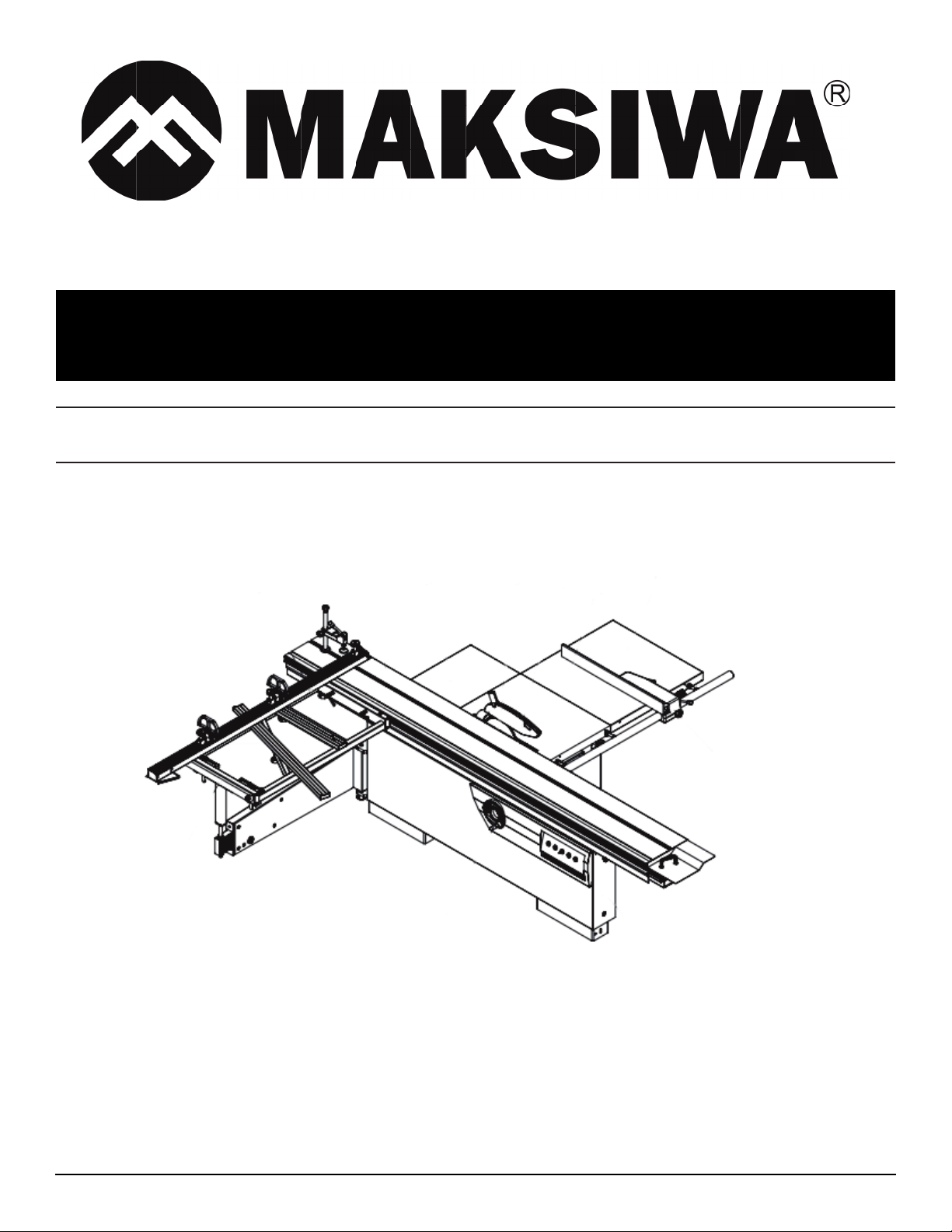

MAKSIWA BMS.3200.IR User manual

1

BMS 3200.IR

INSTRUCTION MANUAL

Sliding Panel Saw 3200 mm

ATTENTION: FOR YOUR SAFETY, READ INSTRUCTIONS CAREFULLY BEFORE ASSEMBLING

OR USING THIS PRODUCT. SAVE THIS MANUAL FOR FUTURE REFERENCE.

2

Greetings,

Congratulations, you just purchased the BMS.3200.IR Precision Saw, which was

developed with the Maksiwa’s highest standards of technology and quality.

Your BMS.3200.IR Precision Saw allows you to have the highest productivity in

woodworking. Besides a great fi nish, the BMS.3200.IR ensures that your cuts are

always precise. It should be noted that to use this machine with maximum effi ciency,

you should read and understand the instructions in this manual.

Visit our website to know about other products and technical assitance:

www.maksiwa.com/usa

3

Attention!: The machine must be inspected immediately upon arrival. If the machine has been

damaged during transport, or if any parts are missing, a written record of the problems must be

submitted to the forwarding agent and a damage report compiled. Also be sure to notify your

supplier immediately.

For the safety of all personnel, it is necessary to study this manual thoroughly before assembly

and operation. This manual must be kept in good condition and should be considered as part

of the machine. Furthermore, the manual must be kept to hand and within the vicinity of the

machine so that it is accessible to operators when using, maintaining or repairing the machine.

!

Maksiwa International Inc.

4100 N Powerline Rd, Suite D3 Pompa-

no Beach, FL

Call us free: 844-319-6594

www.maksiwa.com/usa

4

Contents

1.General.....................................................................................................................................................................05

1.1 Foreword.........................................................................................................................................................05

1.2 Machine Identifi cation ..................................................................................................................................05

1.3 Customer Service recommendations ........................................................................................................05

1.4 Copyright .....................................................................................................................................................06

1.5 Spare Parts .....................................................................................................................................................06

1.6 Disposal .........................................................................................................................................................06

2. Safety Precautions...............................................................................................................................................07

2.1SafetyRegulations...........................................................................................................................................07

2.2 Residual Risks ................................................................................................................................................08

2.3 Safety and Information Signals.....................................................................................................................09

3. Specifi cations......................................................................................................................................................10

3.1 Main Components ..........................................................................................................................................10

3.2 Technical Specifi cation .................................................................................................................................10

3.3 Electrical Connection ...................................................................................................................................11

3.5 Noise Level ....................................................................................................................................................13

3.5 Dust Extraction .............................................................................................................................................13

3.6 Safety Devices...............................................................................................................................................14

4. Installation............................................................................................................................................................15

4.1Contents of Package .....................................................................................................................................15

4.2 Lifting and Unloading ....................................................................................................................................17

4.3 Installation Zone Characteristic .................................................................................................................17

4.4 Install of Loose Parts - Introduction ................................................................................................................18

5. Adjustment ..........................................................................................................................................................21

5.1 Setup and Control ............................................................................................................................................... 21

5.2 Extension Table Flatness Adjustment .............................................................................................................21

5.3 Rip Fence Precision Adjustment ....................................................................................................................22

6. Operating Procedures ........................................................................................................................................26

6.1 Machine Start And Stop ...............................................................................................................................26

6.2 Working Station ............................................................................................................................................26

6.3 Working with the Machine ...........................................................................................................................27

6.4 Correct Use for this Machine .........................................................................................................................28

7. Maintenance ........................................................................................................................................................29

7.1 Repace Saw Blade .........................................................................................................................................29

7.2 Overall Cleaning ............................................................................................................................................29

7.3 General Lubrication .......................................................................................................................................30

7.4 Replacement and Disposal .........................................................................................................................30

8. Trouble Shooting .................................................................................................................................................31

9. Exploded View .....................................................................................................................................................32

10. Terms of Warranty ..............................................................................................................................................56

5

1 General Information

1.1 Foreword

This machine is desinged to make straight and angle cut for wood material, especially for wood board cutting.

Some information and illustrations in this manual may difer from the machine in your possession, since all the

confi gurations inherent in the machine complete with all the optionals are described and illustrated. Therefore,

refer only to that information strictly connected with the machine confi guration you have purchased.

With this manual we would like to provide the necessary information for maintenance and proper use of

the machine. The distribution network is at your service for any technical problem, spare parts or any new

requirement you may have for the development of your activity.

This manual must be read and understood before operating the machine. This will provde a better working

knowledge of the machine, for increased safety and to obtain the best results.

To facilitate its reading, the manual has been divided into sections pointing out the most important operations.

For a quick research of the topics, it is recommended to consult the index. To better stress the importance of

some basic passages, they have been marked by some preceding symbols:

WARNING

Indicates imminent risks which may cause serious injury to the operator or other persons.

Be careful and scrupulously follow the instructions.

CAUTION

A statement advising of the need to take care lest serious consequences result in harm to material

items such as the asset or the product.

1.2 Machine Identifi cation

There is a identifi cation plate fi xed to the machine, containing the manufacturer’s data, year of construction,

serial number and technical specifi cations.

1.3 Customer Service Recommendation

Apply the machine to skilled and authorized technical staff to carry out any operation dealing with parts

disassembly. Keep to the instructions contained in this manual for the correct use of the machine.

CAUTION

Only skilled and authorized staff shall use and service the machine after reading this manual.

Respect the accident prevention regulations and the general safety and industrial medicine rules.

1 General

Indicates imminent risks which may cause serious injury to the operator or other persons.

6

1.4 Copyright

This manual should be handled confi dentially. It is designated solely for those persons who work on or with the

machine. All descriptions, texts, drawings, photos and other depictions are protected by copyright and other

commercial laws. Illegal use of the materials is punishable by law.

This manual, in its entirety or parts thereof, may not be transferred to third parties or copied in any way or

form, and its contents may not be used or otherwise communicated without the express written consent of

the manufacturer.

Infringement of these rights may lead to a demand for compensation or other applicable claims. We reserve

all rights in exercising commercial protection laws.

1.5 Spare parts

Attention: Non genuine, counterfeit or faulty spare parts may result in damage, cause malfunction or

complete breakdown of the machine.

If unauthorized spare parts are fi tted into the machine, all warranty, service, compensation and liability claims

against the manufacturer and their contractors, dealers and representatives shall be rejected. Use only genuine

spare parts supplied by the manufacturer. Unless, specifi ed by manufactor.

1.6 Disposal

Attention!: Used electrical materials, electronic components, lubricants and other auxiliary substances

must be treated as hazardous waste and may only be disposed of by specialised, licensed fi rms.

If the machine is to be disposed of, separate the components into the various materials groups in order to

allow them to be reused or selectively disposed of. The whole

structure is made of steel and can therefore be dismantled without problem. This material is also easy to

dispose of and does not pollute the environment or jeopardize public health. International environmental

regulations and local disposal laws must always be complied with.

1 General

!

7

2 Safety Precautions

2.1 Safety Regulations

WARNING

Indicates imminent risks which may cause serious injury to the operator or other persons.

Be careful and scrupulously follow the instructions.

The manufacturer disclaims all responsibilities for damages to persons or things, which might be caused by

any failure to comply with the safety regulations.

• The machine operator shall have all necessary prerequisites in oder to operate a complex machiery.

• It is prohibited to use the machine when under the infl uence of alcohol, drugs or medication.

• All the operators must be suitably trained for use, adjustment and operation of the machine.

• The operators must carefully read the manual paying particular attention to the warning and safety

notes. Furthermore, they must be informed on the dangers associated with use of the machine and the

precautions to be taken, and must be instructed to periodically inspect the guards and safety devices.

• Before carrying out adjustment, repair or cleaning work, disconnect the machine from the electric power

and lock the disconnect switch in its “OFF” position by setting the main switch to stop.

• After an initial bedding-in period or many hours of operation, the driving belts may slacken; this causes an

increase in the tool stopping time (the stopping time must be less than 10 seconds). Immediately tighten

them.

• The working area around the machine must be kept always clean and clear, in order to have an immediate

and easy access to the switchboard.

• Never insert materials which are different from those which are prescribed for the machine utilization. The

material to be machined must not contain any metal parts.

• Never machine pieces which may be too small or too wide ithrespect to the machine capacity. - Do not

work wood which has evident defects (cracks, knots, metal parts, etc.)

• Never place hands among the moving parts and/or materials.

• Keep hands clear from the tool; feed the piece with the aid of a pusher.

• Keep the tools tidy and far away from those not authorized persons.

• Never employ cracked nor uckled, neither not correctlyreground tools.

• Never use the tools beyond the speed limit recommended bythe producers.

• Carefully clean the rest surfaces of tools and make surethat they fi nd perfectly horizontally positioned, and

with no dents at all.

• Always wear gauntlets when handling the tools.

• Mount the tools in the right machining direction.

• Never start the machine before having correctly installed all the protections.

2 Safety Regulations

Indicates imminent risks which may cause serious injury to the operator or other persons.

8

• Connect the dust suction hoods to an adequate suction system; suction must always be activated when

the machine is switched on.

• Never open doors or protections when the machine or the system is operating.

• Many unpleasant experiences have shown that anybody may wear objects which could cause serious

accidents. Therefore, before starting working, take any bracelet, watch or ring off.

• Button the working garment sleeve well around the wrists.

• Take any garment off which, by hanging out, may get tangled in the MOVING UNITS.

• Always wear strong working footwear, as prescribed by the accident-prevention regulations of all countries.

• Use protection glasses. Use appropriate hearing protection systems (headsets, earplugs, etc.) and dust

protection masks.

• Never let unauthorized people repair, service or operate the machine.

• The manufacturer is not responsible for any damage deriving from arbitrary modifi cations made to the

machine. - Any transport, assembly and dismantling is to be made only by trained staff, who shall have

specifi c skill for the specifi ed operation.

• The operator must never leave the machine unattended during operation.

• During any working cycle break, switch the machine off.

• In case of long working cycle breaks, disconnect the general power supply.

• The operating method to be followed in the event of accident or breakdown, the machine should be

turned off immediately and unplug from main power and ask for assistance for the authorized people. If

a blockage is likely to occur, the workpiece should be move back a little and enable the equipment to be

safely unblocked.

2.2 Residual Risks

Despite observance of all the safety regulations, and use according to the rules described in this manual,

residual risks may still be present, among which the most recurring are:

• contact with tool

• contact with moving parts (belts, pulleys, etc..)

• recoil of the piece or part of it

• accidents due to wood splinters or fragments

• tool insert ejection

• electrocution from contact with live parts

• danger due to incorrect tool installation

• inverse tool rotation due to incorrect electrical connection

• danger due to dust inhalation in case of working without vacuum cleaner.

Bear in mind that the use of any machine tool carries risks.

Use the appropriate care and concentration for any type of machining (also the most simple).

The highest safety is in your hands.

2 Description

9

2.3 Machine Safety

This signals may be applied on the machine; in some cases they indicate possible danger conditions, in others

they serve as indication.

Always take the utmost care.

SAFETY SIGNALS:

Risk of eye injury. Wear eye protection.

Wear hearing protection systems.

Danger of electric shock. Do not access the area when the machine is powered.

Carefully read and understand the manual before using the machine.

INFORMATION SIGNALS:

Indicate the technical characteristics, direction of rotation and inclination, block and release, etc.

Carefully following the directions to simply the use and adjustment of the machine.

The signals are graphically described and do not require further explanation.

10

3 Description

3 Specifi cations

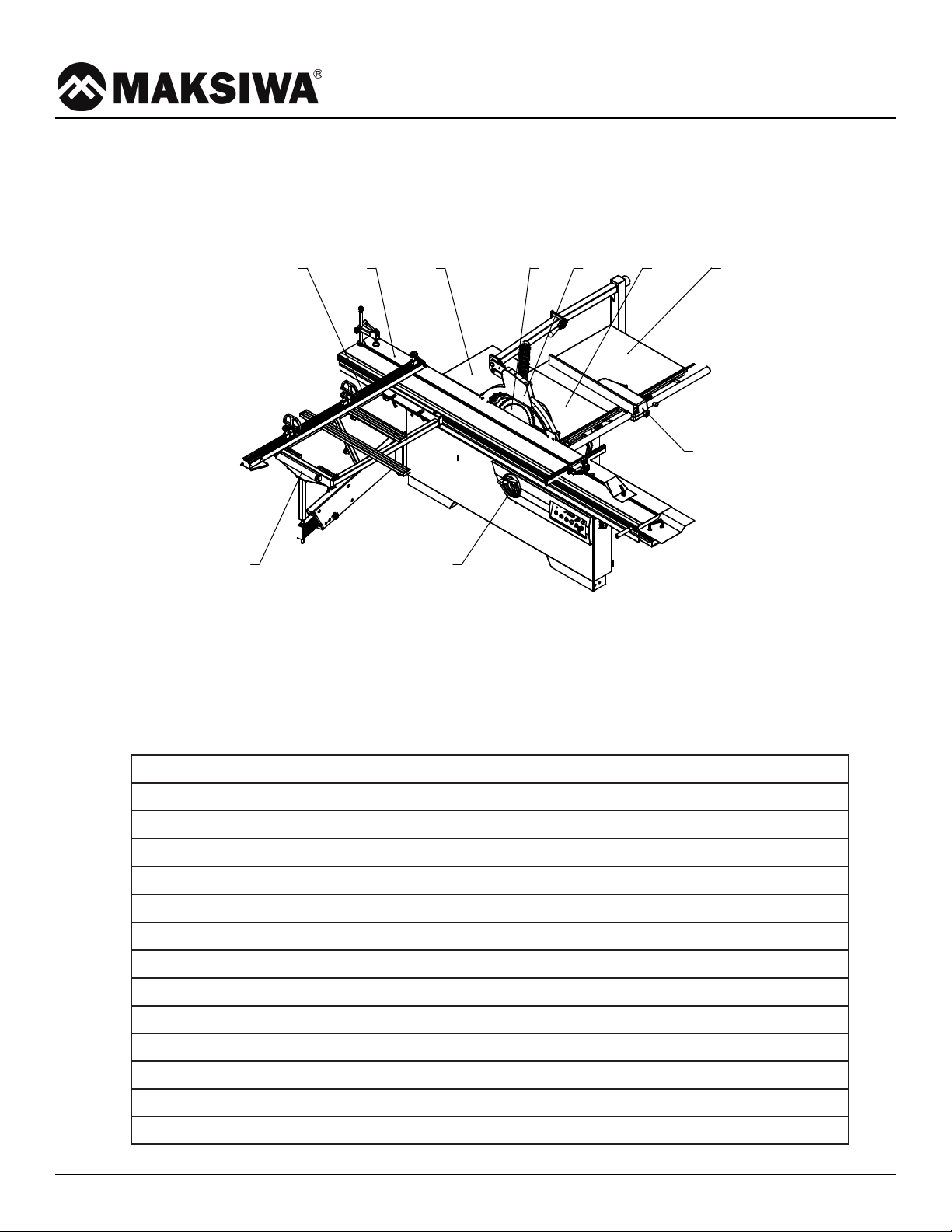

3.1 Main Components

3.2 Technical Specifi cation

3.1 Main Components

Motor Voltage 220V-60Hz/3x220V-60Hz

Main motor power 5HP

Scoring motor power 1HP

Main blade diameter 315-30mm

Main blade speed 4000rpm

Scoring blade diameter 120-20mm

Scoring blade speed 8000rpm

Blade tilt 0~45°

Main table size 800x530mm

Right extension table size 800x820mm

Max.rip capacity 1250mm

Max.depth of cut 95mm@90° | 67mm@45°

Sliding table size 3200x375mm

Square sliding table size 1200x630mm

9 - Tilting handwheel

10 - Rip fance assemnly

1

2

5

67

8

1 - Right extension table

2 - Main table

3 - Blade guard assembly

4 - Blade

9

10

3

4

5 - Rear extension table

6 - Sliding table

7 - Telescopic fence

8 - Square sliding table

11

3 Description

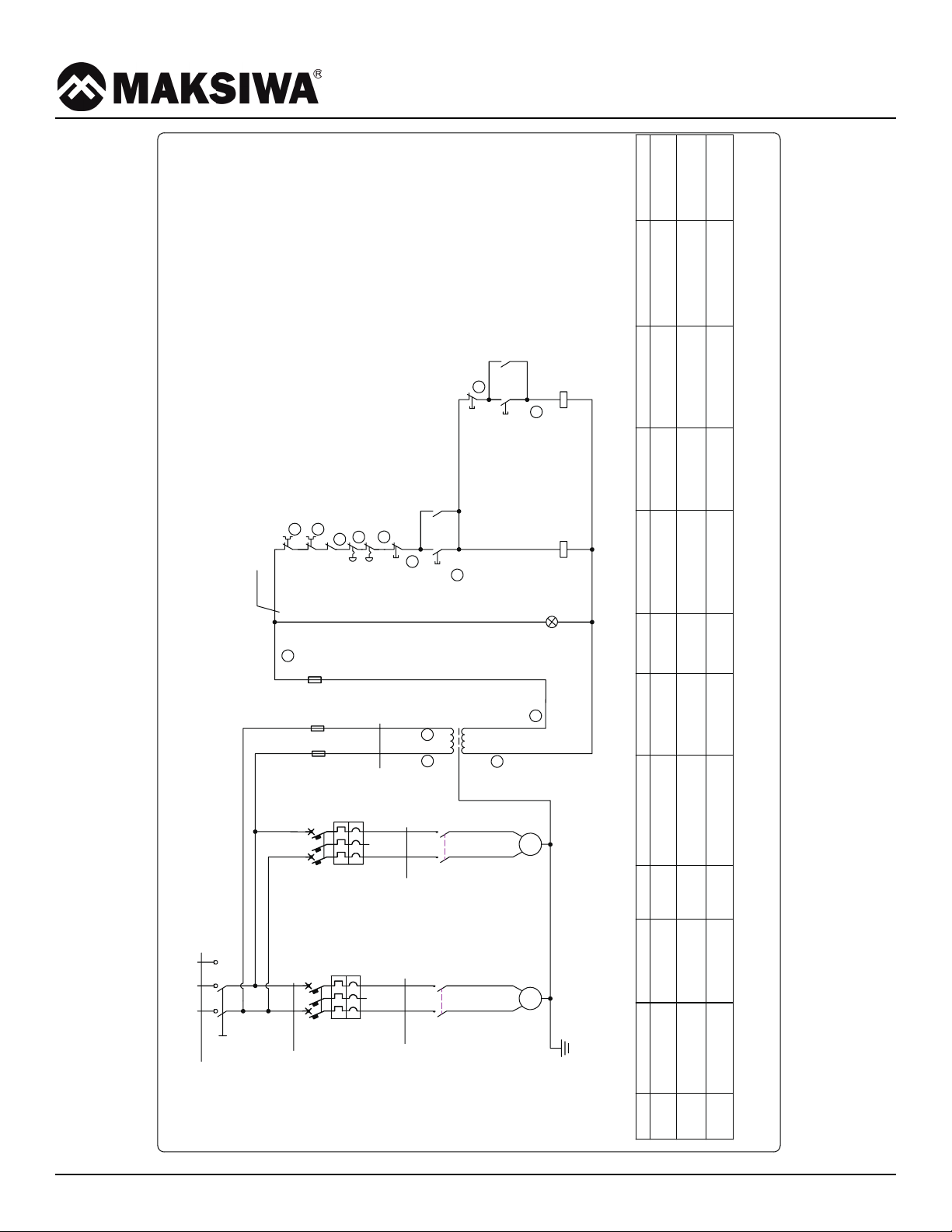

3.3 Electrical Connection

- Electrical installation should be carried out by competent, qualifi ed personnel.

- The mains connection should be made using the terminal box.

- Replacement of the power supply cable should only be done by a qualifi ed electrician.

- Connect the main leads to a standard 220V±10% (60Hz+1%Hz) electrical supply which has protection devices

of under-voltage, over-voltage, over-current the main connection must have maximum 25A time-lag fuse.

WARNING

Indicates imminent risks which may cause serious injury to the operator or other persons.

Be careful and scrupulously follow the instructions.

Indicates imminent risks which may cause serious injury to the operator or other persons.

Be careful and scrupulously follow the instructions.

12

QS1

PE

N

L

U2

M2

KM2

Q1

1L11L21L3

Q2

F1 F2

KM1

1

11

12

13

16

17

18

24V

Q1

SA2

0

SA1

V2

V1

KM2

M1

U1

1L31L11L2

21

14

ST1

SS

Q2

SB1

22

KM2

ST2

SB2

20

15

KM2KM1

HL

19

L1

N

14AWG

14AWG

14AWG

16AWG

16AWG

18AWG

Code

Type

Description

Code

Type

Description

Code

Type

Description

Code

Type

Description

KM1

3RT60251AC20

Contactor

Q2

3RV6011-1FA15

Overload protector

SA1,SA2

HY57B-02

Emergency Button

HL

AD16

Power Light

KM2

3RT60231AC20

Contactor

SB1,SB2

M22-D-G-X1-K10

Start Button

F1,F2

FNQ-1A

1A Fuse

Q1

3RV6021-4BA15

Overload protector

ST1,ST2

M22-D-R-X0-K01

Stop Button

TR

BK-100-230V-24V-A

Transformer

3 Description

13

3 Description

L1 L2 L3

PE

QS1

Q1 Q2

KM1 KM2

1L1 1L2 1L3

U1

V1

W1

U2

V2

W2

1L1 1L2 1L3

F1 F2

Q1

Q2

SA1

SA2

ss

ST1

SB1

KM1

ST2

SB2

KM2

KM1 KM2

HL

M

3~

M

3~

M2M1

24V

13

21

14

15

17

18

19

20

22

11

12

1 0

16

220V,60Hz,4KW

TR

代号 型号

Description

KM1

3RT60251AC20

Contactor

KM2

3RT60231AC20

Contactor

Q1

3RV6021-4BA15

Overload protector

Q2

3RV6011-1FA15

Overload protector

F1/F2

CHM1DU

1A Fuse

TR

BK-100-230V-24V-A

Transformer

SB1/SB2

M22-D-G-X1-K10

Start Button

ST1/ST2

M22-D-R-X0-K01

Stop Button

SA1/SA2

HY57B-02

Emergency button

14

3 Description

3.4 Noise Level

No Load Load

Sound Pressure Level < 80.4cB (A) < 85.7dB (A)

Sound Power Level < 98.1dB (A) < 100.7dB (A)

Associated uncertainty K=4dB

Measurement made in accordance with EN ISO 3746:1995 and EN ISO 11202:1995

The noise levels measured are emission levels and not necessarily the safe working level. Although there is

a correlation between the emission levels and the exposure levels, this cannot be used reliably to determine

whether or not further precautions are required. The factors which affect the actual level of operator exposure

include the duration of exposure, the ambient characteristics and other sources of emission, for example, the

number of machines and other adjacent machining. The permitted exposure values may also vary from country

to country. Nevertheless, this information allows the user of the machine to better evaluate the dangers and risks.

Other factors which reduce exposure to noise are:

• correct tool choice

• tool and machine maintenance

• use of hearing protection systems (e.g. headsets, earplugs,...)

WARNING

Indicates imminent risks which may cause serious injury to the operator or other persons.

Be careful and scrupulously follow the instructions.

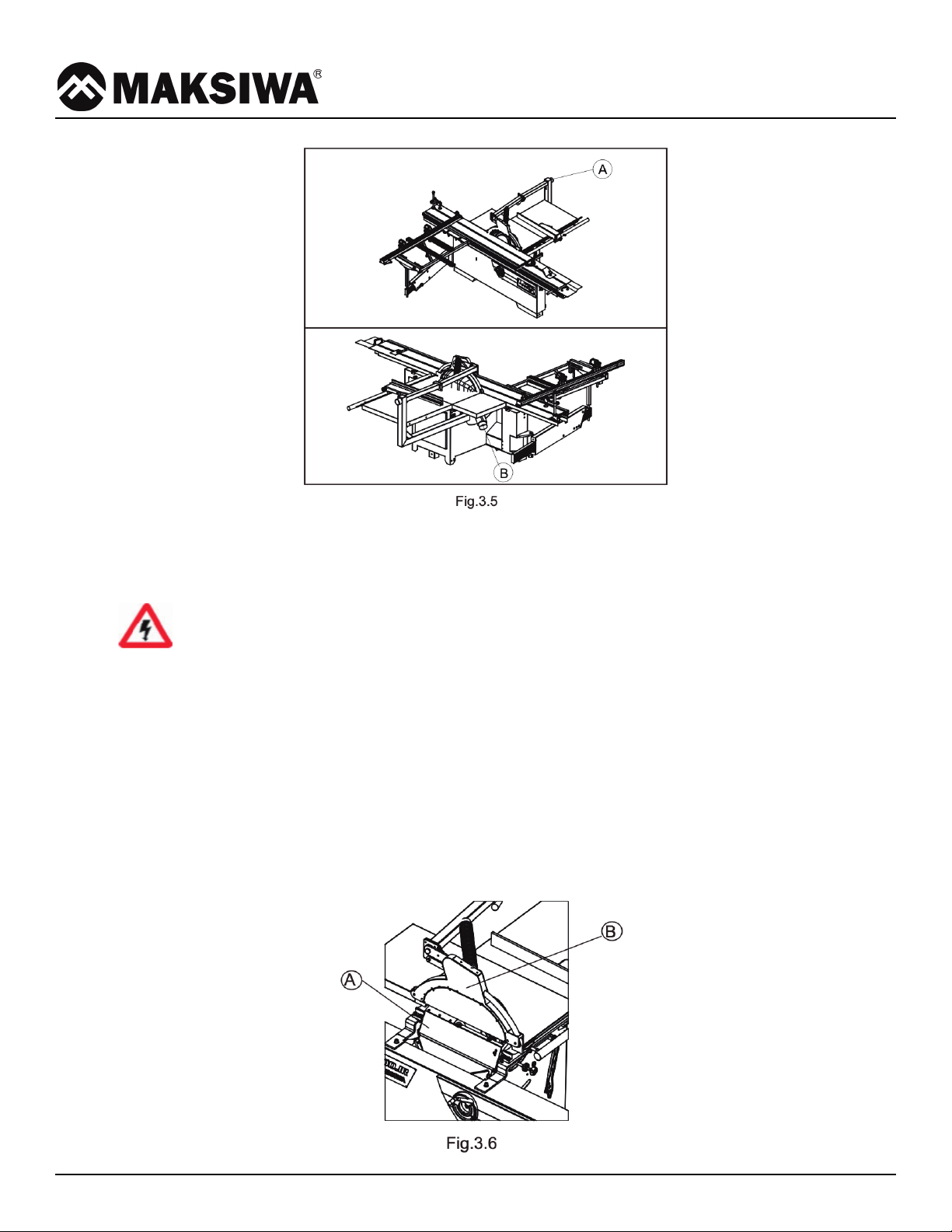

3.5 Dust Extraction

Proper suction eliminates the risks of dust inhalation and aids better functioning of the machine. The tables

list the minimum air fl ow and speed values referenced to each single suction operation.The related pressure

drop at the dust port is 530Pa.

Ensure that the suction system guarantees these values at the hood-houth connection point. (Fig.3.5)

Suction mouth diameter:

A - Blade guard ...... ø100 mm(ø76mm)

B - Body dust suction ...... ø100 mm(ø120mm)

Indicates imminent risks which may cause serious injury to the operator or other persons.

Saw

Upper hood Lower hood

Air fl ow 140 cu.m/h 690 cu.m/h

Minimum air speed 20 m/s

15

3 Description

Connect the mouths to the suction system with fl exible tubes of adequate diameter. Tighten with clamps. The

tube must be positioned in such a way so as not to obstruct the operator during machining.

WARNING

Indicates imminent risks which may cause serious injury to the operator or other persons.

Be careful and scrupulously follow the instructions.

3.6 Safety Devices

The machine is equipped with the following safety devices: (Fig.3.6)

A - Safety Switch.

Stops the machine if the guard D is opened to perform operations on the blade.

B - Saw blade guard

Emergency Switch

When the button is pressed, the power will been cut immediately. It is a mechanical-operated push-button.

Reset this button by turning it clockwise.

Indicates imminent risks which may cause serious injury to the operator or other persons.

Be careful and scrupulously follow the instructions.

16

4 Installation

4 Installation

CAUTION

Assembly need to be done by an experienced and trained person.

4.1 Contents of Package

• The machine is supplied partly assembled. Prior to use, further assembly is required.

• When unpacking the machine the following components are included for the initial assembly.

•If any parts are missing, do not attempt to assemble the machine; plug in the power cord, or turn the switch

on until the missing parts are obtained and properly installed.

Total two carton:

1. Fixed blade cover Assembly

2. Rear extension table

3. Square sliding table

4. Telescopic fence assembly

5. Frame assembly

6. Guide rail

7. Scale bracket

8. Rip fence assembly

9. Right extension table

10. Slide table(packed separately)

17

4 Installation

4.2 Lifting and Unloading

WARNING

Lifting and handing should only be carried out by skilled personel specially trained to execute this kind of

operations. During loading and unloading, avoid knocks to prevent damages to persons and things. Make sure

no one is standing under the overhung load and/or within the bridge crane working range during machine lifting

and handing.

Lifting and handing should only be carried out by skilled personel specially trained to execute this kind of

Lifting may be carried out by bridge crane or self-propelled

lift truck. Before starting the manoeuvres, free the machine

of all the parts used for transport or Packaging that have

remained on the machine. Check that the capacity of the

lifting equipment is adequate for the gross weight of the

machine indicated Fig.4.2.

If hoisting is carried out with a lift truck, proceed as follows:

• adjust the width of the forks A to 550 mm

•Insert forks A as in the fi gure in correspondence to

name plates E ensuring that these are wedged against

the back of the rear feet D.

•If a bridge crane or a crane is available,proceed as

follows:

•provide two slings B of suitable length and capacity

(Belts minimum length 4000mm)

•lift the slings and position them as is shown in the

Fig.4.2

•fasten the slings to the bridge crane C having adequate

lifting power

•move the bridge crane by small steps to allow the

slings B to settle, until optimum stability conditions are

reached – lift carefully and slowly, without causing the

load to swing, and place the machine in the selected

setting

•remove the protective wax coat from all tables and

unpainted surfaces, using kerosene or its derivative

products. Do not use any solvent, petrol or gas oil,

which might dull the paint or oxidate machine parts.

18

4.3 Installation Zone Characteristics

WARNING

It is prohibited to install the machine in explosive environments.

The installation zone must be selected evaluating the work space required depending on the dimension of the

pieces to be machined,and taking into account that a free space of at least 800 mm must be left around the

machine.It is also necessary to check the fl oor capacity and its surface, so that the machine base is evenly

resting on its four supports.A power outlet and a chip-suction system connection shall be close to the selected

machine setting and it must be conveniently lighted (luminous intensity: 500 LUX).

FIXING TO THE FLOOR

1. The machine must be fi xed to the fl oor.

2. -Use bolt / nut A to level the feet to ensure machine is well located.

3. -Put expansion bolts D (not supplied) into ground, use washer / lock washer C and hex nut B to fasten

the bolts.

4 Installation

19

4.4 Install of Loose Parts - Introduction

A few elements will be disassembled from the machine main structure due to packaging and shipping

requirements. These loose parts should be installed as follows.

WARNING

Please tighten all bolts and nuts absolutely. Otherwise, may cause machine wobble or serious injury

to the operator or other persons.

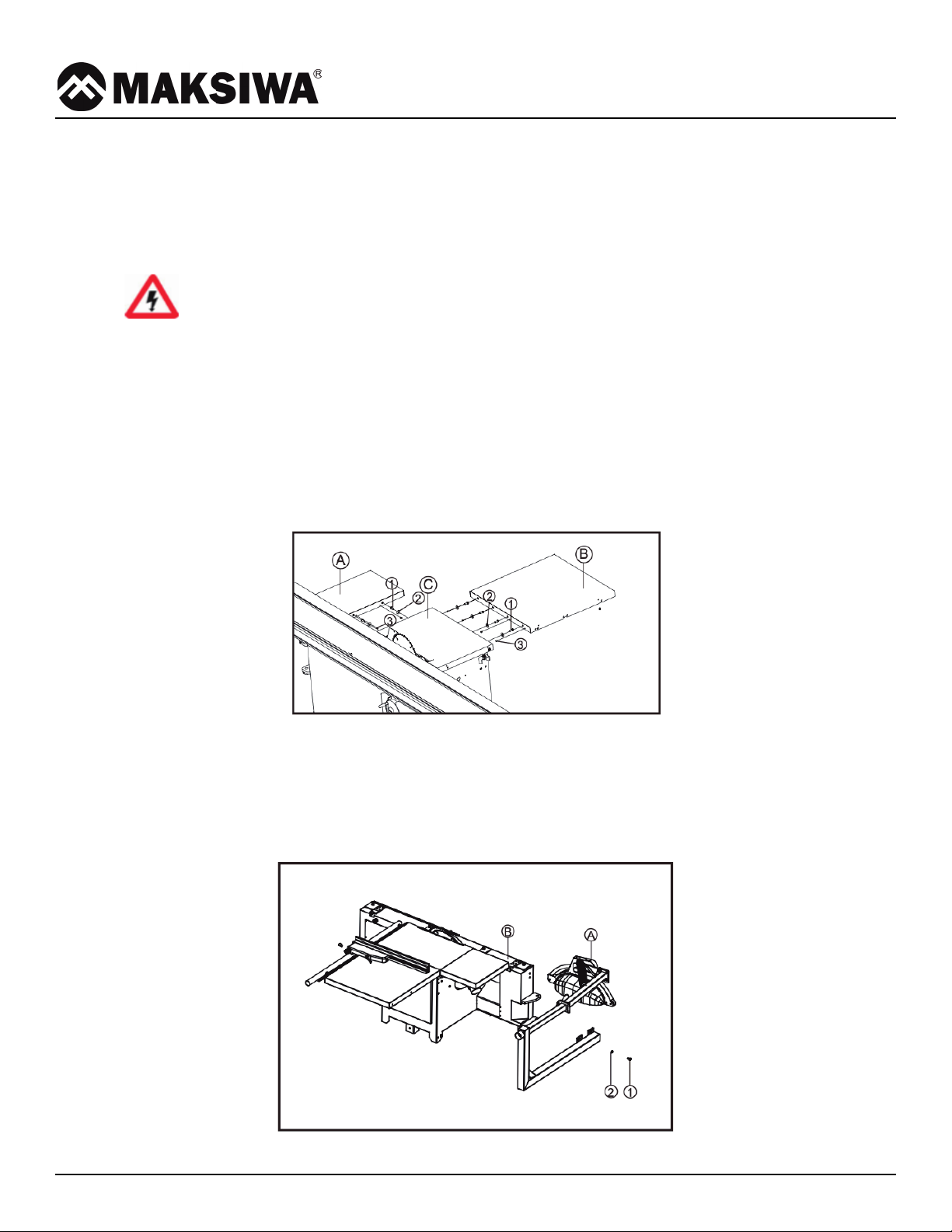

4.4.1 INSTALL EXTENSION TABLE

Tools Required for Assembly:

• Wrench 16mm

• L Wrench 6mm

• Install Extension tables A to main table C with bolt 1 and washer 2.

• Install set screw 3 for micro-adjustment.

4.4.2 INSTALL BLADE GUARD AND HOSE SUPPORT ROD

Tools Required for Assembly:

• Wrench 18mm

• Install blade guard A on body B with parts 1 and 2.

4 Installation

Fig. 4.4.1

Fig. 4.4.2

20

4.4.4 INSTALL SQUARE SLIDING TABLE

• Put the square sliding table C into the slot of sliding table A.

• Tools Required for Assembly: 10mm Allen wrench

• Pass B, C, and D through E and fix them on A (don't fix them too tightly, there are four sets)

• Adjust the slider to the alignment bolt, then tightened the Allen bolts “

• Put the support rod D into the hole of square sliding table C and the hole on support arm E.

• Lock the handle B.

4.4.5 INSTALL TELESCOPIC FENCE

• Put the pin A of telescopic fence intothe hole which is on the square slidingtable, and mount the handle B to the pin.

• Lock the knob C for stable tighting.

• The Knob D is designed to micro-adjust perpendicularity between telescopic fence and blade.

4 Installation

4.4.3 RIP FENCE PRECISION ADJUSTMENT

B

C

D

E

A

Fig.4.4.4

Fig.4.4.5

Fig.4.4.3

Other manuals for BMS.3200.IR

2

Table of contents

Other MAKSIWA Power Tools manuals

Popular Power Tools manuals by other brands

Allied

Allied HO-PAC 4000 SAFETY, OPERATION, MAINTENANCE AND PARTS MANUAL

Scheppach

Scheppach MTC53-4BP Translation from the original instruction manual

Central Machinery

Central Machinery 34542 Assembly and operating instructions

Circassia

Circassia NIOX VERO user manual

Oregon

Oregon 552225 owner's manual

Fein

Fein AFMM 18 QSL instruction manual

King Canada

King Canada 8101S instruction manual

Home Accents Holiday

Home Accents Holiday 36681 instructions

Parkside

Parkside PUD 30 A1 operating instructions

RS

RS 477-517 Instruction leaflet

Palmgren

Palmgren 80177 Operating manual & parts list

JB GURY

JB GURY UNIVERSAL Comet CENTURY Parts and service manual