Edwards A506-36-880 User manual

A506-36-880

Issue A Original

Instruction Manual

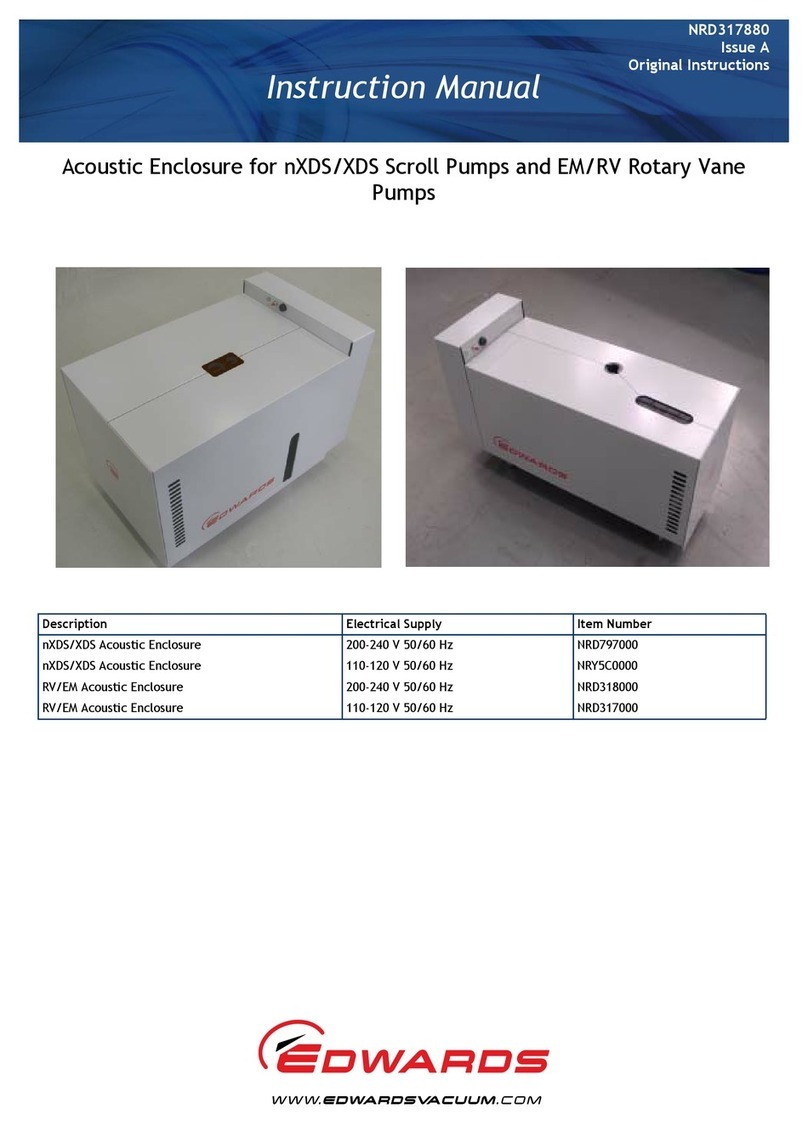

Acoustic Enclosure for XDS Scroll Pumps and Rotary Vane Pumps

Description Electrical Supply Item Number

XDS Acoustic Enclosure 200-240 V 50/60 Hz A506-36-903

XDS Acoustic Enclosure 110-120 V 50/60 Hz A506-36-906

RV/EM Acoustic Enclosure 200-240 V 50/60 Hz A506-35-903

RV/EM Acoustic Enclosure 110-120 V 50/60 Hz A506-35-906

Declaration of Conformity

We, Edwards Limited,

Crawley Business Quarter,

Manor Royal,

Crawley,

West Sussex, RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

EM/RV Enclosure High volts A506-35-903

EM/RV Enclosure Low volts A506-35-906

XDS Enclosure High volts A506-36-903

XDS Enclosure Low volts A506-36-906

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61010-1:2010 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use. General Requirements

EN12100:2010 Safety of machinery. General principles for design. Risk

assessment and risk reduction.

EN50581:2012 Technical Documentation for the Assessment of Electrical and

Electronic Products with respect to the Restriction of Hazardous

Substances

and fulfils all the relevant provisions of

2014/35/EU Low Voltage Directive

2012/19/EU Waste from Electrical and Electronic Equipment (WEEE) Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

10.08.2015, Burgess Hill

P200-07-100 Issue C

Mr Peter Meares

Senior Technical Support Manager, General Vacuum Date and Place

This product has been manufactured under a quality

management

system

certified to ISO

9001:2008

© Edwards Limited 2012. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

A506-36-880 Issue A

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

2 Technical data ....................................................................................2

2.1 Specifications ............................................................................................................. 2

3 Installation .........................................................................................3

3.1 Safety ......................................................................................................................3

3.2 Installing the XDS Acoustic Enclosure ................................................................................. 4

3.3 Installing RV EM Acoustic Enclosure ................................................................................... 5

4 Operation ..........................................................................................8

4.1 Safety ......................................................................................................................8

4.2 Over temperature alarm ................................................................................................ 8

4.3 Buzzer test ................................................................................................................ 8

4.4 Pump Monitoring ......................................................................................................... 8

5 Maintenance .......................................................................................9

5.1 General .................................................................................................................... 9

5.2 Servicing ..................................................................................................................10

5.3 Cleaning ..................................................................................................................10

6 Disposal .......................................................................................... 11

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Specifications of XDS and RV/EM pumps ............................................................................. 2

2 Inserting XDS pump into Acoustic Enclosure ......................................................................... 4

3 Locating left hand panel on side of pump ........................................................................... 4

4 Fitting second cover to right hand side of pump ................................................................... 4

5 Attaching inlet and exhaust fittings .................................................................................. 5

6 Locating first panel on left hand side of pump ..................................................................... 6

7 Fitting second cover to right hand side of pump ................................................................... 6

8 Fitting end cover ......................................................................................................... 6

9 Removing front panel to view sight glass ............................................................................ 9

10 Removing panel to gain access to filler cap ......................................................................... 9

gea/0137/01/11

A506-36-880 Issue A

Page ii © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

Tables

Table Page

1 Pump noise levels ........................................................................................................ 2

Associated publications

Publication title Publication number

Vacuum pump and vacuum system safety P400-40-100

© Edwards Limited 2012. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

A506-36-880 Issue A

1Introduction

1.1 Scope and definitions

The Acoustic Enclosure is designed to be used in an industrial or laboratory environment. All Edwards XDS and nXDS

scroll pumps will fit the XDS Acoustic Enclosure and all RV and EM pumps up to E2M28 will fit the RV/EM Acoustic

Enclosure.

The enclosure is designed to slot together without removable fixings and so requires no tooling to assemble or

dismantle it. It is powered by a power cable fitting into an IEC 320 socket.

Note: The power cable for the pump is connected to its own supply. This supply should have an external means of

isolation and not rely upon the on/off switch located on the pump.

Read this manual before you install and operate the Acoustic Enclosure. Important safety information is highlighted

as WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is

defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The following IEC warning labels appear on the Acoustic Enclosure:

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Warning - refer to accompanying documentation.

Warning - risk of electric shock.

A506-36-880 Issue A

Page 2 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

2Technicaldata

2.1 Specifications

Figure 1 - Specifications of XDS and RV/EM pumps

The fuse rating is 5 amps, Type T, 20mm long x 5mm diameter (RS668-6010 or equivalent).

The Acoustic Enclosure can be used to attenuate the noise from the XDS, nXDS range of scroll pumps, EM and RV

pumps typically by the figures listed in Table 1.

Two fans are fitted. Fan 1 starts up when the power is on. Fan 2 is controlled by a thermal switch set to operate when

the internal temperature exceeds 35 ± 5°C.

Environmental conditions:

XDS RV/EM

Dimensions: Length 778 mm

Width 442 mm

Height 580 mm

Dimensions: Length 790 mm

Width 285 mm

Height 460 mm

Mass: 37 kg Mass: 23 kg

Table 1 - Pump noise levels

XDS5 8 dBA

XDS10 8 dBA

XDS35i 9 dBA

nXDS 5 dBA

RV 7dBA

E2M28 7 dBA

Altitude 2000 m

Ambient temperature 30°C

© Edwards Limited 2012. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

A506-36-880 Issue A

3 Installation

3.1 Safety

A suitably trained and supervised technician must install the Acoustic Enclosure.

Ensure that all equipment is safe and in a suitable condition to be installed in the enclosure.

For safety issues, refer to Edwards Vacuum Pump and Vacuum System Safety Publication P400-40-100 or

contact Edwards if in doubt.

Casters should be locked when the pump is in operation.

Route all electrical cables in a safe manner.

WARNING

Obey the safety instructions given below and take note of appropriate precautions. If you do not,

you can cause injury to people and damage to equipment.

WARNING

Care should be taken when removing the enclosure from the packaging and also when removing

the enclosure side panels.

WARNING

Use suitable lifting equipment or at least two people to lift the empty Acoustic Enclosure.

WARNING

Do not lift the Acoustic Enclosure with a pump installed.

WARNING

Be careful not to drop any of the enclosure panels during assembly/disassembly as this may either

damage the panel or cause injury.

WARNING

Do not install the enclosure on a slope. When the castors are unlocked the enclosure could move

and cause injury.

A506-36-880 Issue A

Page 4 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

3.2 Installing the XDS Acoustic Enclosure

The various elements of the Enclosure are designed to slot together without additional fixings.

Figure 2 - Inserting XDS pump into Acoustic Enclosure

Figure 3 - Locating left hand panel on side of pump

Figure 4 - Fitting second cover to right hand side of pump

© Edwards Limited 2012. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

A506-36-880 Issue A

After removing all packaging:

Remove side panels by lifting (this will disengage the panel from the locating pins) and moving to the side. Be

careful not to drop a panel.

Insert XDS pump - refer to Figure 2.

Attach inlet and exhaust fittings. Note that sufficient length will be needed to clear enclosure.

Locate first panel on left hand side of pump - refer to Figure 3.

Adjust pump position to suit.

Position pump power cable through hole provided.

Switch the Pump start switch to ON.

Fit Second Cover to right hand side of pump - refer to Figure 4.

3.3 Installing RV EM Acoustic Enclosure

The various elements of the Enclosure are designed to slot together without additional fixings.

Figure 5 - Attaching inlet and exhaust fittings

A506-36-880 Issue A

Page 6 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Figure 6 - Locating first panel on left hand side of pump

Figure 7 - Fitting second cover to right hand side of pump

Figure 8 - Fitting end cover

© Edwards Limited 2012. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

A506-36-880 Issue A

After removing all packaging:

Attach inlet and exhaust fittings. Note that an extension piece will be needed if Exhaust Mist Filter (EMF) or

an inlet accessory is to be fitted - refer to Figure 5.

Locate first panel on left hand side of pump - refer to Figure 6.

Adjust pump position to suit.

Position pump power cable through hole provided.

Switch the motor start switch to ON.

Fit Second Cover on right hand side of pump - refer to Figure 7.

Fit end cover - refer to Figure 8.

A506-36-880 Issue A

Page 8 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Operation

4 Operation

4.1 Safety

Plug the power cable into the IEC 320 socket at back of the enclosure.

Switch on the power.

Fan 1 should start up on the power being switch on.

Check there is airflow from the fan by placing your hand over the mesh at the opposite end of the box from

the fan.

Do not block the inlet of the fan or the ventilation mesh. Allow at least 50mm clearance around the Acoustic

Enclosure.

If the internal temperature reaches 35 ± 5 °C the second fan will switch in.

4.2 Over temperature alarm

There is a warning buzzer on the front face of the bulkhead. This is triggered by a thermal switch inside the Enclosure,

which is set to 50 ± 5 °C. The buzzer will be triggered if the fan fails and the pump continues running, interruption

of the power supply or similar event. If the pump overheats it will thermally protect itself.

The buzzer will run for at least 12 hours on battery back up.

4.3 Buzzer test

There is a push button test switch for checking that the battery backed up buzzer works. This can be tested either

with the unit connected to the Mains supply or on battery back up.

4.4 Pump Monitoring

It is recommended that the user should use appropriate techniques to monitor the pump temperature and initiate

protective measures in fault-intolerant applications.

WARNING

This enclosure must only be operated in an upright position. Isolate power before removing the

pump from the enclosure.

© Edwards Limited 2012. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

A506-36-880 Issue A

5Maintenance

5.1 General

Note: The unit is easily movable on its castors.

The enclosure requires no regular maintenance if the indicated temperature is within the guidelines.

For the RV EM pumps regular checks can be carried out.

Figure 9 - Removing front panel to view sight glass

Figure 10 - Removing panel to gain access to filler cap

To check the oil level, remove the front end panel (lift and pull towards you). The sight glass is visible

through the opening in the covers - refer to Figure 9.

If the oil level needs to be topped up, remove panel to gain access to the filler cap - refer to Figure 10.

CAUTION

With the pump enclosed by the Acoustic Enclosure, regular checks of the pump oil level should be made.

A506-36-880 Issue A

Page 10 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

The frequency of checks will depend on the particular application, but note that oil consumption will increase under

the following circumstances:

Running at elevated inlet pressures (either as a result of the application or a vacuum leak.)

Running with gas ballast.

Mist filter in conjunction with an oil return kit not fitted.

5.2 Servicing

The enclosure requires no regular servicing but it is suggested that the Acoustic enclosure is inspected yearly to

ensure safe operation.

If the fan stops turning, check the electrical cable is still connected and that the fuse does not need replacing. If the

fan needs replacing a suitably trained and supervised technician must complete the task.

Ensure that the air duct is checked regularly and clean where appropriate.

Replace battery (PP9 Alkaline-Manganese dioxide cell) annually, or in case of failure (can be tested by sounding

buzzer).

Edwards spare part recommended:

There is no other servicing required.

5.3 Cleaning

The outside surface can be cleaned with a damp cloth and mild detergent. Do not allow water near the electrical

components.

Fan unit A726-01-804

© Edwards Limited 2012. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Disposal

A506-36-880 Issue A

6Disposal

Dispose of any used equipment safely in accordance with all local and national safety and environmental

requirements.

Ensure the battery is disposed of safely in accordance with all local and national safety and environmental

requirements.

A506-36-880 Issue A

Page 12 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

This page has been intentionally left blank.

This page has been intentionally left blank.

Return the equipment or components for service

Before you send your equipment to us for service or for any other reason, you must send us a

completed Declaration of Contamination of Vacuum Equipment and Components – Form HS2. The

HS2 form tells us if any substances found in the equipment are hazardous, which is important for

the safety of our employees and all other people involved in the service of your equipment. The

hazard information also lets us select the correct procedures to service your equipment.

We provide instructions for completing the form in the Declaration of Contamination of Vacuum

equipment and Components – Procedure HS1.

If you are returning a vacuum pump, note the following:

If a pump is configured to suit the application, make a record of the configuration before

returning the pump. All replacement pumps will be supplied with default factory settings.

Do not return a pump with accessories fitted. Remove all accessories and retain them for

future use.

The instruction in the returns procedure to drain all fluids does not apply to the lubricant in

pump oil reservoirs.

Download the latest documents from www.edwardsvacuum.com/HSForms/, follow the procedure in

HS1, fill in the electronic HS2 form, print it, sign it, and return the signed copy to Edwards.

Note: If we do not receive a completed HS2 form, we will not accept the return of the

equipment.

P80081000, Issue A

P800‐80‐000IssueT

edwardsvacuum.com

This manual suits for next models

4

Table of contents

Other Edwards Enclosure manuals

Popular Enclosure manuals by other brands

Gallien-Krueger

Gallien-Krueger Neo series owner's manual

Kingston Technology

Kingston Technology StorCase Technology Rhino JR RJR110 user guide

BE QUIET!

BE QUIET! DARK BASE PRO 901 user manual

Apevia

Apevia Beast 680W user guide

Formcase

Formcase T36 instruction manual

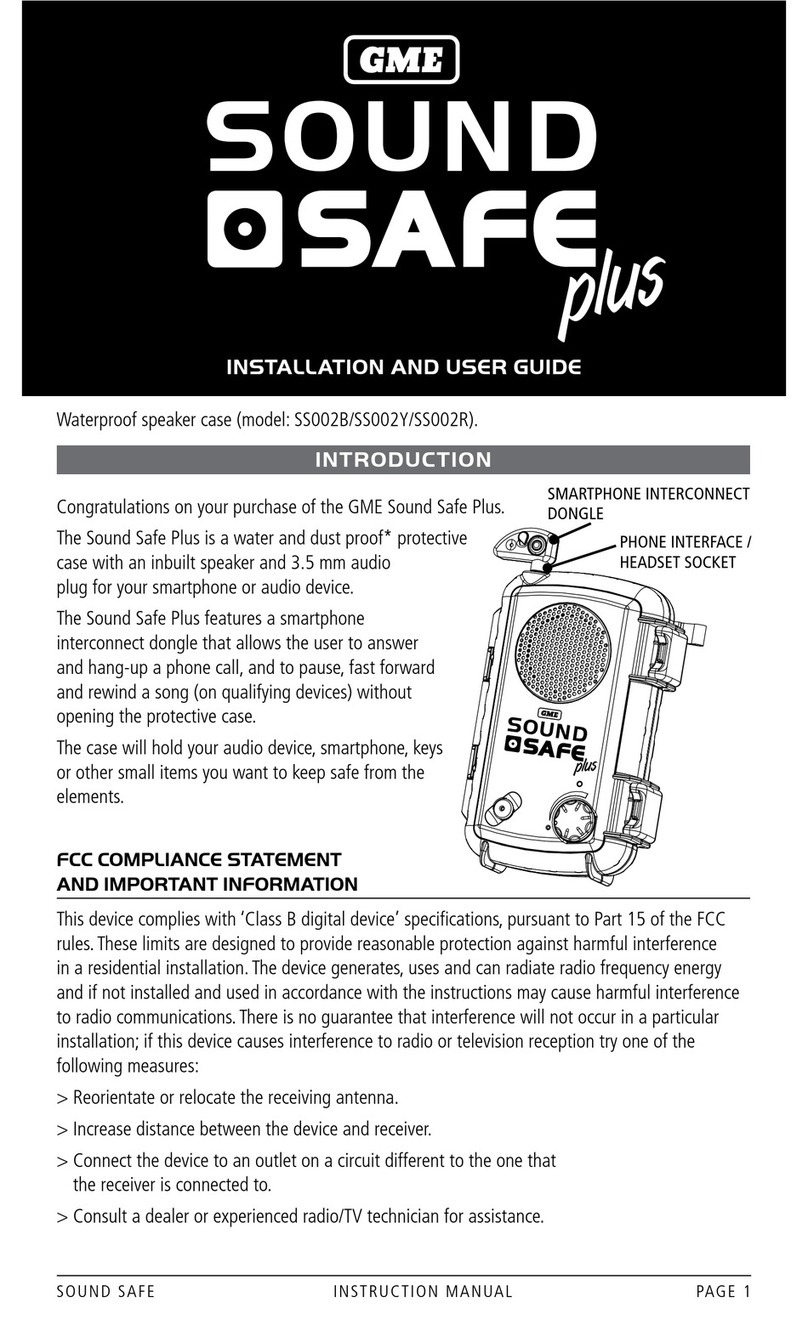

GME

GME SS002B Installation and user guide