Superior PAPER HANDLING SOLUTIONS 6

© 2005-2015 Superior-PHS

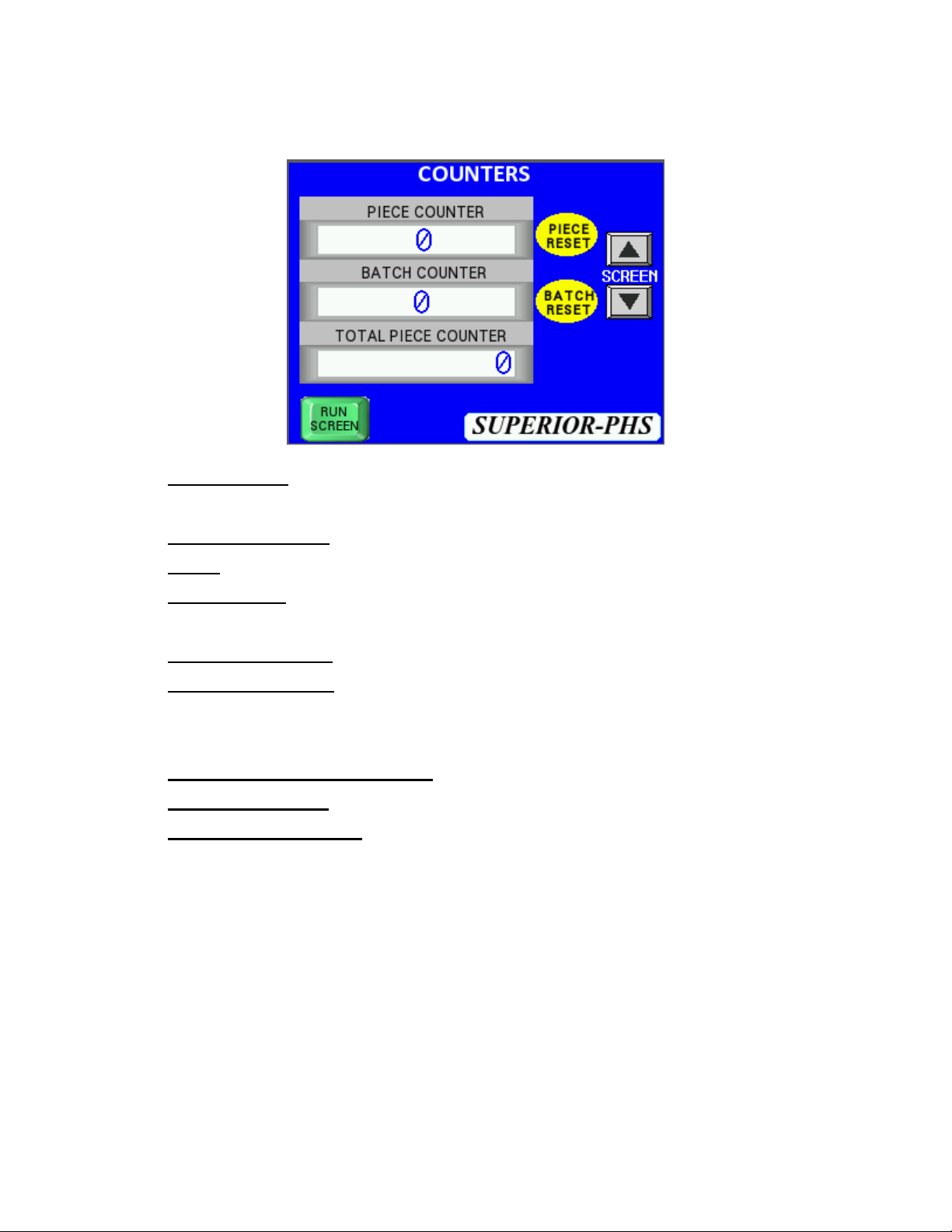

JOB SET FUNCTION

The Job Set Function screen is designed to

break down a set number of pieces into to

smaller batches. For this example: you to

have 200 pieces that need to be broken

down into sets of 5.

1. Set the Batch Size to 5 on the Run

Screen.

2. Press the ‘Total Count’ screen and

set it to 200. Press enter.

3. Press the center on/off button to ‘ON’

4. The circle above the on/off button will illuminate yellow during a job.

5. Cycle the feeder manually or by the trigger sensor.

6. The ‘Count to Total’ screen will count down showing how many pieces are left to

complete the job.

7. The ‘Batch Count’ screen will represent how many sets of 5 have been counted. This is

a mirror image on the ‘Counter Screen’.

8. The ‘Actual Count’ represents how many pieces in each 5 count set have been counted

out. Most likely, the count will happen too quickly to keep up, but in the event of a mis-

feed or miss-count, the ‘Actual Count’ will represent how many pieces in the 5 count set

have been completed. This count is a mirror image of the count on the ‘Run Screen’.

9. The yellow light will have turned blue when the total count is completed.

10. Press and hold the ‘Batch Reset’ to reset the ‘Batch Count’ to ‘0’.

11. Turn the on/off button to ‘OFF’ when not using this function.

At the end of a job, the yellow reset button and red stop button will illuminate and the

yellow light on the screen will turn blue. This means the job is complete. To reset, turn the

Job Set Function to ‘OFF’ then hit the ‘Reset Button’. The red and yellow button will turn off and

the green ready button will illuminate. You can then run in standard mode or start a new job.

For a video demonstration, watch the ‘Job Set Screen’ video at

http://www.superior-phs.com/setup.html