Edwards HPST2375 User manual

Models HPST2375 & HAT2375

Rotary Draw Pipe Benders

INSTALLATION AND OPERATION MANUAL

Part Number: M-ED1-62

Edition 1 06/2023

©2023, Edwards Manufacturing Company

All rights reserved U.S.A.

Model HPST2375 Model HAT2375

Introduction 9

Company Prole . . . . . . . . . . . . . . . . . . . 1

Machine Identication . . . . . . . . . . . . . . . . . 1

Warranty. . . . . . . . . . . . . . . . . . . . . . 1

Operator and Supervisor Information . . . . . . . . . . . 2

Signal Word Denitions . . . . . . . . . . . . . . . . 2

1Safety Information 3

2Product Overview 5

2.1 Key Features . . . . . . . . . . . . . . . . . . 5

3Unpacking 6

3.1 Cleaning . . . . . . . . . . . . . . . . . . . . 6

3.2 Transporting and Lifting . . . . . . . . . . . . . . 6

4Installing & Setup 7

4.1 Installation Location . . . . . . . . . . . . . . . . 7

4.2 Setup . . . . . . . . . . . . . . . . . . . . . 7

5 ProductIdentication 8

6 Specications 9

7Electrical 10

7.1 Power Specications . . . . . . . . . . . . . . .10

7.2 Extension Cord Safety . . . . . . . . . . . . . . . 10

7.3 Power Cord Connection . . . . . . . . . . . . . .10

8Operation 11

8.1 Dry Running Machine . . . . . . . . . . . . . . . 11

8.2 Die Selection and Installation. . . . . . . . . . . . . 11

8.3 Inserting Material . . . . . . . . . . . . . . . . . 13

8.4 Bending Using Main (Top) Degree Dial . . . . . . . . . 13

8.5 Setting the Auto-Stop Position . . . . . . . . . . . . 14

8.6 Material Removal . . . . . . . . . . . . . . . . . 15

8.7 Limitations . . . . . . . . . . . . . . . . . . . 15

8.8 Understanding Spring-Back . . . . . . . . . . . . . 16

8.9 Material Selection. . . . . . . . . . . . . . . . . 16

8.10 Bending Glossary . . . . . . . . . . . . . . . . 18

8.11 Bending Suggestions . . . . . . . . . . . . . . . 19

9Lubrication & Maintenance 21

10 Electrical Diagram 21

11 Hydraulic Diagrams 22

12 Troubleshooting 23

13 Tables, Charts, & Diagrams 24

14 Replacement Parts 29

Table of Contents

Company Prole

Edwards Manufacturing Company manufactures a full line

of high-quality, low-maintenance hydraulic ironworking

machines, associated tooling, and accessories that are used

in the steel fabrication industry. With proper operation, care,

and maintenance, your Edwards Ironworker or Hydraulic Ac-

cessory Tool will provide years of safe, trouble-free service.

Please take time to study this Operator’s Manual carefully

to fully understand this machine and Hydraulic Accessory

Tool safety procedures, set-up, operation, care, maintenance,

troubleshooting, and warranty coverage prior to putting the

machine into production. Any questions not answered within

this manual can be directed to your local Edwards Ironwork-

er dealer or factory representative.

Contact the Factory:

Edwards Manufacturing Company

1107 Sykes Street

Albert Lea, MN 56007

Phone:507.373.8206

Fax: 507.373.9433

www.edwardsironworkers.com

General Questions:

Service Questions:

Warranty

Edwards Manufacturing Company will, within one (1)

year of date of original purchase (proof of purchase re-

quired), replace F.O.B. the factory, any goods, excluding

punches, dies and shear blades, which are defective

in materials or workmanship provided that the buyer

return the defective goods, freight pre-paid, to the

seller, which shall be the buyer’s sole and exclusive

remedy for the defective goods. Hydraulic components

are subject to their manufacturer’s warranty.

Edwards Manufacturing Company will, within thirty (30)

days of date of original purchase (proof of purchase

required), replace F.O.B. the factory, any punches, dies

and/or shear blades, which are defective in materials or

workmanship.

This warranty does not apply to machines and/or com-

ponentswhichhavebeenaltered,changed,ormodied

in any way, or subjected to abusive and abnormal use,

inadequate maintenance and lubrication, or subjected

to use beyond seller recommended capacities and

specications.EdwardsManufacturingCompanyshall

not be liable for labor costs expended on such goods

or consequential damages. Edwards Manufacturing

Company shall not be liable to the purchaser or any

other person for loss, down-time, or damage directly or

indirectly arising from the use of the goods or from any

othercause.Noofcer,employee,oragentofEdwards

Manufacturing Company is authorized to make any oral

representationsorwarrantyoftnessortowaiveany

of the foregoing terms and none shall be binding on

Edwards Manufacturing Company.

Machine Identication

Your Edwards Model HPST2375 or HAT2375 Rotary Draw

Pipe Bender is serialized for quality control, production trace-

ability, and warranty enforcement. When ordering parts or

lingawarrantyclaim,pleaserefertothealuminumidenti-

cation tag with engraved serial number, electrical, and power

specications.

Model Number: ______________________

Serial Number: ______________________

Date Purchased: ______________________

Where Purchased: ______________________

Introduction

1| Introduction

Operator and Supervisor

Information

READ THIS MANUAL BEFORE OPERATING MACHINERY.

Operating machinery before ready and understanding the

contents of this manual greatly increases the risk of injury.

This manual describes ‘best practices’ in handling, install-

ing, operating, and maintaining your machine. The contents

of this manual is subject to change without notice due to

improvements in the machinery or changes in National or

International standards.

All rights reserved. Reproduction of this manual in any form,

in whole or in part, is not permitted without the written con-

sent of Edwards Manufacturing Company.

Keep this manual close to the machine to allow for easy

reference when necessary.

Provideoperatorswithsufcienttrainingandeducationin

the basic functions of the machine prior to machine opera-

tion.

Donotallowforoperationofthemachinebyunqualied

personnel. Edwards Manufacturing Company is not liable for

accidents arising from unskilled, untrained operation.

Do not modify or change the machine without written au-

thorization from Edwards Manufacturing Company. Unau-

thorizedmodicationtothismachinemayresultinserious

operator injury, machine damage, and will void your machine

warranty.

Never leave a powered machine unattended. Turn machinery

OFF before walking away.

This machine is manufactured for use by able-bodied and

able-minded operators only. Never operate machinery when

tiredorundertheinuenceofdrugsoralcohol.

Do not resell, relocate, or export to a destination other than to

the original point of sale. Edwards has designed this machine

to meet the standards of the original receiving country and

is not liable for meeting any governing body or performance

standards beyond those of the original receiving country.

Signal Word Denitions

Indicates a hazardous situation that, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation that, if not avoided,

could result in mild to moderate injury and/or

property damage.

Indicates information considered important but not

hazard related.

Signal Word Panel on Machine

Criticalmachinesafetyinformationisidentiedonsignal

word labels. Labels are attached adjacent to the potentially

hazardous locations of the machine. Reference the Safety In-

formation in this manual for additional information regarding

thepotentiallyhazardousconditionidentiedonthelabel.

Review ALL labels on the machine, reference the Safety In-

formation and the safety warnings within this manual before

operating this machine.

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 2

3| Chapter 1: Safety Information

1Safety Information

Read this owner’s manual carefully and completely.

Improper installation, use, adjustment, servicing,

and maintenance of this machine can cause prop-

erty damage, serious injury, or death.

Safety equipment such as guards, hold-downs,

safety glasses, dust masks, and hearing protection

can reduce your potential for injury. However, safe-

ty equipment will not make up for poor judgment,

carelessness, or inattention. Always use common

sense and operate this machine with caution and

care to lessen the possibility of personal injury. If

a procedure feels dangerous, don’t try it.

ELECTRICAL HAZARD: Dangerous high voltages

are present inside the electrical enclosure of this

machine. Only qualied, authorized maintenance

or service personnel should gain access to the

electrical panel. Do not assume the power to be

off. Follow proper lockout procedures.

LOCKOUT POWER: Electrical circuits are live.

Lockout/tagout upstream power source before

any maintenance is performed.

CUT/CRUSH HAZARD: Moving parts can cut and

crush. Never place your hands, ngers, or any

part of your body in the die area of this machine.

Be aware of the areas on either side of the dies

for crush points created by material movement.

PINCH HAZARD: Keep hands and ngers away

from the drive mechanisms, cylinders, ratchets,

and other moving parts while operating the ma-

chine.

HYDRAULIC FLUID HAZARD: Hydraulic hoses and

cylinders are under pressure. Pressurized uid can

pierce skin and cause severe injury. Always wear

personal protective equipment when servicing

and maintaining this machine.

SAFETY GUARDS: Physical barriers and guards

have been designed and installed (where possi-

ble) to protect from moving parts that can pinch,

cut, and crush. If you must remove a guard for

servicing the bender, immediately replace the

guard after servicing and prior to restoring power

to the machine.

MOVING OBJECTS HAZARD: Always be aware

of the swing area in which the material will travel

during bending operation. The material will swing

with signicant force. Beware of pinch points and

the force of the material movement, which may

cause serious injury.

PROTECT EYES: Wear safety glasses or suitable

eye protection when operating or near this ma-

chine.

PROTECT HEARING: Prolonged exposure to loud

noise can cause hearing impairment or loss. Wear

suitable hearing protection such as ear muffs or

earplugs to protect against loud noises.

1. Do not alter or modify this machine. Altering or

modifying this machine may cause injury to the

operator or others and may damage machine.

Altering and modifying this machine will void the

machine’s warranty.

2. Only allow trained and qualied personnel to

operate this machine.

3. Make sure guards are in place and properly

working before operating machine.

4. Remove any adjusting tools before operating

machine.

5. Keep the work area clean. Clutter invites injury.

6. Do not overload the machine. Overloading the

machine may cause injury from ying parts. Do

not exceed the specied machine capacities.

7. Material may have burrs and sharp edges. Al-

ways chamfer and deburr all sharp edges.

8. Do not force the machine. This machine will do

a better job more safely if used as intended and

within the machine’s rated capacity. Do not use

unapproved attachments or try to exceed the

machine’s rated capacity.

9. Use the right tool for the job. Do not attempt to

force a small tool or attachment to do the work

of a large industrial tool. Do not use a tool on a

process for which it was not intended.

10. Dress appropriately. Do not wear jewelry or

loose tting clothing that can be caught in mov-

ing machine parts. Contain long hair and wear

protective clothing and steel-toe shoes when

operating this machine.

11. Do not overreach. Maintain proper footing and

balance at all times. Do not reach over or across

an operating machine.

12. Stay alert. Watch what you are doing and use

common sense. Do not operate this machine or

any tool when you are tired.

13. Check for damaged parts. Before using this ma-

chine, carefully check any part that appears to

be damaged. Check for alignment and binding

of moving parts that may affect proper machine

operation.

14. Observe work area conditions. Do not use ma-

chine in damp or wet locations. Do not expose

to rain. Keep work area well-lighted. Do not use

this electrically-powered machine in the pres-

ence of ammable gases or liquids.

15. Keep children away. Never allow children in the

work area. Never allow them to handle ma-

chines, tools, or extension cords.

16.

Keep visitors a safe distance from the work area.

17. When not in use, store this machine in a dry area

to inhibit rust. Keep children away from stored

machine.

18. Do not operate this machine while under the in-

uence of alcohol or drugs. Read warning labels

on prescription drugs. If there is a doubt, do not

operate this machine.

19.

Turn off power and disconnect from power source

before checking, cleaning, replacing parts, servic-

ing, repairing, or performing maintenance.

20. Be sure all equipment is properly installed and

grounded according to national, state, and local

codes.

21.

Inspect power and control cables periodically.

Replace if bare wires are exposed or if the cable

is damaged in any way. BARE WIRING CAN KILL!

Do not touch live electrical components or parts.

22. Do not bypass or defeat any safety interlock

systems.

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 4

2Product Overview

5| Chapter 2: Product Overview

The HPST2375 and HAT2375 rotary draw pipe benders

have the features and power to expand your fabrica-

tion capabilities. With a built-in PowerLink™ System,

the HPST2375 rotary draw bender becomes a power

source for the complete line of Edwards PowerLink

hydraulic tools.

Powered by a 120V, 2HP motor, these dual-cylinder

rotary draw-style benders produce up to a 180° bend in

one stroke. The open style drop on tooling, adjustable

Auto-Stop, and heavy-duty mobile cart ensures these

rotary draw benders are simple to use and improves

operator productivity. Whether you are bending an

ornamental piece or a complete vehicle chassis, these

rotary draw benders are the solution.

2.1 KEY FEATURES

Quick-connect plug and play operation (HPST2375 only)

Hand-adjustable Auto-Stop feature

Large, easy to read degree dial for accurate bends

PowerLink source to power other Edwards tools

(HPST2375 only)

Electric foot pedal with integrated jog control

180° bend in one stroke

Powerful and efcient design

Your Edwards machine is shipped complete. Separate

all parts from the packing material and check each

item carefully. Make certain all items are accounted for

before discarding any packing material.

3Unpacking

Your machine may be shipped with a rustproof waxy

coating and/or grease on the exposed unpainted metal

surfaces. Fully and completely remove this protective

coating using a degreaser or solvent cleaner. DO NOT

USE acetone or brake cleaner as they may damage

painted surfaces.

Follow manufacturer’s label instructions when using any

type of cleaning product. After cleaning, wipe unpaint-

ed metal surfaces with a light coating of quality oil or

grease for protection.

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 6

SUFFOCATION HAZARD: Immediately discard any

plastic bags and packing materials to eliminate

choking and suffocation hazards to children and

animals.

CHECK FOR MISSING PARTS: If any parts are

missing, do not place the machine into service

until the missing parts are obtained and installed

correctly.

Do not use gasoline or other petroleum products

to clean the machine. They have low ash points

and can exploded or cause re.

When using cleaning solvents, work in a well-ven-

tilated area. Many cleaning solvents are toxic if

inhaled.

Make sure lifting and carrying operations are per-

formed by skilled workers such as a truck operator,

crane operator, etc. If lifting the machine with a

crane, attach the lifting chain carefully, making

sure the machine is well-balanced.

This waxy coating is not a lubricant and will cause

the machine to stick and lose performance as the

coating continues to dry.

3.1 CLEANING

3.2 TRANSPORTING AND LIFTING

Follow these guidelines when lifting with truck or

trolley:

• The lift truck must be able to lift at least 1.5 – 2

times the machines gross weight.

• Make sure the machine is balanced. While trans-

porting, avoid rough or jerky motion, and main-

tain a safe clearance zone around the transport

area.

• Useaforkliftwithsufcientliftingcapacityand

forks that are long enough to reach the complete

width of the machine.

• Approaching the machine from the side, lift the

machine on the frame taking care that there are

no cables or pipes in the area of the forks.

• Move the machine to the required position and

lowergentlytotheoor.

Follow these guidelines when lifting crane or hoist:

• Use lift equipment such as straps, chains, ca-

pable of lifting 1.5 to 2 times the weight of the

machine.

• Take proper precautions for handling and lifting.

• Check if the load is properly balanced by lifting it

an inch or two.

• Lift the machine, avoiding sudden accelerations

or quick changes of direction.

• Locate the machine where it is to be installed,

thenlowerslowlyuntilittouchestheoor.

7| Chapter 4: Installing & Setup

4Installing & Setup

A shortage of hydraulic oil can cause hydraulic

system breakdown and damage to major mechan-

ical parts due to overheating.

4.1 INSTALLATION LOCATION

IMPORTANT: Consider the following when looking

for a suitable location to place the machine:

• Keep in mind the overall weight of the machine

and the weight and size of the material being

processed.

• Provide needed space for auxiliary stands, work

tables, or other machinery.

• Provide proper clearance from walls and other

obstacles.

• Maintain an adequate working area around the

machine for safety.

• Have the work area well illuminated with proper

lighting.

• Keeptheoorfreeofoilandmakesureitisnot

slippery.

• Remove scrap and waste materials regularly,

and make sure the work area is free from ob-

structing objects.

• If long lengths of material are to be fed into the

machine, make sure that they will not extend

into any aisles.

• FLOOR & LEVELING: This machine distributes a

large amount of weight over a small area. Make

sure this machine is situated on a level, concrete

oor.Thisensurestheooriscapableofsup-

porting the weight of the machine, work stock,

and the operator. If the unit wobbles or rocks

once in place, be sure to eliminate by using

shims.

• WORKING CLEARANCES: Be aware of the ma-

terial sizes to be processed. Make sure to allow

enough space for you to operate the machine

freely.

• POWER SUPPLY PLACEMENT: Locate the

power supply closed enough so the power cord

does not create a tripping hazard. Observe all

electrical codes if installing new circuits and/or

outlets.

Do not connect the machine to the electrical power

supply until the machine is fully assembled and

you read and understand this owner’s manual.

Follow all local and national codes and electrical

guidelines when connecting this machine to the

power supply.

Installing Dies

Read through the remainder of the manual and become

familiar with how to install dies, settings, and normal

operation. See, Section 8.2 Die Selection and Installa-

tion.

Filling Hydraulic Oil Tank

The hydraulic oil is the primary medium for transmitting

pressure and also must lubricate the running parts of

the pump.

After installation of the machine and before machine

startup, bring the oil level up to 90% of capacity. Refer

toanylabelsormarkingafxedtotheoutsideofthe

machine, If none exist, use SHELL BRAND #46 or #68

hydraulicoiloranequivalentwithsimilarspecications.

(Based upon location temperature and availability.)

Verify that any cylinder rams are is in the retracted

positiontopreventoverllingofthetank.Recheckthe

oillevelaftertherstfewhoursofoperationandagain

aftertherstfullweekofoperation.

4.2 SETUP

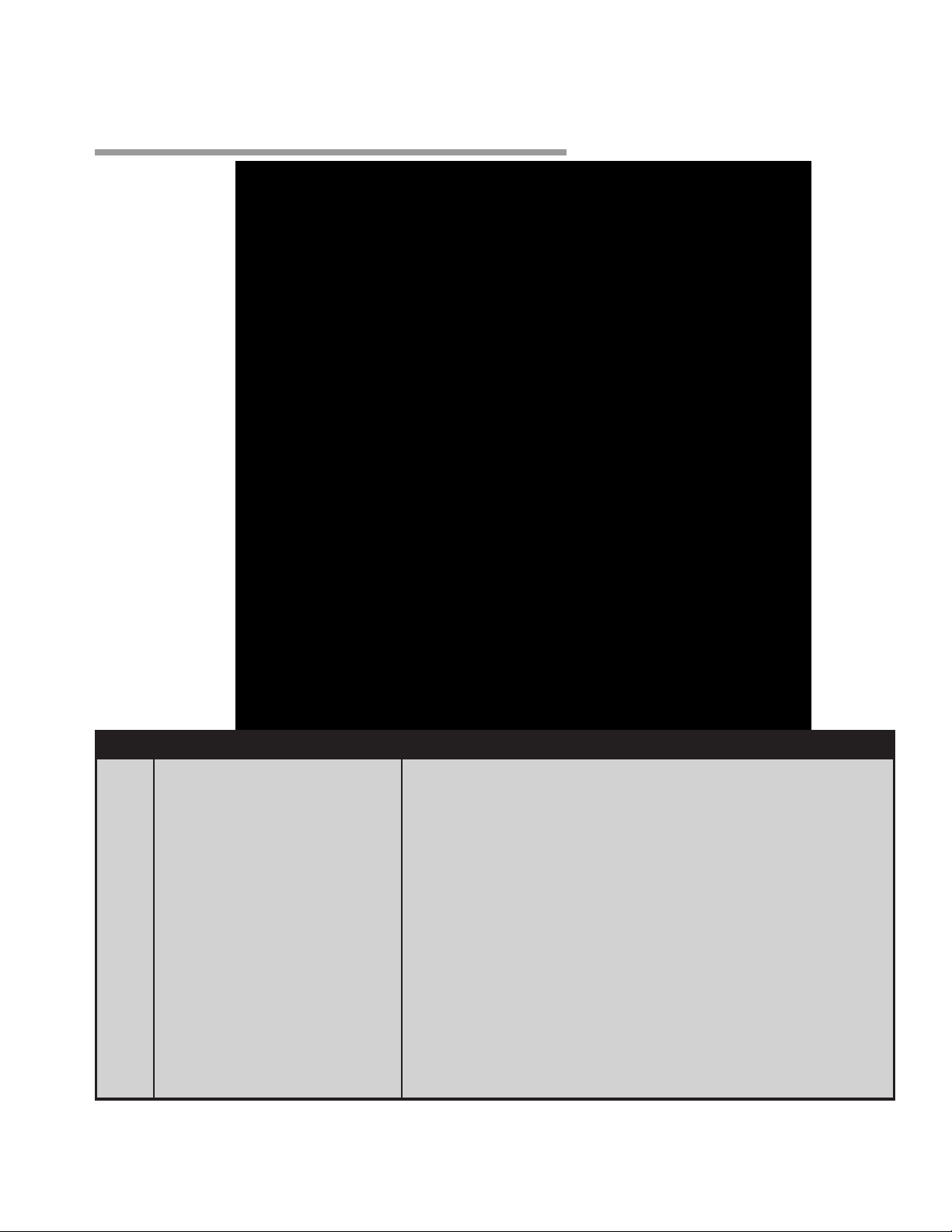

Item Description Function

A Forward Foot Pedal Will operate the machine in the clockwise direction.

B Reverse Foot Pedal Will operate the machine in the counterclockwise direction.

C Bender / PowerLink Switch * Switch between Bender mode and PowerLink mode.

D Emergency Stop Button Depress button to immediately stop the bender action.

E Push-To-Start Button Push this button to start the hydraulic pump motor.

F Power ON/OFF Switch For turning power on and o to bender.

G Remote Function Ports * For connecting to another machine.

H Auxiliary PowerLink Hookups * Male and female hydraulic hookups to power other machines.

I Lower Auto-Stop Bend Angle Scale A scale plate which can be set to stop the bend at preset degrees.

J Upper Bend Angle Indicator Indicates the bend angle the spindle is currently positioned.

K Upper Bend Angle Scale A scale plate used to indicate the current position bend angle.

L Main Spindle and Drive Pins For supporting and driving the forming die.

M Quick Release For pivoting counter die away from bend die to remove material quickly.

N Hydraulic Cylinders Supply the bending force to rotate the forming die.

O Hex Wrench Used for adjusting and tightening the slide plate.

5Product Identication

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 8

* Model HPST2375 only

Model HPST2375 Shown

9| Chapter 6: Specications

Maximum Center Line Radius (CLR) 7”-8” (177.8mm - 203mm)*

Minimum Center Line Radius (CLR) 1/2” (12.7mm)*

Minimum OD 1/4” (6.35mm)

Mild Steel Pipe (Schedule 40) 2” (50.8mm)

Aluminum Pipe (Schedule 40) 2” (50.8mm)

Stainless Steel Pipe (Schedule 40) 1-1/2” (38.1mm)

Mild Steel Round Tube (Wall) 2-1/2 ” (1/8”) (63.5mm [3.175mm])

Aluminum Round Tube (Wall) 2-1/2” (5/32”) (63.5mm [3.96mm])

Stainless Steel Round Tube (Wall) 2-3/8” (1/8”) (60.325mm [3.175mm])

Chromolly Round Tube (Wall) 2” (1/8”) (50.8mm [3.175mm])

Mild Steel Solid Rod 1” (25.4mm)

Mild Steel Square Tube (Wall) 2” (1/8”) (50.8mm [3.175mm])

Power Supply 2 HP, 115VAC, 20A, 1PH, 60Hz

Motor 2HP, 120VAC, 18A, 1ph, 60Hz

Sound Level <70db

Product Dimensions (L x W x H) 55” x 25.5” x 45” (1397 x 648 x 1143mm)

Shipping Dimensions (L x W x H) 60” x 44” x 70” (1524 x 1117 x 1778mm)

Product Weight (Net) 596 lbs. (270kg)

Shipping Weight 696 lbs. (316kg)

* All capacities based on A53 grade A (mild steel) 48,000 psi tensile materials. Heavy wall and high tensile

materials may reduce machine capacity.

6Specications

7Electrical

AMP LENGTH

Rating 25ft 50ft 100ft

1-12 16 AWG 16 AWG 14 AWG

13-16 14 AWG 12 AWG 12 AWG

17-20 12 AWG 12 AWG 10 AWG

21-30 10 AWG 10 AWG No

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 10

This machine operates on 120V electrical power.

Make sure the available electrical power is 120V.

Have any new circuits or outlets installed by a

certied electrician. Follow all local and national

codes and electrical guidelines when connecting

this machine to the power supply.

Make sure to connect this machine to a proper-

ly-grounded electrical outlet. If you are not sure,

have a qualied electrician check the receptacle.

Make sure the grounding wire (green) is properly

connected to avoid electric shock. Do not switch

the position of the green grounding wire if any

electrical plug wires are switched during hookup.

7.1 POWER SPECIFICATIONS

Your machine is 115 volts, 60hz alternating current.

Before connecting the machine to the power source,

make sure the power source is OFF.

Before switching on the power, you must check the

voltage and frequency of the power to see if they meet

with the requirement, the allowed range for the voltage

is ±5%, and for the frequency is ±1%.

Considerations

• Observe local electrical codes when connecting

the machine.

• The circuit should be protected with a time delay

fuse or circuit breaker with an amperage rating

slightly higher than the full load current of ma-

chine.

• A separate electrical circuit should be used for

your machines. Before connecting the motor to

the power line, make sure the switch is in the

“OFF” position and be sure that the electric cur-

rent is of the same characteristics as indicated

on the machine.

• All line connections should make good contact.

Running on low voltage will damage the motor.

• In the event of a malfunction or breakdown,

grounding provides a path of least resistance

for electric current to reduce the risk of electric

shock. This machine is equipped with an electric

cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into a matching outlet that is properly installed

and grounded in accordance with all local codes

and ordinances.

• Improper connection of the equipment-ground-

ing conductor can result in risk of electric shock.

The conductor with insulation having an outer

surface that is green with or without yellow

stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or

plug is necessary, do not connect the equip-

ment-grounding conductor to a live terminal.

• Checkwithaqualiedelectricianorserviceper-

sonnel if the grounding instructions are not com-

pletely understood, or if in doubt as to whether

the machine is properly grounded.

• Repair or replace damaged or worn cord imme-

diately.

7.2 EXTENSION CORD SAFETY

Extension cord should be in good condition and meet

the minimum wire gauge requirements listed below:

An undersized cord decreases line voltage, causing

loss of power and overheating. All cords should use a

ground wire and plug pin. Replace any damaged cords

immediately.

7.3 POWER CORD CONNECTION

1. Turn the main disconnect switch on the control pan-

el to the OFF position.

2. Unwrap the power cord and route the cord away

from the machine toward the power supply. Route

the power so it does NOT create a trip hazard.

3. Connect the power cord to the power supply and

check that the power cord has not been damaged

during installation.

4. When the machine is clear of any obstruction. The

main power switch may be turn ON to test the oper-

ation.

5. Turn the switch OFF when the machine is not in

operation.

11 | Chapter 8: Operation

8Operation

8.1 DRY RUNNING MACHINE

Before actually bending, several “dry runs” should be

performed. This will remove any trapped air from the

cylinders and hoses. Also, this will familiarize you with

the controls and functions of the machine. To do this,

follow the next steps.

1. Set the Auto-Stop (lower) Degree Dial to

200-degrees (see Section 8.5: Setting the Auto-Stop

Position).

2. With no material in the machine, press the Forward

Foot Pedal (see Chapter 5: Product Identication)

until the hydraulic cylinders are fully extend and

“deadheads”. Then press the reverse foot pedal

(see Chapter 5: Product Identication) until the hy-

draulic cylinders are fully retracted and “deadhead”

in the home position. The overload relief valve will

make a squealing noise when the cylinders “dead-

head”; this is normal and will not hurt the function of

the machine.

3. Repeat this sequence as many times as necessary

(usually 5-6 full cycles) to remove any trapped air

and to synchronize the cylinders.

4. The foot pedals have function to provide forward

and reverse operation. The pedals are spring-re-

lease and must be held in the forward or reverse

positions to move the cylinders.

Figure 8.1 - Auto-Stop Dial

8.2 DIE SELECTION AND

INSTALLATION

Before any bending can take place, the proper die set

must be chosen to match the material being bent.

Example: 1-1/2” diameter tubing requires a die set

marked 1-1/2” tube.

Damaged or worn tooling should be replaced be-

fore attempting to bend material. This will ensure

that bends are correct and provide a longer life to

machine components.

When handling large, heavy dies and/or material,

make sure it is properly lifted and supported.

Die and Counter Die Parts ID

A Hook Arm

B Bend Die

C Hold down Bolts

D Plastic Slide

E Counter Die Mount

F Bronze Counter Die Insert

G “0” Mark

H Spindle

I Die Drive Pins

J 1/2-13 Tapped holes for bolting down dies

K Center Pin

L Hitch Pin

M Positioning Bolts

Figure 8.2 - Die and Counter Die Parts ID

Always wear proper eye protection with side

shields, safety footwear, and leather gloves to

protect from burrs and sharp edges.

Keep hands and ngers clear of the dies and swing

arms. Stand to the front of the machine to avoid

getting hit with the material during the bending

process. When handling large heavy materials,

make sure they are properly supported.

Figure 8.3 - Die and Counter Die Parts ID

Note: Pipe and Tube are not the same, (see Table 1,

Chapter 13: Tables, Charts, & Diagrams) for nominal

pipe sizes. All EDWARDS dies are color-coded to avoid

confusion between pipe and tube (see Table 2, Chapter

13: Tables, Charts, & Diagrams).

1. To install the die, slip the die over the centering pin

until the three unequally spaced drive pins engage

the receiving holes formed in the die.

Note:Thediewillonlytoneway.

2. When the drive pins line up the die will drop all the

way down to the spindle.

3. Install and tighten the 1/2-13 socket head bolts

provided with the die. Tighten these bolts enough

toholdthediermlydowntothespindle.Approxi-

mately 30-40ft-lb. (40-54Nm).

4. To install the counter die, remove the hitch pin (L)

and insert the counter die in the opening in the

counter die mount until the 3/4” holes line up.

5. Now insert the hitch pin through all the holes, rein-

stall clip on the hitch pin with the engraved side of

the counter die facing up.

6. The counter die should be positioned approximately

1/8” (3mm) away from the die. This is accomplished

by a combination of the slide plate position and

changing between the two provided quick releases.

(see Table 4, Chapter 13: Tables, Charts, & Dia-

grams).

7. In combination, install the recommended quick

release (silver [shown] or gold) and then position the

slide plate in the recommended holes.

8. Tighten the two socket head bolts (M) to 200ft-lb.

(271Nm).

The two M20 x 2.5 bolts hold the slide plate

mechanism in place against the force generated

during bending.

Incorrect Counter Die Positions

Figure 8.4 - Incorrect: Too Far

Away From Die

Figure 8.5 - Incorrect: Touching

Die

Correct Counter Die Position

Figure 8.6 - Correct: Approximately 1/8” (3mm) Away

Be sure the long end of the counter die points away

from the hook arm or to the right of the machine.

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 12

Failure to properly bolt down die will result in

damage to machine and tooling. Bending material

greater than capacity will damage the machine.

These conditions are not covered under warranty.

13 | Chapter 8: Operation

8.3 INSERTING MATERIAL

1. Once the die set is properly installed, the material

that matches the die can be inserted (Example:

1-1/4” tube would go into a die mark D-1250T-R***).

2. Open the counter die quick release assembly and

insert the material past the hook arm. The start of

bend mark is engraved with an “0” on the top of the

die. Once the material is placed properly, the count-

er die slide block assembly can be tightened.

Important: Liberally apply lubricant along the

Counter Die and the 1/2 of the material that con-

tacts the counter die (A) with a WD-40-style lubri-

cant or equivalent. Do not lubricate the bending die.

Lubricating the bending die will encourage slipping

of material in the bending die.

3. Rotate the quick release counter die assembly until

itrmlystopsagainstitsstopbolt.Insomecases,

usually with pipe, the quick release will not close

all the way. This is ok, as the forward foot pedal is

activated the material will force its way into the die

and bend properly.

Figure 8.7 - Applying Lubricant

8.4 BENDING USING MAIN (TOP)

DEGREE DIAL

1. After the material is installed, bending can take

place.

2. Turn on the power switch

3. Keep hands away from the bending zone.

4. Press the Forward (right) Foot Pedal to rotate the

die forward. Keeping the Forward Foot Pedal acti-

vated, visually watch the Main Degree Dial (A). Hold

until the desired degree is displayed, bumping along

as needed. The material will need to be bent past

desired degree as all material has some “spring-

back”. This varies by material and can even vary

between the same grades of material.

5. If the bend requires more degrees. Increase the de-

grees by further activating the Forward Foot Pedal.

This allows the operator to gradually reach a bend

angleontherstsetuppiece.

6. To determine the amount of spring-back for a

certain material, it is necessary to bend a sample

piece. Using a framing square, bend a piece of

material until a perfect 90° bend is achieved. At that

point, document the Main Degree Dial position (A).

For example, to achieve a 90° bend on the piece

pictured, 105 degrees was the total bend amount

or 15-degrees of spring-back. Now you can add

15-degrees to any nominal bend angle to achieve

accurate results for this material.

Figure 8.8 - Main (top) Degree Dial

Figure 8.9 - Auto-Stop Knob

Figure 8.10 - Auto-Stop Setting

8.5 SETTING THE AUTO-STOP

POSITION

The cylinders must be fully retracted and the Main

(top) Degree Dial must read “0” deg before setting the

Auto-Stop (lower) Degree Dial.

Note: Do not adjust the micro switch mounting brack-

et; this is preset from the factory. Use only the black

Auto-Stop Adjusting Knob (A, Figure 8.9) to adjust the

dial.

1. Method #1: Using the Auto-Stop (lower) Degree

Dial, set the lower pointer to the desired degrees by

loosening the Auto-Stop Adjusting Knob (A, Figure

8.9) and rotating the Auto-Stop degree Dial until the

desired bend angle plus spring-back is displayed

(B, Figure 8.10).

Example: 91-degree = 86-degree bend + 5-degrees

of spring-back.

2. Method #2: You can set the Auto-Stop (lower)

Degree Dial after a bend is complete also.

Example: Bend a piece of material to a desired an-

gle using the Main (top) Degree Dial only. Once you

areatthenalbendposition,stopwiththematerial

still in the machine. Loosen the Auto-Stop Adjust-

ing Knob (A, Figure 8.9) and rotate the Auto-Stop

degree Dial to “0” degrees (B, Figure 8.10). You will

feeladenite“click”latchingthedialinposition;

this is the spring-loaded micro switch (C, Figure 8.9)

holding the dial in position.

3. If the Auto-Stop Degree Dial is set and the desired

angle is more or less degrees than planned / calcu-

lated for, simply advance or retard the Auto-Stop

Degree Dial to compensate for the difference.

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 14

15 | Chapter 8: Operation

8.6 MATERIAL REMOVAL

1. After reaching the desired angle, the material needs

to be removed.

2. Press the reverse (left) foot pedal. Both the die and

the counter die will retract simultaneously. Run in

reverse until all bending pressure is released from

the bend.

3. Activate the quick release counter die lever (A, Fig-

ure 8.11) and completely remove the material.

4. After the material is safely removed, press the re-

verse (left) foot pedal keeping hands clear until both

cylinders fully retract.

5. The machine is now at the “home” position and can

be reloaded for the next bend.

6. Repeat previous steps.

Figure 8.11 - Quick Release Counter Die Lever

8.7 LIMITATIONS

Material Insertion Limitations

• Figure 8.12 shows the recommended minimum /

correct amount of material remaining to be fully

supported in plastic slide after performing the bend.

• Figure 8.12 shows the maximum amount the materi-

al can be pulled through the Counter Die. Pulling the

material further than shown into the counter die will

destroy the plastic slide.

• Figure 8.13 shows the material pulled too far into

the counter-die. This will damage the plastic slide

on the counter-die.

• Figure 8.14 shows bending material with an existing

bend. In this photo, there is not enough material to

complete a 90-degree bend. This bend will damage

the dies. Extreme care must be taken when bend-

ing material with an existing bend. There must be

enough straight material to complete the bend. If

there is not enough material, the bent part of the

material will crash into the counter die and damage

the machine and tooling.

Figure 8.12 - Correct, Recommended Minimum

Figure 8.13 - Incorrect, Material Pulled In Too Far

Figure 8.14 - Bending Material with Existing Bend

Positioning the material in this fashion will cause

damage to your tooling and machine. Do not pull

bent material into the counter die. Make sure you

have enough straight material on the draw side of

the material to create your bend.

Bending More Than 180-Degrees

This machine is set up to make maximum bends of

180-degrees. The machine is capable of making bends

beyond 180-degrees but you must contact EDWARDS

about your application.

This also requires special tooling to allow the removal

of the bent part. If standard tooling is used, the material

will be locked onto the die.

8.8 UNDERSTANDING SPRING-BACK

Spring-backcanbedifculttounderstand.Asmate-

rial is bent, the material’s yield strength resists being

formed.Asanaldegreeisreached,themachinewill

have enough power to hold the bend at a set degree,

but as the machine pressure is released, the material’s

built-in resistance causes it to “springs back”.

Spring-back will vary with every size, type, and wall

thickness. Therefore it will never be consistent from size

to size.

The best way to determine material spring-back is to

do sample bends to 90 degrees until a perfect 90 is

obtained.

• At that point document the actual machine degree

setting.

• Full manual mode is the best method to do these

tests.

• Use the overbend amount and enter that value into

thespring-backeld.

8.9 MATERIAL SELECTION

When selecting material, keep these instructions in

mind:

• Material must be clean and dry (without oil).

• Material should have a smooth surface so it pro-

cesses easily.

• Dimensional properties of material must be consis-

tent and not exceed the machine capacity values.

• Chemical structure of material must be consistent.

• Buycerticatedsteelfromthesamevendorwhen

possible.

Material Layout

In order to create accurate parts, you will have to lay

outthematerialinatform.Firstyouwillneedtode-

termine how much material is used per degree of bend.

Use the multiplier table on Table 3, Chapter 13: Tables,

Charts, & Diagrams to determine the arc lengths for the

die in use. Or use the following formula:

Alternate Arc Length Formula

Example:

6.0 CLR x 2 = 12 12 x 3.14 = 37.699

37.699/360 = 0.1047” per degree

0.1047 x 90 degrees = 9.425” of material used for a

90-degree bend.

Once the arc lengths are determined, you can begin

layout of the material using Figure 8.15 as a reference.

• Example #1 shows a simple part bent on the same

plane in the same direction.

• Example #2 shows bending based off of a center-

line in two directions.

• For symmetrical bends, centerline bending is easi-

est.

• Another way to layout material is to draw them in

a 2D computer software program like Auto Cad.

There are many free programs for download. In a 2D

program, you will draw the parts centerline only with

corresponding CLR’s. Then you will be able to list

individual segments of the bent part. This data can

be directly entered into the control.

• Another program available is BEND-TECH, which

isaprogramspecicallydesignedfortubebend-

ing and will give you all the required data to make

a part. This software is available from EDWARDS

Manufacturing Company.

• Bending with a rotary draw bender required deter-

mining the start of bend point, which will line up

with the “0” mark on the die. The portion of the tube

towards the hook arm will be locked to the die. The

portion of the tube towards the counter die is the

draw side and will slide along the counter die and

conform to the die shape/radius.

EDWARDS MANUFACTURING COMPANY • HPST2375 & HAT2375 ROTARY DRAW PIPE BENDERS | 16

17 | Chapter 8: Operation

Figure 8.15 - Quick Release Counter Die Lever

Example 1

Example 2

This manual suits for next models

2

Table of contents

Other Edwards Power Tools manuals

Popular Power Tools manuals by other brands

Stanley

Stanley BR37 user manual

Erbauer

Erbauer ER2100 Original instructions

Bomag

Bomag BPH 80/65 Operating instructions, maintenance instructions

Greenlee

Greenlee Tugger 640 Operation, service and parts instruction manual

Black & Decker

Black & Decker JS700 instruction manual

EINHELL

EINHELL 45.136.60 operating instructions