code. Use of DynaTrol can be broken down into the following categories:

•Machine Configuration

•Wash Formula Programming

•Operation: Worker and Supervisor Modes

•Managerial Reports on Operation

•Technical Information and Troubleshooting

•Settings

The DynaTrol touch screen control can be setup to work on any DynaWash®washer-

extractor. It must be properly configured to take full advantage of its capabilities.

MACHINE CONFIGURATION

To enter Machine Configuration, press the Configuration button from the Home screen,

then select Machine Configuration. You will need a Level 3 password to continue.

Once you have entered Machine Configuration, you will need to assign a machine series

type:

DynaTrol HMI Touch Screen Control

Page 3

Select a model:

DynaTrol HMI Touch Screen Control

Page 4

The next screens contain information on specific machine parameters which provide

unique model characteristics. They are broken down into the following sub sections:

•Motor Setup

•Water Level Setup

•Ozone / Signal Setup

•Timers Setup

•Miscellaneous Configurable Parameters

A help button is located next to each parameter which further describes the

necessary input or provides a means to set the value.

Enter or change a value by pressing the corresponding number box on the right side of

the screen. A popup window will appear with the current parameter value. Enter a new

value and press ENT to accept, CLR to clear and the X to return without saving.

MOTOR SETUP

Configures motor design and speed settings for the machine.

WATER LEVEL SETUP

Configures values which are affected by level sensing.

DynaTrol HMI Touch Screen Control

Page 5

OZONE/SIGNAL SETUP

Configures DynOzone system and signals working parameters:

TIMERS SETUP

Configures values which are affected by timers.

DynaTrol HMI Touch Screen Control

Page 6

MISCELLANEOUS CONFIGURABLE PARAMETERS

Configures miscellaneous parameters.

LANGUAGE SETUP

To choose Language, press the Configuration button from the Home screen. Then

select the Language button. A level 4 password is required to enter.

Select an available language. This will change all screens except technical information

screens to the selected language. Technical information screens are by default English.

DynaTrol HMI Touch Screen Control

Page 7

PROGRAMMING

The DynaTrol touch screen allows for the entry of up to 50 wash programs with 25 steps

per program, as well as the ability to link programs. Wash programs may contain any of

the following:

•Wash / Rinse Step

•Drain Step

•Extract Step

•Pause Step

To enter Wash Programming, press the Configuration button from the Home screen.

Then select the Wash Programming button. A Level 2 password is required to enter.

Begin by selecting a wash program number. Use the + / - buttons to scroll. Program

names appear in the text box. Twenty factory programs are preloaded. These may be

edited, deleted or re-loaded. To edit name, press the text box.

From this screen you can select a program, change program name, return to previous

menu, delete program, or edit program. To delete, press delete button. This action

cannot be undone. To begin or edit program, press edit for programming options.

DynaTrol HMI Touch Screen Control

Page 8

The main wash programming screen contains six operations:

•Wash / Rinse

•Extract

•Drain

•Pause

•Link Program

•End Program

Press the blue box button next to the operation you wish to perform. A blue operation

box indicates the current step function. From this screen you can press the return button

which will load a program summary screen, delete button which will delete a step, insert

button which will insert a step, or edit button to edit the step.

WASH / RINSE Step

A Wash / Rinse step may contain the following operations: Water fill, temperature

control; rotation control; DynOzone control; and signal control. A time must be entered

for any wash / rinse step.

WATER FILL

Press Cold to activate cold valve; Hot for hot valve, and Reuse for optional reuse valve.

Water fills can be programmed to level and temperature with level being the determining

completion factor.

DynaTrol HMI Touch Screen Control

Page 9

TEMPERATURE CONTROL

Programming a temperature and the Heat button will activate the heating device. This

setting will be maintained for the duration of the step.

ROTATION CONTROL

The step programmable wash cadence is set to a default standard wash rotation. By

pressing the Rotation button a screen with six options will appear. The setting is step

local. Available selections include: Standard Wash; Delicate Wash; Fluff; Forward Only;

Reverse Only; No Rotation. When selecting Standard Wash, Delicate Wash, or Fluff a

new screen will popup with default settings which can then be accepted or modified.

DYNOZONE CONTROL

Selecting the Ozone button will activate the DynOzone system during the wash step.

System will start based on the configured step start parameters and continue for the

duration of step.

SIGNAL CONTROL

Up to 10 signal outputs (depending on model) may be programmed per step. A popup

screen allows for global naming of the signal as well as time entry. A signal time cannot

exceed step time.

DynaTrol HMI Touch Screen Control

Page 10

DRAIN Step

A Drain step may contain the following operations: Sewer Drain; Reuse Drain (option);

Rotation control. A time may be entered for a drain step.

DRAIN CONTROL

Select either sewer drain or reuse Drain (option).

LEVEL CONTROL

Program a time and select level 0% or select a water level without time to drain to a set

point.

EXTRACT Step

An Extract step may contain the following operations: Speed selection; Sewer Drain;

Reuse Drain (option). A time must be entered for an extract step.

SPEED SELECTION

Depending on motor configuration, select a speed for extraction.

DRAIN CONTROL

Select either sewer drain or reuse Drain (option).

DynaTrol HMI Touch Screen Control

Page 11

PAUSE Step

A Pause step may contain the following operations: Pause; Door Open; Sewer Drain;

Reuse Drain (option).

If door open is selected, a drain must be selected;

LINK PROGRAM

Pressing the Link Program button create a program link to any program in memory.

END PROGRAM

Pressing the End Program button will delete all latter steps of the program. When the

Return button is pressed from the main wash programming screen, a program summary

will appear detailing all programmed steps. Press Next to scroll through all 25 steps or

Program Select to return to Configuration menu.

DynaTrol HMI Touch Screen Control

Page 12

OPERATION

To begin wash operation, select the Wash Programs button from the home screen. This

will load the available wash program screen. An available wash program is one that has

already been programmed. Corresponding numbers and program names will appear in

the text box when selected. On this screen, the function key Door is active to allow

opening of the door for loading machine.

Press the Load Program button to go to Start screen. On Start screen, all function keys

are active. Select the appropriate operation.

•START begins program operation.

•STOP pauses machine operation.

•AUTOSTART allows for starting the machine at a time in the future. A popup

screen contains date and time and activation key.

•DOOR activates door lock.

Three pocket, PassThru and tilting models have additional control screens for the jog,

Clean / Soil side controls, AutoSwing Door and tilting features.

DynaTrol HMI Touch Screen Control

Page 13

AUTOSTART

The header includes current loaded program and program name. The body contains

present system time and settings for AutoStart time. Select a day, hour and minute

(AM/PM) and press ENABLE to activate. Press Return to go back to Start screen.

WASH SCREEN

The header indicates the program number, program name, step number and step status.

The body contains bar graphs indicating current water level and current temperature with

a grey bar for programmed set points. Flashing indicators illuminate for water fill valves,

heating, DynOzone operation, and signal outputs. The footer indicates step time and

program time. Pressing step time pops out a step view window. Times indicate

remaining time.

DynaTrol HMI Touch Screen Control

Page 14

The Override button allows changes to the following functions:

•water level

•temperature

•DynOzone

•heating

•rotation

•step time

•step up or down

•end program

Access to these functions requires a Level 1 password. The machine is in a pause

mode during override function and requires the return button and start key to continue or

end program or stop button to abort.

DRAIN SCREEN

The header indicates the program number, program name, step number and step status.

The body contains bar graphs indicating current water level and current temperature with

a grey bar for programmed set points. The footer indicates step time and program time.

Times indicate remaining time. The override function is not available in a drain step.

DynaTrol HMI Touch Screen Control

Page 15

EXTRACT SCREEN

The header indicates the program number, program name, step number and step status.

The body contains bar graphs indicating current water level and current temperature,

and indicator for drain type. A display indicates basket speed. The footer indicates step

time and program time. Times indicate remaining time. The override function is not

available in an extract step.

PROGRAM COMPLETE

At end of program, a Program Complete screen will appear and buzzer will sound. After

safety brake time and safe mode conditions are meet the door can be opened and

goods removed. Return button on Program Complete screen goes to Load Program

screen with most recent run program pre-loaded. Door function key is active on

Program Complete screen.

DynaTrol HMI Touch Screen Control

Page 16

ALARMS AND WARNINGS

During operation safety alarms will appear if a malfunction occurs. Alarms are fatal and

will abort program. Warnings can be reset, by-passed or aborted. Follow screen

instructions for appropriate action required.

Sample Alarm: E-Stop engaged. Machine sent to safe mode. Reset component.

Alarm History screen appears with list of last 100 alarms.

List of Alarms:

•Emergency Stop

•Wash Motor Overload

•Extract Motor Overload

•VFD Overload

•Door Open During Operation

•Low Air Supply

•Ozone Pump #1 Failure

•Ozone Pump #2 Failure

•PowerCell bank less than 50%

•Out of Balance Failure

Sample Warning: Water Level Timeout. Machine sent to pause mode. Reset timer, or

override warning.

List of Warnings:

•Temperature Timeout

•Water Level Timeout •High Temperature in Wash Tub

•High Water Level in Wash Tub

DynaTrol HMI Touch Screen Control

Page 17

REPORTS

The following reports categories are available for viewing the machine's history of

operation:

•Alarms

•Counters

•Program History

To view Reports, press the Configuration button from the Home screen, then select the

Reports.

DynaTrol HMI Touch Screen Control

Page 18

ALARMS

There are three alarm reports:

•Current Alarms are active machine alarms.

•Alarm History contains the last 100 alarms.

•Alarm Frequency details the number of times a particular alarm occurred.

DynaTrol HMI Touch Screen Control

Page 19

COUNTERS

There are three counters. These cannot be reset.

Total Machine Run Time counts hours of machine operation

Total Programs Run counts total programs

Power Cycles count On/Off.

Service Timers count the hours of operation from the last reset. These timers are tied

into the service maintenance pop up screens and are re-settable with password security.

Table of contents

Popular Touchscreen manuals by other brands

2gig Technologies

2gig Technologies 2GIG-SP1-GC3 instructions

Honeywell Home

Honeywell Home PROWLTOUCH Quick installation guide

HDI

HDI Mobi OS Series Operation manual

Digital Touch Systems

Digital Touch Systems DTS-5570KC user manual

Carel

Carel pGDx Touch 4.3" manual

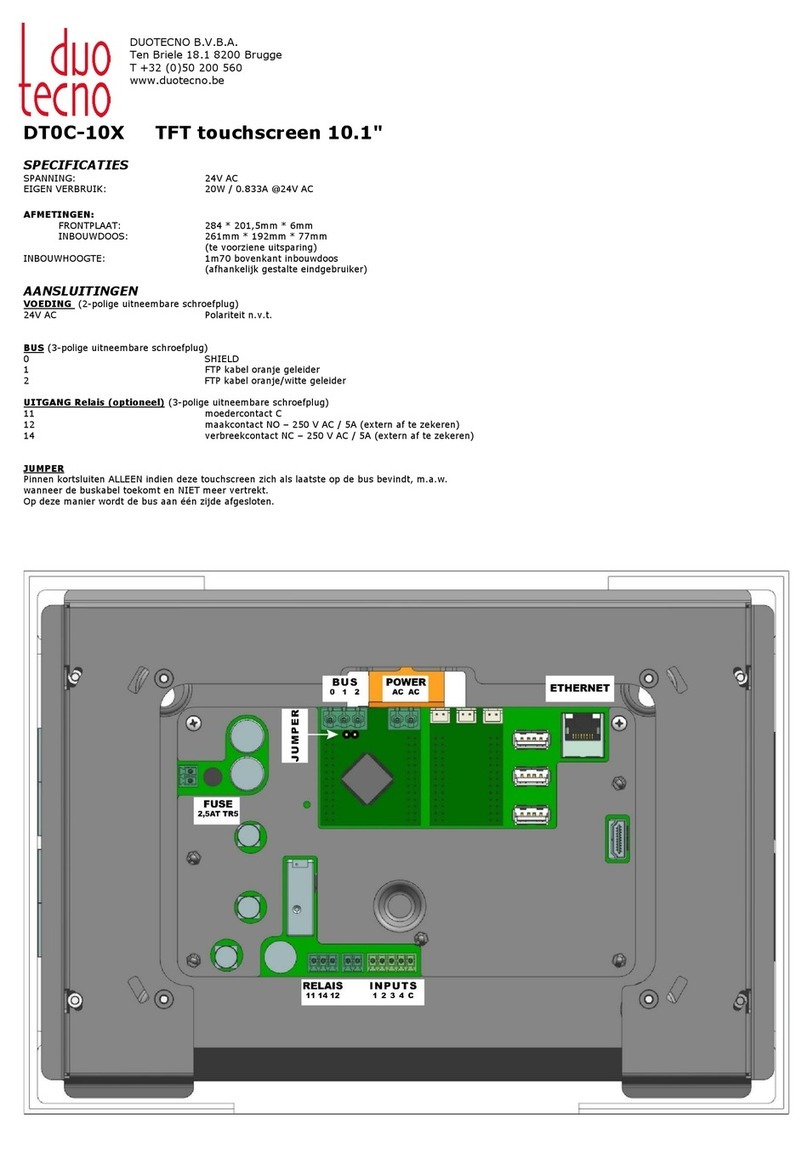

DUOTECNO

DUOTECNO DT0C-10X quick start guide