Edwards IS16K User manual

D059-14-880

Issue D Original

Instruction Manual

Vacuum Interlock Switch IS16K

Description Item Number

Vacuum Interlock Switch IS16K D059-14-000

This product has been manufactured under a quality system registered to ISO9001

Declaration of Conformity

We, Edwards,

Innovation Drive,

Burgess Hill,

West Sussex,

RH15 9TW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

Vacuum Interlock Switch

IS16K D059-14-000

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61010-1: 2010 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use. General Requirements

and fulfils all the relevant provisions of

2014/35/EU Low Voltage Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

11.11.2016, Eastbourne

Mr L. Marini, Senior Technical Manager Date and Place

P200-03-640 Issue D

P200-10-154

IssueA

Material Declaration - China

In accordance with the requirements of the Chinese regulatory requirement on the Management Methods for the

Restriction of the Use of Hazardous Substances in Electrical and Electronic Products Order No. 32 (also known as

‘China RoHS2’) and SJ/T 11364 Marking for the Restricted Use of Hazardous Substances in Electronic and Electrical

Products:

Product Product Label Meaning

D059-14-000 Vacuum Interlock Switch IS16K

D059-15-000 Adjustable Vacuum Switch VS16K 2020

This product contains hazardous substances

in at least one of the homogeneous

materials used which are above the limit

requirement in GB/T 26572 as detailed in

the declaration table below.

These parts can safely be used for the

environmental protection use period as

indicated.

材料成分声明

Materials Content Declaration

部件名称

Part name

有害物质

Hazardous Substances

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr VI)

多溴联苯

Polybrominated

biphenyls (PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

微型开关

Microswitch X O X O O O

电缆/电线/连接器

Cable/wire/connector X O O O O O

机械部件

Mechanical Components X O O O O O

O: 表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

O: Indicates that the hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement in GB/T 26572.

X: 表示该有害物质在该部件的至少一种均质材料中的含量超出 GB/T26572 标准规定的限量要求。

X: Indicates that the hazardous substance contained in at least one of the homogeneous materials used for

this part is above the limit requirement of GB/T26572.

NOTE:These products are EU RoHS compliant, the following Exemptions apply:

6(b) Lead as an alloying element in aluminium containing up to 0.4% by weight

6(c) Copper alloy containing up to 4% lead by weight

7(a) Lead in in high melting temperature type solder (i.e lead based alloys containing 85% by weight or more lead)

(c) I Electrical and electronic components containing lead in a glass or ceramic other than dielectric ceramic in

capacitors, e.g. piezoelectronic devices, or in a glass or ceramic matrix compound

7(c) II Lead in dielectric ceramic in capacitors for a rated voltage of 125 V AC or 250 V DC or higher

8(b) Cadmium and its compounds in electrical contacts

15 Lead in solders to complete a viable electrical connection between semiconductor die and carrier within

integrated circuit flip chip packages

34 Lead in cermet-based trimmer potentiometer elements

This page has been intentionally left blank.

© Edwards Limited 2009. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

D059-14-880 Issue D

Contents

Section Page

1 INTRODUCTION ....................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 Description ................................................................................................................ 1

2 TECHNICAL DATA .................................................................................2

2.1 Operating conditions .................................................................................................... 2

2.2 Performance .............................................................................................................. 2

2.3 Mechanical data .......................................................................................................... 2

2.4 Electrical data ............................................................................................................ 2

2.5 Product item number ................................................................................................... 3

3 INSTALLATION .....................................................................................4

3.1 Unpacking and inspection .............................................................................................. 4

3.2 General .................................................................................................................... 4

3.3 Connection to the Vacuum System .................................................................................... 4

3.4 Connection to the Electrical Circuit .................................................................................. 4

4 OPERATION ........................................................................................6

4.1 Adjustment ............................................................................................................... 6

5 MAINTENANCE .....................................................................................7

6 STORAGE AND DISPOSAL .........................................................................8

6.1 Storage .................................................................................................................... 8

6.2 Disposal ....................................................................................................................8

Index ................................................................................................9

For return of equipment, complete the HS Forms at the end of this manual.

gea/0049/07/09

D059-14-880 Issue D

Page ii © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

Illustrations

Figure Page

1 Vacuum switch plug connections ...................................................................................... 5

2 Dimensions of VS16K vacuum switch .................................................................................. 7

Tables

Table Page

1 Maximum switch ratings ................................................................................................ 2

© Edwards Limited 2009. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

INTRODUCTION

D059-14-880 Issue D

1 INTRODUCTION

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards IS16K Vacuum Interlock

Switch. Read this manual before attempting to install and operate the IS16K.

This manual contains essential safety information which supplements the safety features of the IS16K. Safety

procedures are highlighted as WARNING and CAUTION instructions. You must obey these instructions. The use of

WARNINGS and CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

1.2 General description

The Edwards IS16K Vacuum Interlock Switch is designed for applications where the electrical circuits within the

vacuum chamber must be de-energised when the vacuum system is let up to atmosphere.

Typical applications would be the interlocking of H.T. and R.F. power supplies on vacuum coating systems. The

interlocking switch consists of a positive break microswitch operated by a snap action diaphram to ensure rapid

separation of the microswitch contacts.

The diaphram is enclosed within the vacuum switch housing which is surrounded by atmospheric pressure and is

coupled to the vacuum system by a NW16 flange. The absolute switch point pressure will therefore vary by the same

amount as the atmospheric pressure.

The set-point is non-adjustable and cannot be tampered with.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

D059-14-880 Issue D

Page 2 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

TECHNICAL DATA

2 TECHNICAL DATA

2.1 Operating conditions

2.2 Performance

2.3 Mechanical data

2.4 Electrical data

Maximum switch ratings for different loads and voltages:

2.5 Product item number

Temperature range - operating -5°C to 40°C

Temperature range - storage -20°C to 70°C

Relative humidity (non condensing) 10 to 90%

Maximum operating altitude 3000 m

Installation category (IEC1010) 2 (IEC664/664A)

Pollution category (IEC1010) 2

Enclosure rating IP40

Set-point Within the range 250 to 500 mbar below

atmospheric pressure

Maximum switch point differential 100 mbar

Leak rate < 1 x 10-9 mbar litre/sec-1

Maximum overpressure 1 bar gauge (2 bar absolute)

Weight (unpacked) 0.5 kg

Weight (packed) 0.6 kg

Vacuum connection NW16 Flange

Volume added to vacuum system 7 cm3

Materials exposed to vacuum system Stainless steel and Armco 17/7PH

Electrical connection mPm 283 plug

Accessory supplied mPm 183 mating electrical socket

Table 1 - Maximum switch ratings

Volts

a.c. 50/60Hz Resistive Load

Amps Tungsten Lamp Load

Amps Inductive Load

Amps

125 10 5.0 10

250 10 5.5 10

Description Item Number

Vacuum Interlock Switch D059-14-000

© Edwards Limited 2009. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

D059-14-880 Issue D

3 INSTALLATION

3.1 Unpacking and inspection

Remove all packing materials and protective covers and check the IS16K for damage. If the IS16K is damaged, notify

your supplier and the carrier in writing within three days; state the Item Number of the IS16K together with your

order number and your supplier's invoice number. Retain all packing materials for inspection. Do not use the IS16K.

3.2 General

The vacuum switch should be mounted as close as possible to the point at which the pressure is to be measured. Use

a short branch tube with an internal diameter no less than that of the switch vacuum connection. Long, narrow and

angled connections can cause significant errors.

This equipment is not protected from dripping water from above, unless mounted with the vacuum flange pointing

downwards.

3.3 Connection to the Vacuum System

The vacuum switch may be mounted in any orientation but mounting with the vacuum switch vertical will prevent

the possibility of debris falling into the vacuum port and affecting the performance of the switch.

3.4 Connection to the Electrical Circuit

CAUTION

Ensure that the circuit connected to the vacuum switch is suitably fused to prevent the switch contact rating

being exceeded. The fuse rating must not exceed 10 amps.

WARNING

Do not allow the internal pressure to be higher than 1 bar gauge (2 bar absolute). If the pressure

in your system can be higher than 1 bar gauge, you must fit a suitable pressure relief valve.

Overpressure of the switch could cause injury to persons.

WARNING

Ensure that the electrical installation of the Vacuum Switch conforms with your local and national

safety requirements. It must be connected to a suitably fused and protected electrical supply and

a suitable earth point.

WARNING

If, in your application, failure of this switch could lead to a safety hazard, it is recommended that

the switch should be wired in series with another interlocking device, for example chamber lid

microswitch, to provide a double level of protection.

D059-14-880 Issue D

Page 4 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

Connect the vacuum switch to the equipment using the four pole mPm connector supplied. The contacts on this

connector are internally wired as follows:-

Figure 1 - Vacuum switch plug connections

CAUTION

To ensure that the socket cable gland strain relief is effective a cable with a minimum diameter of 6 mm must

be used.

Select a three or four core cable of a rating suitable for the power supply to be switched. One core should be

coloured green/yellow for the earth connection.

Thread the cable through the cable gland on the mPm socket cover and connect to the appropriate terminals as

shown on the diagram.

Tighten the cable gland and connect the socket to the switch using the sealing gasket and locking screw provided.

Earth connection.

Com Common

Lo Contact made when system

pressure is lower than set-

point.

© Edwards Limited 2009. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

OPERATION

D059-14-880 Issue D

4OPERATION

4.1 Adjustment

The IS16K Vacuum interlock switch is pre-set to operate in the range of 250 to 500 mbar below atmospheric pressure.

No user adjustment is available.

Figure 2 - Dimensions of IS16K vacuum switch

D059-14-880 Issue D

Page 6 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

MAINTENANCE

5 MAINTENANCE

To ensure correct operation this vacuum switch should be tested once per year or every 10 000 cycles whichever is

sooner.

To test for correct operation proceed as follows:

1. Disconnect the electrical supply from the vacuum switch.

2. Connect an electrical continuity meter between the pin marked 'com' and the pin marked 'Lo'. Refer to Figure 1

for pin connections.

3. With the IS16K at atmosphere verify that the meter reads open circuit.

4. Reduce the pressure to below 500 mbar (as measured on a vacuum gauge) and check that the meter reads short

circuit.

5. Raise the pressue to above 500 mbar and check that the meter reads open circuit again.

The outer surfaces of the switch may be cleaned by wiping with a dry cloth. Avoid the use ofsolvents that may attack

the moulded cover.

This product contains no user serviceable parts.

WARNING

Ensure that maintenance is done by a suitably trained and supervised technician. Obey your local

and national safety requirements.

© Edwards Limited 2009. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

STORAGE AND DISPOSAL

D059-14-880 Issue D

6 STORAGE AND DISPOSAL

6.1 Storage

Store in a cool dry place. Do not exceed the limits specified in Section 2.

6.2 Disposal

Dispose of the IS16K in accordance with any local or national safety requirements.

Particular care must be taken if the switch has been used in a hazardous environment.

D059-14-880 Issue D

Page 8 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

Return the equipment or components for service

Before you send your equipment to us for service or for any other reason, you must send us a

completed Declaration of Contamination of Vacuum Equipment and Components – Form HS2. The

HS2 form tells us if any substances found in the equipment are hazardous, which is important for

the safety of our employees and all other people involved in the service of your equipment. The

hazard information also lets us select the correct procedures to service your equipment.

We provide instructions for completing the form in the Declaration of Contamination of Vacuum

equipment and Components – Procedure HS1.

If you are returning a vacuum pump, note the following:

If a pump is configured to suit the application, make a record of the configuration before

returning the pump. All replacement pumps will be supplied with default factory settings.

Do not return a pump with accessories fitted. Remove all accessories and retain them for

future use.

The instruction in the returns procedure to drain all fluids does not apply to the lubricant in

pump oil reservoirs.

Download the latest documents from www.edwardsvacuum.com/HSForms/, follow the procedure in

HS1, fill in the electronic HS2 form, print it, sign it, and return the signed copy to Edwards.

Note: If we do not receive a completed HS2 form, we will not accept the return of the

equipment.

P80081000, Issue A

P800‐80‐000IssueT

edwardsvacuum.com

Other manuals for IS16K

1

Table of contents

Other Edwards Switch manuals

Popular Switch manuals by other brands

D-Link

D-Link DWS-3160-24TC reference guide

Hubbell

Hubbell Circuit-Lock installation instructions

Eaton

Eaton PDI WaveStar BCMS Installation and operation manual

TRENDnet

TRENDnet TEG-S224 - DATA SHEETS Specifications

Sun Microsystems

Sun Microsystems IB Switch 9P Administration guide

Woodward

Woodward DSS-2 user manual

LevelOne

LevelOne GES-2451 Quick installation guide

Siemens

Siemens 3VF9421-1 Series operating instructions

Compaq Storageworks

Compaq Storageworks SAN Switch 16 Installation and hardware guide

Webee

Webee Smartee SM2000 Getting started

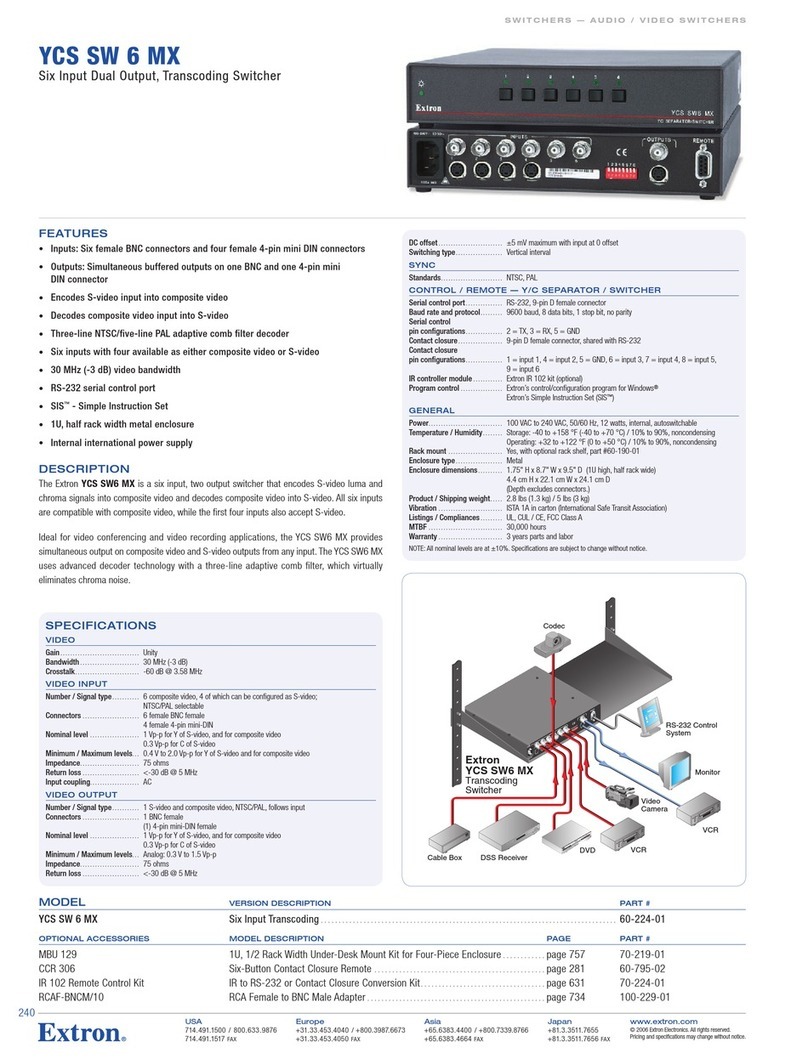

Extron electronics

Extron electronics YCS SW6 MX Specifications

Atlona

Atlona AT-LINE-PRO5-GEN2 user manual