30311161 Issue 1.01

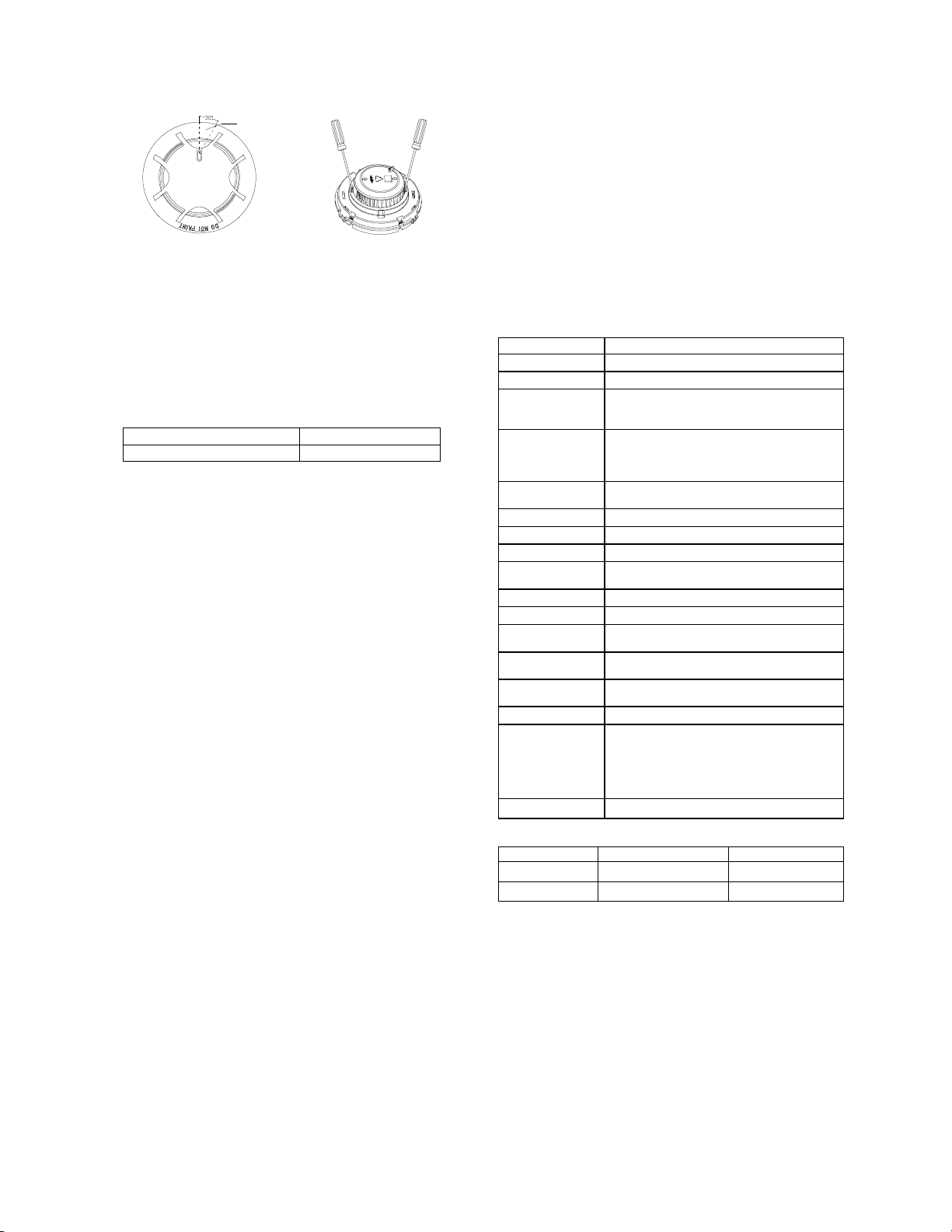

Test zone

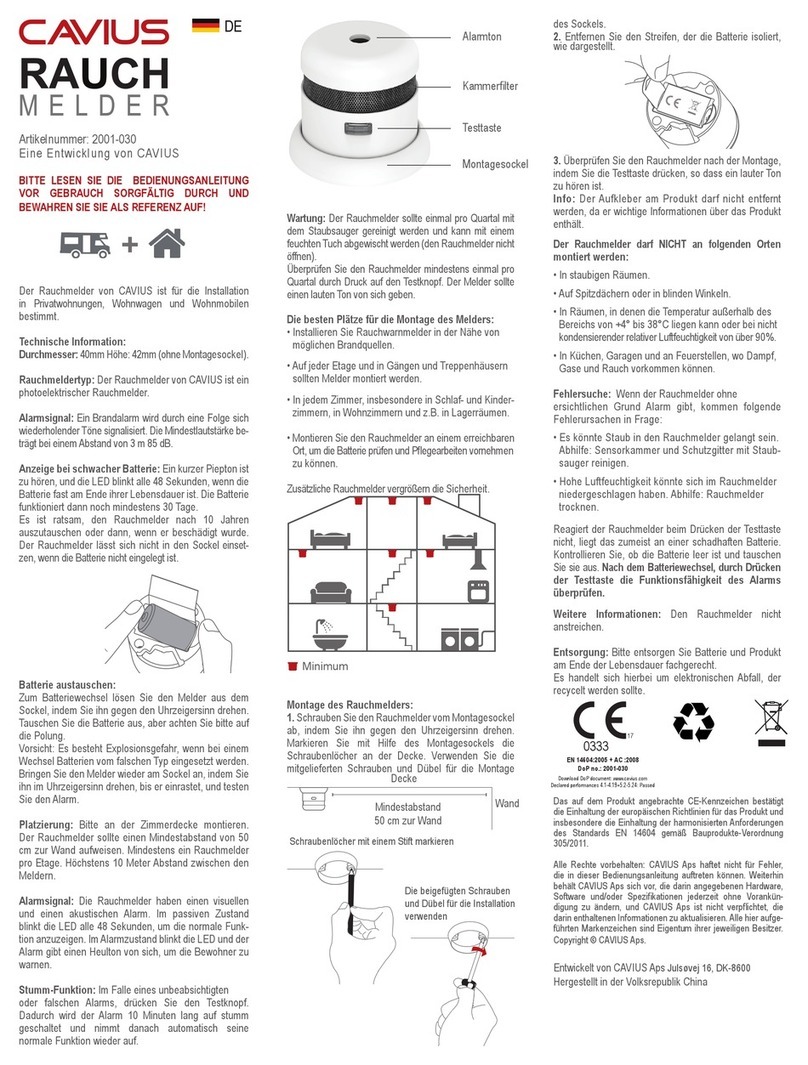

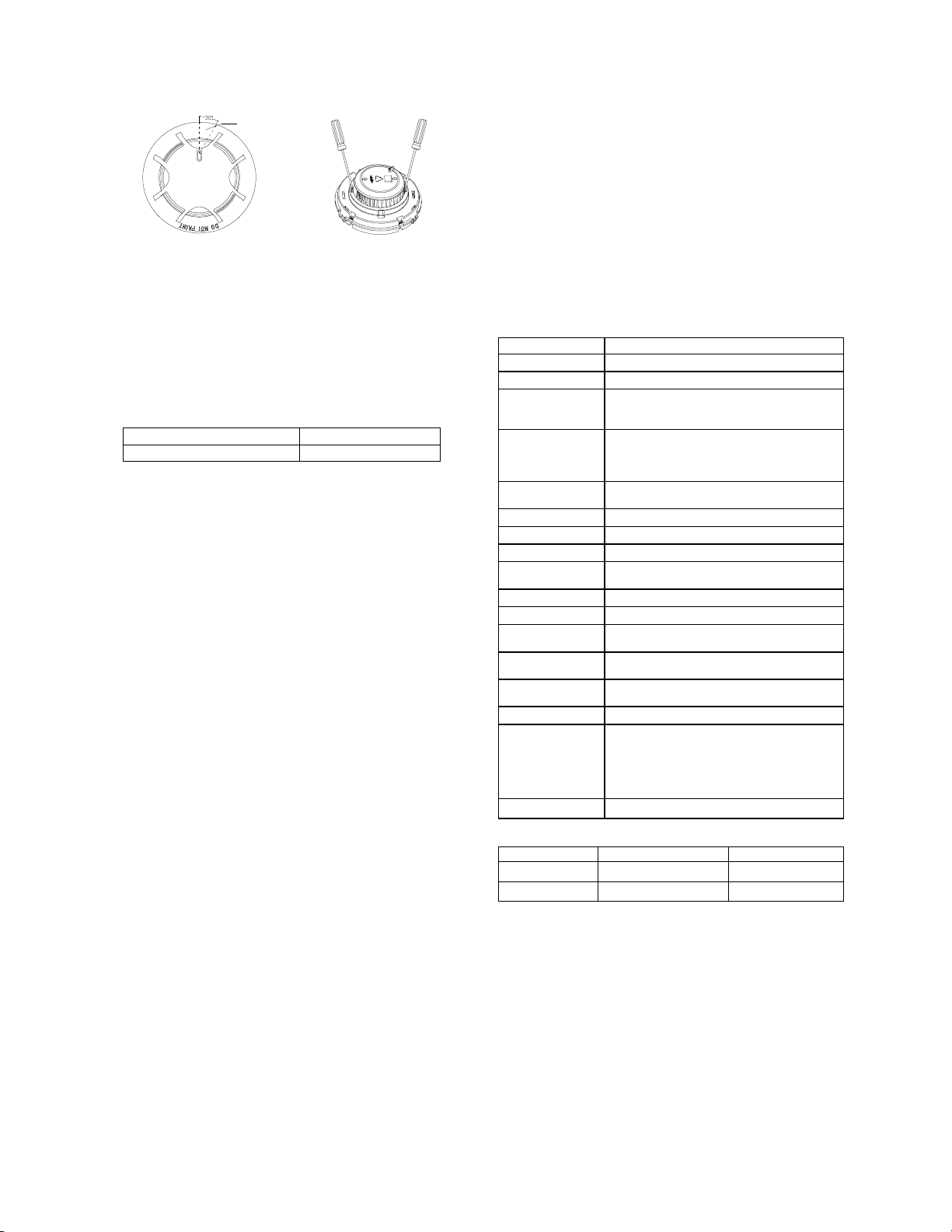

Fig. 5 Fig. 6

1) Reed Switch Testing

Magnet test zone is shown in Fig.5. Put the magnet of commission

tool close to the zone of the detector and hold on for a few seconds

until the detector generates alarm.

1) Smoke test

The Trutest model 300 Aerosol Smoke Detector Tester can be used

for smoke entry testing. Set the generator to represent 4%/ft to 5%/ft

obscuration as described in the Trutest manual. Using the bowl

shaped applicator, apply aerosol until the panel alarms.

Additionally, canned aerosol simulated smoke (canned smoke agent)

may be used for smoke entry testing of the smoke detector.

Recommended aerosol smoke products are:

Manufacturer Model

Trutest AERO400

When used properly, the canned smoke agent will cause the smoke

detector to go into alarm. Refer to the manufacturer’s published

instructions for proper use of the canned smoke agent.

2) After testing, cut off the power above 10 seconds and reset the

detector and then notify the proper authorities that the system is

back in operation.

Warning: Canned aerosol simulated smoke (canned smoke agent)

formulas will vary by manufacturer. Misuse or overuse of these

products may have long term adverse effects on the smoke detector.

Consult the canned smoke agent manufacturer’s published

instructions for any further warnings or caution statements.

When testing is complete, restore the system to normal operation

and notify the proper authorities that the system is back in operation.

Maintenance

1. The detector must be cleaned once a year to ensure normal

operation of the system.

2. Before cleaning, notify the proper authorities that the system is

undergoing maintenance and will temporarily be out of service.

Disable the zone or system undergoing maintenance to avoid

unwanted alarms.

Chamber Clearing Steps:

a) Open the top cover of detector, and draw out the sensing

chamber by slightly lifting its two sides using a straight

screwdriver, as shown in Fig. 6.

b) Use a vacuum cleaner or cleaned, compressed air to

remove dust and debris from the insect guard and the sensing

chamber. The sensing chamber can also be cleaned by clear

water and brush. Put the sensing chamber in clean water to

brush the dust inside and take out to dry it.

c) Install the sensing chamber and the top cover back.

Cautions

1. Dust covers can’t be removed until the project is put into use

formally. Take well care of dust covers for future use.

2. Dust covers effectively but not absolutely prevent dust particles

from going into detectors. So, we recommend that detectors

should be removed prior to construction, decoration, or other

activities producing dust. The proper authority should be informed

of detectors removing.

3. Be careful not to damage the detector in maintenance.

The smoke detector may not sense fire that where smoke cannot

reach it, such as in chimneys, in walls, on roofs, or on the other

side of closed doors.

4. The detector cannot monitor the place beyond protection area.

5. The detector may not warn you about fires caused by

insufficient safety measures, violent explosions, leaking gas,

improper storage of flammable materials like diluents and other

safety hazards, arson or children playing with fire.

6. The alarm of a smoke detector used in high velocity

environment will be delayed due to dilution of smoke by frequent

and fast airflow.

7. Smoke detectors have their own service life. In order to keep

the detector working in good condition, please maintain them

according to recommendations from manufacturers and relative

state standards.

8. The detectors must be tested regularly, at least once a year.

9. Smoke detectors are not to be used with detector guards

unless the combination has been evaluated and found suitable for

that purpose.

Specification

Operating Voltage 16VDC~28VDC

Standby Current ≤60μA

Alarm Current ≤55mA

Fire LED Red, periodically flash once in polling,

Periodically flash twice in fault or sensing

chamber dirty; illuminate in alarming.

Alarm Output Polarized output. Cycle 0.25S, duty ratio 1/2,

Voltage range 13V~24V(built in 10k resistor in

series, maximum output current is 2.0mA);

Max. ripple

voltage 2V(peak to peak value)

Alarm reset Instant power down (10s Min, 1.0VDC Max

Wiring Two-wire, polarity sensitive.

Sensitivity Range 1.23%~3.20% per ft

Environment

Temperature 32℉(0℃)~100℉(+37.8℃)

Relative Humidity ≤95%, non condensing

Material and color ABS, white (RAL 9016)

Ingress Protection

Rating IP2X

Dimension Diameter:100mm Height: 44.5mm (without

base)

Mounting Hole

Spacing 45mm-75mm

Weight About 110g

Compatibility EST3/3x IDC (detector capacity:19)

SIGA-UM/MAB(detector capacity:10)

RZI16-2 (detector capacity:25)

Fireshield Plus(detector capacity:25)

Listing UL268

Accessories and Tools

Model Name Remark

EDB-M01 Base Supplied separately

T-MT Commission tool Supplied separately