Edwards A07199041 User manual

RV Motor Starng Relay and Capacitor

INSTRUCTION MANUAL

A50574840_D Original instrucons

edwardsvacuum.com

DESCRIPTION ITEM NUMBER

RV Motor Starng Relay A07199041

RV Motor Capacitor E21917006

Motor starng relay kit (Europe/USA) A07108732

Motor starng relay kit (Japan) A07108733

Copyright noce

©Edwards Limited 2021. All rights reserved.

Trademark credit

Edwards and the Edwards logo are trademarks of Edwards Limited, Innovaon Drive,

Burgess Hill, West Sussex RH15 9TW.

Disclaimer

The content of this manual may change from me to me without noce. We accept

no liability for any errors that may appear in this manual nor do we make any

expressed or implied warranes regarding the content. As far as praccal we have

ensured that the products have been designed and constructed to be safe and without

risks when properly installed and used in accordance with their operang instrucons.

We accept no liability for loss of prot, loss of market or any other indirect or

consequenal loss whatsoever.

Product warranty and limit of liability are dealt with in our standard terms and

condions of sale or negoated contract under which this document is supplied.

You must use this product as described in this manual. Read the manual before you

install, operate, or maintain the product.

Contents

1. Safety and compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Denion of Warnings and Cauons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Trained personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Safety symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Important safety informaon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Introducon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. Replace the motor starng relay and capacitor. . . . . . . . . . . . . . . . . . 9

4.1 Fied with plasc terminal box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Fied with aluminium terminal box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

03/2021 - ©Edwards Limited

Page 3A50574840_D

List of Figures

Figure 1: Remove/t the motor starng relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2: Motor wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

03/2021 - ©Edwards Limited

Page 4A50574840_D

1. Safety and compliance

1.1 Denion of Warnings and Cauons

NOTICE:

For safe operaon from the start, read these instrucons carefully before you install

or commission the equipment and keep them safe for future use.

Read all the safety instrucons in this secon and the rest of this manual carefully

and make sure that you obey these instrucons. The equipment must only be

operated and maintained by trained personnel in the proper condion and as

described in this instrucon manual.

Obey local and state requirements and regulaons. If you have any quesons about

safety, operaon or maintenance of the device, please contact our nearest subsidiary.

Important safety informaon is highlighted as warning and cauon instrucons. Obey

these instrucons.

WARNING:

If you do not obey a warning, there is a risk of injury or death. Dierent symbols are

used according to the type of hazard.

CAUTION:

If you do not obey a cauon, there is a risk of minor injury, damage to equipment,

related equipment or process.

NOTICE:

Informaon about properes or instrucons for an acon which, if ignored, will

cause damage to the pump or the system.

We reserve the right to change the design and the stated data. The illustraons are not

binding.

Keep the instrucons for future use.

1.2 Trained personnel

“Trained personnel” for the operaon of this equipment are

▪skilled workers with knowledge in the elds of mechanics, electrical engineering,

polluon abatement and vacuum technology and

▪personnel specially trained for the operaon of vacuum pumps.

03/2021 - ©Edwards Limited

Page 5A50574840_D

A50574840_D - Safety and compliance

1.3 Safety symbols

The safety symbols on the products show the areas where care and aenon is

necessary.

The safety symbols that follow are used on the product or in the product

documentaon.

Warning/Cauon

An appropriate safety instrucon must be followed or cauon to a po-

tenal hazard exists.

Warning - Heavy object

Idenes a possible hazard from a heavy object.

Warning - Dangerous voltage

Idenes possible hazards from dangerous voltages.

Warning - Hot surfaces

Idenes a potenal hazard from a hot surface.

Warning - Use protecve equipment

Use appropriate protecve equipment for the task.

Warning - Risk of explosion

There is a risk of explosion when you do the task.

03/2021 - ©Edwards Limited

Page 6A50574840_D

A50574840_D - Safety and compliance

2. Important safety informaon

▪Vacuum pumps are potenally dangerous if incorrectly used, repaired or

maintained. Be cauous when you do the repair or maintenance work.

▪ Any incorrectly ed spare parts could damage your pump and could be

potenally dangerous.

▪ Never allow unqualied personnel to aempt to remove or replace any part of the

pump.

▪If you have any doubts about the servicing procedures or product capabilies,

contact us.

▪Always conform to service schedules unless more frequent servicing is required

due to adverse condions.

▪Report any defect before an accident or consequenal damage can occur.

▪Observe all local and naonal regulaons, norms and guidelines.

▪Never allow anyone to remove large or heavy components without adequate

liing equipment.

▪ Before you start the maintenance work, make sure that the pump is switched o

and isolated from the mains power supply.

▪ The pump may have been exposed to processes that use hazardous substances or

produces by-products that are dangerous to human health and safety, for example,

chemically acve, biologically acve or radioacve substances.

▪ Before working on a pump, make sure that the correct personal protecve

equipment is available and being used. Always wear safety goggles. Wear a

breather mask with posive air pressure and take other precauons if you believe

the pump may be contaminated with hazardous substances and dust.

▪ When applying sealants and lubricants, prevent contact with the skin by wearing

suitable gloves.

▪ Seals may contain uoroelastomer, which when properly handled is not dangerous

but which may produce a toxic and corrosive residue (hydrogen uoride or

hydrouoric acid) in the event of excessive heat or re depending on the

circumstances of degradaon and other materials involved.

▪ On compleon of maintenance, check the pump funcons correctly and that all

guards and protecon devices are ed and working correctly and that the pump

is electrically safe.

▪If the pump is used for handling hazardous substances check the pump for leak-

ghtness before use.

▪Dispose of waste oil and any process by-products in accordance with local and

naonal safety and environmental requirements. It is usually illegal to dispose of

waste oil into drains or watercourses or to bury it.

03/2021 - ©Edwards Limited

Page 7A50574840_D

A50574840_D - Important safety informaon

3. Introducon

This manual provides Installaon instrucon for RV motor starng relay and RV motor

capacitor ed to the 1-phase RV pumps ed with a plasc terminal box or an

aluminium terminal box.

Refer to Replace the motor starng relay and capacitor on page 9 for the RV pump ed

with a plasc terminal box manufactured before January 2010 and the RV pump ed

with an aluminium terminal box manufactured aer January 2010.

03/2021 - ©Edwards Limited

Page 8A50574840_D

A50574840_D - Introducon

4. Replace the motor starng relay and capacitor

4.1 Fied with plasc terminal box

1. Switch o the pump and isolate it from the electrical supply. Allow the pump to

cool to a safe temperature.

2. Refer to Figure: Remove/t the motor starng relay. Unscrew the four screws

which secure the cover to the top of the pump-motor and remove the cover.

3. Partly li the old Motor Starng Relay from its retaining slot to access the relay

terminal connecons.

4. Use a suitable screwdriver to remove the terminal connecons o of the relay.

5. Dispose of the old relay safely in accordance with all local and naonal safety and

environmental requirements.

6. Check the code on the motor starng relay to make sure that you have the new

relay (the code should be '4771xxxxxUBx', where x is any character).

7. Hold the new motor starng relay with terminals 1 and 4 at the top (that is,

nearest the motor cover) and t the terminal connecons to the terminals on the

relay as described in Table: Motor starng relay terminal connecons.

8. Slide the motor starng relay into the retaining slot. Make sure that you do not

trap any of the relay wires when you t the relay.

Note

You may have to cut the cable es which secure the relay terminal wires to allow

you to easily t the relay. On some older pump-motors, you may have to rotate the

relay with pins 2 and 3 at the top to t the cover properly.

9. Partly li the old motor capacitor to access the terminal connecons.

10. Use a suitable tool to remove the terminal connecons from the capacitor.

11. Remove the old capacitor and safely dispose of it in accordance with all local and

naonal safety and environmental requirements.

12. Check the marking on the capacitor to make sure that the new capacitor is new

(the capacitor should be 160 mf, code 'KP8174'.

13. Hold the new capacitor as shown in detail C and t the terminal connecons to the

terminals on the capacitor as described in Table: Capacitor terminal connecons.

14. Slide the new capacitor into the pump-motor enclosure. Make sure that you do not

trap any of the wires.

15. Make sure that the voltage shown on the voltage indicator corresponds with your

electrical supply voltage. If it does not, recongure the pump-motor. Refer to the

RV pump instrucon manual.

16. Use the four screws removed in Step 1 to secure the cover to the top of the pump-

motor. Make sure that you do not trap any of the wires when you t the cover.

17. Reconnect the pump to the electrical supply.

Table 1

Motor starng relay terminal connecons

Terminal connecon wire colour Relay terminal

03/2021 - ©Edwards Limited

Page 9A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

Blue 1

Black 2

Purple 3

Yellow 4

Table 2

Capacitor terminal connecons

Terminal connecon wire colour Capacitor terminal

Purple (8) Le terminal (9)

Yellow (7) Right terminal (6)

Yellow (7) Right terminal (6)

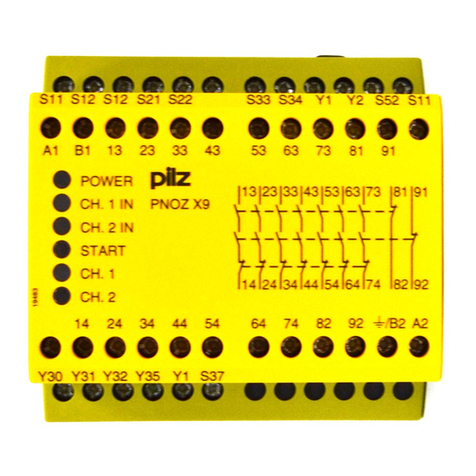

Figure 1 Remove/t the motor starng relay

1. Screw 2. Top cover

3. Capacitor 4. Pump-motor

5. Motor starng relay 6. Terminal

7. Yellow wire 8. Blue wire

9. Terminal

1. Screw 2. Top cover

3. Capacitor 4. Pump-motor

5. Motor starng relay 6. Terminal

7. Yellow wire 8. Blue wire

9. Terminal

03/2021 - ©Edwards Limited

Page 10A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

4.2 Fied with aluminium terminal box

1. Remove four bolts from the top lid of the motor using the Torx screwdriver size

T20.

1. Bolts 2. Top lid

3. Motor

1. Bolts 2. Top lid

3. Motor

2. Remove the two blue and brown cables from the main supply switch.

3. Loosen four screws which are xing the board on the top lid using Torx screwdriver

size T20.

03/2021 - ©Edwards Limited

Page 11A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

1. Main supply switch 2. Blue cables

3. Brown cables 4. Board

5. Screws 6. Top lid

1. Main supply switch 2. Blue cables

3. Brown cables 4. Board

5. Screws 6. Top lid

4. Release the board from the top lid and turn it around.

1. Board 2. Top lid1. Board 2. Top lid

5. Remove the cables from the relay socket.

6. Loosen the bolt xing the relay to the board using Torx screwdriver size T25.

1. Cable 2. Relay socket

3. Fixing bolt

1. Cable 2. Relay socket

3. Fixing bolt

03/2021 - ©Edwards Limited

Page 12A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

7. Replace the relay with the new one depending on the motor type. Refer to Table:

Relay selecon.

A. MA 000 1RO 115 V 50 60 Hz B. MA 000 5RO 100 V 50 60 HzA. MA 000 1RO 115 V 50 60 Hz B. MA 000 5RO 100 V 50 60 Hz

8. Tighten the relay by 3±1 Nm to the board using Torx screwdriver size T25.

1. Relay1. Relay

03/2021 - ©Edwards Limited

Page 13A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

9. Re-connect the cables to the relay (P – grey, J – red, B – orange).

1. Relay 2. Cable1. Relay 2. Cable

10. Place the board on the top lid. Tighten the three short bolts by 3±1 Nm to x the

board using Torx screwdriver size T20.

03/2021 - ©Edwards Limited

Page 14A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

1. Short bolts 2. Board

3. Top lid

1. Short bolts 2. Board

3. Top lid

11. Use the longer screw with a washer to x the earth cables to the lid. Tighten the

bolt by 3±1Nm to x the board using Torx screwdriver size T20.

1. Long screw 2. Washer

3. Earth cable 4. Lid

1. Long screw 2. Washer

3. Earth cable 4. Lid

12. Connect the two brown and blue cables to the mains supply switch.

1. Main supply switch 2. Brown cables

3. Blue cables

1. Main supply switch 2. Brown cables

3. Blue cables

03/2021 - ©Edwards Limited

Page 15A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

13. Place the top lid back to the motor. Tighten four bolts by 3±1 Nm to x the lid using

Torx screwdriver size T20.

1. Top lid 2. Bolts

3. Motor

1. Top lid 2. Bolts

3. Motor

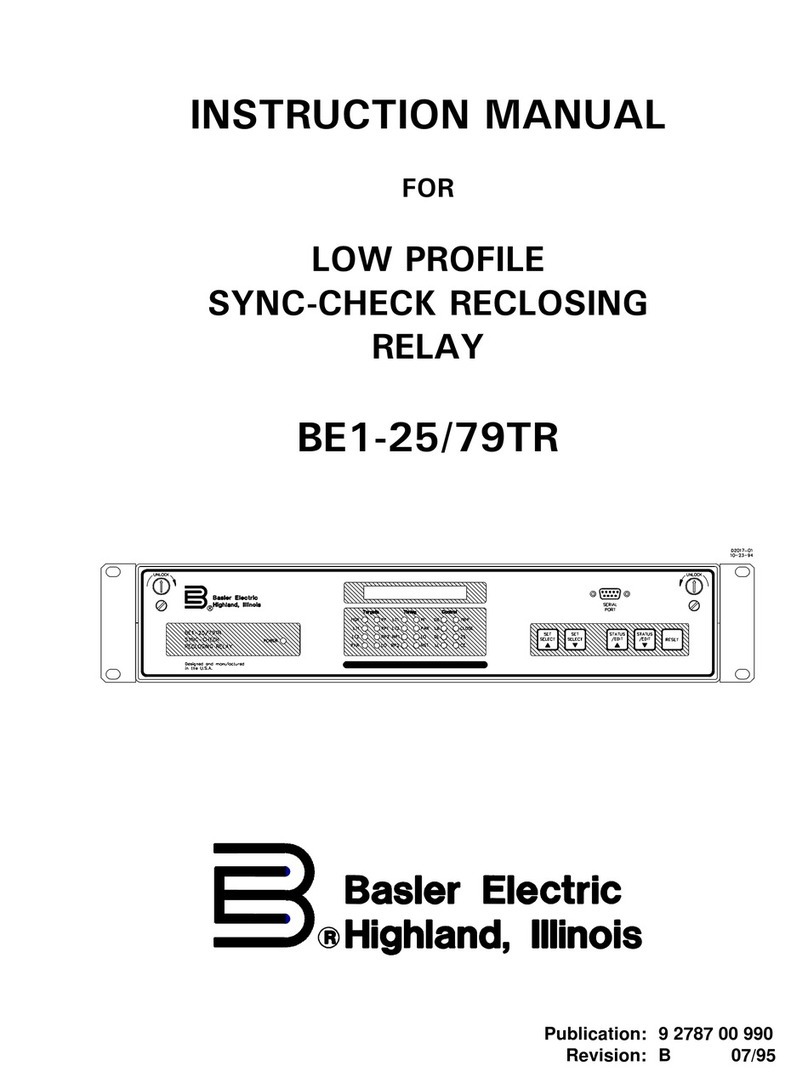

Figure 2 Motor wiring diagram

Table 3

Relay selecon

Relay kit P/N A07108732 A07108733

Relay marking MA 000 1RO 115 V 50 60 Hz MA 000 5RO 100 V 50 60 Hz

03/2021 - ©Edwards Limited

Page 16A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

Colour Green Black

Motor P/N A07108030 A07108031

Variant EUR/USA JAPAN

03/2021 - ©Edwards Limited

Page 17A50574840_D

A50574840_D - Replace the motor starng relay and capacitor

edwardsvacuum.com

This manual suits for next models

3

Table of contents

Popular Relay manuals by other brands

ECR International

ECR International ARGO AR Series Installation, operation & maintenance manual

Hayward

Hayward HLRelay owner's manual

Hobby Components

Hobby Components SmartRFy HCMODU0145 manual

Siemens

Siemens 5TT3426 operating instructions

Emerson

Emerson Fisher OS2 instruction manual

Basler

Basler BE1-50BF instruction manual