Edwards LaserSense HSSD-2 User manual

LaserSense HSSD-2

A

spirating Smoke Detector

Installers Handbook

P/N 9-14565 (EN) • REV 02 • ISS 11ABR13

Copyright © 2013 UTC Fire and Security. All rights reserved.

Manufacture

r

Kidde Products Limited

Unit 2, Blair Way, Dawdon

Seaham, County Durham

SR7 7PP

United Kingdom

Certification 0832.

0832-CPD-1076 (Standard detector)

0832-CPD-1077 (Command module detector)

0832-CPD-1078 (Minimum display detector)

EN 54-20: 2006

Aspirating smoke detectors for fire detection and fire alarm systems

for buildings.

Class A, B, and C

Technical data: See INF48022 and INF48023 held by the

manufacturer.

Contact information For contact information, see www.airsensetechnology.com.

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook i

Content

Important information iii

EN 54-20 compliance v

Chapter 1 Product and component descriptions 1

Introduction 2

Available software for the detector

2

Specifications 3

Standard detector 4

Stand-alone command module or command module detector 6

Standard detector interior view 7

Stand-alone command module interior view 8

Command module detector interior view 9

Detector controls and indicators 10

Display types 11

Chapter 2 Installation and assembly 13

Introduction 14

Antistatic precautions 15

General installation guidelines 15

System design 17

Mechanical installation 19

Electrical installation 22

Power supply connections 28

Demonstration mode 29

Interfacing with fire alarm panels 30

Connecting a command module to an addressable fire

panel 33

Connecting a single detector to an addressable fire panel 35

Connecting to a PC 35

Chapter 3 Programming the unit 37

Introduction 38

Entering programming mode 39

Main menu 40

Navigating through the menus 40

Detector programmable functions 42

Chapter 4 Commissioning 57

Introduction 58

Commissioning 58

Precommissioning preparation 59

Acclimation period 59

Transport time verification 60

Gross smoke testing 60

ii LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Chapter 5 Troubleshooting 63

Troubleshooting the detector 64

Error messages 66

Chapter 6 Maintenance 67

Introduction 68

Scheduled maintenance 68

Maintenance procedures 69

Appendix A External communications 73

Glossary 77

Index 79

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook iii

Important information

Regulatory information

This equipment is Class III as defined in EN 60950 (i.e., this equipment is

designed to operate from Safety Extra Low Voltages and does not generate any

hazardous voltages).

As this equipment is part of a fire detection system, input power should be

supplied from an approved power supply conforming to EN 54-4 or UL/ULC and

FM standards.

In order for the installation to conform to EN 54-20, pipes must conform at least

to EN 61386-1 Class 1131.

This product has been designed to meet the following requirements:

• NFPA 72 National Fire Alarm and Signaling Code

• UL 268 Smoke Detectors for Fire Alarm Signaling Systems

• UL 268A Smoke Detectors for Duct Applications

• UL 864 Control Units for Fire Protective Signaling Systems

• CAN/ULC-S524 Installation of Fire Alarm Systems

• ULC-S527 Control Units for Fire Alarm Systems

• CAN/ULC-S529 Smoke Detectors for Fire Alarm Systems

System reacceptance test after reprogramming (UL/ULC and FM): To ensure

proper system operation, this system must be retested in accordance with

NFPA 72 after any programming change. Reacceptance testing is also required

after any addition or deletion of system components, and after any modification,

repair, or adjustment to system hardware or wiring.

Limitation of liability

To the maximum extent permitted by applicable law, in no event will UTCFS be

liable for any lost profits or business opportunities, loss of use, business

interruption, loss of data, or any other indirect, special, incidental, or

consequential damages under any theory of liability, whether based in contract,

tort, negligence, product liability, or otherwise. Because some jurisdictions do not

allow the exclusion or limitation of liability for consequential or incidental

damages the preceding limitation may not apply to you. In any event the total

liability of UTCFS shall not exceed the purchase price of the product. The

foregoing limitation will apply to the maximum extent permitted by applicable law,

regardless of whether UTCFS has been advised of the possibility of such

damages and regardless of whether any remedy fails of its essential purpose.

Installation in accordance with this manual, applicable codes, and the instructions

of the authority having jurisdiction is mandatory.

While every precaution has been taken during the preparation of this manual to

ensure the accuracy of its contents, UTCFS assumes no responsibility for errors

or omissions.

iv LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Advisory messages

Advisory messages alert you to conditions or practices that can cause unwanted

results. The advisory messages used in this document are shown and described

below.

WARNING: Warning messages advise you of hazards that could result in injury

or loss of life. They tell you which actions to take or to avoid in order to prevent

the injury or loss of life.

Caution: Caution messages advise you of possible equipment damage. They tell

you which actions to take or to avoid in order to prevent the damage.

Note: Note messages advise you of the possible loss of time or effort. They

describe how to avoid the loss. Notes are also used to point out important

information that you should read.

Product Symbols

This symbol appears on the main board of the unit and indicates that the

board contains static sensitive components.

This label is located on the laser chamber at the bottom right of the open

detector and signifies that the unit is a Class 1 Laser product as specified

in IEC 60825-1. The unit incorporates a Class 3B embedded laser which

must not be removed from the detector, as retinal damage may result if

the laser beam enters the eye.

This symbol indicates the Safety ground studs. These are for grounding

cable screens, etc., and should not be connected to 0V or signal earth.

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook v

EN 54-20 compliance

The installation must be designed using PipeCAD software, which is provided

free on the CD shipped with each detector. After designing the installation

including pipes, endcaps, and sampling holes, enter the detector type. To select

the detector type, select Options, select Calculation options, and then select the

detector from the Type drop-down list.

Select Options > Calculate, or click on the calculator icon. The software will

prompt you to choose from Use set hole sizes, Best flow balance, or Max.

permissible transit time. Select the appropriate option, and then click OK. The

results for each pipe (View > Results) show calculations for each sampling hole

on the pipe with the nearest to the detector at the top of the screen, and the

endcap hole at the bottom.

For EN 54-20 compliance the transport time of the last sampling hole shall be

checked following all installation and proven to be less than or equal to that

determined by PipeCAD.

The classification of each sampling device configuration and associated

sensitivity settings are determined by the column headed Hole sensitivity %

obs/m which shows the predicted sensitivity for each hole. For the installation to

comply with EN 54-20 depending on the class of installation, each sampling hole

must be no less sensitive than the following:

Class A: 0.62% obs/m

Class B: 1.95% obs/m

Class C: 4.65% obs/m

The calculation can be further refined by leaving a working detector in the

protected area for at least 24hrs at the intended alarm factor for the installation

(this could be done before or after installation). The detector sensitivity can be

read from the “Sensitivity” figure on the histogram screen of the Remote software

supplied with each detector. Click Options > Calculation options to open the

Hole calculation options dialog box. Enter the sensitivity value obtained from the

practical test, and then click OK. The new calculated value will use the real

sensitivity from the practical test.

The PipeCAD software will determine the classification of any used configuration.

Commissioning and periodic system tests must involve smoke tests to verify that

the system performs as expected and enters Fire (Alarm) 1 alarm within the time

determined by PipeCAD from the farthest hole. The detector sensitivity must also

be inspected to ensure it has not radically fallen from the installed figure. If it has

changed for any reason, the new figure must be re-entered into PipeCAD and the

recalculated hole sensitivities must be confirmed to be within the class limits

shown above.

vi LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

The settings of a compliant system should be recorded, as it is possible by

changing certain programmable functions to make the system non-compliant. If

functions are changed, it is recommended that the system is retested if

continuing compliance is in any doubt.

Note: For EN 54-20 compliant installations the detector requires that the flow

thresholds be set manually to ± 6% of the nominal value, after the FastLearn

phase is completed. For example, if the flow rate is 64% after the completion of

the FastLearn period, the user must manually set the low flow threshold to 58%

and the high flow threshold to 70%.

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook 1

Chapter 1

Product and component

descriptions

Summary

This chapter provides descriptions of the detector features, specifications, and

controls and indicators.

Content

Introduction 2

Available software for the detector

2

Specifications 3

Standard detector 4

Stand-alone command module or command module detector 6

Standard detector interior view 7

Stand-alone command module interior view 8

Command module detector interior view 9

Detector controls and indicators 10

Display types 11

Chapter 1: Product and component descriptions

2 LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Introduction

The detector is a highly sophisticated “next generation” high sensitivity aspirating

smoke detection product that provides all the benefits of air sampling high

sensitivity smoke detection, including very early warning. Designed for easy

installation and commissioning, the detector incorporates a patented “artificial

intelligence” known as ClassiFire, which allows the detector to configure itself to

optimum sensitivity, alarm thresholds, and minimum nuisance alarms for various

environments.

The detector operates by drawing air from a protected space via a supervised

piping network in relatively small areas. The sampled air is passed through a

dust separator (filter) to remove dust and dirt before entering the laser detection

chamber. State-of-the-art electronics are used to analyse the sampled air and

generate a signal representing the level of smoke present.

ClassiFire intelligence also monitors the detector chamber and dust separator

for contamination, continually adjusting the appropriate operating parameters to

counteract the negative effects of any contamination. Aspirating smoke detectors

are unique in being able to provide a consistent level of protection in a very wide

range of environments by continuously making minor adjustments to sensitivity.

The aspirating line of detectors detects “difficult-to-detect” slow growth electrical

overload incipient fires in “difficult” environments.

Available software for the detector

The Remote Control and the SenseNET software packages are available for use

with the detector:

• Remote Control software: Provided free of charge with every detector, this

software package enables the user to set up and configure the programmable

functions of one or more detectors or Command Module from a computer

connected via an RS-232 serial cable.

• SenseNET software: SenseNET software is used to configure and manage a

large network of detectors with a simple, streamlined graphical user interface

from a computer connected to a detector or Command Module via an RS-232

serial cable to RS-485 converter interface.

Chapter 1: Product and component descriptions

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook 3

Specifications

Caution: This equipment is only to be used in accordance with this specification.

Failure to operate the equipment as specified may cause damage to the unit,

injury, or property damage.

Specification Value

SELV rating (EN 60950) Class III

Supply voltage 21.6 to 26.4 VDC

PSU Type: conforming to EN 54-4. Electrical safety

complies with IEC 61010-1

Size 427 × 372 × 95 mm (16.8 × 14.6 × 3.7 in.)

Weight

Detector

Command module detector

Stand-alone command module

Stand-alone command module and

batteries

5.2 kg (11.5 lb.)

5.3 kg (11.6 lb.)

6.2 kg (13.6 lb.)

10.1 kg (22.3 lb.)

Operating temperature range −10 to +60ºC (EN 54-20)

32 to 100°F (0 to 38°C) (UL 268, CAN/ULC-S529,

FM)

Operating humidity range 0 to 90% noncondensing

IEC 61010-1 Pollution degree 1

IEC 61010-1 Installation Cat. II

Sensitivity range

(%obs/m)

(%obs/ft.)

Min. = 25%, Max. = 0.03% FSD

Min. = 7.62%, Max. = 0.00914% FSD

Maximum sensitivity resolution 0.0015% obs/m (0.00046% obs/ft.)

Detection principle Laser light scattering mass detection

Particle sensitivity range 0.0003 to 10 microns

Current consumption

Detector

Stand-alone command module

Command module detector

300 mA (fan speed 1)

470 mA (fan speed 8)

750 mA (fan speed 16)

450 mA

750 mA (fan speed 1)

920 mA (fan speed 8)

1.5 A (fan speed 16)

Relay contact rating 500 mA at 30 VDC

Maximum sampling pipe length 200 m (656 ft. total)

Sampling pipe inlets 4

Maximum number of sampling holes 25 per pipe (100 total)

Sampling pipe internal diameter 3/4 in. (ID) or 27 mm (OD)

Alarm levels 4 (Fire (Alarm) 2, Fire (Alarm) 1, Pre-Alarm and Aux)

Chapter 1: Product and component descriptions

4 LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Specification Value

Bar graph sensitivity range 0.0015 to 25% obs/m (0.00046 to 7.62 obs/ft.)

Bar graph segments 26

Chamber service intervals Greater than 8 years (depending on environment)

Dust separator (filter) replacement

intervals

Greater than 5 years (depending on environment)

Laser lifetime (MTTF) Greater than 1000 years

Programming Front panel or PC via RS-232/RS-485

Data bus cable RS-485 data cable

Data bus length 1,200 m (4,000 ft.)

IP rating IP50

Standard detector

The standard detector may be operated as a stand-alone unit, or may be part of

a network of detectors centrally monitored by a command module. It may be

programmed via its front panel, as in the standard detector and command

module versions, shown in Figure 2 on page 5 and Figure 3 on page 6.

Alternatively, the standard detector can be ordered without a front panel display

(minimum display) as shown in Figure 1 on page 5. The detectors may be

programmed remotely via the detector’s RS-485 terminals using a command

module, or via the detector’s RS-232 port using a PC running the Remote Control

software. A copy of this software is supplied with each detector.

The standard detector without a front panel display is housed in a rugged sheet

metal steel enclosure. This detector includes LEDs to indicate alarms, faults, and

normal operating conditions. The standard detector with display (and command

module) can also be ordered with the steel enclosure.

Chapter 1: Product and component descriptions

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook 5

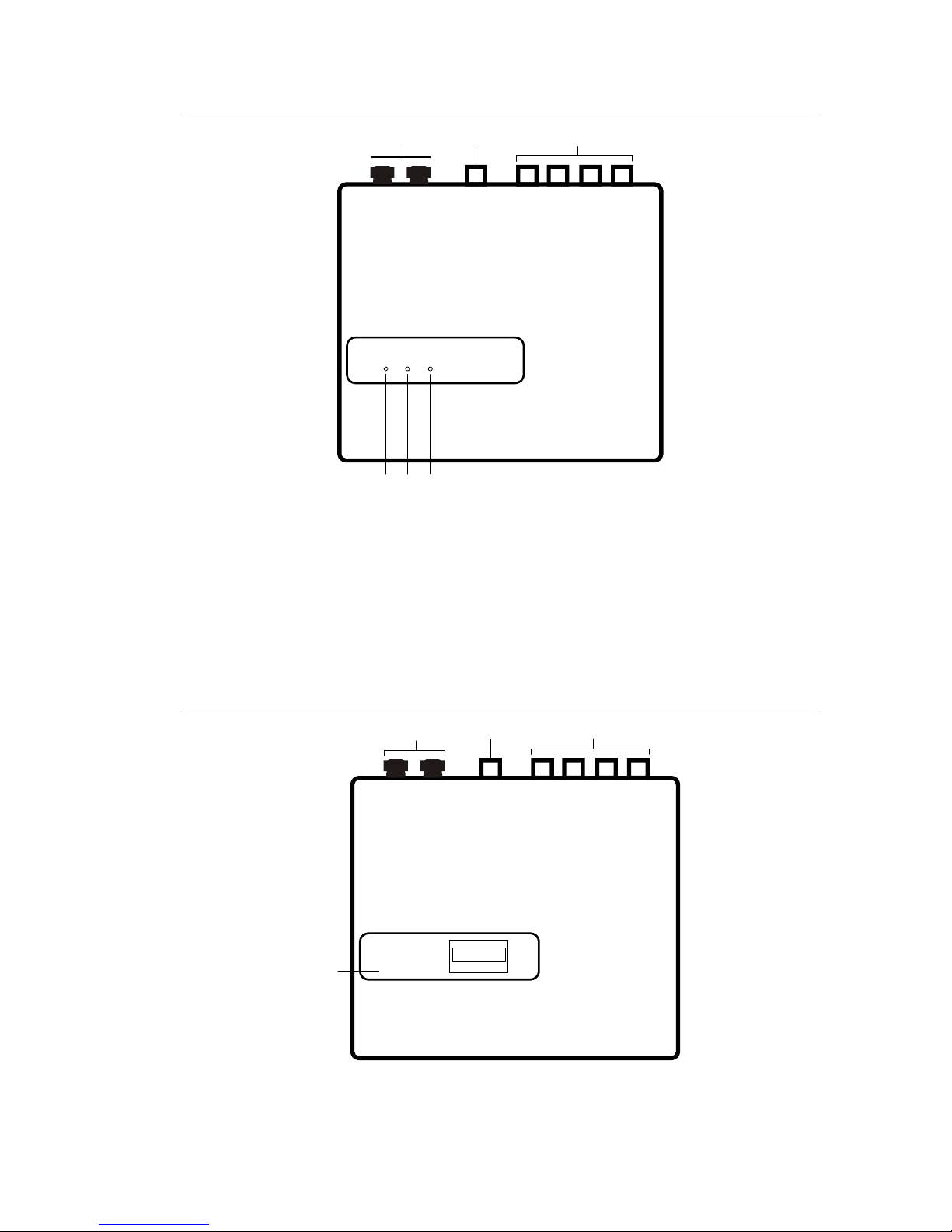

Figure

1

: Minimum display detector

(

2

)

(

3

)

(

4

)

(

1

)

(

5

)

(

6

)

(1) Cable glands

(2)

Exhaust port

(3) Sampling ports

(4) Alarm LED: Illuminates when the alarm

level has been reached and the

appropriate time delays have expired.

(5) Fault LED: Illuminates when the unit has

a fault and a fault signal is being sent to

the fire alarm panel.

(6) OK LED: Illuminates to show normal

operation when there are no faults. The

OK lamp will flash during the 15-minute

FastLearn period when the detector is

first learning about its environment.

Figure

2

: Standard detector

(2) (3)

(4)

(1)

(1) Cable glands

(2)

Exhaust port

(3)

Sampling ports

(4)

Front panel display

Chapter 1: Product and component descriptions

6 LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Stand-alone command module or command

module detector

When multiple detectors are networked together, a command module may be

used to tie all the detectors together and to provide a centralized point for

network access and programming, running diagnostics, and PC and fire panel

connection.

The command module can be mounted either inside a detector or as a stand-

alone unit in its own housing without an aspirator or smoke detection circuitry. If

detectors attached to the Command Module are mounted in different fire zones

then the Command Module must be mounted in its own housing with separate

power supply to comply with BS5839 and EN 54.

When a command module is mounted inside a detector, the Standard detector

display is replaced with a dedicated command module display. The programming

buttons and display on the front of the detector belong to the command module.

Programming at the command module is very similar to programming a detector,

the main difference being that the command module has extra functions to

control all the aspirating detectors connected in the network.

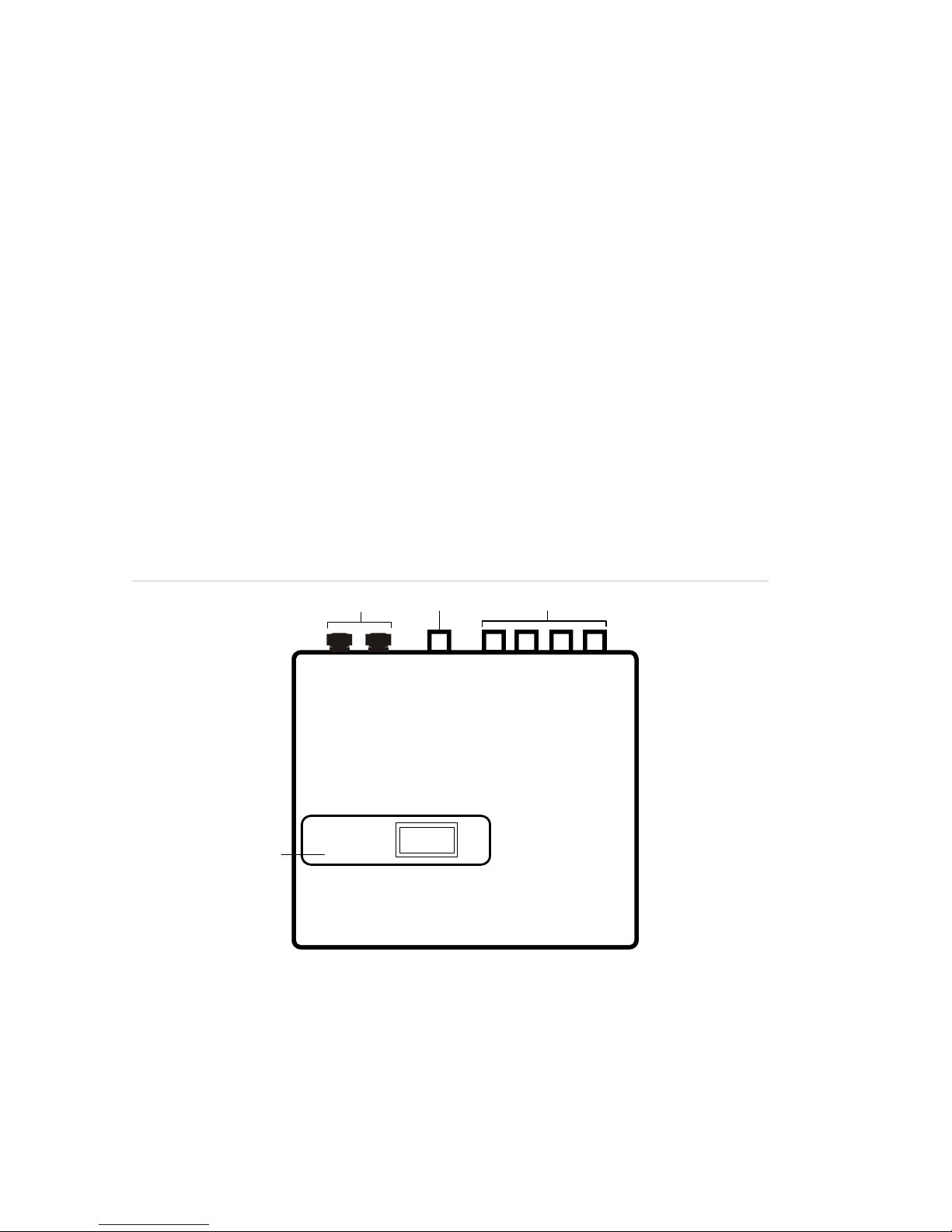

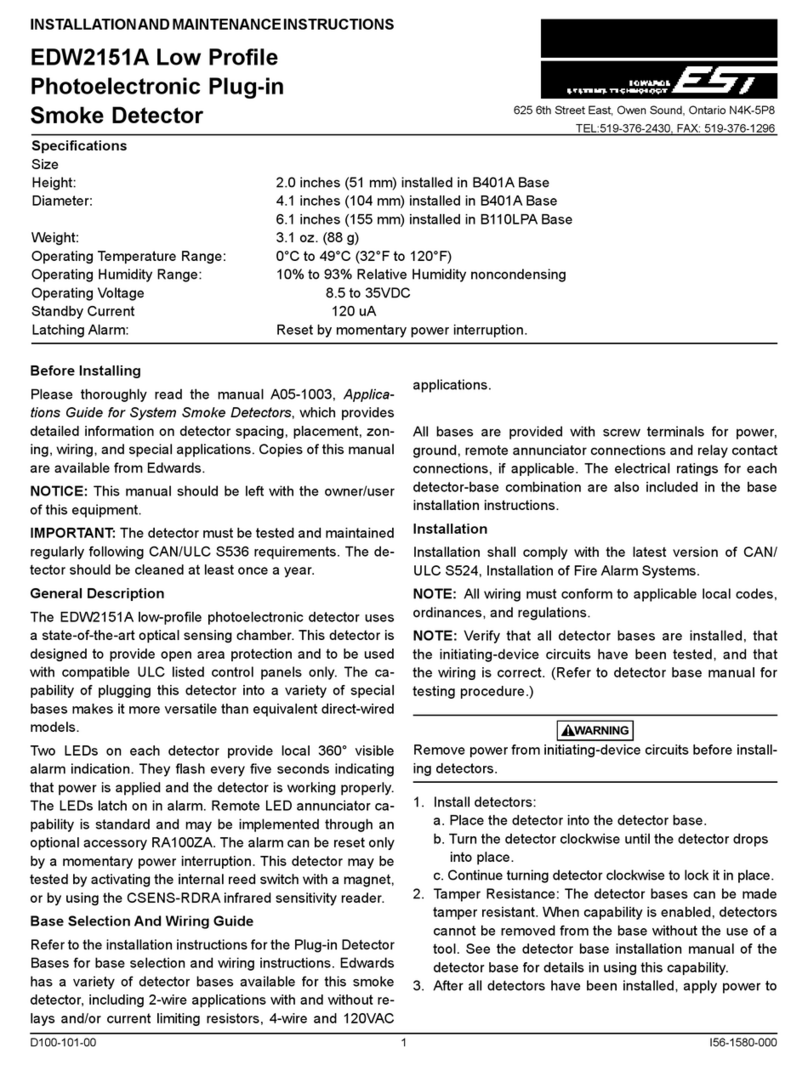

Figure

3

: Command module detector

(4)

(

2

)

(

3

)

(

1

)

(1) Cable glands

(2)

Exhaust port

(3)

Sampling ports

(4)

Front panel display

Chapter 1: Product and component descriptions

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook 7

Standard detector interior view

Figure

4

: Standard detector interior view

(10)

(5)

(7)

(

3

)

(8)

(4)

(9)

(6)

(

2

)

(

1

)

(1)

RS-232

serial

port

(2)

Safety earth studs

(3)

1 A 5 x 20mm T-type protection fuse

(4) Dust separator (filter) removal handle

(5) Detector address DIP switch

(6)

Front panel display connectors

(7)

Display attachment screws

(8)

24 VDC power supply connections

(9)

RS-485 terminal connections

(10)

Terminal block connections

Chapter 1: Product and component descriptions

8 LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Stand-alone command module interior view

Figure

5

: Stand-alone command module interior view

(1) (2) (3) (4)

(5)

(6)

(7)

(1)

RS-232

serial

port

(2)

Safety earth studs

(3) 24 VDC power supply connections

(4)

500 mA 5 x 20mm T-type protection fuse

(5) Front panel display connectors

(6) Display attachment screws

(7) Terminal block connections

Chapter 1: Product and component descriptions

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook 9

Command module detector interior view

Figure

6

: Command module detector interior view

(

1

)

(

2

)

(3)(4)(5)

(6)

(7)

(8)

(9)

(10)

(11)

(1)

RS-232

serial

port

(2)

Safety earth studs

(3) Dust separator (filter removal handle

(4)

Detector display connection

(5) Detector address DIP switches

(6) Command module display connection

(7) Display attachment screws

(8) Command module CPU board

(9) Command module CPU board -

terminal block connections

(10) Detector CPU board

(11) Detector CPU board - terminal block

connections

Chapter 1: Product and component descriptions

10 LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Detector controls and indicators

The standard detector and the command module detector controls and indicators

are very similar.

Figure

7

: Standard detector

(

1

)

(

2

)

(

3

)

(

4

)

(

5

)

(

6

)

(

7

)

(

8

)

(

9

)

(

10

)

Figure

8

: Command module detector

(1) The <TEST> Button starts a lamp test which makes the detector show its nominal operating

sensitivity as calculated by the ClassiFire Artificial Intelligence System.

(2) The <RESET> Button clears any latched alarms or faults and sets the status display back to

its normal operation display. To comply with national standards, detectors are supplied with

the RESET function disabled as the default.

(3) MENU Buttons are used when programming the unit, which is password-protected. See

“Navigating through the menus” on page 46, for more information. Pressing the UP or

DOWN arrow keys when not in Programming Mode (the access code has not been entered)

scrolls through the detector’s event log. Refer to “Event log” on page 61 for more information

(4) The OK Indicator illuminates to show normal operation when there are no faults. On the

command module, this means that the command module and all detectors on the loop are

operating normally.

(5) The Fault Indicator illuminates when the unit has a fault and a fault signal is being sent to

the fire alarm panel. On the command module, this also indicates a fault in a detector on the

communications loop, or in the loop itself.

Chapter 1: Product and component descriptions

LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook 11

(6) The <ISOL> Button toggles the unit‘s isolation state. When isolated, the unit cannot

generate any alarms and will signal a fault condition and the text display will show Panel

Isolate. A detector is shipped with its <ISOL> Button disabled as default. These three

buttons can be individually enabled or disabled. The factory default state of the detector is:

<TEST> button enabled and <RESET> and <ISOL> buttons disabled.

(7) Status Display (if fitted) shows all events as they happen in real time and is also used to

configure the unit.

(8) Smoke Density Indicators (scaled smoke levels) display absolutely scaled smoke levels

above 1% obscuration per metre (0.30% obscuration per foot) to a maximum of 25% obs/m

(7.62% per foot). The Alarm 2 activation level is programmed normally somewhere in this

range. The bar graph display will show a continually cycling pattern when the unit is in

FastLearn mode. On the command module display, this will occur when any unit on the

RS-485 communications loop is in FastLearn. Otherwise, the bar graph display on the

command module mimics the bar graph display on the highest-reading detector on the loop.

(9) Aux. Alarm, Pre-Alarm, Alarm (Fire), and Alarm (Fire) 2 indicators illuminate when the set

alarm level has been reached and the set time delays have expired. On a command module,

the indicators signify an alarm condition from any detector on the communications loop.

(10) Smoke Density Indicators (1 through 10) are the relatively scaled ClassiFire bar graph and

changes in steps of half a segment.

Display types

The standard detector display is a two-line LCD which allows basic programming

of the detector. See Figure 9.

Figure 9: Standard detector display

The command module display contains more information than the standard

detector display. The command module display instructs the user with graphic

symbols. See Figure 10.

Figure

10

: Command module display

Chapter 1: Product and component descriptions

12 LaserSense HSSD-2 Aspirating Smoke Detector Installers Handbook

Table of contents

Other Edwards Smoke Alarm manuals

Edwards

Edwards SIGA-270 User manual

Edwards

Edwards EST EDW2151A User manual

Edwards

Edwards SIGA-OSD Assembly instructions

Edwards

Edwards 3100738 User manual

Edwards

Edwards ModuLaser User manual

Edwards

Edwards Signature Series Assembly instructions

Edwards

Edwards EDC-M9102 User manual

Edwards

Edwards SIGA-PHS User manual

Edwards

Edwards LaserSense 100 User manual

Edwards

Edwards 562NSTT-OEM-ATT01 User manual